?;19!:E!!'19!!

2012

ii.

ql

;

.!+,

,

:lt;

PROCEEDN{GS

2"'r

inleurational

Colfcr

enc,:

orr

SLrstrinlrblc

Technology

Dcvclor)rlcltl

(ratsTD)

'

D,

tcl,

1'tt,p

Su.rtttinahi,

lr.11.1.

tneI

.for

A llctter

Futut

c

Bati.

October 31''

201?

I

I

PP.OCEEDINCS

2'r

lnremarional C.nfercDcc onSu nanrabl e TecluoloAy Deve l.pnr c D r

- De te lopi ti

e S t6 t o i n ab I

e

7 e c h tn

togt

/brlRenerF tut.

B:ti, Ocrob€r115,,2ntl

scicntific connnree:

rr,ol r

..v"rrr

Ren.ni(uday?na un,veFiry lndoss,r)Por. sa!,qh (Pcidetrorwodd Renevable En.r$,)

I'nf. I)rl Kue Choi lchonbuk NarioMl Unrvc6n),, Sou$

(ora)

l,rf

tsudhiroIndBatu(Uriviv6iry

of wolrongons, AunEtia) frof. ,ae Klm Lin (Chonbuk N.ridalUnimnr

Soull) Kora)o'o' tr r R rihud r Hurch- Un:v6try ot s4ene

,rc

I 6\-

.tvey..hmj

Pof MonkserDewidar(s.urhvatlcy Univ€6ny, Ecypr)Pror lcxandc.Cufiben0Jni!6iryoaNe* souh wat6, AdjRtia)

Parf TJokGd. Tina Nindhia (Ud,yana UniEsny, lndonera)

Pnf

r M .dc Ab I Karyawans

(udayanaunilm

n,, Indones ia )P'oa I

l\

Gdantari (Uday,m Uni16iry, I'rlons'a)trr vu Cons

Hc

(Ho chi Mirh Ciry Univ$iry of l c.hnology. Vidnan)Dr (' A

M

Sudik(Uday,n, Unilcniry. tMon.:ia)rt

tr

.jcde AJi:nim (Udayd Unn rsny,bd.icsia)Or

Dll

l,ryanrlEW.(Uday,n.Unilccirxrdon6ii)

Dr rK

(i

Dharn'r Pnrn (LJdayana Ljmvtr\iry.tr

oncsr)Publish.dby,

Uday:nr Umvdary PE-5'

N{ECtl,l^_lCAl, ENCINIiERINC

N4 0r

MO?

(ID I

(Dt

(ID I

Ml3

oD

rll)

fuzzy

PID

ltrrio

((rn'fllo ot An

Elrcrni\tlrtr,,

rn.,toJ)

Conriounr- vJ'irhlf

liansmissor

tar

\trrnjrii\.

^mlrcariitr,

'Ihe lariaron ol6ltulc ntrnrbcr rnd ihe

tuhti.ral

ol'.rr.r

n,rr

09)

rarious wnd occurr.nc.(iiiriburi.N

of tlrc clcan antlr1i.\xl.1.

\dd po*crmichmc.

...

...

fF,..,p!,f

hr'

\' i'..t\pont'ol.r\

M.l

l

Mll

(lD I

ll)

/-

arDl]si

M

10

Psrom;n{.oaReiarniv€rtit!-tTtoe'sDc"lturikt\'nnE+

ilrr

I'nl

frnn'(reet.i,p,

\rd

Pcrfonnatue

olD'ir!r,l

Cu(nrglbol

20)

Srai'ncssSrcel aoDf.r idd Alumiriumid

'l': Iul

i,-

1,!. ,'

Tnnc Studr

.\ml\:rr

.l

I-ooJSeNic.\

UsingiUjr,

\Tr!trrt

aoDfaiis.i

vi.l.:r

H.,,dr.\!

ofwelding AluNnrLr: I\tC

ifl

wilh weldrn

tf.

Nl.r.l

Lt(

Cas(Mlc)

Jndlungnrf

tDeLrCr\

tTlG)

..M

12

A Creen Manufidurins Proccss For Smrttvcrliclt

,\\n \riid

IrD

la')

Iu'bincblode

..Sludy

Plr)siqlrdd

Mc.fianicalPropd,€

of vcAdatMd.r

r

oro'rpo.ire !tu,

r

M16

CFDas AidiDEltrlro

lr.dr.l

Airflowrnd ThcnnrtpolnnfrDre(lDl5a) of

tsuilr]rngs.

CJr

SruJy:Airllow

Paller

.n1] th.nrr

Perrnmaice

ir

Classnr.r. I IDivc6iryotArDrliy!

NI8J!l l7

Eltur

.l

chenr.rl

rcihnc.b on

rher.nllc n,ri, tr

.Ltrl,lL ,. rl..'1bl'

'.,rt t1 rt '.rr{"("-,.

. \

11

lS

lne

Ass.nbltrrs I'r\cnigdi(niofTlrr*

wtre(l\

B,.\rtr

tjr!

lJ

th.\t,.L,

F \'.dr\\

\t

tolM

l9

r.nsllf

A

d lnrp&rsr$slh.t

B3nlboo Frbo ltejrl,trlfJ

I

I \\

M 0r (tD t25)

COIIIPARISON

VICKllllS

IIARDNDSSOf

WnLDIh_GALUlllINlfli\'l-MG

5083 WI'I'II WELDED FOR METALIN'RTCAS(NIIG)

ANDI'TJNGSTENINERTCAS(TI(D

ICus(iNg!r.[A'n0trar.Tjoko'.licde li'laNindhia].lMadeNidiy.n.l

Abnmd:

wirh

nany developne.t bcins donein

lems

ol

weldins lshnology.wclding Gchnology {eldins

.luninud

is pan of thar requnes precision and skill Aluminuir and rlu.rinun alloys, inclnding lidltweighrdet.l

tharhs,

hiell stEnEh,Fsishnr

ro

corosiondd

is

a fairly

good elecGcal conductor weldingis

atrirdispensablc pa'1oflhe groMh

oflhe

indusrry incesed,bduse

the nrain rolc inenginccrin3 and

Epa; ot

neral poduclion. Soir

rakesa

research orienred andscieDiinc $o& ro imFov€$e quahyofweldedjoinb lbmarion hish efiiciency,

lov

cod. energy salinss rnd €nersy sali.ss as

Fssible

Ihis $ud)uses-llc

\relding (rlDgsrcnin.n

gas) and MIC weldinc (M€r.l lnenOd).

Neldingof

ihe resulLsbctw€etr ihc

t*o

dinecnr $eldndd

hardnes is aho obrainrd diflerent. spccinrensusd in lhis nudy is .luninum Ms 508:i plat witn a dickn.ss of

rmn.

K.y Nords: weidins,

brd.6s,aluninuh

Mg508lI.INTRODUCTION

wirh

d&y

developm€nrb.ing

donein lems

ol

weldiq

l(bnoloBy,

weldi.gt€cnnolder *cldins

alunirrn

is p.n of lhal rcquircs pNision and skill. Aluninumand aluninun alloys, imludine lighrweiShr

h€l'l

lhal has a hieh sEnedr. Esislant lo comsion mdi

a fanly s@d elecdctl conducror. ?\lun .um has good duclilily incold cond'rnrns and have hish corcsion

*sisc.cc.

welding aluminuhn

onc of lheeraarine rechniquc to nch some nelals in rhe paanr

ncbl

and fillcr mcral snh orsirliour

preisLr..nd

wi$

or *irhout metal €nhancei and produces a conlinuousconnecrion

ofrhnnnun

can also be connected lvnh th€$

called high specd wcldin8rnd srn weded jojnts produced a prclly good. Wirb manyd€relopmenr beingdone in

remrs

ol$eldi.a

rechnolosy,Elding

tchnology velding aluminun is p,n of tharrcqunes pr€cisioD and skill. Aluninum and aluminun alloys. incLlding lighrveighr

nreral thxr lrN a high nrengh,

icsGbr

looiiosion

andk

a iairly good electricalconlucro. ,\lunridunr

hd

good ducrilny in cold conditions.id

halc hi-.h comsion re\isr.oceWhil.

{heDchl

,s rypic,lly used,s elemenaol

rlu'nmunr allols are:coprcr(Cu).silLcon (si).niasnesium (Ms), manganese(Nlt. zinc (Zn).

mn(Fe)..nd

sofdn,

Tb. addnnr olcoppti ro alumrnum elemens ro Inm ch.nricd compounds,so lhar rlrd

d,(hrrrrl

nrcngrh\ill

increGe. lhc conposnionoi$r

rl0DriNn allo]can

b. \lricJ

ii

r.cordanc.trilh

rhe requiredtol€nies

onIh.

xtplic.rjonof

afor c\anrtlc the nt.d

dla

coDnrucrion mlreriallirr.ndxli

andcrli.e

componenrs\

uminumhJ r

o

b,.'

J..eoped$ rlrr rr

'

erJtt,.JLm

,.,

\!t.i

bJildins

i

teryir rfotun' rou'da

rJ'.J in er.Jrer derdr' n'tr

n,c,n

prdlnro r Jnd

pL?

r

ol

Li r.'J.\.

od4enil

't-ra.oot

\,.e.d,d,r.-d

Ln'rlm

qe.dtr'. 1 trsj,

1l't'r

ru

I'c.h@, r tU' rn tvp,

rr.,,,.,Ili,ii

2,THDORY

alrmrnum

n

a lg\r$e.shr Terdl hd, emd.uro

ron rc.n'Jnc".,nJjo d

.rlbi

coldu.dvny&d

orher prcpenie, tu'h.

pmpenres ot borhmekt,

t1 aJd ron;-m6hd(al

sknsrhi.

SRarly'nc'eaed

b)

rhe add'lion ot ( u.vs.

n, Mr.l;

dc , indnidualb or oge'le'. g:!'ngrle

sood pdpenres such6..*.,"",..,.,,

l@!resisrsre.lor

(o"ir,c'enr or erp"tuion andsoon.thFm

eriJtI

\-r)tr(

use nor onty tor hoGehold applieces bd

at$

tbe nDreial us.a ro.rt" pu.pos,

diRrcfr..d...h'p..

@n.rru,rio'mo

o'odh

Fhh.n'.

-..2o'

aor.;,,e,r

alun num

ha

.

puntyof

upb

99 96%od

aijnimum ot

gel"

tenqo;

sul.nr.r 6fdc

clcnenrs Fc -ndj.

Ium.nJmJ.to).hJlcJ\,a..,,

.

io..

'he .ontmt oamcjo. el.henF

rmlrol

an,lmino'

trOio'.t"-...

-,

r,", vc

r,rniZn.

Cu.ad

Si$h€F6nr,or

(lemenrssucha\.'

.c.

Pb Ae,Ie. sn/, I

b

mi

oLheF. A lloyine ele menK

'

n aluminm majorrnLlude:

L Coppd (Cn),

incree

strensrhsd

hardness. but lower etonsarion (he tcnlrhpull.d'

Aluh'FUm ronrenr orru

n'he mo{

opr'r,ti.

brN+n L

oo

-2. 3.

Zinc

ortnc

(zn),incres

erensile valu€.Mmeee*

(Mn),iicisc

sbgrh

in hish remperarure.Mrgd€iu

(Mg),alminnn

pow€rEi$

dd

lower lhe vatwof

ns ducrjlity.comsion

6inec€

&d wrdabilirym

ale

g@d.silicon (Si),ledine ro

ince&d haidncsof:lunnrn

alo]s.B6ed on the dendnion of Deurche lndustn€ NorDen (DtN) welding is r

m.r.

uqicrtbond

!t

tic junction of mdal or heral alloy is cadied our in a notlen o. tiquid jaL.This

denniftn

€n

b€ funnd chbordred rhar rhc weld is$e

tcat

coMecbo.ori

meral

od.

In lhenO

welding p@edures have b€€r desisned in accordancc rviriAwS,

ils slanddds of qlalfuy re$ed wnh alziely

oa €srins borhlh.

NDt

(NonDestrucdf'fso md the m€chanical

rei

rcsull. as evidenced by a qMtiricari.n c.u.dlhe quarificarion

pceduE.

Inplemcnbrn,nofdeq!.ljficatiois

tr

by Ljin! dFm.lcncrgy. ASME srandard

lX

secr. Weldin! ofrhe mosl popular in IndoDesi( nanrly,cl.cti.

,lane

dc

wclding \ynh(sNt\w),

in

somc indunn€s nDrb!

rdrDc.dr€chnolosy. have

bee

using rhis qpc olwetdil]s Ttc_Mtc

and etecric r.!i$ncaseld (ERw).

a

\eths,<r'imerscd ircn€ldinsts^wj

2

l

The Tunssrer lnen Gosdc treldins (1tG)welding Nas

fiN

di$overed nr rbe Lrs^ (19,10J. o.iginar€dlioh

re \.L.hng rlloFlor

rlrc.rrcbfi

body

PnnciplcIt.

hcdlot

$e

arcecured

bco\.entrrg{.i

-l-."derdpd,1r

nlra

s'l

n,

'rn.na.tJ.ltLLe

aruns{.nct".r.,d.,

oln " lJed rnEredrenr

l-le.t'.

J',

-

..

rr'dn4.(tret-c'rcd€.p"nd11

h_-

1{

_Jlis a heal

eurcq

for $cldingfld.tid

nl

equiDpcdrnh.

cerdnric nozTte rop'!dr

MT'

2.5

ll

rhcdrd\crsrrclectneeas\tlding

ranoDrrheoursidearnEri,Dcor\etdin! Mosrot

rh.:

dedn$rc'dt

r

Led

wirtF rr

nrn.o,.

e etc.rrcdeqhr.1.,

r,o'.cd Jndbrcusht

b

rhem

berwn

tunastcn clcc&odeba*

nrarerirt rjsed as a pmr{rive lassdcn .s argon in n

s6.

hehm orI

mirxtrc ol bodr ea*-s is rhal irsus

deFDds;nlhe

'ype

ol

nreral rob.

wetdod TtC rvetdnrg rodh

lsua y cootcd *,ith lcssvar$

Fisor€ 2 I The cas Tunssten Atc weldins(CTAV) AFSA.2004.

2 5 The Focess or Neldins M€bl In d Ca (MIC)

As wirh

Ilc

weldins. MIC weldi.s isals

$e

heal sen€Ered by an eleckic arcberw&n rso elecrrcns and rn€

be

nal€dal. Elechd€ n a wiE coil which noves in rnc fom ol rolleB aEdged by rhe conpl€ se&-d;een €t.cftic motor. Movoenr canbe adjuskd

d

necesy.

'trtc shdl is equipped wirh a nozle weldnekt

rocomd

rhc protectire

96

is supplied Gom the sas bonl€ rhougn theg6

hose CO2s$

istred ao. veldins

nild n

.l

6d

st€el. Argo. cr a Dixrue of arso.rd

helim

forwld

aluninun andsdnl6

stel. MIC weldincpr@s

@

be seni autonalic or autmalic. S€mi-auronaiicwldins

mat

ndually,

white lhe auromztic wctdinS iseri€d

our ehlnely auronalic. The eletuodes exir ihbugh the sctks roseth€r wirih,

,:igure2

I

Theprocessolgdneratarcwetdinc(CrlrAw)^FSA_

Hddness r.sr

k

one resloi

ro deremine rbe naruE tudsr.nllh

oaa res isurd

lo dm

lU n

u\hle|

k.'

q

haloadotI kr

Hrdre.

r'a,r.,c

rdhod

rnaccordaDce lo

.\ST\l

scndads (E 92-82, 2003),vicke*

h3.dtress .ufrber can b€detenni,rcd

by

E lollowirg equarioh:MIG

ri,

s4

DT

(No

Vi.ier!

re{iot. !J,, hc \<en'

F!ud

FiguE2l llctrii.,plcolV,ckerslesr(ASlME92

Sl.llir)jr

Re*arch model willbc u$dlo co ndRt e \p€rinrenlal

resarn

srudies dircdlJr{ing

lo

det€mine ln€ efect md causcdd

elleclof

rhe setdi.B process!o

rtrl

rh€haldn€s values obrai.ed fron rhe nti6 of:luminunrMg 5081afier rvcld.d

srh

Ttcweldins md MIC s€lding.

I

AlurinumMs

5081wil[

dnncnsions 150\40x]nn

Al

N.1!illsr

trdh thecomposirion: 91.I % ?\1.0.1% S,.0.,1%

fe.0.l%

Cu 0 4% l\tn..l!,;

\tr.lr lj%

Cr.(),2i%2n0.

15%Ti.005.rherelemcnrs2 El{lqlcs

uscd in this nudy,s lhe composilionolrh.

ER Si. 0.1% Cu. I 0% Vn, 5 5% N1g. 015% Cr. 0 - 15% Zr.lquipnEor

u*d

in rhisnldr

rrc:Welding nachine TlG (Tlnsslcn I'i.n

ca)

rndtttG

rctdin!

I cnsilc r.sting mrchinc

il

5l

lr

WeldiDg

pr..s\

ol\.ld

\ilh

NllC5it6

is us.d\

rr a d'rnertr of Il

rype2

5mndla

rcrcrEri5li6

I 4

lh.rcsult\.lthe

*.kl;"

the prre.r

nrra

$.d

srsI

nnn r[ick alunrnlum plare\irh

I

\jddrot

11) turLterr

Iof_rc,

Tl(.r.o1d:l'1r

.uroJh

\elded..

rhebr r,,r.,o\

.t-,1..,.,

.,

or or

^ ..dc,

d

m\nonn.{dhl,hed .

m

)'r

tor perenr,o,i,he {..

I

r

.,,

of

scld.re

. , qc ser aeooJ

d pencdI'cJre

I

tJnJ:..

...rrr...r,

{ t.

lhrrn,lrrot

rhe ueldligpocess iscur!ros$\!.

irc rhe ptcru,tsclJn,!

\

h brn i1,i'nr.rraljoD

fledrdt

Fttnnn Ior

llai

qcldi'r!rlcqEd.r

useLtr..

rtsodr

Figuc

LI

TheTIc weldinrlicr.. j

I

(' o.s secrion\reldir!,.srhs

I

o"c

I

rlrd', c dr.'.r

r.4trour'.rgr.slonq\e'tc't.'r I J' r4

cr.ss secrion.l Nelded tieces {erc rhen r6ted wilhlhe

rc$

rtu

vick.r

h.rdn6

(Filure

3l)

lesring of nicm Vicke^ h:rdness resl ohaiNd wirh rhe re! (sutrs6

recorded

inTlbls:l

1uniill:ll

$e tullo*inglable:Table:l I Res;oml Hadness tlAZ

Ls

TIC 30/\MT

\tral

-€/

I shors dre r.s!

tsrn

)\]tr.s.'

rh€llAl

ro Ncld*nh

1221+32.73+35.4)

2

i

j

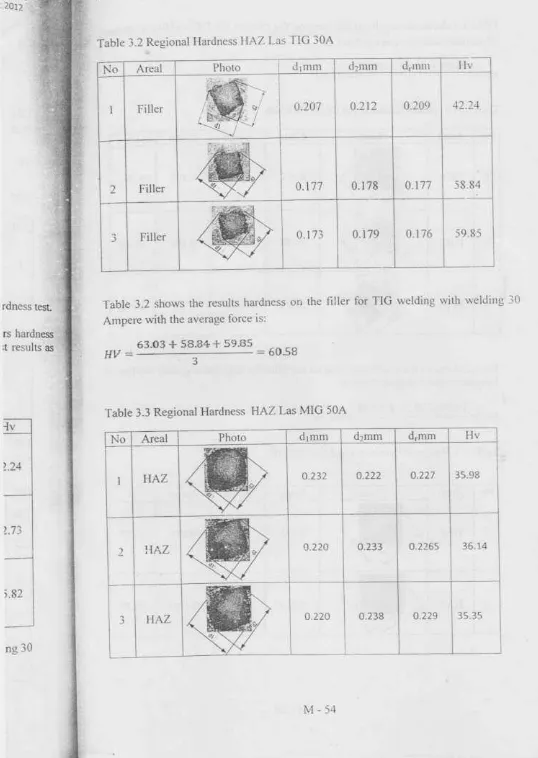

Tablc 1.2 Rceional Hardn.ssllAz L.sTIG

ioA

Table 1.2 shows $e

6ults

hardn€ss on the filler fot TIC qelding wilh *eldine l(rAmFrc vilb lnc avme.

foe

n:Tablc 3.1 R.sional Haidress

t24

I

Tdble

I

I

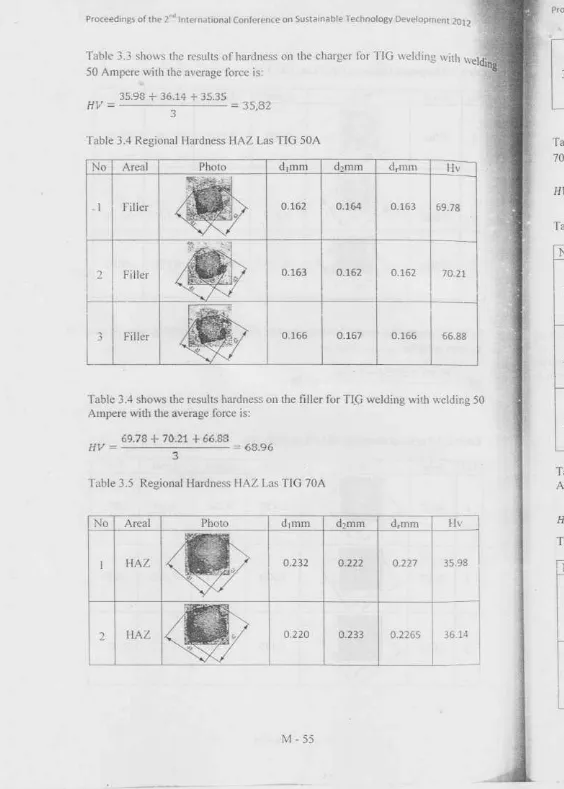

shors lhc icsul$ of hardncss on rlF charBf for TIC selditrg sirlr50

Amp€reurh

reavcmge lorcc is:= 35.8?

rabE

]a

Re8ional llardness HAZ Las TIC 50AHV

I

&

Iabl.3.4 sbows rhc raults nddnFs on lhe

nlbr

for TIC welding wilh *eldins Ahpcrc Pitb ih. av.dge lorce is:6928+70.2!+64la

3

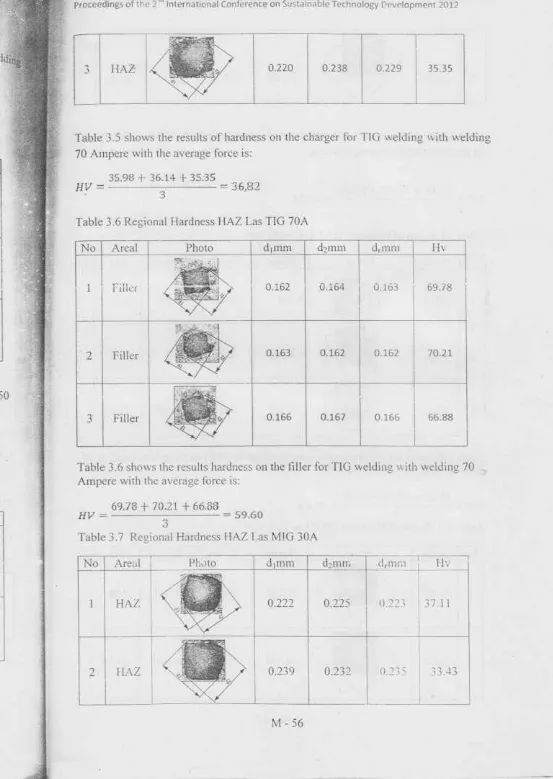

Table 3.5 Regional ltrdness HAZ L6 TIC 70A

M

Table

I

s shovs the Fsulls ol hardness on rhe charger lorTl(l

s€lding\nh

*elding'70 Ampei€ vnh rhe lvemse foree is:

= 36,A2

Table

I6

R€Ei"nzl IlardncssTablc 1.6 shoss $c .esults hardness on the fill€r fo. TIC wetnrg u nh $eldins ?0

Amperc

rith

the areage fo*c is:EV=-=59.60

3

on

Lhe.h,rs{

torMlC$cldi

g wtrh wetdh83

'rable

I

3 RegionalHirdncssTablc

I

8 shows thcrsul$

har,l .ss on thefillerlorMlG

w€ldinewnh weldnrei0Amp€€virh rhe averaqe nnr. is

15.22+10.21i72.12

3

'Iablc 1.9 Rqionalllardness

llAr

l-rs MIC 504\

\'I

lN.

-! 50?

Ll

I

lrr

i{eS, nJlHr Lln!,-H\Z

Lrs MICi i.:)\

Table

I

l0sh.Bs1ht..ruhsh.rdtrcsson rhc Iillcr Ior NllG\.lding

*jrhu€l.hnq 50Arnp.rc wnh r[c trr.mge

ircr

isI

r\

VICi8

*F!.

..Fd/

lil

Tlb!e

I9

sh.ws rhe'tsul$ olhardDess or rhe ch.rA$ for

illl(;

\!elding !virh weldnrS50 Amper€ virh rhe rvera-qc forc. is:

3593+ 16.11+ 35 35

6dghe

minrhab

e rednoroe o@bp;enr2 H^Z

s

0.212-:'

02i5

11.41t0.t9

HAZ 0.245 0 249 0.241

3t.tI+

3343+30.39

Table

I

I2

Resonal Hardne$ HAZ LJ\ 1\l lC 704llv

l

ffir

ECT

Tablc

I

l2 shows lhe resuhs hardnes on rhe tillcr tor MtC s€tding wnh *eldins 70Anperc wnh the avcmg€ lorce isl

Iable

I

ll

Bae nretal H.rdnes!rabb

l.ll

showsrte

Esulrsof

hard.es on\rlding

70 Amp€re qnb $e average foee is:aN;

I

v""rT

phe

rhe chdeer lor MrC

r.tCh8

!i

M

t

t

n.rrl

hdrd..ss\virhh l!cu,r.

[idness rcsrhs945

rt

17 + 10.41H(= ----

-e.13

TalEl L l5

Avme.

Vicles HardnesVit[

fie €rer.d''bmr'"n uqd in

rheMi(nvnte'"r3nbe

irn

rriuuFt.lT.

FisuE

l5

Czlibrrsi d = 00j0t

'nni Mrqtrified400y

^s

r

rcacr€nce lbr calculados$e

Lasgtd

lt!a:

ol

rvl,.r.

vickcBre{

resulrsLrd

torehhr:lion with d 0.0505

nn

(Fi$re 1.5) sirhr

pressure dccrease conpularioD tnne byll

seconds. Ay

n.kine

thc diiance spccilicd tcnt.inb

hken rhe resr rhree rinres on each ited- RI]S U LTS ,\ND DISCUSSION

\licro

Hard css iesl resul8ol

vickeF leentld

rhr

hnldncssol

$e

mehlfiller

mddlncFrsed dN to.hmees in neial nrucrurc cruscd [y rlErnralcliidr olwelding

i.

$hich rhenricrosrructure of rhc

nebl

will

becom€ moE righrlle

$ar thenebl

chatreesi$

nartE.vi.kux

rlr'ilms{ \\ nh tir. e\erI

166',170/\ HAZ

l0A fill.r

coN(L

Itv,t8.i

MIC

s

r\sTM.- 21

es hard Fom ribles

r:ll

\isibtcrlt

1.luc hardress lronr bdsc Detal\ho

or ver|6 hear

b.

obFiDed v.luc $trilc€ hard.es amountinalo

Hv

978sh'rcin

tbnis will etevatd in cgions

llAZ

and rhen ilic nraxinun ils value on 'rcas lhal aENCLUSTON

'dinp rcsul$ ofwelding tials vickers hardness obllined

wldio! hddn

$an TIG $elding lvnh rhe h.rdness MICrcsulrs oa €sca(h ard $udv in rhis te$aEh lecluF Ahminum:Mg 5081

TIC weldine and MIG welding $e aurhor dnss sone con'hrionr rclared

fiV48jt.

by hed $€ldins arlvllc

\eunrs

TIG $eldingllIG

teldi.eTlG l

2nn

vhile th€I5

nrnr'virh nsins value of hardtess thcn n rrcpenics of mdat becone more

d.gEde;e slensrh tensile lron Aluninum lvtg

50lr'

REFERENCES

..2003

Annuotsooi

of

tsTMt,nzl,,dt

Sccrion 3. Volume 0101,pp

234_2rs.A.2OO4me VeLlinsofAlu'ninl,r,I//{,

&

G Fustoasorim

Africa,H

B. 1994.Modq,

weLlinafe.hn.to$.

^

simon &S.hut

r CompanvI

C@rse

F

vrndervon.

2W

Jtedtntr

oflJMirtunt crlr€t

vol"me9 ot $e

"ISM1

tad6o,&,

ASM lnkndionalItiDnick. wirliam

H

(1996).and

11tt3!rh1'.

wtllins

Handbool.Ii&t !!4'

!lll!.s!:Goodheart - willcox ConrpanY

ld,

C*io

aary",. l9'8

Opt"tj.h"n

ol

tvel.ling TechnoloqtIor

User.va\$a

Ptrncaltsrri.lakn..

\h"n!,

lo'l /rr,LFr

11,t!/,'r' / : -

lr'n(l d Iip'r'

I+'ni

SNl0i-07r9 1989.

M,trzlti.l.,J

bchun t) m93,n\a)

JenAan t9 N 'aru4i

terasl/1".rr'ro H

aoA.T.Ina\4 r'

-\' " / ""' lldn$'

JaLJturesulG ol hardDess re$ lor MIC

Hv52.3l and tie hddNss TIG