Incorporation of Surface Texture, Skid Resistance and Noise into PMS

Alauddin, Mohammad Ahammed, M.A.Sc., P.Eng., Ph.D. Candidate Department of Civil and Environmental Engineering

University of Waterloo 200 University Avenue West Waterloo, Ontario, Canada, N2L 3G1

Tel. (519) 888-4567 x 33872 Fax: (519) 888-4300

E-mail: maahamme@engmail.uwaterloo.ca

Susan L. Tighe, Ph.D., P. Eng.

Canada Research Chair in Pavement & Infrastructure Management, Associate Director CPATT and

Associate Professor

Department of Civil and Environmental Engineering University of Waterloo

200 University Avenue West Waterloo, Ontario, Canada, N2L 3G1

Tel.: (519) 888-4567 x 33152 Fax: (519) 888-4300 E-mail: sltighe@uwaterloo.ca ABSTRACT

Skidding contributes to a substantial portion of crashes on the roadway. The resistance to skidding is therefore an important component of highway safety. Improved and durable friction can be achieved by increasing the surface texture. These may, however, influence the tire-pavement interaction noise and may, at some point, be unacceptable to the commuters and/or residents. In fact, noise is an environmental problem and a growing concern all over the world. Alternatively, durability of the pavement itself is vital to sustainability of natural resources and economy of the country. All these factors combined result in many challenges to highway engineers/agencies as they must balance the pavement durability and users comfort (smooth and quiet) with economy but without compromising the safety.

Published literature/reports indicate some advancement in surface friction and tire-pavement noise studies. However, no specific guidance is provided in current state/provincial specifications on improving the surface texture and friction to reduce the number of crashes. Furthermore, little emphasis is given on specifying the desirable noise levels which resulted in a large variation in noise levels, even among similar pavements.

This paper provides an insight into the desirable surface characteristics that ensures both drivers comfort and safety. The up to date results of a study, involving the skid resistance and acoustic performance of various asphalt and concrete surfaces, at University of Waterloo Centre for Pavement and Transportation Technology (CPATT) are presented. The process of accommodating the pavement durability and safety, smoothness, and noise into pavement management system (PMS) are addressed.

INTRODUCTION

About 157,000 crashes were reported in 2004 on Canadian roads with annual economic loss of about $25 billion (1). Highway crashes cost the United States over $200 billion annually (2). Skidding on wet pavements contribute to 13.5% of fatal and up to 25% of all accidents (3). The resistance to skidding is therefore of paramount importance in selecting a surface type. Increased temperature and surface polishing significantly reduce the available friction with increased potential for skid related accidents. Variation of available friction with time is therefore an important measure of pavement deterioration (4). Pavement surface should therefore be designed so that sufficient friction is available throughout the life of the pavement and in varying weather condition.

pavement performance. Highway engineers/agencies are challenged as they must balance the surface texture characteristics for comfort (smooth and quiet) and durability but not compromise safety. However, no Canadian agencies specify the desirable surface texture for adequate and durable friction. Furthermore, no specification or guideline is provided for acceptable noise levels in pavement perspective, although the environmental agencies/departments provide some guidance on traffic noise levels for noise barrier consideration. This resulted in a large variation in noise levels among the pavements already constructed or under construction. It is therefore time to develop a specification or guideline for the desired minimum surface texture or friction and the maximum noise levels for the pavements to be newly constructed or rehabilitated.

This paper describes different aspects of pavement surface characteristics that could be utilized in optimizing the surface performance, namely the resistance to skidding and noise. Skid testing on several surfaces of concrete and asphalt pavements has been carried out as part of the research program. Consequently, criteria and a process for incorporating the surface characteristics, together with pavement stability/durability, into the PMS are presented. The possible measures in project and network levels are also addressed to facilitate dealings with existing pavements.

FUNDAMENTALS OF SURFACE TEXTURE

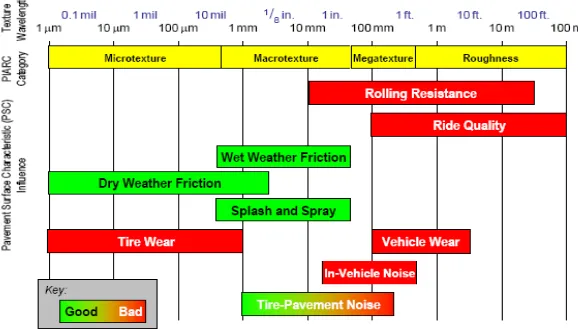

The irregularities of pavement surface from its smooth horizontal plane surface are known as surface textures. The available surface textures depend on aggregate mineralogy, aggregate size and gradation in the surface mix, voids in surface mix, pavement finishing and texturing techniques, and surface wear as well as profile. The surface textures are classified into microtexture, macrotexture, megatexture and unevenness (roughness) based on texture sizes as indicated by texture amplitude (depth) and wavelength. The classification suggested by the Permanent International Association of Road Congresses (PIARC) is shown is Figure 1(6). It summarizes possible tire-pavement interaction effects. Microtexture refers to surface irregularities with wavelengths of less than 0.5 mm and vertical amplitudes of less than 0.2 mm while macrotexture wavelengths ranges from 0.5 mm to 50 mm with vertical amplitudes ranging from 0.1 mm to 20 mm. Megatexture have wavelengths in the order of 50 mm to 500 mm and vertical amplitudes of 0.1 mm to 50 mm. Surface irregularities having wavelengths exceeding the megatexture size i.e. 500 mm are called roughness or unevenness (7).

FIGURE 1 Ranges of texture and anticipated effects (6).

TEXTURE-FRICTION (SAFETY)-NOISE RELATIONSHIPS

Concrete pavements are known to provide high stability and long service life. However, higher tire-pavement noise and texture durability are major concerns. Grooved concrete surfaces were shown to exhibit a skid number (SN40) of 62.0 at 64 km/h (40 mph) with Mean Texture Depth (MTD) of 1.70 mm (0.067 in.) and a SN40 of 34.8 for MTD of 0.41 mm (0.016 in.). Pavement grooves of 4.76 mm (3/16 in.) wide on 19 mm (3/4 in.) centers were found to wear at a mean rate of 0.33 mm (0.013 in.) per million vehicle passes. A Mean Groove Depth (MGD) of 1.27 mm (0.05 in.) was found to be necessary to ensure minimum acceptable SN40 of 32 (9). A long term frictional performance model using Long Term Performance Program (LTPP) data of 197 concrete pavement sections was developed as part of a research at University of Waterloo as given by Equation 1 (10).

FN = 63.467 - 0.517 S + 4.248 TC - 0.041 VPC - 0.131 VT + 0.451 CS (1)

Where, FN = Friction Number, S = Vehicle Speed in mph, TC = Texture Code (1 for grooved and 0 for dragged, VPC = Volume of PC (= Age*PC AADT) in thousand, VT = Volume of Truck (= Age*Truck AADT) in thousand, CS = Compressive Strength in ksi.

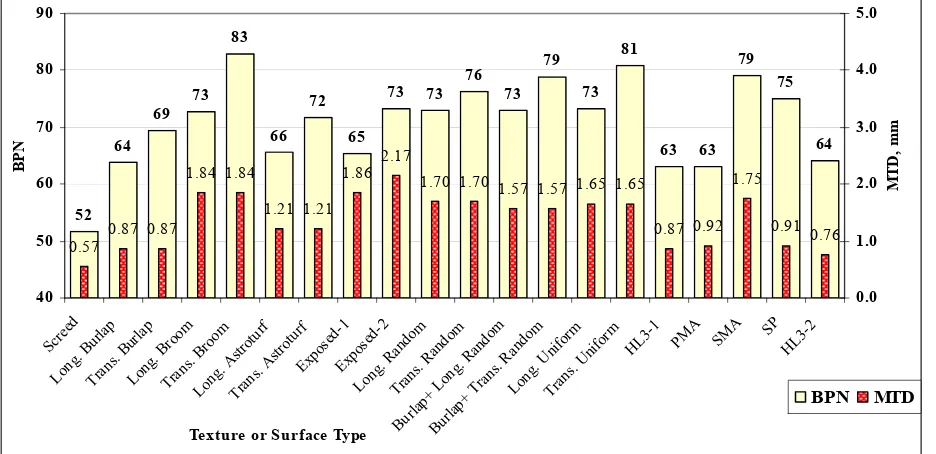

Dense graded asphalt surfaces maintain SN40 in the range 40 to 50. Open graded asphalt pavement surface exhibit better skid resistance and lower noise but need frequent cleaning maintenance (8). Figure 2 shows the variation of skid resistance (British Pendulum Number, BPN) measured during a study (by the authors) at University of Waterloo, using a portable skid resistance tester (British Pendulum), on fifteen concrete and five asphalt surfaces. Deep transverse broom and transverse tine (4 mm deep, 3 mm wide, spaced at 16 mm) on concrete surfaces, and stone mastic asphalt (SMA) were shown to provide the highest skid resistance. Exposed aggregate surface, with the highest MTD (2.17 mm), exhibited relatively low BPN. This is probably due to loss of sand microtexture with washed out mortar and it may therefore not be a preferred texture for concrete pavement. In this study, textured concrete surfaces were shown to absorb 4% to 6% of the sound.

52

FIGURE 2 Variation of textures and skid resistances on selected surfaces

68

64 67

63 71

66 76

71

73

71 72 71 63 63 65 65 62 72

60 70 80

Feb ruar

y

Mar ch-S

tart

Mar ch-E

nd Ap

ril

May June July Au

gust

Septe mbe

r

Tes ting Time

BP

N

AC PCC

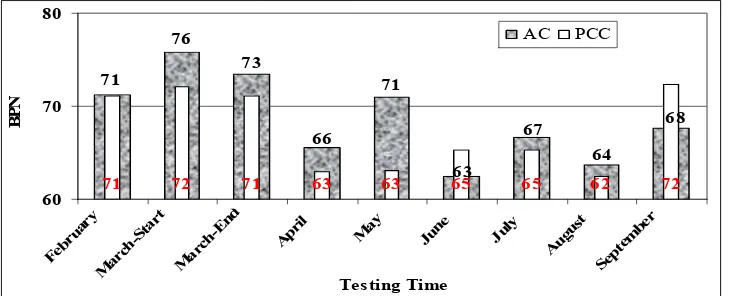

FIGURE 3 Seasonal variations of skid resistance on concrete and asphalt surfaces

OPTIMIZATION OF PAVEMENT SURFACE CHARACTERISTICS

As mentioned earlier, an increased texture is desired for increased and durable friction, and thereby safety and economy. Increased texture, however, may affect the driver/residents comfort and economy in terms noise, vehicle vibration, fuel consumption, and tire and vehicle wear. The selection of a suitable texture is therefore a complex task as several aspects need be considered for optimizing the pavement surface characteristics and performances. The challenge is to balance noise with other more important requirements such as safety, as related to surface friction, pavement durability, structural capacity, noise mitigation and safety over time, ride quality and economy (14). A survey among highway agencies around the world rated various design criteria of pavement based on relative importance on a scale of 1 (very important) to 3 (relatively unimportant) (7). Pavement durability (average rating 1.2) and safety as related to skid resistance (average rating 1.3) are considered as the most important factors in selecting a pavement or surface type. These are followed by safety as related to splash and spray (average rating 1.9), exterior noise (average rating 2.3) and in-vehicle noise (average rating 2.4). The rolling resistance (average rating 2.7) and tire wear (average rating 2.8) were considered less important. Therefore, the main purpose of texturization or selection of surface course should be to reduce the number and severity of wet accidents, and the safety and durability should not be compromised for slight reduction in noise. A balance between safety and noise would be the best option or happy median in practicing highway design (15).

Minimum Surface Texture and Skid Resistance for Safety

30 50 70 90

0 0.5 1 1.5 2 2.5 3

MTD, mm

BP

N

FIGURE 4 Variations of skid resistance on concrete and asphalt surfaces with MTD

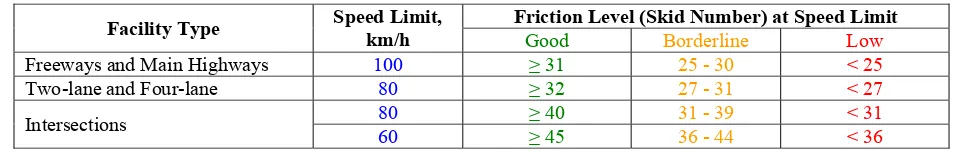

In fact, the wet pavement safety is a complex function of vehicle and driver performance/ behaviour and surface condition. Setting an absolute minimum requirement, especially for the vast network of existing pavements, is not a simple task because the adequacy of the existing pavements may be questioned. Accordingly, no transportation agencies in Canada or the United States set standards for minimum surface friction, because of litigation risk that may arise from skidding accidents (4). Tentative guidelines therefore developed by some agencies in North America. A tentative guideline, as shown in Table 1, is used by Ontario Ministry of Transportation (MTO) to assess the surface friction level (17).

Some agencies outside North America however provide some standard for minimum surface friction. For example, the United Kingdom provides a comprehensive standard for the desired minimum surface friction levels for different road classes and sections. The investigatory level of Sideways Force Coefficient Routine Investigation Machine (SCRIM) friction coefficient starts from a minimum of 0.35 at 50 km/h for motorway to 0.60 at 20 km/h for sharp bend with radius ≤100 m (speed limit >40 km/h) during the summer. Implementation of this standard has resulted significant benefits in terms of accident reduction (18).

TABLE 1 Tentative guideline for friction classification system in Ontario (17)

Friction Level (Skid Number) at Speed Limit Facility Type Speed Limit,

km/h Good Borderline Low

Freeways and Main Highways 100 ≥ 31 25 - 30 < 25

Two-lane and Four-lane 80 ≥ 32 27 - 31 < 27

80 ≥ 40 31 - 39 < 31

Intersections

60 ≥ 45 36 - 44 < 36

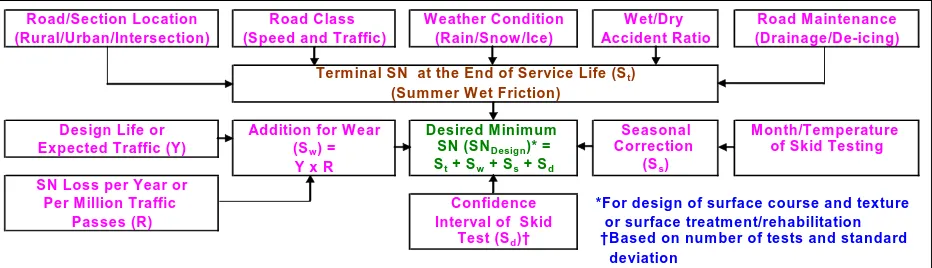

Road/Section Location Road Class W eather Condition W et/Dry Road Maintenance (Rural/Urban/Intersection) (Speed and Traffic) (Rain/Snow /Ice) Accident Ratio (Drainage/De-icing)

Design Life or Addition for W ear Desired Minimum Seasonal Month/Temperature Expected Traffic (Y) (Sw) = SN (SNDesign)* = Correction of Skid Testing

Y x R St+ Sw+ Ss+ Sd (Ss) SN Loss per Year or

Per Million Traffic Confidence *For design of surface course and texture Passes (R) Interval of Skid or surface treatment/rehabilitation

Test (Sd)† †Based on num ber of tests and standard deviation

Term inal SN at the End of Service Life (St) (Summ er W et Friction)

FIGURE 5 General framework for selection of design SN or treatment decision Acceptable Maximum Noise Level

Noise Abatement Criteria (NAC) in the United States, which is monitored by the Federal Highway Administration (FHWA), requires that noise abatement must be considered when traffic noise level approaches or exceeds 67 dBA (Leq) or 70 dBA (L10) (15). The threshold for interior noise levels are 52 dBA (Leq) or 55 dBA (L10). The Ontario Ministry of Environment (MOE) recommends for road noise control measures if the predicted daytime hours (07:00-23:00) sound level (Leq) in the outdoor living area exceeds 60 dBA (19). A Noise Policy is enforced in the Region of Waterloo, Ontario. Developers must construct noise barrier if the expected 16-hour Leq noise levels at nearby residence’s backyard after 10 years exceed 60 dBA. When improving an existing road, the Region constructs noise barriers if the projected noise levels after 10 years exceed the current level by more than 5 dBA or exceed the threshold of 65 dBA (20). The current certified types of physical mitigations include construction of noise barriers and earth berm to control noise level at the outdoor living area. Such noise mitigation methods are neither economical nor effective because they can only prevent the noise propagation, but not actually reduce the traffic noise from the source. Pavements can play an important role in noise reduction at the source because the interaction between tire and pavement becomes the dominant noise source when the vehicle travels at speed of 35 km/h or more (21). However, no agencies in the U.S. and Canada specify the acceptable noise level for the selection of pavement or texture types.

Several studies have determined the tire-pavement noise on various asphalt and concrete surfaces with no universal conclusion. Wide variation in as-built surfaces due to construction variability has resulted in wide variations in noise levels among the sections, even for a specified texture pattern. A good quality control of tine spacing, depth and width is therefore essential to avoid variation in as-built surface textures from the agency specified patterns if a national guideline is to be developed (22). Variation in noise level has also been observed for asphalt sections with same surface mix making it difficult to generalize the result. Despite such variation, evaluating the noises and surface textures on 57 sections of asphalt and concrete pavements in six US states, it was recommended that a desirable surface should exhibit a maximum of 83 dBA exterior and 68 dBA interior noises with ROSAN ETD of 0.7 or above (23).

must be checked when selecting the surface texture or mixes with acceptable maximum overall noise.

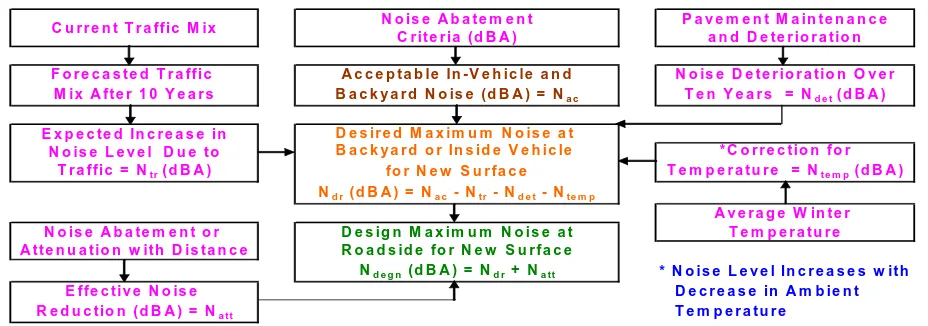

N o is e A b a t e m e n t P a v e m e n t M a in t e n a n c e C r it e r ia (d B A ) a n d D e te r io r a t io n

F o r e c a s t e d T r a ff ic A c c e p t a b le In - V e h ic le a n d N o is e D e t e r io r a t io n O v e r M ix A ft e r 1 0 Y e a r s B a c k y a r d N o is e ( d B A ) = Na c T e n Y e a r s = Nd e t ( d B A )

E x p e c te d In c r e a s e in D e s ir e d M a x im u m N o is e a t

N o is e L e v e l D u e t o B a c k y a r d o r In s id e V e h ic le * C o r r e c t io n f o r T r a f fic = Ntr (d B A ) fo r N e w S u r fa c e T e m p e r a t u r e = Nt e m p ( d B A )

Nd r (d B A ) = Na c - Ntr - Nd e t - Nte m p

A v e r a g e W in te r N o is e A b a te m e n t o r D e s ig n M a x im u m N o is e a t T e m p e r a t u r e A t t e n u a t io n w it h D is t a n c e R o a d s id e fo r N e w S u r f a c e

Nd e g n (d B A ) = Nd r + Na tt * N o is e L e v e l In c r e a s e s w it h

E f fe c t iv e N o is e D e c r e a s e in A m b ie n t R e d u c t io n (d B A ) = Na t t T e m p e r a tu r e

C u r r e n t T r a ff ic M ix

FIGURE 6 General frameworks for design noise level for a new surface

INCORPORATION OF PAVEMENT SURFACE CHARACTERISTICS INTO THE PMS

Project Level PMS

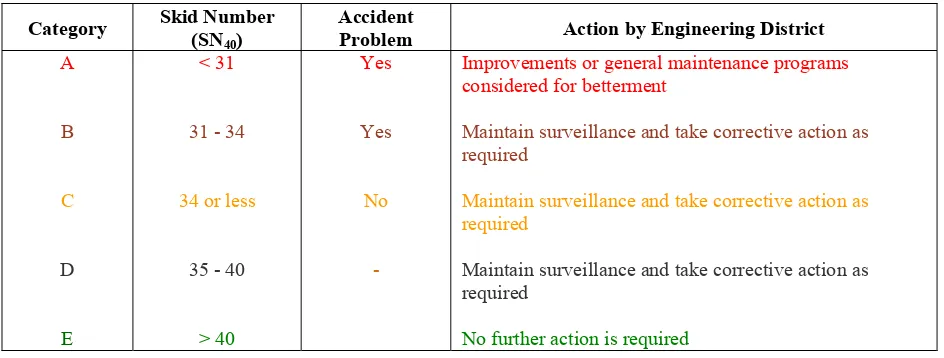

Routine monitoring of the surface friction is essential to ensure safety of the road users, especially in wet-weather. However, although as-built construction smoothness have been incorporated into specifications of several U.S. states, the surface texture and skid properties have not yet quantitatively defined and included in most specifications (24). Monitoring of surface friction is an important part of pavement management system that helps to evaluate quality of pavement surface (25). Tighe (26) also emphasized that pavement surface properties and safety improvements must be incorporated in the pavement management system (PMS), and taken into account simultaneously when planning the maintenance program and selecting the treatment strategies. Although, no transportation agencies in North America set standards for minimum surface friction, different agencies have developed some criteria for identifying low friction surface and initiating possible countermeasure. An example of such guideline, developed in Pennsylvania, is shown in Table 2 (4). On the noise side, a recent study in New Zealand found that change in noise level by 1 dBA is noticeable and annoying to public, especially when the existing noise level is high, reverting previous knowledge that noise increase by 3 dBA is just noticeable to most public. Based on community survey for the degree of annoyance and disturbance, a noise guideline (Table 3) was then developed for changes in urban road surfaces (27).

TABLE 2 Criteria for identifying low friction pavement surface (4)

Category Skid Number (SN40)

Accident

Problem Action by Engineering District A

B

C

D

E

< 31

31 - 34

34 or less

35 - 40

> 40

Yes

Yes

No

-

Improvements or general maintenance programs considered for betterment

Maintain surveillance and take corrective action as required

Maintain surveillance and take corrective action as required

Maintain surveillance and take corrective action as required

No further action is required

TABLE 3 Extent of improvement in noise environment from road surface change (27) Changes in Noise Level

(dBA) <60 dBA Leq24 60-69 dBA Leq24 ≥ 70 dBA Leq24

≥ 3.6 Improvement Big Improvement

1.1 - 3.5 Small Improvement Small Improvement Improvement Reduction

0 - 1 Little Change Little Change Small Improvement

No Change 0 N/A N/A N/A

0 - 1 Little Change Little Change A Little Worse

1.1 - 3.5 A Little Worse Worse

Increase

≥ 3.6 A Little Worse Worse Much Worse

TABLE 4 Guideline for evaluation of pavement surfaces in project level

Overall Noise Level with Respect to the Maximum Acceptable Limit

Pavement Classification

Action by the Agency

>5 dBA higher Very noisy Actively consider for surface change/ treatment to reduce the noise level

3-5 dBA higher Noisy Candidate for surface change/treatment

Within ± 2 dBA Normal Check at 1-2 years interval for potential increase

3-5 dBA lower Less Noisy Check every five years for potential increase

>5 dB lower Noise Reducing No action is needed

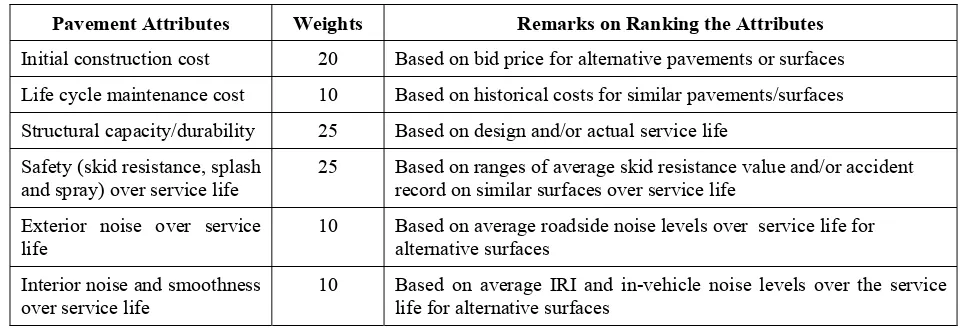

pavements. Overall initial and life cycle costs, constructability, maintainability, durability, comfort and economy in terms of rolling resistance and fuel consumption, and noise rather should be taken into account together with project location (rural/urban), roadway type (freeway/major/local), and traffic class/mix and speed. A revised but simplified list of factors, together with their corresponding weights, is being suggested in Table 5 for use in the decision-making process. Each factor can be assigned a score in the scale of 0-10 or 0-100 with 0 indicating most inferior and 100 or 10 denoting the most superior.

TABLE 5 Value engineering approach for selection of surface and pavement type

Pavement Attributes Weights Remarks on Ranking the Attributes

Initial construction cost 20 Based on bid price for alternative pavements or surfaces

Life cycle maintenance cost 10 Based on historical costs for similar pavements/surfaces

Structural capacity/durability 25 Based on design and/or actual service life

Safety (skid resistance, splash and spray) over service life

25 Based on ranges of average skid resistance value and/or accident record on similar surfaces over service life

Exterior noise over service life

10 Based on average roadside noise levels over service life for alternative surfaces

Interior noise and smoothness over service life

10 Based on average IRI and in-vehicle noise levels over the service life for alternative surfaces

Network Level PMS

Noise performance can also be incorporated into the network level PMS. The strategies as suggested in Denmark are (28):

1. Over ten years, no pavement should belong to the very noisy pavement class.

2. Over six years, all pavements in densely populated area should be noise reducing types

3. Over ten years, all pavements in areas with detached residential houses should only belong to the less noisy types.

4. For any spot increase in the maximum noise level, the road surface shall be visually inspected to determine the reason of such increase. Pavement related noise problem should be solved within two years with appropriate repair/ remediation.

Similar management strategies can also be developed for skid resistance and smoothness. Based on this research, the management strategies for surface friction in network level are being suggested as follows:

1. Over 10-15 years, no pavement should have skid resistance below the desired minimum value.

2. Over 3-5 years, all high speed (≥100 km/h) and highly traveled facilities with annual design lane ESALs of >3 million should have surface friction exceeding the desired minimum SN.

3. Over 5-10 years, all high speed (≥90 km/h) and highly traveled facilities with annual design lane ESALs of 1-3 million should have surface friction exceeding the desired minimum SN.

4. Over two years all black spot locations on a) sharp curves ≥4° for 100 km/h (60 mph) speed limit, ≥6° for 80 km/h (50 mph) speed limit, and ≥9° for 60 km/h (37 mph) speed limit; b) steep grades of >4%; c) merges; and d) approaches to stop signs and traffic signals should have surface friction exceeding the desired minimum SN.

5. Friction related problem at all spot locations other than specified in item 3 should be solved within 2- 5 years with appropriate treatment or rehabilitation.

CONCLUDING REMARKS

proposed.

ACKNOWLEDGEMENTS

The authors gratefully acknowledge the financial support of the Natural Science and Engineering Research Council (NSERC) of Canada, Ontario Ministry of Transportation (MTO) and Canada Foundation for Innovation (CFI) for financial support for the complete research on pavement surface characteristics. The contribution of Dufferin Ready Mix Supplier who donated and delivered the concrete mix for the laboratory samples is also acknowledged.

REFERENCES

1. Transport Canada. Canadian Motor Vehicle Traffic Collision Statistics 2004 and Road Safety in Canada: An Overview. Transport Canada Website http://www.tc.gc.ca/ (Accessed on November 07, 2006).

2. Noyce, D. A., H. U. Bahia, J. M. Yambo, and G. Kim. Incorporating Road Safety into Pavement Management: Maximizing Asphalt Pavement Surface Friction for Road Safety Improvements. Draft Literature Review and State Surveys. Midwest Regional University Transportation Center Traffic Operations and Safety (TOPS) Laboratory, April 29, 2005.

3. Anon, “What’s all the Noise About? Separating the truth from myths about tire-pavement noise”, Better Roads Volume 73 Issue 8, Special Concrete Section, August 2003, pp 8- 14.

4. Transportation Association of Canada. Pavement Design and Management Guide. Ottawa, Ontario, 1997. 5. PWC Consulting, Health Insider No. 7: Noise Proprietary Questions for Health Canada Contract No.

H1011-010139/001/CY, 2002 http://www.hc-sc.gc.ca/ewh-semt/pubs/noise-bruit/insider7/method_e.html

(Last accessed August 2007).

6. Centre for Transportation Research and Education (CTRE), Evaluation of U.S. and European Concrete Pavement Noise Reduction Methods, National Concrete Pavement Technology Center, Iowa State University, Ames, IA , July 2006.

7. Henry, J.J. Evaluation of Pavement Friction Characteristics. NCHRP Synthesis of Highway Practice 291, Transportation Research Board, National Research Council, Washington, D.C., 2000.

8. Hibbs, B.O., and R. M. Larson. Tire Pavement Noise and Safety Performance. Publication No. SA-96-068, FHWA, U.S. Department of Transportation, 1996

9. Grady, J. E. and W. P. Chamberlin. Groove-Depth Requirements for Tine- Textured Pavements. In

Transportation Research Record: Journal of the Transportation Research Board, No. 836, TRB, National Research Council, Washington D.C., 1981, pp 67-76.

10. Ahammed, M. A. and S. L. Tighe. Evaluation of Concrete Pavements Surface Friction Using LTPP Data. Proceedings: 86th Annual Meeting of Transportation Research Board (CD-ROM), TRB, National Research

Council, Washington D.C., 2007.

11. Hoerner, T. E. and K. D. Smith. High Performance Concrete Pavement: Pavement Texturing and Tire-Pavement Noise. Publication No. FHWA-DTFH61-01-P-00290. FHWA, U.S. Department of Transportation, 2002.

12. Rizenbergs, R. L, J. L. Burchet, and L. A. Warren. Relation of Accidents and Pavement Friction on Rural Two-Lane Roads.In Transportation Research Record: Journal of the Transportation Research Board, No. 633, TRB, National Research Council, Washington D.C., 1976, pp 21-27.

13. Jayawickrama, P. W. and B. Thomas. Correction of Field Skid Measurements for Seasonal Variation in Texas.In Transportation Research Record: Journal of the Transportation Research Board, No. 836, TRB, National Research Council, Washington D.C., 1981, pp 82-86.

14. Snyder, M. B. Pavement Surface Characteristics: A Synthesis and Guide. Engineering Bulletin EB235P, American Concrete Pavement Association (ACPA), Skokie, IL, 2006.

15. Wayson, R. L. Relationship Between Pavement Surface Texture and Highway Traffic Noise. NCHRP Synthesis of Highway Practice 268, Transportation Research Board, National Research Council, Washington D.C., 1998.

16. Highway Engineering Division. The Use of Bituminous Surface Course Types on Provincial Highways,

Directive PHY-C-016, Ontario Ministry of Transportation (MTO), May 23, 2002. 17. Kamel N., and T. Gartshore. Ontario’s Wet Pavement Accident Reduction Program. Pavement Surface

Characteristics and Materials, ASTM STP 763, American Society for Testing and Materials, Philadelphia, 1982, pp 98-117.

18. Gargett, T. The Introduction of a Skidding-Resistance Policy in Great Britain. Surface Characteristics of Roadways: International Research and Technologies, ASTM STP 1031, American Society for Testing and Materials, Philadelphia, 1990, pp 30-38.

http://www.ene.gov.on.ca/envision/gp/3517e.pdf (Accessed 26 August, 2007).

20. Regional Municipality of Waterloo (RMW). Implementation Guidelines for Noise Policies. Report No. E-04-052, Waterloo, Ontario, 2004.

21. McDaniel, R., Thornton, W. Field Evaluation of a Porous Friction Course for Noise Control, Proceedings: 85th Annual Meeting of the Transportation Research Board (CD-ROM), TRB, National Research Council, Washington, D.C., 2005.

22. Kuemmel, D. A., R. C. Sonntag, J. A. Crovetti, Y. Becker, J. R. Jaeckel, and A. Satanovsky. Noise and Texture on PCC Pavements- Results of a Multi-State Study. Report No. WI/SPR-08-99, Wisconsin Department of Transportation, Madison, 2000.

23. Kuemmel, D. A., R. C. Sonntag, J. R. Jaeckel, J. A. Crovetti, Y. Z. Becker and A. Satanovsky. Using a Road Surface Analyzer to Explain Noise Characteristics of Portland Cement Concrete Pavement Surface Texture. In Transportation Research Record: Journal of the Transportation Research Board, No. 1716, TRB, National Research Council, Washington D.C., 2000, pp 144- 153.

24. Flintsch, G. W., E. de Leon, K. K McGhee, and I. L. Al-Qadi. Pavement Surface Microtexture Measurement and Application. In Transportation Research Record: Journal of the Transportation Research Board, No. 1860, TRB, National Research Council, Washington D.C., 2003, pp 168-176.

25. Song, W., X. Chen, T. Smith, A. Hedfi. Investigation of Hot Mix Asphalt Surfaced Pavements Skid Resistance in Maryland State Highway Network System. Proceedings: 85th Annual Meeting of Transportation Research Board (CD-ROM), TRB, National Research Council, Washington D.C., 2006. 26. Tighe, S., N. Li, L. C. Falls, and R. Hass. Incorporating Road Safety into Pavement Management. In

Transportation Research Record: Journal of the Transportation Research Board, No. 1699, TRB, National Research Council, Washington D.C., 2000, pp 1-10.

27. Dravitzki, V. Keeping a cap on noise. Land Transport NZ Research Report, Issue 8, 2006, pp 5-7.

28. Bendtsen, H. and B. Schmidt. Integrating Noise in Pavement Management Systems for Urban Roads.