C O MPRESSIVE A ND TENSILE STRENG TH O F EXPA NDED PO LYSTYRENE BEA DS C O NC RETE

Te ng ku Fitria ni L. Sub ha n *

Ab stra k

Pe ne litia n ini b e tujua n untuk m e m p e la ja ri p ro p e rty d a ri b e to n ring a n ya ng m e ng a nd ung e xp a nd e d p o lystyre ne b e a d s, ya itu kua t te ka n (c o m p re ssive stre ng th) d a n kua t ta rik (te nsile stre ng th). Pro p e rty te rse b ut ke m ud ia n d ib a nd ing ka n d e ng a n b e to n no rm a l (b e to n ta np a e xp a nd e d p o lystyre ne b e a d s) se b a g a i c a m p ura n p e ng o ntro l.

Ha sil p e ne litia n ini m e nunjukka n b a hwa jum la h p o lystyre ne b e a ds ya ng d im a sukka n se b a g a i c a m p ura n b e to n m e m p e ng a ruhi p ro p e rty b e to n; ya itu d a p a t m e nurunka n kua t te ka n b e to n. Te ta p i, p a d a c a m p ura n b e to n d e ng a n 15 % p o lystyre ne b e a d s (Mix II) p a d a 28 ha ri kua t te ka nnya d a p a t b e rta ha n hing g a 86 % d a n kua t ta riknya 87 % jika d ib a nd ing ka n d e ng a n b e to n no rm a l.

Ka ta kunc i: b e to n, p o lystyre ne b e a ds

Abstrac t

The ma in p urp o se o f this inve stig a tio n is to study the p ro p e rtie s (c o mp re ssive a nd te nsile stre ng ths) o f lig htwe ig ht c o nc re te c o nta ining e xp a nd e d p o lystyre ne b e a ds. Its p ro p e rtie s a re c o mp a re d tho se o f the no rma l we ig ht c o nc re te (c o ntro l mix).

The re sults sho we d tha t the a mo unt o f p o lystyre ne b e a ds inc o rp o ra te d in c o nc re te influe nc e the p ro p e rtie s o f ha rde ne d c o nc re te ; tha t is lig htwe ig ht a g g re g a te c o uld re duc e the stre ng th o f c o nc re te . Ho we ve r, the c o mp re ssive stre ng ths o f lig htwe ig ht c o nc re te with 15 % p o lystyre ne b e a ds (Mix II) a t 28 da ys fo r e xa mp le , c o uld ma inta in up to 86 % c o mp a re d to tho se o f no rma l we ig ht c o nc re te , while the te nsile stre ng th wa s 87%.

Ke ywords: c o nc re te , p o lystyre ne b e a ds

* Sta f Pe ng a ja r Jurusa n Te knik Sip il Fa kulta s Te knik Unive rsita s Ta d ula ko , Pa lu

I. Intro duc tio n

1.1. C o m p re ssive Stre ng th

Stre ng th o f c o nc re te is the m o st im p o rta nt, a ltho ug h o the r c ha ra c te ristic m a y a lso b e c ritic a l a nd c a nno t b e ne g le c te d . Stre ng th is a n im p o rta nt ind ic a to r o f q ua lity b e c a use stre ng th is d ire c tly re la te d to the struc ture o f ha rd e ne d c e m e nt p a ste .

Eve n tho ug h stre ng th is no t a d ire c t m e a sure d ura b ility o r d im e nsio na l sta b ility, it ha s a stro ng re la tio nship with the wa te r to c e m e nt ra tio o f the c o nc re te , whic h in turn influe nc e s d ura b ility, d im e nsio na l sta b ility a nd o the r p ro p e rtie s o f c o nc re te (Sha h, S.P. a nd Ahma d , S.H., 1994).

The stre ng th m e a sure d in c o nc re te d e p e nd s o n so m e fa c to rs

inc lud ing the a g e , d e g re e o f hyd ra tio n, ra te o f lo a d ing , me tho d o f te sting , sp e c im e n g e o m e try, a nd the p ro p e rtie s a nd p ro p o rtio ns o f the c o nstitue nt ma te ria ls. Mo stly, c o nc re te stre ng th im p ro ve s with the inc re a se o f a g e .

The stre ng th o f sa tura te d sp e c im e ns m a y ha ve lo we r stre ng th tha n d ry sp e c im e ns. C o m p re ssive stre ng th m e a sure d in im p a c t lo a d ing will b e hig he r tha n tha t in a no rm a l ra te o f lo a d ing . C ub e sp e c im e ns ma y re sult hig he r stre ng th tha n c ylind e r sp e c im e ns.

(0% PB) a s a mix c o ntro l, Mix II (15 % PB), Mix III (30 % PB), a nd Mix IV (45 % PB).

Ta b le 3 sho ws the c o nc re te ma te ria ls, whic h we re b a tc he d b y we ig ht fo r e ve ry m ix. The a m o unt o f fine a g g re g a te wa s c ha ng e d fo r d iffe re nt mixe s a c c o rd ing to p e rc e nta g e o f p o lystyre ne b e a d s p ut in the mixe s. The hig he r the a m o unt o f p o lystyre ne b e a d s, the lo we r the a m o unt o f sa nd . Po lystyre ne a g g re g a te c o m p o sitio n is va rie d a m o ng the c o nc re te mixture s to

d e te rmine the m a xim um lig htwe ig ht a g g re g a te ne e d e d c o nc re te a nd to se e the e ffe c t o f p o lystyre ne b e a d s in the hig h stre ng th c o nc re te . The a m o unt o f m a te ria ls a nd wa te r ne e d e d we re c a lc ula te d b e fo re mixing , the m o isture c o nte nt a nd a b so rp tio n c a p a c ity o f a g g re g a te we re c a rrie d o ut. The n, a d a y b e fo re mixing c o nc re te , the c o a rse a nd fine a g g re g a te we re a ir d rie d to a c hie ve unifo rm m o isture c o nte nt.

Ta b le 2. Mix C o m p o sitio n (kg / m3)

Ma te ria ls Mix I Mix II Mix III Mix IV

C e me nt 448 457 465 464

Fly Ash 102 104 106 106

Wa te r 140 143 145 145

Sup e rp la stic ise r 9.9 10.1 10.3 10.3

Fine Ag g re g a te 626 541 453 356

C o a rse Ag g re g a te 1088 1112 1128 1128

Po lystyre ne Be a d s 0 208 3.92 6.03

W+S/ C +F 0.27 0.27 0.27 0.27

A/ C +F 3.12 2.95 2.77 2.70

Ta b le 3. Ba tc h we ig ht o f m a te ria ls (kg ) fo r e a c h m ix

Ma te ria ls Mix I

(0% PB)

Mix II (15% PB)

Mix III (30% PB)

Mix IV (45% PB) C o a rse

Ag g re g a te 37.4 37.4 37.4 37.4

Fine Ag g re g a te 21.5 18.2 15 11.8

Po lystyre ne Be a d s 0 0.07 0.13 0.2

C e me nt 15.4 15.4 15.4 15.4

Fly a sh 3.5 3.5 3.5 3.5

Sup e rp la stic ise r 0.34 0.34 0.34 0.34

Ho we ve r, b e fo re p o uring c o nc re te m ixture it is e sse ntia l to d o m o isture c o nte nt te sts fo r the c o a rse a nd fine a g g re g a te s in o rd e r to a d just wa te r c o nte nt. The m o isture c o nte nt o f c o a rse sa nd just b e fo re p o uring c o nc re te fo r e xa m p le wa s 9 %, whic h is hig h wa te r a b so rp tio n, so the a mo unt o f wa te r fo r mixture sho uld b e re d uc e d . Fo r fine sa nd , o n the c o ntra ry, it wa s ve ry d ry with the m o isture c o nte nt wa s m uc h lo we r, tha t wa s 0.05 %. The re fo re sp e c ific a mo unt o f wa te r sho uld b e a d d e d .

Fo r Mix II, III, a nd IV, the p o lystyre ne b e a d s we re sp re a d e d e ve nly b e fo re the c o a rse a g g re g a te wa s a d d e d . Afte r mixing o f c o nc re te , the te m p e ra ture o f mixture wa s m e a sure d . The fre sh c o nc re te p ro p e rtie s (we t d e nsity slum p ) we re im m e d ia te ly te ste d a c c o rd a nc e with AS 1012 (1970). The c o nc re te te m p e ra ture wa s fo und to

18 oC .

3. C o m pre ssive Stre ng th

All c o mp re ssive stre ng th te sts in this stud y we re p e rfo rme d b y using Ave ry unive rsa l te sting m a c hine with lo a d ing ra te 20±2 MPa p e r minute a c c o rd ing to AS 1012.9-1999. The te st

sp e c im e ns we re 3 c ub e s o f 100x100x100 m m fo r e a c h a g e , te ste d a t 3, 7, 28, a nd

56 d a ys a t the ro o m te m p e ra ture o f 20o

C a nd 65 % RH. Afte r re m o va l fro m the c uring e nviro nm e nt, the surp lus wa te r o n a ll c ub e s wa s wip e d o ut a s so o n a s p o ssib le a nd d ime nsio ns a nd we ig ht we re d e te rm ine d .

3.1 C o m p re ssive stre ng th d e ve lo p m e nt with a g e

C o mp re ssive stre ng th

d e ve lo p m e nt re sults a re sum m a rize d in b o th Ta b le 4 a nd Fig ure 3, while re la tive c o mp re ssive stre ng th d e ve lo p me nt with a g e is sho wn in Ta b le 5 a nd Fig ure 4. It is sho wn tha t the c o m p re ssive stre ng th o f a ll c o nc re te mixture s inc re a se d with the inc re a se o f a g e .

It is c le a r fro m the Ta b le 4 tha t the la rg e r the a m o unt o f p o lystyre ne b e a d s in c o nc re te , the le sse r the c o mp re ssive stre ng th. As e xp e c te d , the no rm a l we ig ht c o nc re te ha s the la rg e st c o mp re ssive stre ng th fo r a ll d a ys c o mp a re d to lig htwe ig ht c o nc re te . At 28 d a ys, it wa s fo und tha t c o mp re ssive stre ng th o f Mix II, Mix III, a nd Mix IV c o m p a re d to c o ntro l c o nc re te we re 86%, 65%, a nd 59%, re sp e c tive ly.

Fig ure 1. C o m p re ssive stre ng th te st Fig ure 2. Sp litting o f sp e c ime n und e r

In Mix I, a t 3 d a ys the c o mp re ssive stre ng th wa s 53 MPa , the n a t 28 d a ys it inc re a se d c o nsid e ra b ly to 80 MPa . During the ne xt 28 d a ys the stre ng th wa s inc re a se d to 81 MPa . In Mix II a nd Mix III o n the o the r ha nd , the c o mp re ssive stre ng th inc re a se d fro m 28 d a ys to 56 d a ys a b o ut 6 MPa a nd 5 MPa , re sp e c tive ly.

The c o mp re ssive stre ng th o f c o ntro l c o nc re te inc re a se d fro m 53 MPa

a t 3 d a ys to 80 MPa a t 28 d a ys (inc re a se d o f 51%). Ho we ve r, with 15% o f fine a g g re g a te re p la c e d b y p o lystyre ne b e a d s, the 28-d a y stre ng th o f Mix II wa s inc re a se d b y 60.5% fro m its 3-d a y stre ng th (69 MPa ). Whe n the a m o unt o f lig htwe ig ht a g g re g a te inc re a se d up to 30% to re p la c e the fine a g g re g a te (Mix III); the inc re a se o f c o m p re ssive stre ng th a t 28 d a ys is 40.5%.

Ta b le 4. C o m p re ssive stre ng th d e ve lo p m e nt with a g e

Mixture s C o mp re ssive stre ng th (Mp a )

3 d a ys 7 d a ys 28 d a ys 56 d a ys

Mix I 53 67 80 81

Mix II 43 51 69 75

Mix III 37 47 52 57

Mix IV 28 33 39 42

0 10 20 30 40 50 60 70 80 90

0 7 14 21 28 35 42 49 56 63

Age (Days)

C

ube

s C

o

m

p

ressi

ve

S

tr

e

n

g

th

(

M

P

a

)

Mix I

Mix II

Mix III

Mix IV

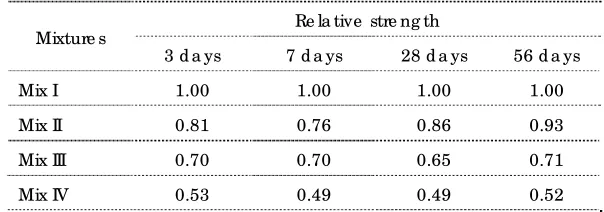

Ta b le 5. Re la tive c o mp re ssive stre ng th d e ve lo p m e nt with a g e

Mixture s

Re la tive c o mp re ssive stre ng th d e ve lo p m e nt with a g e

3 d a ys 7 d a ys 28 d a ys 56 d a ys

Mix I 1.00 1.26 1.51 1.53

Mix II 1.00 1.19 1.60 1.74

Mix III 1.00 1.27 1.40 1.54

Mix IV 1.00 1.18 1.40 1.50

1.00 1.10 1.20 1.30 1.40 1.50 1.60 1.70 1.80

0 7 14 21 28 35 42 49 56 63

Age (days)

R

e

lat

ive

st

re

n

g

th

Mix I

Mix II

Mix III

Mix IV

Fig ure 4. Re la tive c o m p re ssive stre ng th d e ve lo p m e nt with re sp e c t to 3-d a y stre ng th

Ta b le 6. Re la tive c o m p re ssive stre ng th o f p o lystyre ne a g g re g a te c o nc re te

Mixture s

Re la tive stre ng th

3 d a ys 7 d a ys 28 d a ys 56 d a ys

Mix I 1.00 1.00 1.00 1.00

Mix II 0.81 0.76 0.86 0.93

Mix III 0.70 0.70 0.65 0.71

0.0 0.2 0.4 0.6 0.8 1.0 1.2

0 7 14 21 28 35 42 49 56 63

Age (days)

R

e

la

ti

ve

str

e

n

g

th

Mix I Mix II Mix III Mix IV

Fig ure 5. Re la tive c o m p re ssive stre ng th o f p o lystyre ne a g g re g a te c o nc re te

3.2 Re la tive c o mp re ssive stre ng th o f

p o lystyre ne a g g re g a te c o nc re te The re la tive c o mp re ssive stre ng th o f p o lystyre ne a g g re g a te c o nc re te is sho wn in Ta b le 6 a nd Fig ure 5. As re p re se nt in Ta b le 6, Mix I ha s a ro le a s c o ntro l mixture . Fo r Mix II, the re la tive d e ve lo p m e nt o f c o m p re ssive stre ng th va rie d b e twe e n 76% a nd 93%, while Mix III ha s lo we r va ria tio n o f stre ng th d e ve lo p me nt; fro m 65% to 71%. In Mix IV, the d e ve lo p m e nt o f stre ng th e ve n lo we r, va rie d a mo ng 50%.

4.Te nsile Stre ng th o f c o nc re te a t 28 da ys

In this inve stig a tio n, te nsile

stre ng th te st wa s d o ne with 3 c ylind e rs o f 100x200 mm fo r e a c h mix a t the a g e o f

28 d a ys a fte r c ure d in 20 oC wa te r, using

ind ire c t te nsile te st, a c c o rd a nc e with AS 1012.10-2000. Te ste d we re d o ne in ro o m

te m p e ra ture o f 20 oC a nd 65% RH. Fig ure

2 sho ws o ne o f the te nsile stre ng th te sts o f c o nc re te .

Afte r ta ke n o ut fro m the wa te r c uring a nd the surp lus wa te r wa s wip e d o ut, the m e a n d ia m e te r a nd le ng ths o f sp e c im e ns we re m e a sure d . The

ha rd b o a rd b e a ring strip s we re p la c e d b e twe e n the p la te n o f the m a c hine a nd sp e c im e n to a vo id lo c a l c rushing . The lo a d is a t the ra te o f 1.5±0.15 MPa p e r min.

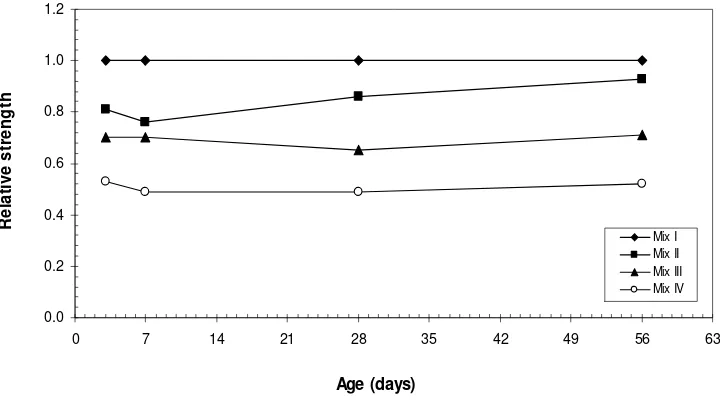

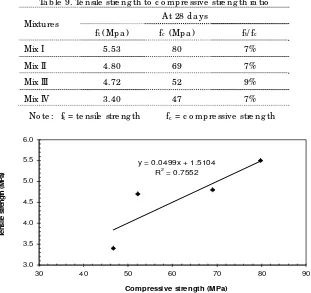

Ta b le 7 a nd Fig ure 6 sho w the re sults o f te nsile stre ng th o f c o nc re te a t 28 d a ys. It is c le a r fro m the b a r c ha rt tha t the hig he r the a m o unt o f p o lystyre ne b e a d s in c o nc re te mixture , the lo we r the te nsile stre ng th. Re la tive te nsile stre ng th o f lig htwe ig ht c o nc re te c o m p a re d to no rm a l we ig ht c o nc re te a re sho wn in Ta b le 8, while Ta b le 9 re p re se nts the c o m p a riso n b e twe e n te nsile stre ng th a nd 28 d a ys c o mp re ssive stre ng th o f a ll c o nc re te mixture s a s we ll a s the ra tio b e twe e n the m .

0 1 2 3 4 5 6

Mix I Mix II Mix III Mix IV

In

d

ir

e

c

t t

e

n

s

ile

s

tr

e

n

g

th

(

M

P

a

)

Fig ure 6. Te nsile Stre ng th a t 28 d a ys

Ta b le 7. Te nsile stre ng th o f c o nc re te mixe s a t 28 d a ys

Mixture s Te nsile stre ng th (MPa )

Mix I 5.53

Mix II 4.80

Mix III 4.72

Mix IV 3.40

Ta b le 8. Re la tive te nsile stre ng th o f lig htwe ig ht c o nc re te to no rm a l we ig ht c o nc re te a t 28 d a ys

Mixture s Mix I Mix II Mix III Mix IV

Te nsile Stre ng th (MPa ) 5.53 4.80 4.72 3.40

Re la tive stre ng th 1.00 0.87 0.85 0.62

4.1 Re la tive te nsile stre ng th

It is c le a r fro m Ta b le 8 tha t te nsile stre ng th d e ve lo p m e nt up to 28 d a ys o f c o nc re te with the lo we st p o lystyre ne b e a d s c o nte nt (Mix II) wa s the hig he st a m o ng lig htwe ig ht c o nc re te a s m uc h a s 87%. Sub se q ue ntly, the hig he r the lig htwe ig ht a g g re g a te in c o nc re te , the lo we r the re la tive stre ng th.

4.2 Te nsile stre ng th to c o mp re ssive

stre ng th ra tio

As sho wn in Ta b le 9 a nd Fig ure 7, the hig he r the c o m p re ssive stre ng th, the hig he r the te nsile stre ng th. The re la tio nship b e twe e n te nsile stre ng th

a nd c o m p re ssive stre ng th is no n-line a r (ft

= A (fc)0.3. The ra tio b e twe e n te nsile