This article was originally published in

Encyclopedia of Dairy Sciences, Second

Edition, published by Elsevier, and the attached copy is provided by Elsevier for the

author’s benefit and for the benefit of the author’s institution, for non-commercial

research and educational use including without limitation use in instruction at your

institution, sending it to specific colleagues who you know, and providing a copy to

your institution’s administrator.

All other uses, reproduction and distribution, including without limitation

commercial reprints, selling or licensing copies or access, or posting on open

internet sites, your personal or institution’s website or repository, are prohibited.

For exceptions, permission may be sought for such use through Elsevier’s

permissions site at:

http://www.elsevier.com/locate/permissionusematerial

Akuzawa R, Miura T, and Surono IS (2011) Fermented Milks | Asian Fermented

Milks. In: Fuquay JW, Fox PF and McSweeney PLH (eds.),

Encyclopedia of Dairy

Sciences, Second Edition, vol. 2, pp. 507–511. San Diego: Academic Press.

Asian Fermented Milks

R Akuzawa and T Miura, Nippon Veterinary and Life Science University, Tokyo, Japan

I S Surono, University of Indonesia, Jakarta, Indonesia

ª2011 Elsevier Ltd. All rights reserved.

This article is a revision of the previous edition article by R. Akuzawa and I. S. Surono, Volume 2, pp 1045–1049, ª2002, Elsevier Ltd.

Introduction

The origins of fermented milk are unclear. However, when the goat was first domesticated in Mesopotamia in about 5000 BC, the nomadic communities stored the milk warm in animal skin bags or in crude earthenware pots in a hot climate, which led to spontaneous curd formation. Fermented milks probably originated in the Middle East before the Phoenician era. The Old Testament mentions that fermented cream existed in Mesopotamia inc.1300 BC and laban rayed and laban khad were manufactured perhaps as early as 5000 BC. Kumys was probably known in the Ukraine around 2000 BC and dahi was fermented in India as early as 1500 BC. The skills of making fermented milk were introduced to Russia and other European areas by the Tartars, and to central Asia by the Huns and Mongols. The ‘Silk Road’ contributed to the early development and spread of fermented milks. A common characteristic of all fermented milks is the presence of lactic acid.

Various methods have been used for the manufacture of traditional fermented milks. The bacteria essential for fer-mentation originate from ferfer-mentation vessels, raw milk, the alimentary tract of animals, and plants. Warm raw milk from the cows, sheep, goats, water buffaloes, camels, or horses of the nomads was turned into clabber or curd by indigenous bacteria, by means of traditional fermentation.

Dahi (Dadhi)

Yogurt-like products are widely produced in the Mediterranean area, Asia, Africa, and central Europe. In India, dahi, which resembles yogurt, is still made tradi-tionally at home using the milk of various mammals, for example, water buffaloes, cows, and goats. Dahi is a semi-solid product obtained from pasteurized or boiled milk by souring naturally, or otherwise using a lactic acid culture. A commercially available mixture of buffaloes’ and cows’ milk is used. The milk is boiled, cooled, inoculated with dahi starter left over from the previous day, and incubated at ambient temperature for 4–6 h until it turns to a thick consistency. Dahi made from buffaloes’ milk is thick

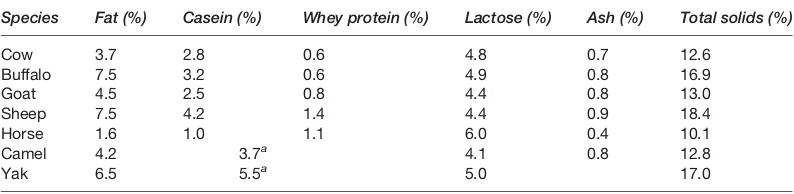

because of the higher solids content of buffaloes’ milk. The composition of the milk of various dairy species is shown in Table 1. Industrial production of dahi is now being attempted in metropolitan areas.

Mild dahi is made with mesophilic lactococci.

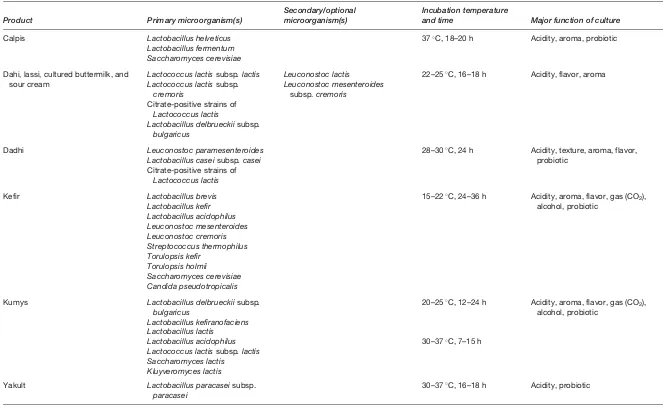

Leuconostoc strains can be used as adjunct organisms for added buttery odor and flavor. Sour dahi contains addi-tional cultures of thermophilic microorganisms, which are generally employed in the manufacture of yogurt. It takes less than 4 h to produce dahi. Dahi makes an important part of Indian meals. It is an essential material to make Indian cold soup ‘raita’ and curry ‘kadhi’. Additionally, dahi may be consumed as a sweet or savory ‘lassi’ drink or as a dessert containing sugar and fresh-diced banana, orange slices, mango, and other seasonal fruits. The microorganisms involved in the production of dahi and other fermented milks of Asia, as well as the major func-tions of starter cultures, are listed inTable 2.

Kumys

Kumys (koumiss, kumis) (seeFermented Milks: Koumiss)

is a unique lactic acid–alcohol fermented milk drink that originated in central Asia. The name is derived from the Kumanese, who survived until 1235 as a Kumane River tribe on the central Asian steppes. The proteins of horses’ milk are somewhat different from those of the milk of other species because when the milk is fully renneted, it forms no visible curd, owing to higher whey protein and lower casein content. The fat content of horses’ milk is lower than that of cows’ milk. Traditionally, kumys was made from horses’ milk, but now that horses’ milk is scarce, cows’ milk is used for the preparation. To overcome the difference in the casein and whey protein ratio between horses’ and cows’ milk, a membrane ultrafiltration method is used. By this method, the whey protein content could be adjusted, so that whey protein is concentrated, but not lactose.

Lactose-fermenting yeasts, such as Candida spp.,

(LAB) are responsible for acid production, and the yeasts are responsible for the production of ethanol and carbon dioxide. Some starter cultures may include Lactobacillus acidophilusandLactococcus lactis, as shown inTable 2.

In the commercial manufacture of kumys from horses’ milk, the bulk starter is prepared first. A yeast culture of

Torulaspp. and the LAB culture are inoculated separately into pasteurized skim milk from cow and incubated at 30C for 15 h and at 37C for 7 h, respectively. To

pre-pare the bulk starter, the incubated cultures are added to horses’ milk and incubated at 28C for about 4 days, after

which the titratable acidity usually reaches 1.4%. Thirty percent of the bulk starter is added to the fresh horses’ milk at 28C and the milk is agitated vigorously to

introduce air essential for good yeast growth. The fer-menting milk is dispensed into bottles with crown-capped closures and incubated for a further 2 h at 20C. The

product is stored at below 6C until sold.

Large-scale production of kumys from cows’ milk is carried out by adding 2.5% sugar and 10% starter (Lb. delbrueckii subsp. bulgaricus, Lb. acidophilus, and

Saccharomyces lactis). The inoculated milk is incubated at 26–28C until a firm curd forms at the titratable acidity of

approximately 0.8%. It is held at approximately 17C

with aeration and intermittent stirring for the optimum yeast growth and, after several hours, the titratable acidity reaches 0.9%. The acidified milk is then bottled. Accumulation of alcohol and carbon dioxide occurs dur-ing ripendur-ing and the product is subsequently stored at or below 6C until sold.

Kumys is a milky white liquid with a grayish cast. It is not watery but possesses a uniform consistency without any tendency to flake or whey off. A starter for kumys patented in 1990 in the former USSR consisted ofLc. lactis

subsp.lactis,Lb.delbrueckiisubsp.Bulgaricus, and the yeast

Torula spp. The milk is first aerated by stirring for 20–25 min and is then kept at room temperature for 2–3 h. Lactic acid, ethanol, and carbon dioxide are the end products. Hence, kumys has a sourish flavor and bubbles on shaking.

Kumys is produced with varying contents of lactic acid and alcohol. It is classified into three categories depending on the extent of fermentation. Mild-flavored kumys has an acidity of 0.6–0.8% with an alcohol content of 0.7–1.0%; medium-flavored kumys contains 0.8–1.0% lactic acid and 1.1–1.8% alcohol; and strong-flavored kumys has an acidity of 1.0–1.2% with 1.8–2.5% alcohol. Viable counts of 4.97107 and 1.43107 cfu ml 1 for bacteria and yeast, respectively, have been reported in kumys.

Yakult

Today, yakult is the best-known fermented milk product in the world on account of various claims of its health-promoting properties. After the Meiji Restoration (1868) in Japan, dairy products gained general acceptance and were appreciated as a special food for the sick, because this was the period when people were suffering from chronic malnutrition and infections, particularly intestinal infec-tions such as dysentery and colitis. At that time, M. Shirota was aware that certain indigenous intestinal bacteria played a role in the body’s defense mechanisms, including by competing with invading pathogenic bacteria. In 1929, he succeeded in isolating and cultivatingLactobacillus casei

strain Shirota (now reclassified as Lactobacillus paracasei

subsp. paracasei), an indigenous human intestinal bacter-ium, and in 1935 he developed a fermented milk drink named yakult. Commercially produced yakult is made by fermenting skim milk with this organism. The total milk solids are rather low, about 3.7%, and yakult has 14% added sugar. The fermentation time is around 16–18 h at 37C. The viable count at the end of the fermentation

exceeds 108 cfu ml 1. LAB are widely distributed in nature, but not all of them can survive in the human intestine.Lactobacillus paracaseisubsp.paracaseiis occasion-ally found in the intestine and is capable of reaching the intestine in a viable state. The strain used in yakult manufacture is resistant to gastric juice and bile.

Table 1 Composition of milks used in the preparation of fermented milks

Species Fat (%) Casein (%) Whey protein (%) Lactose (%) Ash (%) Total solids (%)

Cow 3.7 2.8 0.6 4.8 0.7 12.6

Table 2 Starter cultures involved in the manufacture of commercial and traditional fermented milks of Asia

Product Primary microorganism(s)

Secondary/optional microorganism(s)

Incubation temperature

and time Major function of culture

Calpis Lactobacillus helveticus 37C, 18–20 h Acidity, aroma, probiotic

Lactobacillus fermentum Saccharomyces cerevisiae

Dahi, lassi, cultured buttermilk, and sour cream

Lactococcus lactissubsp. lactis Leuconostoc lactis 22–25C, 16–18 h Acidity, flavor, aroma Lactococcus lactissubsp.

cremoris

Leuconostoc mesenteroides

subsp.cremoris

Citrate-positive strains of

Lactococcus lactis

Lactobacillus delbrueckiisubsp. bulgaricus

Dadhi Leuconostoc paramesenteroides 28–30C, 24 h Acidity, texture, aroma, flavor,

probiotic

Lactobacillus caseisubsp. casei

Citrate-positive strains of

Lactococcus lactis

Kefir Lactobacillus brevis 15–22C, 24–36 h Acidity, aroma, flavor, gas (CO2),

alcohol, probiotic

Lactobacillus kefir Lactobacillus acidophilus Leuconostoc mesenteroides Leuconostoc cremoris Streptococcus thermophilus Torulopsis kefir

Torulopsis holmii

Saccharomyces cerevisiae Candida pseudotropicalis

Kumys Lactobacillus delbrueckiisubsp.

bulgaricus

20–25C, 12–24 h Acidity, aroma, flavor, gas (CO

2),

alcohol, probiotic

Lactobacillus kefiranofaciens Lactobacillus lactis

Lactobacillus acidophilus 30–37C, 7–15 h

Lactococcus lactissubsp. lactis Saccharomyces lactis

Kluyveromyces lactis

Yakult Lactobacillus paracaseisubsp.

paracasei

30–37C, 16–18 h Acidity, probiotic

FromKosikowski FV (1982)Cheese and Fermented Milk Foods, 2nd edn., pp. 37–57. New York: FV Kosikowski and Associates;International Dairy Federation (1988)Fermented milks: Science and technology.

International Dairy Federation Bulletin no. 227. Brussels, Belgium: IDF;Sansawa H (1999)Mass production ofLactobacillus caseistrain Shirota. In: Yakult Central Institute for Micro-biological Research (ed.) Lactobacillus caseiStrain Shirota, pp. 97–102. Tokyo, Japan: Yakult Honsha;Watanabe J, Ikeda N, Mizutani J,et al. (1998)Comparison of microbiological and chemical characteristics among types of traditionally fermented milk in Inner Mongolia in China and Calpis sour milk (sannyuu).Milk Science47: 1–8;Lang F and Lang A (1970)A study of kumys manufacture as a potential new outlet for milk.Milk Industry

Many culture methods have been studied to alleviate the inhibition of growth medium. These included batch culture, continuous culture, fed-batch culture, dialysis culture, and extractive fermentation. The best results were obtained in fed-batch culture, by supplying fresh medium to the culture broth continuously or intermit-tently to maintain a desirable growth environment. In the fed-batch system, culture broth containing lactic acid is separated by filtration and an equal amount of fresh medium is added. This method achieves a very high final cell concentration. A final cell mass of 40 g l 1was obtained using this technique. Batch culture is the sim-plest method, but both final cell concentration and metabolites are generally low, while continuous culture keeps the culture environment constant and cell produc-tivity has been reported to be 1.05 g cell h 1l 1, over 3 times higher than that reported for batch culture (0.33 g cell h 1l 1).

The characteristic light coffee color of yakult is the result of the Maillard reaction. Glucose, added to skim milk before the heat treatment, plays a major role in this reaction.

Other Traditional Fermented Milks

Products of Mongolia

The fermented milks of the state of Mongolia and the province of Inner Mongolia in China are obtained using LAB and yeast fermentation.

Although fermented milk products are regarded as pre-dominantly lactic fermentations, the frequent interaction of yeast and LAB has led to specific product characteristics and quality. Types of fermented milks from this region include ‘edosensuu’, ‘airag’, and ‘tarag’. Edosensuu is made from cows’ milk and it resembles soft yogurt in appearance. It is fermented byLc. lactis,Leuconostoc lactis, and yeast at 17–20C, which results in the production of small

quan-tities of lactic acid (0.8%) and alcohol (0.2%). The cream layer is removed after fermentation.

Airag (also called tsege in Inner Mongolia) is made from the milk of various mammals, and especially horse milk and camel milk are considered most valuable. In the traditional Mongolian procedure, the milk is poured into a large sack made of cows’ or sheep’s leather, or alterna-tively, a vat made of wood can be used. Within these containers, the milk is stirred with a wooden paddle over 1 or 2 days. This suggests that milk must be supplied with air. The oxygen in the air helps the fermentation process by a combination of lactic acid bacteria and yeast.

Lactobacillus helveticus,Lc. lactis, and yeasts are the domi-nant microflora of this product, which contains a small amount of carbon dioxide and up to 1–3% of alcohol.

Tarag (also called airag in Inner Mongolia) is like a hard-type yogurt made from cows’ milk or sometimes

from the skim milk of sheep or goats. Lactobacillus kefiranofaciens dominates the microflora of this product. A bacterial culture is added when the boiled milk has cooled to the touch. It takes a few hours until curd is formed. Tarag contains relatively high amounts of lactic acid (pH 3.6–3.9). Tarag is usually consumed just by itself with some fruit added. Additionally, these alcoholic milk products will often be distilled to Mongolian milk liquor (arkhi) with a homemade distiller.

These Mongolian fermented milk products are con-sidered to be a rich source of vitamins and minerals for nomads.

Tsege is often classified as airag, but it is a unique product basically made from horse milk. Traditional tsege contains Lb. helveticus, Lactobacillus fermentum, and

Saccharomyces cerevisiae. A similar culture has been used in Japan in the commercial manufacture of a pasteurized fermented milk drink called Calpis.

Calpis was developed in Japan and first manufactured in 1919 based on the fermented milk of Mongolian nomads. This pasteurized fermented milk drink was man-ufactured from two fermentation processes using Lb. helveticusandS. cerevisiae. First, a starter culture of yeast andLactobacillus is added to skim milk, thereby turning it into the lactobacillus-cultured milk. In the second fermentation process, sugar is added. Together with the yeast, this gives Calpis its sweet and tangy taste with the hint of an aroma and yogurt flavors.

Calpis contains several peptides derived from milk proteins, which provide a physiological effect such as lowering of blood pressure in spontaneously hypertensive rats and also in hypertensive human subjects. The starter organisms are responsible for the release of a range of potent bioactive peptides.

The well-studied milk peptides are the tripeptides iso-leucine–proline–proline (IPP) and valine–proline–proline (VPP), derived from - and -casein, and they inhibit angiotensin-I-converting enzyme (ACE). For more than 90 years, Calpis has continued to be in favor far and wide.

Dadih, which is similar to Indian dahi, has been produced in Indonesia for hundreds of years. The root word seems to be common. The Minangkabaus of West Sumatra traditionally ferment raw milk from buffaloes in fresh bamboo tubes capped with banana leaves to produce dadih. Interestingly, no heat treatment is applied to milk, which is fermented spontaneously by indigenous LAB present in the raw milk from buffaloes. The milk curdles after 24 h fermentation at 28–30C. At

the end of fermentation, the total count of LAB is typically 108 cfu g 1.

The major bacterial species found in this product are

]-indole. The composition of LAB involved in spontaneous fermentation may vary depending on the conditions of fermentation.

It is believed in West Sumatra that dadih has a bene-ficial effect on health. Claims of prophylactic and therapeutic properties of indigenous LAB isolated from dadih warrant further investigation. These bacteria may be a useful addition to the probiotic organisms currently used in the commercial manufacture of fermented milks around the world.

See also:Fermented Milks: Health Effects of Fermented Milks; Kefir; Koumiss; Middle Eastern Fermented Milks; Starter Cultures; Types and Standards of Identity;Yeasts and Molds: Yeasts in Milk and Dairy Products.

Further Reading

Degan AA (2007) Sheep and goat milk in pastral societies.Small Ruminant Research68: 7–19.

Fernandes CF, Chandan RC, and Shahani KM (1992) Fermented dairy products and health. In: Wood BJB (ed.)The Lactic Acid Bacteria, Vol. 1, The Lactic Acid Bacteria in Health and Disease, pp. 297–339. London: Elsevier Applied Science.

Fox PF and McSweeney PLH (1998).Dairy Chemistry and Biochemistry. London: Blackie Academic and Professional.

Hayakawa K, Sansawa H, Nagamune T, and Endo I (1990) High density culture ofLactobacillus caseiby a cross-flow culture method based on kinetic properties of the microorganism.Journal of Fermentation and Bioengineering70: 404–408.

International Dairy Federation (1988) Fermented milks: Science and technology.International Dairy Federation Bulletin no. 227. Brussels, Belgium: IDF

Korhonen H and Pihlanto A (2006) Bioactive peptides: Production and functionality.International Dairy Journal16: 945–960.

Kosikowski FV (1982)Cheese and Fermented Milk Foods, 2nd edn., pp. 37–57. New York: FV Kosikowski and Associates.

Lang F and Lang A (1970) A study of kumys manufacture as a potential new outlet for milk.Milk Industry67: 22–25.

Ling ER, Kon SK, and Porter JWG (1961) The composition of milk and the nutritive value of its components. In: Kon SK and Cowie AT (eds.)

Milk, Vol. 2 pp. 195–263. London: Academic Press. Nakamura Y, Yamamoto K, Sakai A, Okubo S, Yamazaki I, and

Takano TI (1995) Purification and characterization of angiotensin I-converting enzyme inhibitors from sour milk.Journal of Dairy Science78: 777–783.

Sansawa H (1999) Mass production ofLactobacillus caseistrain Shirota. In: Yakult Central Institute for Micro-biological Research (ed.) Lactobacillus caseiStrain Shirota, pp. 97–102. Tokyo, Japan: Yakult Honsha.

Sukumar DE (1980)Outlines of Dairy Technology, p. 404. Delhi, India: Oxford University Press.

Surono IS and Hosono A (1996) Antimutagenicity of milk cultured with lactic acid bacteria from Dadih against mutagenic Terasi.

Milchwissenschaft51(9): 493–497.