LAPORAN KEMAJUAN

PENELITIAN PASCASARJANA

DANA ITS 2020

Mikroenkapsulasi Senyawa Bioaktif Biji Alpukat

dengan Metode Spray Drying

Tim Peneliti :

Ketua: Dr. Eng. Widiyastuti, ST., MT. (Teknik Kimia/FT-IRS)

Anggota 1: Dr. Eng. Siti Machmudah, ST., M.Eng. (Teknik Kimia/FT-IRS)

Anggota 2: Prof. Dr. Ir. Heru Setyawan, M.Eng. (Teknik Kimia/FT-IRS)

Mahasiswa S-2: Duhaul Biqal Kautsar (Teknik Kimia/FT-IRS)

DIREKTORAT RISET DAN PENGABDIAN KEPADA MASYARAKAT

INSTITUT TEKNOLOGI SEPULUH NOPEMBER

Daftar Isi

Daftar Isi ... i

Daftar Gambar ... ii

Daftar Lampiran ... iii

BAB I RINGKASAN ... 1

BAB II HASIL PENELITIAN ... 2

Pemodelan Matematis Mikroenkapsulasi dengan Spray Drying ... 2

Asumsi Drying Model ... 2

Persamaan Model Matematika ... 2

Validasi Model Matematika ... 5

Pengaruh suhu udara pengering pada karakteristik partikel ... 6

Eksperimen pengeringan mikroenkapsulasi ... 8

BAB III STATUS LUARAN ... 9

BAB V KENDALA PELAKSANAAN PENELITIAN ... 10

BAB VI RENCANA TAHAPAN SELANJUTNYA ... 11

BAB VII DAFTAR PUSTAKA ... 12

BAB VIII LAMPIRAN ... 15

Daftar Gambar

Gambar 1

Ilustrasi pengeringan mikrokapsul ……… 3

Gambar 2

Perbandingan hasil (a) moisture content partikel, (b) diameter partikel, (c)

densitas partikel, dan (d) suhu udara pengering ……….… 5

Gambar 3

Pengaruh suhu udara pengering masuk spray drying pada (a) kadar air

partikel, (b) diameter partikel, (c) densitas partikel, dan (d) profil suhu.… 6

Gambar 4

Citra SEM partikel enkapsulasi ekstrak minyak biji alpukat oleh gum

Arabic ……….. 8

Daftar Lampiran

BAB I RINGKASAN

Produksi buah alpukat termasuk tinggi di Indonesia, namun yang dimanfaatkan hanya daging buahnya saja

sedang bijinya dibuang. Padahal biji alpukat mengandung senyawa bioaktif yang berfungsi sebagai

antioksidan alami yang mampu menangkal radikal bebas. Biji alpukat masih belum termanfaatkan secara

optimal di Indonesia dikarenakan senyawa bioaktif dalam biji alpukat tidak stabil dan dapat teroksidasi

ketika terkena sinar, oksigen, dan suhu tinggi.

Untuk itu diperlukan upaya melindungi ekstrak biji alpukat selama penanganan dan penyimpanan.

Mikroenkapsulasi dengan bahan lain sebagai bahan pelapis atau bahan dinding diperlukan untuk

mempertahankan fungsi dan fisiokimia ekstrak biji alpukat sebagai bahan inti.

Sebagai bahan dinding dipilih gum Arabic yang mempunyai sifat pengemulsi yang baik, kelarutan tinggi

dalam air, dan viskositas rendah. Selanjutnya mikroenkapsulasi dilakukan dengan metode spray drying.

Variasi dilakukan pada variasi perbandingan berat gum Arabic terhadap berat ekstrak biji alpukat. Selain itu

ekstraksi yang dipilih adalah pada ekstraksi soklet. Analisa yang dilakukan adalah kandungan antioksidan

dan kemampuan sebagai antibakteri sebelum dan sesudah proses enkapsulasi.

Selain itu, untuk menghasilkan produk mikroenkapsulasi dengan spray drying yang baik, perlu diketahui

kondisi operasi dan parameter optimum dari proses yang dilakukan. Maka dari itu perlu dilakukan suatu

permodelan yang dapat menggambarkan proses serta hasil akhir dari mikroenkapsulasi yang dilakukan. Pada

penelitian ini core material berupa ekstrak dari biji alpukat dan wall material berupa gum Arabic. Disini telah

dipelajari pengaruh suhu inlet udara pengering 160, 180, dan 200 C terhadap moisture content partikel,

diameter partikel, densitas partikel, dan suhu outlet udara pengering menggunakan model matematika

berdasarkan kinetika single droplet drying yang membagi pengeringan menjadi dua stage. Selain itu telah

dilakukan eksperimen spray drying mikroenkapsulasi ekstrak biji alpukat dalam gum Arabic dan dievaluasi

degradasi antioksidannya dibanding dengan tanpa enkapsulasi.

Target luaran dari penelitian ini adalah diterima pada Chemical Papers (terindeks Scopus Q2) namun belum

dapat dipenuhi tahun ini karena data yang diperoleh perlu klarifikasi kembali. Selain itu pada tahun depan

mahasiswa S2 dapat menyelesaikan laporan thesisnya dan lulus pada tahun tersebut. Penelitian tahun ini

telah dipresentasikan pada 5th International Conference on Science, Infrastructure Technology and Regional

Development (ICoSITeR) pada 23-25 Oktober 2020 dan paper juga sudah disubmit untuk dipublikasikan ke

IOP Conference Proceeding, prosiding terindeks Scopus.

Ringkasan penelitian berisi latar belakang penelitian,tujuan dan tahapan metode

penelitian, luaran yang ditargetkan, kata kunci

BAB II HASIL PENELITIAN

Pemodelan Matematis Mikroenkapsulasi dengan Spray Drying

Asumsi Drying Model

Model matematika dilakukan dengan pendekatan simulasi 1-D. Pada pendekatan simulasi 1-D,

keseimbangan massa, panas, dan momentum dilakukan pada tingkat droplet individu dengan

mengikuti waktu pengeringan. Kinetika pengeringan yang dimasukkan dalam pendekatan ini

memungkinkan prediksi profil laju pengeringan.

Asumsi yang digunakan pada model matematika ini adalah:

(a) Media pengering adalah udara yang sudah dipanaskan dan pelarut dari larutan yang di-spray

adalah air.

(b) Udara pengering dan liquid yang teratomisasi co-current.

(c) Steady-state untuk keduanya, baik udara dan fase droplet/partikel.

(d) Droplet berbentuk bulat.

(e) Plug flow untuk keduanya, baik udara dan fase droplet/partikel (variasi arah radial dari

ukuran droplet/partikel rata-rata, suhu droplet dan udara, kandungan air droplet dan udara,

dan kecepatan droplet dan udara diabaikan).

(f) Gaya gerak untuk evaporasi adalah perbedaan antara humiditas udara, mempertimbangkan

kejenuhan pada permukaan droplet dan humiditas relative udara bulk.

(g) Profil kandungan air dan suhu dalam droplet diabaikan.

(h) Aglomerasi dan kerusakan droplet diabaikan.

(i) Perpindahan panas antara droplet dan udara dipertimbangkan.

(j) Spray dryer mengalami pertukaran panas dengan udara sekitar melalui dinding chamber.

(k) Chamber dianggap silinder.

(l) Diameter ekstrak biji alpukat dalam emulsi droplet sebesar 6

m.

(m) Hanya mempertimbangkan fungsi jarak yaitu arah aksial atau fungsi axial distance, dan

tidak mempertimbangkan fungsi waktu.

Persamaan Model Matematika

Model ini digunakan untuk mengetahui kondisi / parameter optimum pada mikroenkapsulasi

biji alpukat dengan spray drying, dimana ekstrak biji alpukat dalam emulsi droplet diasumsikan

sebesar 6 mm (Boger dkk., 2018). Berikut adalah ilustrasi pengeringan dari mikroenkapsul yang

ditunjukkan pada Gambar 1.

Gambar 1 Ilustrasi pengeringan mikrokapsul

Variabel yang digunakan pada penelitian ini adalah suhu inlet drying air dengan variasi yaitu 160,

180, 200

oC.

Humiditas dari sampel dihitung menggunakan persamaan berikut ini:

𝑑𝑊𝑝 𝑑𝑧

= −

𝜋𝑑𝑝2𝑚̇𝑣

𝑣𝑝𝑚𝑠

, 𝑊

𝑝(𝑧

0) = 𝑊

𝑝0... (1)

Laju evaporasi didapat dari persamaan:

𝑚̇

𝑣= 𝛽(𝑌

𝑠𝑎𝑡− 𝑌

𝑏) ... (2)

𝑌

𝑠𝑎𝑡=

𝑃𝑣𝑀̃𝑤(𝑃−𝑃𝑣)𝑀̃𝑎

... (3)

b dihitung sebagai fungsi koefisien perpindahan panas (a):

𝛽 =

𝛼𝜌𝑎𝐷𝑒𝑓𝑓𝑘𝑎

... (4)

Untuk koefisien perpindahan panas, korelasinya dinyatakan oleh Ranz dan Marshall (1952) untuk

satu droplet atau partikel terisolasi digunakan (Negiz dkk., 1995; Pinto dkk., 2014).

𝑁𝑢 =

𝛼𝑑𝑝 𝑘𝑎= 2 + 0.6𝑅𝑒

0.5𝑃𝑟

0.33... (5)

𝑅𝑒 =

𝜌𝑎𝑑𝑝 𝜇𝑎(𝑣

𝑝− 𝑣

𝑎) ... (6)

𝑃𝑟 =

𝑐𝑝𝑎𝜇𝑎 𝑘𝑎... (7)

𝑣

𝑎=

𝑀̇𝑎 𝜌𝑎𝐴𝑐... (8)

Semua property udara dihitung sebagai fungsi dari suhu udara (T

a) dan dihitung sesuai Welty dkk.

(2008), begitu juga dengan D

effyang dihitung pada 298 K.

Untuk suhu droplet dihitung dengan persamaan:

𝑑𝑇𝑝 𝑑𝑧

=

𝜋𝑑𝑝2[𝛼(𝑇𝑎−𝑇𝑝)−𝑚̇𝑣∆𝐻𝑒𝑣] 𝑣𝑝𝑚𝑠(𝑐𝑝𝑠+𝑊𝑝𝑐𝑝𝑤), 𝑇

𝑝(0) = 𝑇

𝑝0... (9)

Ketika W

p≥ W

pc 𝑑𝑑𝑝 𝑑𝑧=

𝑑𝑝0𝑚̇𝑣𝜋𝑑𝑝2 3𝑚𝑠𝑣𝑝(

𝜌𝑝0−𝜌𝑤 𝜌𝑝−𝜌𝑤)

−2/3 𝜌 𝑝0−𝜌𝑤 (𝜌𝑝−𝜌𝑤) 2𝜌

𝑠 1−𝜌𝑠 𝜌𝑤 (1+𝜌𝑠 𝜌𝑤𝑊𝑝) 2, 𝑑

𝑝(0) = 𝑑

𝑝0... (10)

𝑑𝜌𝑝 𝑑𝑧= −

𝑚̇𝑣𝜋𝑑𝑝2𝜌𝑠 𝑚𝑠𝑣𝑝𝜌

𝑠 1−𝜌𝑠 𝜌𝑤 (1+ 𝜌𝑠 𝜌𝑤𝑊𝑝) 2, 𝜌

𝑝(0) = 𝜌

𝑝0... (11)

Ketika W

peq< W

p< W

pc 𝑑𝑑𝑝 𝑑𝑧= 0 ... (12)

𝑑𝜌𝑝 𝑑𝑧= −

6𝑚̇𝑣 𝑑𝑝𝑣𝑝... (13)

Ketika W

p< W

peq 𝑑𝜌𝑝 𝑑𝑧= 0 ... (14)

Perubahan dari kecepatan droplet (v

p) dihitung melalui neraca momentumnya. Gaya total

yang dihasilkan diseimbangkan dengan percapatan droplet sehingga menghasilkan

𝑑𝑣𝑝 𝑑𝑧

= 𝑔 (

𝜌𝑝−𝜌𝑎 𝜌𝑝𝑣𝑝) −

3 4 𝐶𝐷𝜌𝑎 𝑑𝑝𝜌𝑝𝑣𝑝(𝑣

𝑎− 𝑣

𝑝)

2, 𝑣

𝑝(0) = 𝑣

𝑝0... (15)

Dimana g adalah percepatan gravitasi dan C

Dadalah koefisien drag, yang dihitung sebagai berikut

𝐶

𝐷=

24𝑅𝑒

... (16)

Untuk moisture content digunakan persamaan:

𝑑𝑌𝑏 𝑑𝑧

= 𝑁

𝑡𝑚̇𝑣𝜋𝑑𝑝2

𝑀̇𝑎𝑣𝑝

, 𝑌

𝑏(0) = 𝑌

𝑏0... (17)

Jumlah droplet (Nt) yang masuk ke dalam chamber, yang dihitung dengan

𝑁

𝑡=

𝑀̇𝑙𝑉𝑝0𝜌𝑝0

... (18)

Neraca energi untuk media pengering diberikan sebagai berikut

𝑑𝑇𝑎 𝑑𝑧

= −

𝑁𝑡𝜋𝑑𝑝2(𝑚̇𝑣𝑐𝑝̅̅̅̅𝑣+𝛼)(𝑇𝑎−𝑇𝑝) 𝑣𝑝𝑀̇𝑎(𝑐𝑝𝑎+𝑋𝑏𝑐𝑝𝑣)+

𝑈(𝑇𝑎−𝑇𝑝)𝜋𝐷𝑐 𝑀̇𝑎(𝑐𝑝𝑎+𝑋𝑏𝑐𝑝𝑣), 𝑇

𝑎(0) = 𝑇

𝑎0... (19)

U melambangkan koefisien perpindahan panas global, yang menyumbangkan loss yang diakibatkan

oleh konduksi melalui dinding chamber. Suhu udara awal T

a0dihidtung berdasarkan suhu masuk

dari udara pengering dan atomisasi, D

cadalah diameter chamber dan cp

vadalah heat capacity uap

𝑐𝑝

̅̅̅

𝑣=

1𝑇𝑝−𝑇𝑎

∫ 𝑐𝑝

𝑣𝑑𝑇

𝑇𝑝𝑇𝑎

... (20)

Penelitian ini dilakukan secara simulasi menggunakan software matrix laboratory (Matlab)

menggunakan metode numerik Euler untuk melakukan permodelan mikroenkapsulasi dengan spray

drying.

Validasi Model Matematika

Validasi dilakukan dengan membandingkan hasil simulasi dengan hasil simulasi dan

eksperimen Cotabarren (2018). Validasi dilakukan menggunakan data-data properties bahan serta

kondisi operasi mengikuti jurnal yang bersangkutan. Dengan boundary condition pada sistem yaitu

jarak tempuh partikel dalam chamber mulai dari titik ujung nozzle sama titik dimana partikel keluar

dari chamber (asumsi 0 sampai 0,5 meter).

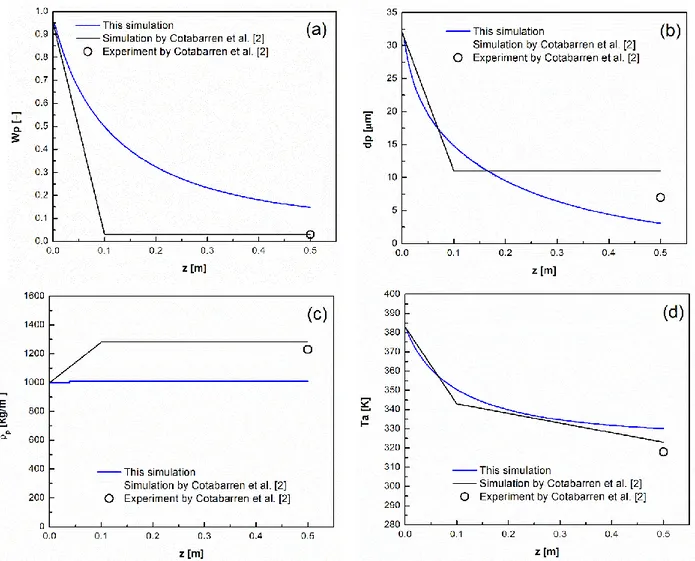

Berdasarkan hasil simulasi data validasi yang dilakukan, didapatkan bahwa moisture

content partikel, diameter partikel, densitas partikel, suhu outlet udara pengering terhadap jarak

tempuh partikel dalam chamber. Pada Gambar 2a, dapat dilihat bahwa nilai akhir moisture content

partikel hanya mencapai 0,156 sedangkan pada data simulasi dan eksperimen Cotabarren keduanya

mencapai 0,03, sehingga didapatkan error sebesar 422%. Begitu pun pada Gambar 2c, densitas

partikel perubahannya sangat sedikit dibandingkan dengan hasil jurnal, dengan densitas akhir

sebesar 1010,220 kg/m

3sedangkan pada jurnal data simulasi dan eksperimen mencapai 1275 kg/m

3dan 1230 kg/m

3, sehingga didapatkan error sebesar 21,07% dan 17,87%. Untuk diameter akhir

partikel, pada Gambar 2b hasil akhirnya sebesar 3,532 m, melampaui data simulasi jurnal yaitu 11

m dan data eksperimen yaitu 7 m, sehingga didapatkan error sebesar 67,89% dan 49,54%.

Sedangkan untuk suhu outlet drying air pada Gambar 2d nilainya sudah mendekati dengan hasil

simulasi dan eksperimen jurnal yaitu 330,554 K pada hasil simulasi ini dan 323 K serta 318 K pada

hasil simulasi dan eksperimen jurnal, sehingga didapatkan error sebesar 2,33% dan 3,94%.

Jika dilihat dari trendline yang terbentuk, hasil simulasi yang dilakukan sudah sesuai dengan

hasil simulasi pada jurnal. Namun jika dilihat dari persen error nya, untuk moisture content masih

menyimpang, untuk diameter dan densitas hasilnya sudah cukup baik karena error nya tidak terlalu

besar, dan untuk suhu udara pengering hasilnya sudah baik karena error nya sangat kecil. Pada

grafik moisture content, diameter, dan densitas, hasil simulasi juga tidak menunjukkan titik kritis

dan garis konstan.

Gambar 2 Perbandingan hasil (a) moisture content partikel, (b) diameter partikel, (c) densitas

partikel, dan (d) suhu udara pengering

Pengaruh suhu udara pengering pada karakteristik partikel

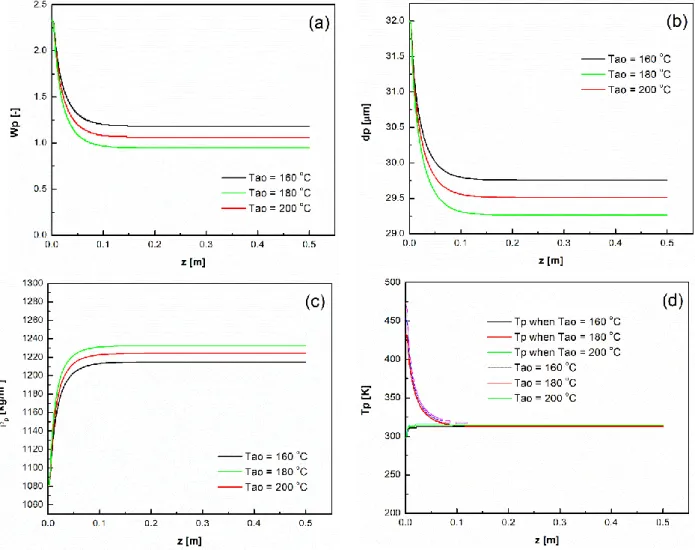

Gambar 3(a) menunjukkan pengaruh suhu inlet udara pengering pada kandungan air pada

partikel. Dapat dilihat bahwa dengan meningkatnya suhu udara pengering dapat meningkatkan

pelepasan pelarut dari droplet menghasilkan kandungan air dalam partikel menurun. Hal ini terjadi

karena peningkatan driving force pengeringan pada suhu lebih tinggi. Tahap pengeringan pertama

lebih singkat pada 200C dibanding 160 dan 180 C. Suhu udara pengering lebih tinggi akan

meningkatkan laju penguapan, selanjutnya mempercepat pembentukan lapisan luar mengeras dan

menyebabkan titik kritis tercapai lebih cepat. Akan tetapi, dari hasil simulasi, kadar air akhir

terendah hanya mencapai 0.933 pada 200 C. Hal ini menunjukkan bahwa kadar air dari partikel

akhir masih tinggi. Hal ini terjadi karena kadar air pada kesetimbangan yang digunakan adalah

bukan gum arabic tetapi ciprofloxacin hydrochloride (CIP).

Gambar 3(b) menunjukkan pengaruh udara pengering masuk spray drying pada diameter

partikel. Peningkatan suhu udara pengering menghasilkan partikel dengan diameter lebih kecil. Saat

menguap, The droplet volume, which initially contains much water, will evaporate, leaving particles

with much less water content, so the final particles' volume also shrinks, which is related to the

shrinking particle diameter. Selain itu, karena suhu tertinggi menghasilkan kadar air terendah, maka

diameter yang dihasilkan adalah yang paling kecil. Namun demikian, dari hasil simulasi, dapat

dilihat pengecilan ukuran diameter partikel tidak terlalu signifikan, dimana diameter terkecil dapat

dicapai 29.23 μm pada suhu 200 C atau hanya 3 μm penurunannya dari diameter droplet

mula-mula. Hal ini terjadi karena kadar air kritis yang dapat dicapai masih tinggi sehingga pengecilan

ukuran partikel tidak terlalu signifikan.

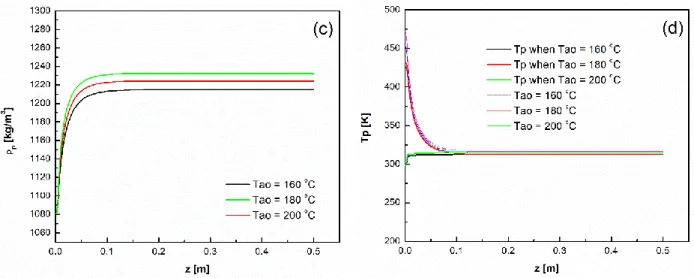

Gambar 3(c) menunjukkan pengaruh suhu udara pengering masuk terhadap densitas

partikel. Peningkatan suhu udara pengering akan menghasilkan densitas partikel lebih tinggi. Saat

diameter mengecil, volume droplet juga berkurang karena penguapan sehingga meningkatkan

densitasnya. Dibandingkan dengan teori, peningkatan densitas ini hanya terjadi pada permulaan

proses penguapan hingga kadar air mencapai titik kritisnya. Namun demikian, dari hasil yang

diperoleh, tidak terlalu terjadi perubahan dalam densitas.

Gambar 4(d) menunjukkan profil suhu udara pengering dan suhu partikel sepanjang jarak

tempuh. Dari hasil simulasi dapat terlihat bahwa suhu udara pengering menurun, sementara suhu

partikel meningkat. Hal ini disebabkan perpindahan panas terjadi dari udara pengering ke partikel

akibat air yang menguap. Pada akhirnya, suhu keluar dari udara pengering dan partikel mencapai

nilai sama.

Gambar 3. Pengaruh suhu udara pengering masuk spray drying pada (a) kadar air partikel, (b)

diameter partikel, (c) densitas partikel, dan (d) profil suhu

Eksperimen pengeringan mikroenkapsulasi

Citra SEM dari partikel enkapsulasi ekstrak minyak biji alpukat oleh gum Arabic dengan

konsentrasi keduanya dalam larutan awal sebelum spray drying masing-masing sebesar 5% dan

10% ditunjukkan pada Gambar 4.

BAB III STATUS LUARAN

Hasil penelitian ini telah dipresentasikan pada seminar internasional pada International Conference on

Science, Infrastructure Technology and Regional Development (ICoSITeR) pada tanggal 23-25 Oktober

2020.

Simulation of Microencapsulation Avocado Seeds Oil by Spray

Drying

Naqiyyah Salsabilah, Marwa Efira Karuniahaj, Duhaul Biqal Kautsar, Widiyastuti*,

Heru Setyawan

Department of Chemical Engineering, Institut Teknologi Sepuluh Nopember, Surabaya,

Indonesia

*Corresponding author’s email: widi@chem-eng.its.ac.id

Abstract. Drying air inlet temperature is one of the important variables in the

microencapsulation process by spray drying. However, when spray drying is carried out at

inappropriate drying air inlet temperature, it can cause damage to the particle produced. This

study presents a simulation of spray drying from a mathematical model was developed to

determine the effect of drying air inlet temperature on moisture content, particle diameter,

particle density, and drying air outlet temperature in the microencapsulation process of

avocado seeds oil as core materials and Arabic gum as wall materials. For this aim, the

mathematical model developed was then simulated using a matrix laboratory (MATLAB)

computer program with Euler numerical method for drying air inlet temperature 160, 180,

and 200°C. The simulation results of the developed mathematical model show that the

moisture contents of particles are 1.170, 1.049, and 0.933 kg/kg, which deviated error of

422%, the particle diameters are 29.733, 29.486, and 29.23 μm with the error of 67.89% and

49.54%, particle densities are 1215.723, 1225.210, and 1233.253 kg/m

3with the error of

21.07% and 17.87%, and relatively good drying air outlet temperature 39.769, 41.945, and

43.888°C with the error of 2.33% and 3.95%. According to the results, higher temperatures

caused lower particle moisture contents, smaller particle diameter, higher particle density,

and outlet drying air temperatures are always the same as the outlet particle temperatures.

Keywords: Avocado seeds oil, drying air inlet temperature, MATLAB,

microencapsulation,

spray drying

BAB V KENDALA PELAKSANAAN PENELITIAN

Kendala analisa yang terlambat sehingga sampai laporan akhir ini hasil eksperimen spray drying belum

semua dapat dilaporkan.

BAB VI RENCANA TAHAPAN SELANJUTNYA

Tahap selanjutnya adalah menyelesaikan analisa produk untuk beberapa variabel dan menulis draft

publikasi jurnal internasional bereputasi.

BAB VII DAFTAR PUSTAKA

Bae, E.K. dan Lee, S.J. 2008. Microencapsulation of avocado oil by spray drying using whey

protein and maltodextrin. Journal of Microencapsulation, Vol. 25, No. 08, Hal. 549-560.

Bakry, A.M., Abbas, S., Ali, B., Majeed, H., Abouelwafa, M.Y., Mousa, A., dan Liang, L. 2016.

Microencapsulation of Oils: A Comprehensive Review of Benefits, Techniques, and

Applications. Comprehensive Reviews in Food Science and Food Safety, Vol. 15, Hal.

143-182.

Boger, B.R., Georgetti, S.R., dan Kurozawa, L.E. 2018. Microencapsulation of grape seed oil by

spray drying. Food Sci. Technol, Hal. 1-8.

Carneiro, H.C.F., Vonon, R.V., Grosso, C.R.F., dan Hubinger, M.D. 2012. Encapsulation efficiency

and oxidative stability of flaxseed oil microencapsulated by spray drying using different

combinations of wall materials. Journal of Food Engineering, Vol. 115, No. 2013, Hal.

443-451.

Chimsook, Thitiphan. 2017. Microwave Assisted Extraction of Avocado Oil from Avocado Skin and

Encapsulation Using Spray Drying. Key Engineering Materials, Vol. 737, Hal. 341-346.

Correa-Filho, L.C., Lourenco, M.M., Moldao-Martins, M., dan Alves, V.D. 2019.

Microencapsulation of β-karoten by Spray Drying: Effect of Wall Material Concentration and

Drying Inlet Temperatur. International Journal of Food Science, Vol. 2019, Hal. 1-12.

Cosmas, Ujowundu Onyekachi. 2011. Biochemical composition and anti microbial activities of

seed extracts of avocado (Persea americana). Journal of Microbiology and Antimicrobials,

Vol. 03, No. 07, Hal. 184-190.

Cotabarren, I.M., Bertin, D., Razuc, M., Ramirez-Rigo, M.V., dan Pina, J. 2018. Modelling of the

spray drying process for particle design. Chemical Engineering Research and Design, Vol.

132, Hal. 1091-1104.

Ge, Y., Si, X., Wu, B., Dong, X., Xu, Z., dan Ma, W. 2018. Oil Content and Fatty Acid Composition

of The Seeds of 16 Avocado (Persea Americana) Accessions Collected from Southern China

and Their Application in a Soap Bar. Journal of Agricultural Science, Vol. 10, No. 11, Hal.

69-78.

Krokida, M.K. 2018. Advances in Drying Science & Technology: Thermal and Nonthermal

Encapsulation Methods. Boca Raton: CRC Press, Taylor & Francis Group.

Kuriakose, R. dan Anandharakrishnan, C. Computational Fluid Dynamics (CFD) Applications in

Le, T.H., Tran, T.M.V., Ton, N.M.N., Tran, T.T.T., Huynh, T.V., Nguyen, T.N., Quang, S.P., dan

Le, V.V. M. 2016. Combination of whey protein and carbohydrate for microencapsulation of

pumpkin (Cucurbita spp.) seed oil by spray drying. International Food Research Journal,

Vol. 24, No. 03, Hal. 1227-1232.

Mezhericher, M.; Levy, A.; dan Borde, I. 2014. Multi-Scale Multiphase Modeling of Transport

Phenomena in Spray Drying Processes. Drying Technology: An International Journal, Hal.

1-70.

Negiz, A., Lagergen, R., Cinar, A. 2995. Mathematical models of cocurrent spray drying. Ind. Eng.

Chem. Res., Vol. 34, Hal. 3289-3302.

Pinto, M.A., Kemp, I., Bermingham, S., Hartwig, T., Bisten, A. 2014. Development of an

axisymmetric population balance model for spray drying and validation against experimental

data and CFD simulations. Chem. Eng. Res. Des., Vol. 92, Hal. 619-634.

Pratama, R.N., Widarta, I.W.R., dan Darmayanti, L.P.T. 2017. Pengaruh Jenis Pelarut dan Waktu

Ekstraksi Dengan Metode Soxhletasi Terhadap Aktivitas Antioksidan Minyak Biji Alpukat

(Persea Americana Mill.). Media Ilmiah Teknologi Pangan, Vol. 4, No. 02, hal. 85-93.

Premi, M. dan Sharma, H.K. 2017. Effect of different combinations of maltodextrin, gum Arabic

and whey protein concentrate on the encapsulation behavior and oxidative stability of spray

dried drumstick (Moringa oleifera) oil. International Journal of Biological Macromolecules,

Hal. 1-28.

Qin, X. dan Zhong, J. 2016. A Review of Extraction Techniques for Avocado Oil. Journal of Oleo

Science, Hal. 1-8.

Ranz, W.E., Marshall, W.R. 1952. Evaporation from Drops. Parts I & II. Chem. Eng. Prog., Vol.

48, Hal. 141-146, 173-180.

Re, M.I. 1998. Microencapsulation By Spray Drying. Drying Technology: An International

Journal, Vol. 16, No. 06, Hal. 1195-1236.

Satriana, Supardan, M.D., Arpi, N., dan Mustapha, W.A.W. 2018. Development of methods used in

the extraction of avocado oil. European Journal of Lipid Science and Technology, Hal. 2-29.

Shamaei, S., Seiiedlou, S.S., Aghbashlo, M., Tsotsas, E., dan Kharaghani, A. 2016.

Microencapsulation of walnut oil by spray drying: Effects of wall material and drying

conditions on physiochemical properties of microcapsules. Innovative Food Science and

Emerging Technologies, Vol. 39, No. 2017, Hal. 101-112.

Shamei, S., Seiiedlou, S.S., Aghbashlo, M., dan Valizadeh, H. 2016. Mathematical modelling of

drying behavior of single emulsion droplets containing functional oil. Food and Bioproducts

Processing, Hal. 1-32.

Sotelo-Bautista, M., Bello-Perez, L.A., Gonzales-Soto, R.A., Yanez-Fernandez, J., dan

Alvarez-Ramirez, J. 2019. OSA-maltodextrin as wall material for encapsulation of essential avocado

oil by spray drying. Journal of Dispersion Science and Technology, Hal. 1-8.

Tran, T.T.H., Jaskulski, M., Avila-Acevedo, G.A., dan Tsotsas, E. 2016. Model Parameters for

Single Droplet Drying of Skim Milk and Its Constituents at Moderate and Elevated

Temperatures. Drying Technology: An International Journal, Hal. 1-71.

Vinha, A.F., Moreira, J., dan Barreira, A.V.P. 2013. Physicochemical Parameters, Phytochemical

Composition and Antioxidant Activity of the Algarvian Avocado (Persea Americana Mill.).

Journal of Agricultural Science, Vol. 5, No. 12, Hal. 1-10.

Welty, J.R., Wicks, C.E., Wilson, R.E., dan Rorrer, G.L. 2008. Fundamentals of Momentum, Heat,

BAB VIII LAMPIRAN

LAMPIRAN 1 Tabel Daftar Luaran

Program

: Penelitian Pascasarjana

Nama Ketua Tim

: Dr. Eng. Widiyastuti, ST., MT.

Judul

: Mikroenkapsulasi Senyawa Bioaktif Biji Alpukat dengan

Metode Spray Drying

1.Artikel Jurnal

No

Judul Artikel

Nama Jurnal

Status Kemajuan*)

*) Status kemajuan: Persiapan, submitted, under review, accepted, published

2. Artikel Konferensi

No

Judul Artikel

Nama Konferensi (Nama

Penyelenggara, Tempat,

Tanggal)

Status Kemajuan*)

Simulation of Microencapsulation

Avocado Seeds Oil by Spray

Drying

International Conference

on Science, Infrastructure

Technology and

Regional Development

(ICoSITeR) pada tanggal

23-25 Oktober 2020

presented

*) Status kemajuan: Persiapan, submitted, under review, accepted, presented

3. Paten

No Judul Usulan Paten

Status Kemajuan

*) Status kemajuan: Persiapan, submitted, under review

4. Buku

No

Judul Buku

(Rencana) Penerbit

Status Kemajuan*)

*) Status kemajuan: Persiapan, under review, published

5. Hasil Lain

No

Nama Output

Detail Output

Status Kemajuan*)

No Nama Mahasiswa

NRP

Judul

Status*)

DUHAUL BIQAL

KAUTSAR

02211950012001 Mikroenkapsulasi

ekstrak biji

alpukat dengan

metode spray

drying

In progress

International Conference on Science, Infrastructure Technology

and Regional Development (ICoSITeR) 2020

INSTITUT TEKNOLOGI SUMATERA

Jl. Terusan Ryacudu, Way Hui, Jati Agung, Lampung Selatan 35365

Telp. 085274244743, email : icositer2020@itera.ac.id, http://icositer.itera.ac.id/2020

South Lampung, November 24

th, 2020

No.

: 251/ ICoSITeR/ XI/ 2020

Subject

: Full Paper Acceptance

Dear Authors,

We are pleased to inform you that your full paper submitted to the 5th

International Conference on Science,

Infrastructure Technology and Regional Development (ICoSITeR) 2020 entitled :

Paper ID

: ID-094

Tittle

: Simulation of Microencapsulation Avocado Seeds Oil by Spray Drying

Authors

: Naqiyyah Salsabilah, Marwa Efira Karuniahaj, Duhaul Biqal Kautsar, Ni Made

Intan Putri Suari, Widiyastuti, Heru Setyawan

has been accepted and will proceed to be reviewed by internal ICoSITeR’s reviewer. We will send the

results of the review paper to the author as soon as possible.

Sincerely Yours,

Prof. Dr.-Ing. Mitra Djamal

Chairman

ICoSITeR 2020

IOP Publishing

IOP Conf. Series

https://doi.org/XXXX/XXXX

Simulation of Microencapsulation Avocado Seeds Oil by Spray Drying

Naqiyyah Salsabilah, Marwa Efira Karuniahaj, Duhaul Biqal Kautsar, Ni Made Intan Putri

Suari, Widiyastuti*, Heru Setyawan

1

Department of Chemical Engineering, Institut Teknologi Sepuluh Nopember, Surabaya,

Indonesia

*Corresponding author's email: widi@chem-eng.its.ac.id

Abstract. Drying air inlet temperature is one of the critical variables in the microencapsulation

process by spray drying. However, when spray drying is carried out at inappropriate drying air inlet

temperature, it can impact the particle produced. This study presents a simulation of spray drying

from a mathematical model was developed to determine the effect of drying air inlet temperature

on moisture content, particle diameter, particle density, and drying air outlet temperature in the

microencapsulation process of avocado seeds oil as core materials and gum arabic as wall materials.

For this aim, the mathematical model was developed then simulated using a matrix laboratory

(Matlab) computer program with Euler numerical method for drying air inlet temperatures of 160,

180, and 200 °C. The selected model was validated with Cotabarren's experimental results

indicating the model was acceptable. The particles' moisture contents predicted from simulation

results are 1.170, 1.049, and 0.933 kg water/kg solid for 160, 180, and 200 °C, respectively. On the

other hand, the predicted particle diameters are 29.73, 29.49, and 29.23 μm for 160, 180, and 200

°C, respectively. The predicted particle densities are 1215.72, 1225.21, and 1233.25 kg/m

3for 160,

180, and 200 °C, respectively. The prediction of drying air outlet temperatures was 39.76, 41.94,

and 43.89 °C for inlet air temperatures of 160, 180, and 200 °C, respectively. The proposed models'

simulation results show that the higher temperatures caused lower particle moisture content, smaller

particle diameter, and higher particle density. Also, the outlet drying air temperatures were always

the same as the outlet particle temperatures.

Keywords: Avocado seeds oil, drying air inlet temperature, Matlab, microencapsulation, spray

drying

1. Introduction

Microencapsulation is the widely used technique to protect core material from damage caused by hazardous environmental conditions by entrapping core in shell material and forming small particles with a diameter of 1–1000 μm. Spray drying is one of the technologies that has been developed successfully to produce small particles powder, which has advantages of relatively simple, rapid, and reproducible, allowing easy scale‐up compared to other encapsulation techniques, justifying its preferred use in the industrial sector, flexible process, and lower production costs [1]. However, encapsulation using spray drying is a very sensitive thermal process, and drying inlet temperature is one of the main parameters leading to variations in particle size, process yield, particle morphology, crystalline state, moisture content, and density, among others. Therefore, it would be disadvantageous to find these particles characterization by trial and error, which needs time, high costs, large waste generation, and operations distant from the optimal points, and considerable difficulties in ensuring the product's quality [2]. The developed mathematical models are applied as solutions to these problems to predict the characteristics of the particles produced, and it is advantageous to determine suitable operating conditions to obtain the desired particle characteristics.

Generally, spray drying has four operation stages. They are atomization of liquid feed into a spray chamber, contact between the spray and the drying medium, moisture evaporation, and separation of dried products from airstream [3]. On the other side, emulsion droplets undergo two drying stages. Firstly, the droplet with excess liquid is subjected to a stream of drying gas and gains sensible heat, and vaporization begins. The evaporation results in droplet shrinkage and a simultaneous increase of solids

ICoSITeR 2020

IOP Publishing

IOP Conf. Series

https://doi.org/XXXX/XXXX

concentration near the droplet surface. In turn, it leads to the precipitation of solid components at the droplet surface, and, eventually, all the surface becomes covered with a solid layer called the crust. At this moment, the droplet turns into a wet particle, and the second stage of drying commences. In the second stage, the drying process is hindered by additional resistance to the crust layer's evaporation. The second drying stage continues until the particle moisture content reduces to equilibrium with the drying medium. After this point, the drying process stops, and the particle is heated up to the equilibrium temperature [4]. These drying kinetics can be used as underlying the mathematical models to determine the effect of drying air inlet temperature.

A previous study has reported a steady-state mathematical model for a co-current spray dryer is developed to give a more phenomenological insight in the production of inhalable particles, ciprofloxacin hydrochloride (CIP), and then implemented in the gPROMS Environment [2]. However, the droplets were studied has no emulsion content. Furthermore, it is still an important challenge to understanding the drying kinetics of single droplets containing emulsion. Therefore, this study's objective was to combine mathematical models that apply to single droplets containing emulsion, which in this study avocado seeds oil as core material and gum arabic as wall material.

2. Methodology

This research aims to simulate a mathematical model for avocado seed extract's microencapsulation process with spray drying using Matlab.

2.1 Mathematical Model Assumptions

The mathematical model is carried out with a 1-D simulation approach. In the 1-D simulation approach, mass, heat, and momentum balance is carried out at the individual droplet level following the drying time. The drying kinetics incorporated in this approach allows the prediction of the drying rate profile.

1. The assumptions used in this mathematical model as follows [2]:

2. The drying medium is preheated air, and the solvent of the sprayed solution is water. 3. The drying air and the atomized liquid are co-current.

4. Steady-state for both air and droplets/particles phases is applied. 5. Droplets are spherical.

6. Plug flow for both air and droplet/particles phases (variations in the radial direction of mean droplet/particle size, droplet and air temperature, content water droplets, and air, and droplet and air velocities are negligible).

7. The evaporation force is the difference between air humidity, considering the droplet surface's saturation and bulk air's relative humidity.

8. The water content and temperature profiles in the droplets are neglected. 9. Agglomeration and breakage of droplets are neglected.

10. Heat transfer between droplets and air is considered.

11. The spray dryer undergoes heat exchange with ambient air through the wall chamber. 12. Chamber is considered to be a cylinder.

13. The diameter of the avocado seed extract in the droplet emulsion is 6 m.

14. Consider only the distance function, i.e., axial direction or axial function distance, and do not consider the time function.

2.2 Mathematical Model Equations

This model is used to determine the optimum conditions/parameters for the microencapsulation of avocado seeds by spray drying, where the avocado seed extract in a droplet emulsion is assumed to be 6 μ m [5]. The illustration of the drying of the microencapsulation is shown in Figure 1.

The variables used in this study were the inlet drying temperature of the water with variations of 160, 180, 200 C. The humidity of the sample is calculated using the following equation:

𝑑𝑊𝑝

𝑑𝑧 = − 𝜋𝑑𝑝2𝑚̇

𝑣

𝑣𝑝𝑚𝑠 , 𝑊𝑝(𝑧0) = 𝑊𝑝0 ... (1)

The evaporation rate is obtained from the equation:

𝑚̇𝑣= 𝛽(𝑌𝑠𝑎𝑡− 𝑌𝑏) ... (2)

𝑌𝑠𝑎𝑡= 𝑃𝑣𝑀̃𝑤

ICoSITeR 2020

IOP Publishing

IOP Conf. Series

https://doi.org/XXXX/XXXX

Figure 1. The mechanism of the microencapsulation process in spray drying

calculated as a function of the heat transfer coefficient (): 𝛽 =𝛼𝜌𝑎𝐷𝑒𝑓𝑓

𝑘𝑎 ... (4)

One droplet or isolated particle assumption is used to calculate the heat transfer coefficient [6-8]: 𝑁𝑢 =𝛼𝑑𝑝 𝑘𝑎 = 2 + 0.6𝑅𝑒 0.5𝑃𝑟0.33 ... (5) 𝑅𝑒 =𝜌𝑎𝑑𝑝 𝜇𝑎 (𝑣𝑝− 𝑣𝑎) ... (6) 𝑃𝑟 =𝑐𝑝𝑎𝜇𝑎 𝑘𝑎 ... (7) 𝑣𝑎= 𝑀̇𝑎 𝜌𝑎𝐴𝑐 ... (8)

All air properties were calculated as an air temperature function (Ta) and calculated [7] and Deff, which is calculated at 298 K.

For the droplet temperature calculated by the equation:

𝑑𝑇𝑝 𝑑𝑧 = 𝜋𝑑𝑝2[𝛼(𝑇𝑎−𝑇𝑝)−𝑚̇𝑣∆𝐻𝑒𝑣] 𝑣𝑝𝑚𝑠(𝑐𝑝𝑠+𝑊𝑝𝑐𝑝𝑤) , 𝑇𝑝(0) = 𝑇𝑝0 ... (9) When Wp≥ Wpc 𝑑𝑑𝑝 𝑑𝑧 = 𝑑𝑝0𝑚̇𝑣𝜋𝑑𝑝2 3𝑚𝑠𝑣𝑝 ( 𝜌𝑝0−𝜌𝑤 𝜌𝑝−𝜌𝑤) −2/3 𝜌𝑝0−𝜌𝑤 (𝜌𝑝−𝜌𝑤)2𝜌𝑠 1−𝜌𝑠 𝜌𝑤 (1+𝜌𝑠 𝜌𝑤𝑊𝑝) 2, 𝑑𝑝(0) = 𝑑𝑝0 ... (10) 𝑑𝜌𝑝 𝑑𝑧 = − 𝑚̇𝑣𝜋𝑑𝑝2𝜌𝑠 𝑚𝑠𝑣𝑝 𝜌𝑠 1−𝜌𝑠 𝜌𝑤 (1+ 𝜌𝑠 𝜌𝑤𝑊𝑝) 2, 𝜌𝑝(0) = 𝜌𝑝0 ... (11) When Wpeq < Wp < Wpc 𝑑𝑑𝑝 𝑑𝑧 = 0 ... (12) 𝑑𝜌𝑝 𝑑𝑧 = − 6𝑚̇𝑣 𝑑𝑝𝑣𝑝 ... (13) When Wp < Wpeq 𝑑𝜌𝑝 𝑑𝑧 = 0 ... (14)

The change in droplet velocity (vp) is calculated through its momentum balance. The total force generated is balanced with

the droplet density to produce

𝑑𝑣𝑝 𝑑𝑧

= 𝑔 (

𝜌𝑝−𝜌𝑎 𝜌𝑝𝑣𝑝) −

3 4 𝐶𝐷𝜌𝑎 𝑑𝑝𝜌𝑝𝑣𝑝(𝑣𝑎

− 𝑣

𝑝) 2, 𝑣

𝑝(0) = 𝑣

𝑝0….…..…..…..…..….…..….……….... (15)Where g is the acceleration due to gravity and CD is the drag coefficient, which is calculated as follows

𝐶𝐷 = 24

ICoSITeR 2020

IOP Publishing

IOP Conf. Series

https://doi.org/XXXX/XXXX

For moisture content, the equation as follows:

𝑑𝑌𝑏 𝑑𝑧 = 𝑁𝑡

𝑚̇𝑣𝜋𝑑𝑝2

𝑀̇𝑎𝑣𝑝 , 𝑌𝑏(0) = 𝑌𝑏0 ... (17)

The number of droplets (Nt) that enter the chamber, which is calculated by

𝑁𝑡= 𝑀̇𝑙

𝑉𝑝0𝜌𝑝0 ... (18)

The energy balance for the drying medium is given as follows

dTa dz = − Ntπdp2(ṁvcp̅̅̅̅v+α)(Ta−Tp) vpṀa(cpa+Xbcpv) + U(Ta−Tp)πDc Ṁa(cpa+Xbcpv), Ta(0) = Ta0 ... (19)

U represents the global heat transfer coefficient, contributing to conduction loss through the chamber wall. The initial air temperature Ta0 is calculated based on the intake temperature of the drying air and atomization, Dc is the chamber diameter,

and cpv is the steam heat capacity calculated by:

𝑐𝑝 ̅̅̅𝑣= 1 𝑇𝑝−𝑇𝑎∫ 𝑐𝑝𝑣𝑑𝑇 𝑇𝑝 𝑇𝑎 ... (20)

This research was conducted in a simulation using matrix laboratory software (Matlab) using Euler's numerical method to perform microencapsulation modeling by spray drying. The flow of the simulation is shown in Figure 2.

Figure 2.Simulation flowchart

2.3 Material Properties and Operation Condition

In this study, the materials used for validation were CIP solution with the properties shown in Table 1. The same model was also applied to study the microencapsulation in spray drying using the avocado seed extract as the core material, gum arabic as the wall material, and water as the solvent. In this study, the new droplets entered the chamber had a composition, namely gum arabic, avocado seed extract, and water. So that the density can be calculated as follows [8]:

ICoSITeR 2020

IOP Publishing

IOP Conf. Series

https://doi.org/XXXX/XXXX

As for the solid-state of the particles, the composition is gum arabic, and avocado seed extract. The avocado seed extract is considered a solid because it does not evaporate as it does in water. So that the solid density and heat capacity can be calculated as follows:

𝜌

𝑠= 𝑥

𝐺𝐴𝜌

𝐺𝐴+ 𝑥

𝐴𝐸𝜌

𝐴𝐸... (22)

𝑐𝑝

𝑠= 𝑥

𝐺𝐴𝑐𝑝

𝐺𝐴+ 𝑥

𝐴𝐸𝑐𝑝

𝐴𝐸... (23)

The initial condition, the operating condition, and parameter data used in the simulation are depicted in Tables 2-4.

Table 1. Material properties for validation and research

No Parameter Validation Research

Ciprofloxacin hydrochloride (CIP) Avocado Extract Gum Arabic

1. Density (kg/m3) 1000 (CIP 10)

1100 (CIP solid) 1000 1300

2. Heat capacity (J/kg.K) 1568 (CIP solid) 1670* 1500**

* Avocado seed extract heat capacity uses the heat capacity vegetable oil because avocado seed extract could not be found.

** The heat capacity gum arabic value uses the maltodextrin heat capacity value because the value for gum arabic cannot be found. Maltodextrin is chosen because it is commonly used as wall material and is often combined with gum arabic to become a better wall material.

Table 2. The initial condition for simulation

No Parameter Validation Research

1. Initial temperature drying air (K) 383 433, 453, 473

2. Initial temperature droplet (K) 298 298

3. Initial droplet moisture content (kg air / kg solid) 0.95 2.33

4. Initial droplet diameter (μm) 32 32

5. Initial droplet density (kg/m3) 1000 1081

6. Initial humidity drying air (kg air / kg udara) 0.0015 0.0015 7. Initial velocity droplet/particle (m/s) 1.897x10-4 1.897x10-4

Table 3.Operation Condition

No Parameter Validation Research

1. Total solid concentration in emulsion 10 (mg/mL) 30 (% mass) 2. Core material concentration in solud - 10 (% mass) 3. Flowrate feed liquid (m3/s) 3 × 10−6

60

9.72 x 10-8

4. Flowrate atomization air (m3/s) 667 × 10−12

3600

-

5. Flowrate drying air (m3/s) 0.0097 0.0203

6. Delta z 10-6 10-6

Table 4.Determined Parameter

No Parameter Validation Research

1. Termal glass conductivity (W/mK) 0.8 0.8

2. Air molecular weight (g/mol) 28.97 28.97

3. Water molecular weight (g/mol) 18.02 18.02

4. Atmospheric pressure (Pa) 101325 101325

ICoSITeR 2020

IOP Publishing

IOP Conf. Series

https://doi.org/XXXX/XXXX

No Parameter Validation Research

6. Water critical temperature (K) 647.3 647,3

7. Enviroment temperature (K) 298 298

8. Thickness of the surrounding air barrier layer(m) 8.97 x 10-4 8,97 x 10-4

9. Chamber diameter (m) 0.2304 0.5

10. Diameter nozzle feed liquid (m) 0.77 x 10-3 0.77 x 10-3

11. Chamber wall thickness (m) 0.0025 0.0025

12. Gravitation acceleration (m/s2) 9.8 9.8

13. Gas constant (J/molK) 8.314 8.314

14. Global heat transfer coefficient (W/m2K) 1.5144 1.5144

3. Results and Discussion

This study aims to create a simulation of a mathematical model for spray drying microencapsulation and determine the effect of drying air inlet temperature on particle moisture content, particle diameter, particle density, and drying air outlet temperature. The variable used in this simulation is the drying air inlet temperature (Ta0), which is 160, 180, 200 C.

3.1 Mathematical Model Validation

In this study, validation was carried out by comparing the simulation results with the simulation and experimental results from the Cotabarren experiment and simulation [2]. The validation aims to examine whether the selected mathematical model is suitable for existing experimental data. The system's boundary condition was determined to be the distance traveled by the particles in the chamber starting from the nozzle's tip to the point where the particles leave the chamber (assumed 0 to 0.5 meters). The validation data simulation results with experiment and simulation by Cotabarren [2] consisted of particle moisture content profiles, particle diameter, particle density, and the drying air outlet temperature to the distance traveled by the particles in the chamber were shown in Figure 3.

Figure 3(a) shows that the final value of particle moisture content only reached 0.156, while in the Cotabarren experiment and simulation, both reached 0.03, so the error is 422%. Likewise, in Figure 3(c), the particle density changed very little compared to the reference results, with a final density of 1010.22 kg/m3. In contrast, in the reference, the simulation and

experiment reached 1275 kg/m3 and 1230 kg/m3, so the error is 21.07% and 17.87%. For the final particle diameter, in Figure

3(b), the final result is 3.53 m, exceeding the reference simulation data of 11 m and experimental data of 7 m, so the error of 67.89% and 49.54% is obtained. Figure 3(d) shows that the dying air temperature is close to the reference results, namely 330.55 K in this simulation and 323 K and 318 K for the simulation and experiment results from reference error of 2.33% and 3.94% is obtained.

The trendline simulation results are the same as Cotabarren's simulation results. However, if it is seen from the error percentage, moisture content gives a high deviation, diameter and density results are good enough because the error is not too high, and for drying air temperature, the results are good because the error is deficient. The simulation results also do not show critical points and constant lines on moisture content, diameter, and density. These deviations are probably caused by the difference in the simulation software used. The data from the reference used are the simulation result data that have the most significant error.

ICoSITeR 2020

IOP Publishing

IOP Conf. Series

https://doi.org/XXXX/XXXX

Figure 3. The result of mathematical model validation for (a) particle moisture content, (b) particle diameter, (c)particle

density, and (d) drying air temperature.

3.2 Effect of drying air inlet temperature on particle characteristics

Figure 4(a) shows the effect of drying air inlet temperature on the particle's moisture content. It can be seen that increasing the temperature of drying air can increase the release of moisture from the droplets, resulting in particles with lower moisture content. It happened due to an increase in the driving force from drying at higher temperatures. The first drying stage is shorter at 200C compared to 160 and 180 C. The higher temperature of drying air increases the evaporation rate, thereby accelerating crusts' formation and causing the critical point to be reached faster. However, from the simulation results, the lowest final moisture content only reaches 0.933 at 200 C. It indicates that the moisture content of the final particles is still a lot, even almost half. It might happen because the equilibrium moisture content formula for CIP was used instead of gum arabic.

Figure 4(b) shows the effect of the drying air's inlet temperature on the particle's diameter. It can be seen that increasing the temperature of the drying air results in lower diameter particles. The droplet volume, which initially contains much water, will evaporate, leaving particles with much less water content, so the final particles' volume also shrinks, which is related to the shrinking particle diameter. Furthermore, since the highest temperature resulted in the lowest moisture content, automatically the diameter is also the smallest. However, from the simulation results, it can also be seen that the shrinkage of the particle diameter is not too significant, where the smallest diameter that can be achieved is only up to 29.232 μm at a temperature of 200 C or only 3 μm less than the initial one. It might happen because the critical moisture content achieved is still high so that the shrinkage of the particle size is not significant.

ICoSITeR 2020

IOP Publishing

IOP Conf. Series

https://doi.org/XXXX/XXXX

Figure 4(c) the effect of drying air inlet temperature on the density of the particle. It can that increasing the drying air temperature results in a higher particle density. As the diameter shrinks, the particles' volume also shrinks, or there is volume lost due to evaporation, so their density increases. Compared with theory, this increase in density should only occur at the beginning of evaporation until the moisture content reaches its critical point. After that, although the droplet diameter is constant, the porosity increases, so the density decreases. Nevertheless, from the results, there is no drop in density. It might happen due to the final moisture content, which is still large, causing the particles obtained are still wet, so the porosity does not increase.

Figure 4(d) shows the temperature trend for drying air as well as particles. From the simulation results, it can be seen that the drying air has decreased in temperature, while the particles have increased in temperature. It is caused by the transfer of heat from the drying air to the particles used to evaporate the water. So the output of the drying air and the particles fall at the same temperature.

From the simulation results above, if the graph is zoomed in, it will show that the trend for moisture content and diameter is following the single droplet drying kinetics as shown before, where the shape of the graph is divided into four parts. In the first part, changes are taking place very slowly. The heat from the drying air still heats the particles' surface before starting to evaporate the moisture. There is a drastic change caused by moisture evaporation from the particles' surface in the second part. The first and second parts are called the first drying stage, which occurs when the droplets enter the chamber until they reach their moisture content's critical point. In the third part, critical moisture content has been reached, and a transition has begun to occur towards its equilibrium point, marked by a sloping slope. This section is called the second drying stage. Then in the fourth part, the slope is linear, where the particles do not change anymore.

Figure 4. The effect of drying air inlet temperature on (a) particle moisture content, (b) particle diameter, (c) particle density,

ICoSITeR 2020

IOP Publishing

IOP Conf. Series

https://doi.org/XXXX/XXXX

Conclusion

A simulation of a mathematical model for microencapsulation with spray drying has been made. The simulation has been validated resulted in the particle moisture content with a very high deviation of 422%. The particle diameter and density of simulation results have an acceptable deviation of 49.54% and 17.87%, respectively, from Cotabarren's experimental results. Whereas the air temperature with a very low deviation of 3.95%. By varying the drying air inlet's temperature, higher temperatures produce lower particle moisture content, smaller particle diameter, and higher particle density. Moreover, drying air and particles has the same temperature at the outlet.

Acknowledgments

We would like to thank the Directorate of Research and Community Service, Institut Teknologi Sepuluh Nopember, Ministry of Education and Culture, for funding this research through the Postgraduate Research ITS Grant (Contract Number: 933/PKS/ITS/2020).

References

[1] Bakri A M, Abbas S, Ali B, Majeed H, Abouelwafa M Y, Mousa A, and Liang L 2016 Comprehensive Reviews in Food Science and

Food Safety 15 143

[2] Cotabarren I M, Bertin D, Razuc M, Ramirez-Rigo M V, and Pina J 2018 Chemical Engineering Research and Design 132 1091 [3] Kuriakose R and Anandharakrishnan C 2010 Trends Food Sci Tech 21 383

[4] Mezhericher M, Levy A, and Borde I 2014 Drying Technology: An International Journal 4 [5] Boger B R, Georgetti S R, and Kurozawa L E 2018 Food Sci. Technol. 3

[6] Ranz W E and Marshall W R 1952 Chem. Eng. Prog. 48 141

[7] Negiz A, Lagergen R, and Cinar A 1995 Ind. Eng. Chem. Res. 34 3289

[8] Pinto M A, Kemp I, Bermingham S, Hartwig T, and Bisten A2014 Chem. Eng. Res. Des. 92 619 [9] Welty J R, Wicks C E, Wilson R E, andRorrer G L 2008 Wiley & Sons 572