All sources 100 Internet sources 43 Results of plagiarism analysis from 2017-12-06 08:31 UTC

Compatibilized natural rubber recycled ethylene propylene diene rubber blends by biocompatibilizer.pdf

[88] journals.sagepub.com/doi/abs/10.1177/0095244314557975 0.4% 2 matches

[89] onlinelibrary.wiley.com/doi/10.1002/app.10361/full?scrollTo=references 0.5% 3 matches

[90] ejournal.kemenperin.go.id/mkkp/article/view/688 0.6% 2 matches

[92] https://www.scientific.net/AMM.754-755.130 0.5% 2 matches

[93] scholar.google.com/citations?user=cqlxtpwAAAAJ&hl=en 0.6% 2 matches

[94] onlinelibrary.wiley.com/doi/10.1002/pol.1961.1205015404/full 0.4% 2 matches

[95] www.tandfonline.com/doi/pdf/10.1080/03602559909351564 0.4% 2 matches

[96] https://www.researchgate.net/publication..._and_fatigue_studies 0.4% 2 matches

[97] www.tandfonline.com/doi/pdf/10.1080/00914030008033888 0.4% 1 matches

[99] https://www.sciencedirect.com/science/article/pii/S0009250906003332 0.3% 1 matches

[100] onlinelibrary.wiley.com/doi/10.1002/app.1987.070340613/abstract 0.3% 1 matches

[101] https://www.scientific.net/AMM.754-755.125 0.5% 2 matches

[102] https://www.chemweb.com/articles/01429418/00320002 0.5% 2 matches

[103] mdpi.com/2313-4321/2/3/16/xml 0.4% 3 matches

[104] https://www.sciencedirect.com/science/article/pii/S0142941807001110 0.3% 2 matches

[105] https://www.researchgate.net/publication...om_devulcanized_EPDM 0.3% 1 matches

[106] https://www.sciencedirect.com/science/article/pii/S0142941814001810 0.3% 1 matches

13 pages, 6100 words

PlagLevel: selected / overall

314 matches from 107 sources, of which 90 are online sources.

Settings

Data policy: Compare with web sources, Check against my documents, Check against my documents in the organization repository, Check against organization repository, Check against the Plagiarism Prevention Pool

--Full Terms & Conditions of access and use can be found at http://www.tandfonline.com/action/journalInformation?journalCode=gpac20

Download by: [Universiti Sains Malaysia] Date: 24 April 2016, At: 02:08

International Journal of Polymer Analysis and

Characterization

ISSN: 1023-666X (Print) 1563-5341 (Online) Journal homepage: http://www.tandfonline.com/loi/gpac20

Compatibilized natural rubber/recycled

ethylene-propylene-diene rubber blends by

biocompatibilizer

Nabil Hayeemasae, Indra Surya & Hanafi Ismail

To cite this article: Nabil Hayeemasae, Indra Surya & Hanafi Ismail (2016):

Compatibilized natural rubber/recycled ethylene-propylene-diene rubber blends by biocompatibilizer, International Journal of Polymer Analysis and Characterization, DOI: 10.1080/1023666X.2016.1160970

To link to this article: http://dx.doi.org/10.1080/1023666X.2016.1160970

Accepted author version posted online: 03 Mar 2016.

Published online: 03 Mar 2016.

Submit your article to this journal

Article views: 14

View related articles

INTERNATIONAL JOURNAL OF POLYMER ANALYSIS AND CHARACTERIZATION http://dx.doi.org/10.1080/1023666X.2016.1160970

Compatibilized natural rubber/recycled ethylene-propylene-diene

rubber blends by biocompatibilizer

Nabil Hayeemasae a

Engineering, Engineering Campus, Universiti Sains Malaysia, Nibong Tebal, Penang, Malaysia

ABSTRACT

Biocompatibilizer-based refined, bleached, deodorized palm stearin was successfully used as compatibilizer for natural rubber/recycled ethylene– propylene–diene rubber (NR/R-EPDM) blends. It seems effective in improving the state of cure, tensile properties, as well as the swelling resistance and morphology of the blends, indicating an improvement in compatibility between the NR matrix and R-EPDM rendered by biocompatibilizer. This was clearly verified by the dynamic mechanical properties of the blends. The dynamic responses obtained were clearly corresponding to the swelling result. It proves that the cross-link density plays a major role in the changes of storage modulus and degree of entanglement.

ARTICLE HISTORY

Ethylene-propylene-diene rubber (EPDM) has been the fastest growing rubber among the synthetic rubbers since its introduction in 1963.[ ] 1It represents 7% of world rubber consumption, and it is most widely used for non-tire rubber.[ ] 2 The cross-linked EPDM is thermoset and insoluble; thus, it causes the straight reprocessing of EPDM become more complicated. This polymeric material cannot return to the ecological environment through biological degradation and is most often discarded after a cer -tain period of time. Recycling of EPDM rubber is an interesting topic in connection with the continu-ous market growth of EPDM. To solve this environmental issue, waste EPDM has been used in an effort to create value-added rubber materials based on a blend of natural rubber (NR) and recycled EPDM (R-EPDM).

The blending of NR and R-EPDM has been studied previously.[ ] 3 However, satisfactory state of cure and mechanical properties are difficult to attain due to the differences in the unsaturation levels of NR and R-EPDM. To widen the focus, enhancing such properties is a keen challenge for the blends

based on NR and R-EPDM. [60]The key factors for improving the performance of rubber blends are compatibility among two blending components where a strong interfacial adhesion between matrices

is of interest.[ ] 4[60]Homogeneous distribution of R-EPDM and their respective compatibility have been a

potent challenge in such blend.

Currently, the demand for utilization of renewable resources for the production of biosustainable materials is increasing in research areas and manufacturing. One of the renewable resources that are of great relevance to Thailand and the neighboring countries is the growth of palm oil industry. Palm

oil is a renewable and sustainable source of fatty acids that represent raw materials that can replace

the activator used in rubber compounding. For example, Ismail and Anuar[ ] 5 studied the effect of

CONTACT Nabil Hayeemasae [email protected] Department of Rubber Technology and Polymer Science, Faculty of Science and Technology, Prince of Songkla University, Pattani Campus, 181 Chroenpradit Road, Rusamilae, Muang, Pattani 94000, Thailand.

palm oil as an activator in NR compound. [96]It was presented that this material can be replaced the

stea-ric acid to activate the vulcanization process.

In palm oil industry, crude palm oil (CPO) is extracted from fresh palm (Elaeis guineensis) and it can be used as raw material for manufacturing of refined palm oil. The CPO has to undergo extensive processing before it reaches the consumer. Refined, bleached, and deodorized palm stearin (RBDPS) is derived from the refinery process of CPO that has been used mainly in shortening and margarines.[ ] 6 The cost of the RBDPS is cheaper when compared to the major component. Being an economically viable material, RBDPS has been widely used in many industries, especially in food industry. However, the applications of this material in rubber matrices are still largely unexplored.

Generally, the fatty acid compositions of RBDPS consist of highly saturated and triglyceride contents.[ ] 7 [69]Fatty acids or their methyl esters (triglyceride) can react with primary and

secondary amines such as monoethanolamines and diethanolamines to produce the corresponding

alkanolamides.[ ] 8[56]The idea of this study is to use the alkanolamide-based RBDPS as a biocompatibilizer

for NR/R-EPDM blends[56]. Several methods of mixing and functionalization have been reported to

improve the compatibility in the rubber blends such as the use of third polymers,[9] reactive

mixing,[10] radiation curing,[11] to name a few. [56]But no reports are available on the detailed

tions concerning the use of biocompatibilizer-based RBDPS known as alkanolamide to improve the

compatibility in such blends. With the surface chemistry of biocompatibilizer-based RBDPS and its

waxy appearance in nature, it is believed to improve the dispersion and compatibility of the blends.

Experimental details

Materials

The formulation used for blending is presented in Table 1. Natural rubber (SMR L grade) was supplied by Mardec Berhad, Selangor, Malaysia. Recycled ethylene-propylene-diene rubber (R-EPDM) obtained from gaskets and O-rings were supplied by Zarm Scientific (M) Sdn. Bhd. Penang, Malaysia. The R-EPDM was ground into a powder form using table-type pulverizing machine from Rong Tsong

[70]

Precision Technology Co. Ltd., Taiwan, [70] to obtain particles approximately 10–200 µm in size. R-EPDM

was in irregular and rough shape and was broken by a mechanical crusher. The specific gravity of

the R-EPDM was found to be 1.06 g cm 3. The carbon black content in R-EPDM was 29.33%. The physical characteristic of R-EPDM has been reported in our previous study.[ ] 3The N330-grade carbon black was supplied by Malayan Carbon (M) Ltd, Malaysia. Other compounding ingredients, such as zinc oxide, stearic acid, N-cyclohexyl-benzothiazyl-sulfenamide (CBS), and sulfur were purchased from Bayer (M) Ltd.

Synthesis of biocompatibilizer based refined, bleached, deodorized palm stearin

Biocompatibilizer-based RBDPS can be synthesized according to the optimum conditions described by Surya et al.[12] It was carried out at atmospheric pressure in a 1,000 mL reaction vessel fitted with a

Table 1. Formulation of the blends.

Amount (phr)

stirrer. First, sodium methoxide was added in the ethanol and stirred in the reaction flask. The

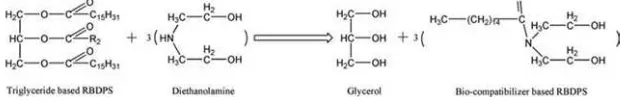

mixture of RBDPS and diethanolamine were then added in the solution and mildly stirred (1 mol of RBDPS always contents 3 mol of the corresponding diethanolamine, sodium methoxide, and ethanol, respectively). Next, the mixture was heated, and the reaction temperature was kept constant at 70°C for 5 h. The resultant mixture was extracted with diethyl ether and washed with saturated sodium chloride solution. Finally, the crude product was purified with anhydrous sodium sulfate and concentrated by a rotary evaporator. The final product was then characterized for their respective [102] functional groups using Fourier transform infrared spectroscopy (FT-IR). The reaction procedure of biocompatibilizer-based RBDPS is shown in Figure 1. Biocompatibilizer-based RBDPS is in a

Our previous work[ ] 3[70]has reported that the blend ratio at 70/30 (phr/phr) of NR and R-EPDM provided

satisfactory properties. Thus, this blend ratio was selected to further study the effect of biocompatibi

-lizer. The entire amount of additives as well as NR and R-EPDM were prepared in a laboratory-sized two-roll mill (model XK-160) at ambient temperature. The resulting blends were later tested for its curing characteristics using a Monsanto Moving Die Rheometer (MDR 2000). The compounds were

subsequently compression-molded using a stainless steel mold at 150°C with a pressure of 10 MPa using a laboratory hot-press based on respective curing times.

Curing characteristics

The curing characteristics of the rubber blends were obtained by using a Monsanto Moving Die

Rheometer (MDR 2000), which was used to determine torques, scorch time (ts2), and curing time (tc90) according to ASTM: D2084-11 samples of the respective blends were tested at 150°C. The cure rate index of the blends was calculated as follows:

CRI¼

[33] 100

ðtc90 ts2Þ

ð Þ1

Fourier transform infrared

The FTIR spectra of the biocompatibilizer-based RBDPS was analyzed using Perkin–Elmer Spectrum

One FTIR spectrometer and attenuated total reflection (ATR) technique was adopted. The selected spectrum resolution and the scanning range were 4 cm1 and 550 to 4000 cm1, respectively.

Measurement of tensile properties

Dumbbell-shaped samples were cut from the molded sheets according to ASTM: D412-06ae2. [64]Tensile

tests were performed at a cross-head speed of 500 mm min1. Tensile tests were carried out with a [92]

universal tensile machine Instron 3366 to determine the tensile properties such as tensile

strength, elongation at break, stress at 100% (M100), and 300% (M300) elongation. The hardness

Figure 1. Proposed chemical reaction of bio-compatibilizer based RBDPS, adapted from Surya et al.[12]

INTERNATIONAL JOURNAL OF POLYMER ANALYSIS AND CHARACTERIZATION 3

the toluene was removed from the samples' surface, and the weight was determined. Calculation of

the changes in mass is as follows:

Swelling¼

The examination of tensile fractured surfaces was carried out using a scanning electron microscope (SEM) model Zeiss Supra-35VP to obtain information on the possible presence of micro-defects. The fractured pieces were coated with a layer of gold palladium to eliminate electrostatic charge build-up during examination.

Dynamic mechanical analysis

Dynamic mechanical properties were measured by using dynamic mechanical analyzer (Mettler Toledo, DMA 861e), supplied by Mettler-Toledo (M) Sdn. Bhd. The samples were subjected to a cyclic tensile strain with force amplitude of 0.1 N at a frequency of 10 Hz. Storage modulus ( ), loss modulus E′

( ), and damping factor (tan ) were determined in the temperature range from 100 to 60°C at a E″ d

heating rate of 2°C min1.

Results and discussion

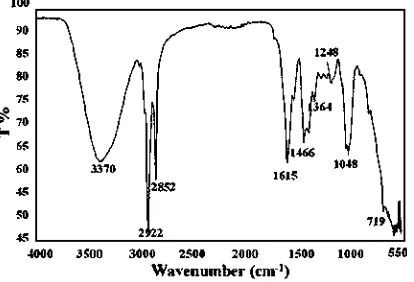

FT-IR analysis of biocompatibilizer

saturated and unsaturated portions exist in the molecule.[14] The umbrella mode at 1364 cm1 con-firms the presence of a methyl group (CH3) that attached to the carbon atom. The (CH2) rocking band at 719 cm 1 means that there are more than four methylene atoms in a row in the molecule. The C=O

stretch is at 1615 cm1, and the amide C–N stretch is at 1248 cm 1.[12] The obtained spectrum is

clearly corresponding to the functional groups presented in biocompatibilizer-based RBPDS.

Curing characteristics

Curing characteristics of control and compatibilized blends are tabulated in Table 3. It was observed that the minimum torque (ML) decreased with the addition of biocompatibilizer. ML is commonly considered to be a representative of the uncured stock's elastic modulus and also provides valuable

information about a compound's processability.[15] This result indicated that biocompatibilizer had improved the processability of the blends. Biocompatibilizer used in this study originated from waxy RBDPS; it was then acting as internal plasticizer resulting to lower the viscosity and improve the pro -cessability of the blends. The maximum torque (MH) increased with further increase of the biocompa-tibilizer. As mentioned in the preceding section, the biocompatibilizer was synthesized from RBDPS and diethanolamine. The structure of biocompatibilizer is similar to aminebased accelerator. There -fore, it could enhance the cross-link density to the blends leading to improve the maximum torque. Similar observation was found for the torque differences (MH–ML), as the torque difference is widely accepted to be indirectly related to the degree of cross-linking.[16] [54]The total cross-linking is contributed by the sulfidic cross-links and physical cross-links[17][54]; this finding could indicate that the cure

compati-bility of NR and R-EPDM enhanced significantly when the biocompatibilizer is added to the blends. The responsible amine content in biocompatibilizer also fastened the scorch and cure times of the

[54]

blends, indicating that biocompatibilizer could act as a co-curing agent or secondary accelerator in

the curing process of NR/R-EPDM blends. Amine is an alkaline substance that increases the pH of

Figure 2. FT-IR spectrum of bio-compatibilizer based RBDPS.

Table 2. The wavenumbers of functional groups of bio-compatibilizer based RBDPS.[14]

Wavenumber (cm1) Assignments

INTERNATIONAL JOURNAL OF POLYMER ANALYSIS AND CHARACTERIZATION 5

the rubber compound and, in most instances, enhances the cure rate. [38]Any material that gives the

rub-ber compound more basic character will then enhance the cure rate since acidic materials tend to

retard the effect of the accelerator.[12 18, ] According to Bateman,[19] and Ismail and Ng,[20] [38]a certain

organic substance containing nitrogen atoms promotes the curing process of olefinic rubber, com -prising sulfur and primary accelerators, through the formation of complexes that are responsible

for the fission of the sulfur molecules to form cross-links between the linear rubber chains. [38]It is expected that the amine content of the biocompatibilizer would accelerate the cure and is responsible

for enhancing the cure rate and the cure state of the blends.

Tensile properties and swelling results

[64]

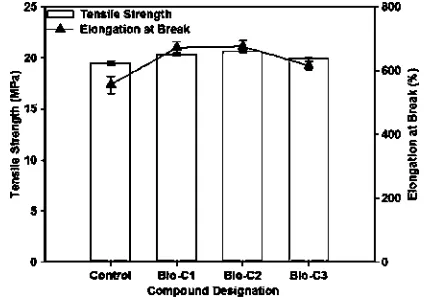

Figure 3 shows the effect of biocompatibilizer content on the tensile strengths and elongation at break

of the blends[62]. It was observed that the tensile strength increased up to the maximum level of 2 phr and

then decreased with further increases in the biocompatibilizer content. According to Hertz,[21] and

Ismail and Chia,[22] the tensile strength is dependent on the degree of cross-linking, as the cross-link

density increases, the elastic properties, such as tensile strength increase, whereas viscous loss pro-perties, such as hysteresis, decrease.[23] [62]Further increases in the cross-link density will then produce

a vulcanizate that tends toward brittle behavior. Thus, at a higher cross-link density, such elastic

properties as mentioned earlier begin to decrease.

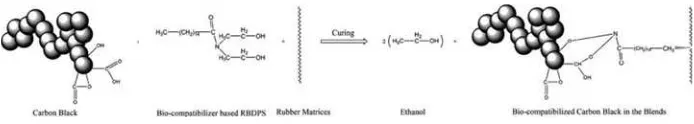

Another possible reason might be due to the highly dispersed carbon black, arising from the inter -action of biocompatibilizer and carbon black in the blends. As can be seen in Figure 4 the ethanol is , released during the curing process of the blends that has brought to the reactive amine group ready to couple with the available carboxylic group and/or hydroxyl group in carbon black while the non-polar hydrocarbon of biocompatibilizer interacts physically through dipole interaction with the long chain of

Table 3. Curing characteristics of control and compatibilized NR/R-EPDM blends.

the rubber component. With such mechanism, highly dispersed carbon black and better stress transfer are formed.

Surprisingly, incremental small amount of biocompatibilizer (1–3 phr) into the NR/R-EPDM

[64]

blends resulted in improving the elongation at break of the blends[64]. This can be attributed to the func

-tion of the biocompatibilizer itself acting as an internal plasticizer of the blends. Biocompatibilizer is a waxy and solid material derived from RBDPS, a type of natural oil. Although biocompatibilizer has a

smaller molecular size compared to NR and R-EPDM, it could provide a monolayer in the rubber

compound that then gives a free volume, allowing more mobility/flexibility for the rubber chains. Increasing the biocompatibilizer content has the same effect as an increase in free volume of the blends.

Table 4 shows the tensile modulus (M100 and M300), hardness, swelling, and cross-link density of control and compatibilized blends. Stress at 100 and 300% elongation exhibited lower value when bio -compatibilizer was added but increased with further increase the bio-compatibilizer content. The lower tensile modulus when biocompatibilizer was added is attributed to the softening effect of the biocom -patibilizer itself. As the biocom-patibilizer is waxy and solid material, it acts as an internal plasticizer, which results in reduced tensile modulus. However, the increment of tensile modulus upon increasing biocompatibilizer content is due to the improved cross-link density.[23] [62]Further increases in the cross-

link density produce a vulcanizate that tends towards brittle behavior. This observation was also found for the hardness property of the blends where the trend was similar to that of tensile modulus.

The swelling uptake and cross-link density of the control and compatibilized blends determined by equilibrium swelling method in toluene is also shown in Table 4. It is widely accepted that the swelling

is directly correlated to the cross-link density of a network chain, with less solvent uptake or penetration into the blends indicating higher cross-link density. The swelling percentage decreased toward the addition of biocompatibilizer. This revealed that the compatibilized blends contained more cross-links than the control counterpart. The increment of cross-link density could be attributed [54] to more responsible amine content in biocompatibilizer that acts as a co-curing agent or secondary

accelerator in the curing process of NR/R-EPDM blends.

Tensile-fractured surfaces

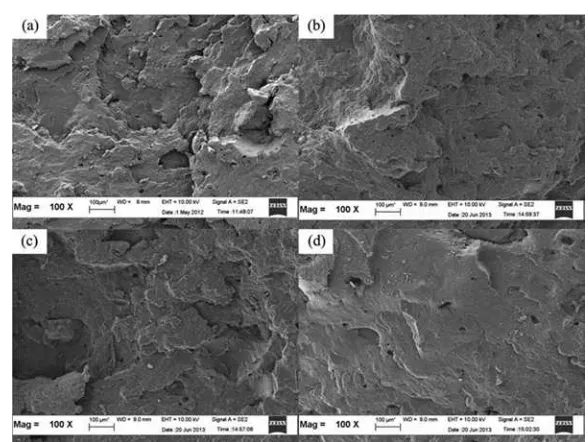

Figure 5 illustrates the SEM micrographs of the tensile-fractured surfaces of the control and

compatibilized NR/R-EPDM blends at a magnification of 100 . The micro-fractured surfaces �

obtained from the SEM results are significantly in agreement with the results on the tensile strength. The surface roughness and tearing lines were observed in the control blend (Figure 5a), meaning more energy was needed to break the sample. However, rougher surfaces and number of tear lines were more pronounced and visible in the blends with the biocompatibilizer of 1 and 2 phr, respectively (Figure 5b and c). The sample had altered the crack path, which led to more resistance for crack propagation and,

Figure 4. Possible mechanism between bio-compatibilizer and carbon black in the blends.

Table 4. Tensile modulus, hardness property, swelling and cross-link density of control and compatibilized NR/R-EPDM blends. Sample codes M100 (MPa) M300 (MPa) Hardness (shore A) Swelling (%) Cross-link density ( 10� 5 INTERNATIONAL JOURNAL OF POLYMER ANALYSIS AND CHARACTERIZATION 7

hence, resulted in higher tensile strength. The development in the micro-fractured surface of this blend might be attributed to the formation of more cross-links of compatibilized blends. However, the micro-fractured surface of the compatibilized blends tended to be smoother and had a smaller cracking area when the biocompatibilizer content went beyond 2 phr (Figure 5d). The reduction in the tearing lines with higher biocompatibilizer (3 phr) was responsible for the tensile strength results, which indicated that lower energy was required to initiate the crack or reduce the ability of the matrix to deform when subjected to strain. This is simply due to more pronounced plasticizing or lubricating effect of the excessive biocompatibilizer. Similar observations were reported elsewhere,[10 24, ]

cerning the dependence of micro-fractured surfaces and tensile properties in conjunction with the use of compatibilizers in rubber blends.

Dynamic mechanical properties

Figure 6a shows the storage modulus (E′) as a function of temperature of control and compatibilized

blends. The raw output is also summarized in Table 5. The curves show three separated regions: a

glassy region where the segmental mobility and molecular chains are restrained, a transition zone where a considerable decrease in the E′values with increasing the temperature, and a rubbery region

or flow region (Figure 6a) where a drastic drop in the modulus is a function of temperature. At [45] presented temperature (25°C), the findings clearly revealed that the storage modulus ( ) of compatiE′ -bilized blends increased with increasing the content of biocompatibilizer. [55]It is widely suggested that the storage modulus is directly related to the degree of elasticity and, thus, cross-link density.[10 25, ] [55]A rel-evant explanation is therefore associated to the higher degree of cross-linking assisted by the addition

of biocompatibilizer[55]. It is well elucidated earlier that the amine contained in biocompatibilizer is

responsible for the higher cross-link density of the compatibilized blends. Besides, an augmentation

of storage modulus in compatibilized blends can be also influenced by the improved interaction

between carbon black and biocompatibilizer as depicted in Figure 4 . The presence of active amine content in biocompatibilizer tended to couple the carbon black and rubber matrices during the curing

process, forming highly dispersed carbon black. As a result, the storage modulus increased with an increase in biocompatibilizer content.

Dependence of loss modulus ( ) as a function of temperature is shown in E″ Figure 6b. The loss modulus ( ) peak generally reflects the energy loss in internal motion per unit deformation of the E″

polymer chains.[26] As shown in Table 5 , the compatibilized blends exhibited comparatively lower maximum loss modulus peak than control blends and it decreased with an increase in the biocompa -tibilizer content. This is simply due to the decrease in energy loss being raised from the higher degree of cross-linking of the compatibilized blends. This finding corresponds to the damping characteristics of the blends as shown in Figure 6c Damping characteristic is a crucial parameter related to the study of . viscoelastic behavior of the rubber vulcanizate. It is obvious that the value of tan dmax (see Table 5) decreased with increasing the content of biocompatibilizer. Higher cross-linking toward the addition of biocompatibilizer strongly affects the reduction of damping characteristic (tan dmax) in the blends containing higher biocompatibilizer content.

The glass transition temperature (Tg) of control and compatibilized blends given by tan dmax are tabulated in Table 4. It can be seen that Tg of these two blends gradually increased in the presence of biocompatibilizer. The Tg of control and compatibilized blends increased from 50.67°C (control)

to 50.10°C (Bio-C1), 48.50 (Bio-C2), and 46.98°C (Bio-C3), respectively. The changes of Tg are greatly influenced by higher cross-linking of compatibilized blends. Generally, any type of molecular interactions that manipulate the molecular motion leads to shift to a higher temperature. Besides, the

Figure 6. Dependence of storage modulus (a), loss modulus (b) and damping factor (c) as a function of temperatures and

apparent activation energy and degree of entanglement (d) of control and compatibilized NR/R-EPDM blends.

Table 5. Storage modulus (E0) at 25°C, maximum loss modulus (E 00

INTERNATIONAL JOURNAL OF POLYMER ANALYSIS AND CHARACTERIZATION 9

Tg, increased slightly with the addition of biocompatibilizer. The small increment of this value

might be due to the compromising effect between the plasticizing nature of biocompatibilizer and the formation of the proposed interaction (see Figure 4). A monolayer of waxy-appearance bio -compatibilizer provides free volume, thus allowing the mobility for the rubber chains. This has brought

the compromise between mobility and/or immobility in the rubber chains that resulted in a small increase in the Tg eventually.

Apparent activation energy for glass transition

According to Manzur and Hernández-Sánchez,[27] both storage modulus ( ) and loss modulus ( ) E′ E″

are related to the viscosity of the blend by the following relation:

g¼ non-Arrhenius behavior of viscosity using Vogel–Fulcher–Tammann (VFT) equation:[28]

g¼g0exp 2 303: RTgT0

�

Eað T T0Þ

� �

ð Þ7

where is absolute temperature and T T0 is defined as the VFT temperature, which is roughly 50°C below the Tg. T0 is the temperature which viscosity ( ) also reaches its maximum point. The apparent acti-g vation energy (Ea) for glass transition temperature can be determined from Equation (7). This expression

represents a linear fit with the slope equal to 2.303 RTg/Ea when log is plotted against g T0/ –T T0. The apparent activation energy (Ea) values for glass transition temperature of control and compa-tibilized blends are illustrated in Figure 6d. It was observed that the Ea increased with an increase in the biocompatibilizer. This indicates that [33] the mobility of the rubber chain is decreased in the presence

of biocompatibilizer, arising from the shifting of Tg to higher temperatures. Thus, higher apparent activation energy (Ea) is essential to mobilize the rubber chains in the range of glassy region.

Correlation of the apparent activation energy (Ea) and the molecular mobility can be extensively clarified by the peak height of damping factor (tan d as depicted in Table 5). The higher the tan dmax, the higher the peak height is. Here, the damping peak appears in the range of the glassy region where the material changes from a rigid to a rubbery state, contributing to the movement of small groups and molecular chains within the polymeric structure that are initially frozen. Therefore, lowering of the peak height can be attributed to the lowering of the mobility of the polymer chains. Consequently, with this effect, it is concluded that the molecular restriction increases with an increase in the content

analyzer. The storage modulus output can be applied for determining the entanglement density. Calculation of degree of entanglement is expressed as follows:[26]

N¼ E 0

6RT ð Þ8

control and compatibilized blends is also shown in Figure 6d. A higher degree of entanglement occurs

with increasing the content of the biocompatibilizer. This is simply due to the cure compatibility between highly unsaturated NR and highly saturated EPDM. It generally leads to superior mechanical properties of the vulcanizates caused by even distribution of cross-link density. The available amine

content in biocompatibilizer is responsible on the enhancement of cross-linking distribution. As a

result, the blends revealed superior degree of entanglement with an increase in the content of the biocompatibilizer.

Conclusions

The reactive amine–contained biocompatibilizer has a strong influence on the promotion of compati-bility between NR and R-EPDM. It provided simultaneous formation of co-curing process and highly dispersed carbon black to the blends. This can [65] be clearly seen from the enhancement of overall tensile properties, swelling resistance, and morphology as well as the state of cure and dynamic mechanical

properties of the blends. The compatibilized [65] NR/R-EPDM blends impart higher values of tensile

strength, hardness, and elongation at break than the control blends. The storage modulus increased with increasing content of biocompatibilizer whereas reverse trend was found for loss modulus and damping behavior (tan d). Biocompatibilizer also affected the Tg of the blends by presenting higher Tg when the content of biocompatibilizer was increased. At the glassy region, compatibilized blends

disclosed lower chains mobility as confirmed by higher apparent activation energy (Ea) whereas a

higher molecular restriction for NR/R-EPDM blends was found in the rubbery region, as evidently

shown in degree of entanglement. The dynamic responses obtained from storage modulus, degree of entanglement, and apparent activation energy are clearly corresponding to the swelling result. It proves that the cross-link density plays a major role in the changes of storage modulus and degree of entanglement irrespective of the methods of the determination.

References

[1] Sutanto, P., F. Laksmana, F. Picchioni, and L. Janssen. 2006.[88]Modeling on the kinetics of an EPDM devulcanization in an internal batch mixer using an amine as the devulcanizing agent.Chem. Eng. Sci. 61:6442–6453. [2] Hayeemasae, N., and H. Ismail. 2015. Thermo-mechanical performance of natural rubber/recycled ethylene-

propylene-diene rubber blends in the presence of ZnO nanoparticles. Int. J. Polym. Anal. Charact. 20:514–528. [3] Nabil, H., H. Ismail, and A. Azura. 2013.[87]Compounding, mechanical and morphological properties of carbon- black-filled natural rubber/recycled ethylene-propylene-diene-monomer (NR/R-EPDM) blends. Polym. Test. 32:385–393.

[4] Suma, N., R. Joseph, and K. George. 1993.[60]Improved mechanical properties of NR/EPDM and NR/butyl blends by precuring EPDM and butyl.J. Appl. Polym. Sci. 49:549–557.

[5] Ismail, H., and H. Anuar. 2000.[79]Palm oil fatty acid as an activator in carbon black filled natural rubber compounds[96]: Dynamic properties, curing characteristics, reversion and fatigue studies.Polym. Test. 19:349–359. [6] Technical Report of Refined. Bleached Deodorized Palm Stearin. Available at: http://www.bepcthai.com/our-

products.html (accessed on February 18, 2016).

[7] Man, Y. C., T. Haryati, H. Ghazali, and B. Asbi. 1999. Composition and thermal profile of crude palm oil and its products. J. Am. Oil. Chem. Soc. 76:237–242.

[8] Adewuyi, A., R. A. Oderinde, B. Rao, and R. Prasad. 2012. Synthesis of alkanolamide: A nonionic surfactant from the oil of Gliricidia sepium J. Surfact. Deterg. . 15:89–96.

[9] Chang, Y. W., Y. S. Shin, H. Chun, and C. Nah. 1999.[51]Effects of trans-polyoctylene rubber (TOR) on the properties of NR/EPDM blends.J. Appl. Polym. Sci. 73:749–756.

[10] Nabil, H., H. Ismail, and A. Azura. 2013.[51]Effects of virgin ethylene-propylene-diene-monomer and its preheating time on the properties of natural rubber/recycled ethylene-propylene-diene-monomer blends. Mater. Design 50:27–37.

[11] Rahman, W., J. Alam, and M. R. Khan. 2015. Effect of manganese on radiation vulcanization of natural rubber. Int. J. Polym. Anal. Charact. 20:406–413.

[12] Surya, I., H. Ismail, and A. R. Azura. 2013.[63]Alkanolamide as an accelerator, filler-dispersant and a plasticizer in silica-filled natural rubber compounds.Polym. Test. 32:1313–1321.

[13] Flory, P. J., and J. Rehner Jr. 1943.[101]Statistical mechanics of cross-linked polymer networks II. Swelling. J. Chem. Phys. 11:521–526.

INTERNATIONAL JOURNAL OF POLYMER ANALYSIS AND CHARACTERIZATION 11

[14] Smith, B. C. 1998. Infrared Spectral Interpretation: A Systematic Approach. Boca Raton: CRC Press.

[15] Nabil, H., H. Ismail, and C. Ratnam. 2014.[65] Simultaneous enhancement of mechanical and dynamic mechanical

properties of natural rubber/recycled ethylene-propylene-diene rubber blends by electron beam irradiation. Int. J. Polym. Anal. Charact. 19:272–285.

[16] Gardiner, J. B. 1968.[78]Curative diffusion between dissimilar elastomers and its influence on adhesion. Rubber. Chem. Technol. 41:1312–1328.

[17] Polmanteer, K., and C. Lentz. 1975. Reinforcement studies-effect of silica structure on properties and crosslink density. Rubber. Chem. Technol. 48:795–809.

[18] Surya, I., H. Ismail, and A. R. Azura. 2014.[84]The comparison of alkanolamide and silane coupling agent on the properties of silica-filled natural rubber (SMR-L) compounds.Polym. Test. 40:24–32.

[22] Ismail, H., and H. Chia. 1998. The effects of multifunctional additive and epoxidation in silica filled natural rubber compounds. Polym. Test. 17:199–210.

[23] Ignatz-Hoover, F., A. R. Katritzky, V. S. Lobanov, and M. Karelson. 1999. Insights into sulfur vulcanization from QSPR quantitative structure-property relationships studies. Rubber. Chem. Technol. 72:318–333.

propylene–diene monomer rubber and styrene–butadiene rubber blends. J. Appl. Polym. Sci. 112:72–81. [27] Manzur, A., and F. Hernández-Sánchez. 2006. Activation energy for the glass transition of a confined elastomer in

HDPE/PP blends. J. Macromol. Sci. B Phys. 45:139–152.

[28] Sastry, S. 2001. The relationship between fragility, configurational entropy and the potential energy landscape of glass-forming liquids. Nature 409:164–167.