[ 2 1] Kamal T. Hindy

Utilizatio n o f c o ntro lle d c e me nt dust as a c o nc re te mate rial in the Unite d Arab Emirate s

Enviro nme ntal Manage me nt and He alth

8 / 1 [1 9 9 7 ] 2 0 –2 7

Se p a r a t ion of su s p en d ed p a r t icu la t e m a t t er fr om a ga s st r ea m by h igh volt a ge elect r ost a -t ic p r ecip i-t a -t ion r eq u ir es -t h r ee b a s ic s-t e p s: 1 elect r ica l ch a r gin g of t h e su sp en d ed m a t

-t er ;

2 collect ion of t h e ch a r ged p a r t icu la t e m a t -t er on a gr ou n d s u r fa ce; a n d

3 r em ova l of t h e p a r t icu la t e m a t t er t o a n ext er n a l r ece p t a cle.

T h e ch a r ge is a p p lied by p a ssin g t h e s u sp en d ed p a r t icles t h r ou gh a h igh -volt a ge, d ir ect cu r r en t cor on a . T h e cor on a is est a b -lish ed b et w een a n elect r od e m a in t a in ed a t h igh volt a ge a n d a gr ou n d ed collect in g su r -fa ce. T h e p a r t icles t h er eby b ecom e h igh ly

Table I

Clinke r and c e me nt c apac itie s o f the

inve s tigate d c e me nt c o mpanie s in Unite d Arab Emirate s

Clinker Cement

Company Emirate capacitya capacitya

Ajman Cement Co. Ajman – 0 .7 5 0

Fujairah Cement Co. Fujairah 0 .5 2 0 0 .7 9 0

Union Cement Co. Ras

Al-Khaimah 0 .9 9 0 1 .2 7 0

National Cement Co. Dubai 0 .4 9 5 2 .0 0 0

Note:

aMillion tonnes per annum

Source: International Cement Review (1 9 9 2 )

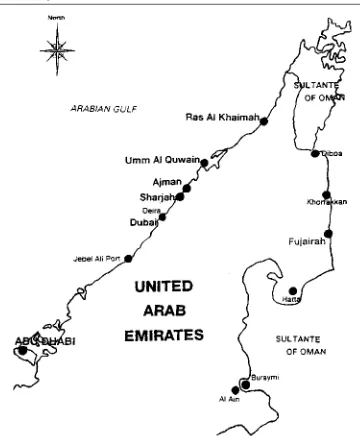

Figure 1

Kamal T. Hindy Utilizatio n o f c o ntro lle d c e me nt dust as a c o nc re te mate rial in the Unite d Arab Emirate s

Enviro nme ntal Manage me nt and He alth

8 / 1 [1 9 9 7 ] 2 0 –2 7

ch a r ged w ith in a fr a ction of a secon d a n d m igr a te tow a r ds th e gr ou n ded collectin g su r -fa ce. Th e pa r ticu la te m a tter is dislodged fr om th e collectin g su r fa ce by m ech a n ica l m ea n s, su ch a s vibr a tin g w ith r a pper s. Th e collected pa r ticu la te m a ter ia l fa lls to a h opper fr om wh er e it is r em oved by m ech a n ica l m ea n s.

With a fa br ic fi lter, th e du st-bea r in g ga s is pa ssed th r ou gh a gla ss or n eedlefelt fa br ic in su ch a m a n n er th a t du st pa r ticles a r e r eta in ed on th e u pstr ea m or dir ty-ga s side of th e fa br ic, wh ile th e ga s pa sses th r ou gh th e fa br ic to th e dow n str ea m or clea n -ga s side. Du st is r em oved fr om th e fa br ic by gr avity a n d/ or m ech a n ica l m ea n s su ch a s r a pper s or via a ir pu lses.

T h e over a ll collect ion efficien cy of elect r o-st a t ic p r ecip it a t or s, in m a n y ca ses, is h igh er t h a n 99 p er cen t (Br a u er a n d Va r m a , 1981). T h e over a ll collect ion efficien cy of t h e fa b r ic fi lt er w a s fou n d t o b e a r ou n d 99 p er cen t (H in dy, 1989). How ever, d u s t s u p p r es s ion by t h e t wo m ea n s on t h e d r y p r ocess lin es fa ces a sp ecia l p r oblem r ela t ed t o t h e d is p os in g of t h e collect ed cem en t d u s t . Con t r olled cem en t d u s t in t h r ee of t h e in ves t iga t ed fou r cem en t p la n t s is d isp os ed of on t h e s u r fa ce of t h e op en d es er t . T h is m ay ca u s e ser iou s en v ir on -m en t a l p r oble-m s, s u ch a s a ir a n d gr ou n d w a t er p ollu t ion .

T h e p r es en t in vest iga t ion t r ies t o fi n d ou t a su it a ble m ea n s, n ot on ly for d isp os in g of t h e con t r olled cem en t d u st in t h e fou r fa ct or ies, on ly a ls o for it s u t iliza t ion a s a u s efu l bu ild -in g m a t er ia l.

Experimental work

In a ccor d a n ce w it h t h e r eq u ir em en t s of t h e p r es en t in ves t iga t ion w h ich is lim it ed t o t h e

u t iliza t ion of cem en t d u st collect ed by t h e elect r os t a t ic p r ecip it a t or s (E SP ) a n d fa b r ic fi lt er s (F F ), t h e exa m in ed sa m p les w er e t a k en fr om 21 p la ces. T h ese a r e list ed in Ta ble III. T h e collect ed s a m p les w er e t h en su b ject ed t o p h y sica l t est s a n d ch em ica l a n a ly sis.

Physical tests

P h y sica l t est s in clu d ed in t h e p r es en t st u dy w er e su r fa ce a r ea , 45 µm s ieve r esid u e, 90µm -sieve r esid u e, set t in g t im e (in it ia l a n d fi n a l), a n d s et t in g t im e (t h r ee-d ay, seven -d ay a n d 28-d ay t est s). Tes t in g p r oce28-d u r es 28-d evelop e28-d for P or t la n d cem en t w er e a p p lied for t h e cem en t d u st .

P r oced u r es of ch em ica l a n a ly sis in volve d et er m in in g in solu ble r esid u e a n d t h e loss on ign it ion . T h e la t t er r eq u ir es ign it in g t h e d r ied sa m p le t o a con st a n t w eigh t in a m u ffle fu r n a ce a t 800°C u sin g u n cover ed p or cela in cr u cible. Req u ir ed ch em ica l d et er m in a t ion s a r e t h en m a d e u sin g p r oced u r es w h ich a r e t h e sa m e a s t h ose u sed in t est in g P or t la n d cem en t a n d d e p en d on X-r ay fl u or escen ce q u a n t om et er p lu s com p u t er, w h ich p r ov id es ch em ica l a n a ly sis a n d d a t a p r in t ou t of n in e elem en t s in less t h a n t h r ee m in u t es. T h ese elem en t s a r e ca lciu m (Ca ), silicon (Si), a lu -m in iu -m (Al), ir on (Fe), sod iu -m (N a ), p ot a s-siu m (K), su lp h u r (S), m a gn es-siu m (Mg) a n d ch lor in e (Cl).

Results and discussion

Physical properties

T h e su r fa ce a r ea (fi n en ess), set t in g (h a r d en -in g) t im e, a n d com p r essive s t r en gt h a r e t h e t h r ee p r in cip a l p h y sica l p r op er t ies w h ich sh ou ld b e t a k en in t o con sid er a t ion w h en eva lu a t in g t h e cem en t m a t er ia l. T h e r esu lt s of t h e p h y sica l t es t s of t h e con t r olled cem en t d u st sa m p les com p a r ed w it h t h e Br it ish St a n -d a r -d r eq u ir em en t s of or -d in a r y P or t la n -d cem en t (OP C) a r e given in Ta ble IV.

F r om t h e r esu lt s p r esen t ed , t h e follow in g m ay b e n ot ed .

Surfac e are a

T h e su r fa ce a r ea of t h e exa m in ed s a m p les r a n ges fr om < 50m2/ k g in sa m p le N o. 25 t o > 700m2/ k g in sa m p le N os 11, 12, 16, 18, 19, 20, 21, 23 a n d 26. Wit h t h e exce p t ion of sa m p le N os 13, 22 a n d 25, a ll ot h er exa m in ed sa m p les h ave a su r fa ce a r ea m or e t h a n t h e BS r eq u ir e-m en t (225e-m2/ k g).

T h e a b ove r esu lt s a r e m a in ly a s socia t ed w it h t h e elect r ost a t ic p r ecip it a t or s a n d fa b r ic fi lt er s u sed in t h e in vest iga t ed fou r cem en t p la n t s for t h e se p a r a t ion of t h e cem en t d u st fr om t h e ga s s t r ea m .

F in en ess of t h e fl y a sh h a s a s ign ifi ca n t in fl u en ce on it s p er for m a n ce in con cr et e.

Table II

Type and annual c o ns umptio n o f raw mate rials us e d in the inve s tigate d fo ur c e me nt

c o mpanie s

Annual consumption

Company Raw material (tonnes)

Ajman Gypsum 1 0 ,0 0 0

National Limestone

Bauxite Iron oxide

Union Limestone 1 ,3 3 8 ,8 2 6

Silic a 4 4 6 ,1 7 7

Bauxite 4 0 ,0 0 0

Iron oxide 2 8 ,0 0 0

Gypsum 5 0 ,0 0 0

Fujairah Limestone 4 9 0 ,0 0 0

Marl 1 8 9 ,0 0 0

Alluvium 1 8 7 ,0 0 0

Bauxite 8 ,7 0 0

Iron oxide 1 3 4 ,0 0 0

[ 2 3]

3 Ajman Separation FF Outlet 7 CS-1 air separator

4 Ajman Separation FF Outlet 7 CB-1 separation

produc t

5 Ajman Separation FF Outlet 7 CS-2 air separator

6 Ajman Separation FF Outlet 7 CB-2 separation

produc t

7 Ajman Cement pumping FF Outlet Mill 2 produc t

8 Ajman Cement pumping FF Outlet Mill 1 produc t

9 Ajman Silo loading FF Outlet OPC silo

10 Ajman Silo loading FF Outlet SRC silo

11 National Clinker produc tion ESP Inlet Main kiln

12 National Silo homogenizing FF Inlet Raw mill

13 National ESP Outlet Cement mill II

14 National Clinker produc tion ESP Inlet Main by-pass

15 National Clinker produc tion ESP Outlet Main kiln by-pass

16 National Clinker produc tion ESP Outlet Main kiln

17 National ESP Outlet Cement mill II

18 National Silo dedusting FF Outlet Raw mill

19 National After nodulizer

20 Union Clinker produc tion ESP Outlet Kiln 1

[ 2 7] Kamal T. Hindy

Utilizatio n o f c o ntro lle d c e me nt dust as a c o nc re te mate rial in the Unite d Arab Emirate s

Enviro nme ntal Manage me nt and He alth

8 / 1 [1 9 9 7 ] 2 0 –2 7

Sa m p le N o. 10 h a s SO3a n d LOI m or e t h a n t h e BS r eq u ir em en t s. A com b in a t ion of h igh SO3 a n d low M gO (a s fou n d in t h e s t u d ied sa m -p les ) in a clin k er m ix m ay b e d et r im en t a l t o st r en gt h d evelop m en t . T h is is a t t r ibu t ed t o t h e ev id en ce d r aw n by Gu t t a n d Sm it h (1968) t h a t in t h e p r esen ce of C3A t h ou gh n ot of C4AF, for m a t ion of C3S is r ed u ced by h igh SO3 con t en t , bu t t h is is cou n t er a ct ed by t h e p r es -en ce of M gO. T h e r es u lt s of p h y sica l t est s of in ves t iga t ed sa m p les (Ta ble IV), h ow ever, in d ica t e com p r es s ive st r en gt h va lu es for s a m p le N o. 10 h igh er t h a n t h e BS r eq u ir e-m en t s. At t h e sa e-m e t ie-m e, t h e r es u lt s of ch ee-m i-ca l a n a ly s is sh ow m a xim u m C3S con t en t for sa m p le N o. 10 in com p a r is on w it h ot h er su g-gest ed s a m p les (Ta ble V). T h is m ea n s t h a t t h e sa m p le ca n b e s a fely u sed a s a con cr et e m a t e-r ia l. On t h e ot h ee-r h a n d , t h e s ligh t in ce-r ea se in LOI con t en t of t h e sa m p le t h a n t h e BS r eq u ir em en t ca n b e con s id er ed in effect ive in ch a n gin g t h e ch a r a ct er is t ics of t h e con cr et e. It s h ou ld b e n ot ed t h a t t h e a lk a li con t en t of t h e cem en t d u st s a m p les su gges t ed t o b e u s ed a s con cr et e m a t er ia l is less t h a n t h e BS s p eci-fi ca t ion s, i.e. N a2O + 0.658 K2O = < 0.6 p er cen t for low -a lk a li cem en t .

Conclusion

T h e con clu s ion t h a t ca n b e d r aw n fr om t h e p r es en t in ves t iga t ion is t h a t t h e cem en t d u st collect ed by con t r ol m ea n s (e.g. elect r os t a t ic p r ecip it a t or s a n d fa b r ic fi lt er s ) m ay b e in ves -t iga -t ed fu r -t h er a s -t o i-t s u s e a s a con cr e-t e m a t er ia l.

T h e st u dy r evea ls t h a t con t r olled cem en t d u st collect ed fr om eigh t p oin t s on d r y p r ocess lin es a t a cem en t p la n t in t h e Un it ed Ar a b E m ir a t es h a s t h e s a m e p h y sica l a n d ch em ica l sp ecifi ca t ion s r eq u ir ed for or d in a r y P or t la n d cem en t . T h e con t r ol m ea n s u sed a t t h ese p oin t s is t h e fa b r ic fi lt er a n d t h e d r y p r ocess lin es a r e: se p a r a t ion (fou r p oin t s); cem en t p u m p in g (t wo p oin t s); a n d silo loa d -in g (t wo p o-in t s).

References

ACI Com m it t ee 226 (1987), Use of Fly A sh in Con -crete, ACI 226 3R-87, Am er ica n Con cr et e In st i-t u i-t e, Dei-t r oii-t , MI.

ASTM (1983), A m er ica n S ta n d a rd T est M eth od for Fin en ess of H yd ra u lic Cem en t b y th e 45-µm (N o. 325) S iev e, C 430-83.

Bogu e, R.H . (1929), In d . E n gn g. A n a lyt. E d n , Vol. 1 N o. 4, p. 192.

Br a u er, H . a n d Va r m a , Y.B.J . (1981), A ir Pollu tion Con tr ol E qu ip m en t, Sp r in ger -Ver la g, Ber lin , p p. 183-218.

Gu t t , W. a n d Sm it h , M.A. (1968), T ra n sa ction s of th e B r itish Cera m ics S ociety, Vol. 87, p. 487. H in dy, K.T. (1989), “P u ls e jet fa b r ic fi lt er op er a

-t ion : a n exp er im en -t a l s-t u dy ”, in Ch er em is i-n off, P.N. (E d .), E i-n cyclop ed ia of E i-n v ir oi-n m ei-n ta l Con tr ol T ech n olog y. Volu m e 2: A ir Pollu tion Con tr ol, Gu lf P u blis h in g, H ou s t on , TX, p p. 981-1002.

H in dy, K.T. a n d At t ia , A.A. (1988), Pr oceed in gs of 3rd In ter n a tion a l Con feren ce on E n v ir on m en -ta l Con -ta m in a tion , Ven ice (S ep tem b er ), CE P Con s u lt a n t s Lt d , E d in bu r gh , p p. 476-8. H in dy, K.T. a n d At t ia , A.A. (1993), E n v ir on m en ta l

E d u ca tion a n d In for m a tion , Vol. 12, p. 35. In ter n a tion a l Cem en t R ev iew (1992), Feb r u a r y,