RICE FLOUR

PRACTICAL TRAINING REPORT

This practical training report is submitted for the partial requirement

for Bachelor Degree

By :

Rr. Panulu Puspita M

12.70.0025

DEPARTMENT OF FOOD TECHNOLOGY

FACULTY OF AGRICULTURAL TECHNOLOGY

SOEGIJAPRANATA CATHOLIC UNIVERSITY

SEMARANG

ii

THE EFFECT OF MILLING METHODS ON THE

PHYSICOCHEMICAL AND PASTING PROPERTIES OF

RICE FLOUR

Practical Training at Assumption University, Bangkok, Thailand

By:

Rr. PANULU PUSPITA MARUTA Student ID : 12.70.0025 Faculty: Agricultural Technology

This Practical training report has been approved and supported by examiner in Practical Training Exam on June 12th 2015

Semarang, June 12th 2015 Department of Food Technology Faculty of Agricultural Technology Soegijapranata Catholic University

Practical Training Advisor I Practical Training Advisor II

Dr. TatsawanTipvarakarnkoon Kartika Puspa Dwiana, STP., Msi.

Dean

iii

iv PREFACE

Praise in the name of Jesus Christ, who has given His blessings and affection to the

author for taking the time to complete this practical training report entitled "The Effect

of Miling Methods on the Physicochemical and Pasting Properties of Rice Flour”. This report is the complete accountability from the practical training conducted in Bangkok ,

Thailand which took place from January 16th to March 26th 2015 and this practical

training report is to equip one of the requirements to gain a bachelor degree from the

Faculty of Agricultural Technology.

In finishing this report, the author really gives regards and thanks for people who has given huge support and guidance and very helpful people around the author so these report could be complete. So, in this occasion author want to say a bunch thankyou for :

1. Almighty God Jesus Christ that already blessed, saved, and guided author in every step of training in Thailand

2. Dr. Tatsawan Tipvarakarnkoon, the advisor, who has given her best guidance for this practical training, from conducting the test until finishing paper.

3. Dr. Churdcai Cheowtirakul, Dean of Faculty of Biotechnology, Assumption University, who has given the opportunity to carry on the practical training in his faculty.

4. Dr. V. Kristina Ananingsih, ST., MSc., Dean of Faculty of Agricultural Technology, Soegijapranata Catholic University, for giving the information and chance to join the practical training abroad.

5. Kartika Puspa Dwiana, S.TP, Msi for helping me and advising me to make this practical training report better.

6. P.Porn and P.Tok as a laboratory assistant in Assumption University, who have helped me.

7. Author’s family, parents and elder brothers for always support me and saying my name in every prayer.

v

9. Pooriwut Maneechoold, Ploypleng, Stuart Chuah Sin Hwang, Thar Win, Tanyanan, Thanawin Pothibanchong and all others friends who I can’t say it one by one that always support me and accompany me.

10. Last but not least, I would like to all people who has directly and indirectly helped during the practical training until finishing the report.

Finally, the author realized that this report is still far from perfect. However, the author hope that this report can be an inspiration and provide knowledgeto all those in need and really allows the reader give suggestion to improve the content in order to make as on of the good examples.

Semarang, May 25th 2015

vi

TABLE OF CONTENT

Page

ENDORSMENT SHEET ... ii

ACKNOWLEDGEMENT ... iii

PREFACE ... iv

TABLE OF CONTENT... vi

LIST OF TABLES... x

LIST OF FIGURES ... xi

1. INTRODUCTION……….. 1

1.1. Background………. .... 1

1.2.Purpose of Practical Training ... 1

1.3.Time and Place of Practical Training ... 2

2. INSTITUTIONAL PROFILE ... 3

2.1.Assumption University 3 2.2.Faculty of Biotechnology 4

2.3.Vision, Mission, and Strategy of the Faculty ... 4

2.3.1. Vision ... 5

2.3.2. Mission ... 5

2.3.3. Strategy ... 5

2.4. Faculty Member ... 6

2.4.1. Administrator 6 2.4.2. Instructors 6 3. RESEARCH PROJECT ... 8

3.1.Research Project ... 8

3.2.Background of Research ... 8

3.2.1.Rice Flour ... 8

3.2.2.Dry and Wet Milling ... 9

vii

3.2.3.3.Acetylated ... 11

4. RESEARCH METHODOLOGY ... 12

4.1. Color Measurement ... 13

4.1.1. Materials and Tools ... 13

4.1.2. Methods ... 13

4.2. Light Microscope ... 13

4.2.1. Material and Tools ... 13

4.2.2. Methods ... 13

4.3. Rapid Visco Analyzer ... 14

4.3.1. Materials and Tools ... 14

4.3.2. Methods ... 14

4.4.Moisture Content ... 14

4.4.1. Materials and tools ... 14

4.4.2. Methods ... 14

4.5. Swelling Power ... 15

4.5.1. Materials and Tools ... 15

4.5.2. Method ... 15

4.6. Amylose Content ... 16

4.6.1. Materials and Tools ... 16

4.6.2. Methods ... 16

5. RESULT AND DISCUSSION ... 17

5.1. Physical Analysis ... 17

5.1.1.Color Analysis... 17

5.1.2.Microscopic Granule Examination Analysis ... 18

5.1.2. RVA Analysis ... 20

5.2. Chemical Analysis ... 22

5.2.1.Moisture Content... 22

viii

5.2.3.Amylose Content... 24

6. CONCLUSION ... 26

7. REFERENCES ... 28

ix

Table 1. Research Project Schedule ... 11

Table 2. Color Measurement Result of Sample ... 17

Table 2.1. Color measurement result of sample type 1... 30

Table 2.2. Color measurement result of sample type 2... .30

Table 3. Data of Rapid Visco Analyzer ... 21

Table 3.1. Data of RVA Rice Flour ... 31

Table 4. Data of Moisture Content Rice Flour ... 23

Tabel 4.1. Data of Moisture Content Rice Flour C,D,E,F ... 33

Table 5. Data of Swellung Power Rice Flour ... 24

Tabel 5.1. Data of Swelling Power Rice Flour C,D,E,F (80 mesh, 100 mesh) ... 36

Table 6. Data of Amylose Rice Flour ... 25

x

LIST OF FIGURES

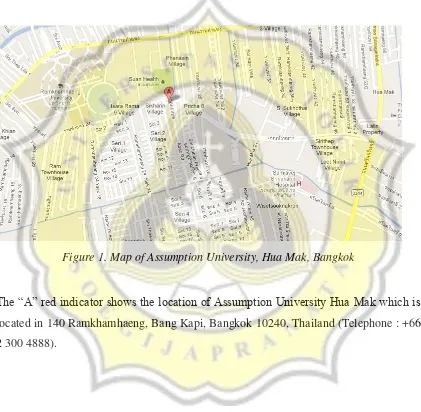

Figure 1. Map of Assumption University, Hua Mak, Bangkok ... 2

Figure 2. Logo of Assumption University of Thailand ... 3

Figure 3. Logo of Biotechnology Faculty ... 4

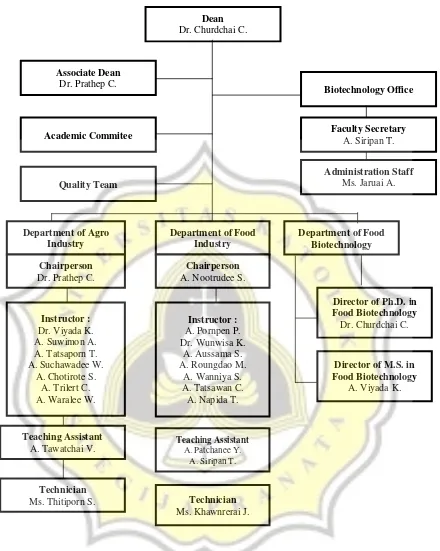

Figure 4. Faculty Member ... 7

Figure 5. Thai Rice Noodle ... 9

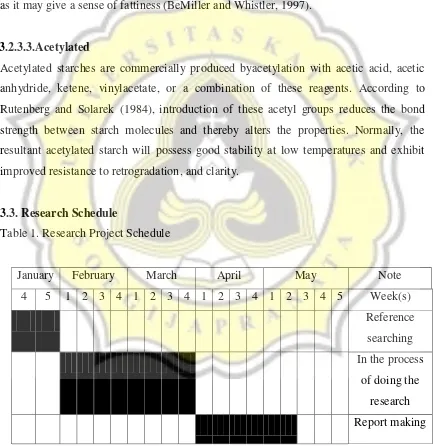

Figure 6. Analysis Method of Thai Rice Noodle... 12

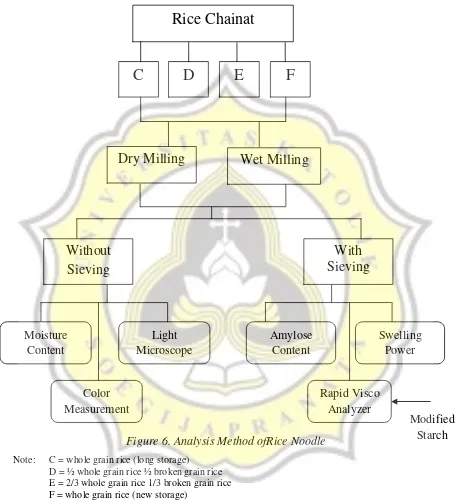

Figure 7. Five different part of the Petridish ... 13

Figure 8. Microscopic Granule Examination Data of Sample Without Iodine ... 18

Figure 9.Microscopic Granule Examination Data of Sample With Iodine ... 19

Figure 10. RVA graph paramater ... 20

Figure 11.RVA graph of Sample rice flour ... 32

Figure 12. RVA graph of Modified Starch ... 32

Figure 13. RVA graph ofF1 80 mesh – Succinic Anhydride ... 32

Figure 14. RVA graph of F1 80 mesh - Octenyl Succinic Acid ... 33

Figure 15. RVA graph of F1 80 mesh – Acetylated ... 33

1

Food is one of the three primary needs of human life. In its role as a primary need, food has a role to supply energy and nutritional value which is human needs to live. Simply said, people can not live withoutfood. Recently, consumer demands of food become higher. People not only expect to have delicious and nutritious food but they also have a great concern on the safety. It means that the challenge of food industries also increase, as they have to fullfill the demand of high quality food; delicious, healthy, and safe.

This fact becomes the main reason to conduct the practical training for students from department of Food Technology, Soegijapranata Catholic University. The students of food technology are obligated to undergo an internship program or practical training in food industry during their study to improve their knowledge about the development and the demand of food products. This program has a purpose to fit up the students with the food-related research or the experience in real world practice of food industry, either in food industries or food technology related institutions for developing skills and experience in order to face the opportunities and challenges in food technology development.

Faculty of Biotechnology, Assumption University, Thailand, is chosen as the practical training workplace because this faculty is advanced in field of biotechnology and microbiology sectors. Those sectors are become the important food sectors recently. Furthermore, with choosing this internship program, it will also give the opportunity for food technology students to do research abroad, and for experiencing cultural diversity as global citizen. This opportunity can be achieved by the food technology students, Soegijapranata Catholic University, because of the internship program between the Soegijapranata Catholic University and Assumption University.

1.2.Purpose of Practical Training

2

b. To give the student an opportunity to adapt with new circumstances and society. c. To broaden the student’s knowledge and experience from the international exposure. d. To make an international network.

1.3.Time and Place of Practical Training

The practical training was conducted in the Faculty of Biotechnology, Assumption University Hua Mak Campus, Bangkok, Thailand, in16th January to 26th March 2014.

Figure 1. Map of Assumption University, Hua Mak, Bangkok

The “A” red indicator shows the location of Assumption University Hua Mak which is

3

Assumption University (AU) is the first International Private Catholic University in Thailand, which was initially originated from Assumption Commercial College in 1969 as an autonomous higher education institution under the name of Assumption School of Business. In May 1975, it was accredited by the Ministry of University Affairs and students could go from ABAC into graduate programs at public and private universities. The university is led by the Brother of St. Gabriel, who have been active in education in Thailand since 1901. Recently, AU has three campuses located in Hua Mak, Central World Plaza in downtown Bangkok and Suvarnabhumi areas of Samut Prakan Province.

Assumption University is noted for attracting large numbers of foreign students from countries including Russia, China, Burma, India, Bangladesh, Pakistan and other Asian countries. Teaching conducted in English has always been ABAC and Assumption’s hallmark, and thus students and professors from over a hundred different countries attend school and work here. Faculty members, like students, are free to maintain their native cultural and religious identity without discrimination or pressure to “convert” to something else. The university prides itself in its openness and welcoming attitude, and its core value of moral integrity and high ethical standards in personal, civic, and business relationships.With strong commitment to education, Assumption University offers high-quality and internationalised education at the undergraduate, post-graduate and doctoral levels and joint programs with many leading universities in academic areas including business, law, engineering, and architecture. Other programs include languages, risk management, nursing, and the arts.

4

2.2.Faculty of Biotechnology

Biotechnology literally means the application of life sciences to industrial processes. Principles of science learned in the classroom and the laboratory may be used by industry to develop and improve products, which can give benefits to the consumer and can provide a healthy profit for the producer. Because biotechnology is closely related to the agricultural sector, it has an impact on the lives of many Thai who are involved in agriculture and related industries. In service industries, biotechnology plays a major role in both aqueous and solid waste treatment, waste valorization and water purification. Because Assumption University is aware of the importance of biotechnology for the development of Thailand and all of Southeast Asia, it offers the

Bachelor’s Degree of Biotechnology courses. And for Faculty of Biotechnology was found on 1993 as the ninth faculty in Assumption University to produce graduates working in biotechnology field and its related fields. The Faculty has been offering two 4-year bachelor's programs in Agro Biotechnology and Food Biotechnology. Both programs were approved of their academic standard by the Ministry of University Affairs in 1997. Since then the Faculty has produced 4 classes of graduate with the degree of BS in Agro-Industry and in Food technology, to the country.

Figure 3. Logo of Biotechnology Faculty

2.3.Vision and Mission, and Strategies of Faculty

In line with the university’s philosophy of education, the Faculty of Biotechnology has

2.3.1.Vision

The application of life sciences to industrial processes yielding products and services that ultimately benefit the consumers through bio-resources and technology.

2.3.2.Mission

1. To provide the nation with highly trained professionals who are able to apply basic and applied scientific principles to continuous improvement of the safety, quality and value of biotechnological services and products.

2. To produce graduates characterized by moral and ethical principles

3. To produce graduates who are competent to pursue advanced studies in fields related to biotechnology.

4. To develop and implement food biotechnologies to ensure the wholesomeness of foods.

2.3.3.Strategy

Thailand is a major producer of agricultural commodities used in bioprocessing and a significant food manufacturing sector. However, the food manufacturing lags behind the international average in the amount of value added in processing so goverment needed to further develop the quality of Thai food and other agricultural products to the make them better known in the international market.

6

2.4. Faculty Member 2.4.1.Administrators

The main administrators of the faculty are in follow:

a. Dr. Churdchai Cheowtirakul: Dean and Director of Ph.D. program in Food Biotechnology.

b. Dr. Prathep Chiaravanond: Associate Dean and Chairperson of Department of Agro Industry.

c. Dr. Viyada Kunatheekarn: Director of MS Program in Food Biotechnology. d. A. Nootrudee Siriboon: Chairperson of Department of Food Technology.

2.4.2.Instructors

In academic year 2005, the Faculty of Biotechnology has 19 full-time instructors, three teaching assistants, one administrative staff and two laboratory technicians. The faculty also invited 14 part-time qualified instructors to teach the students from 1st year to 4th year. Academic ratios of the full-time instructors and part time instructor in 2004 are as follows.

- Full time instructor Ph.D.: MS : BS = 3:13:3 - Part time instructor Ph.D.: MS : BS = 5:8:0

8 3. RESEARCH PROJECT

3.1.Research Overview

The topic of the research was “The Effect of Milling Methods on The Physicochemical and Pasting Properties of Rice Flour”. There was Chainat of rice with 4 different formulas of rice used in this project; (1) rice type C with whole grain rice (long storage), (2) type D with a half whole grain rice and a half broken grain rice, (3) type E with two thirds of sections whole grain rice and one thirds of sections broken grain rice, (4) type F with whole grain rice (new storage). The rice were examined particularly on the differenceof the milling methods; wet milling and dry milling, and with 2 size mesh for each; 80 mesh and 100 mesh. But on this opportunity, rice type F with wet milling treatmentand rice flour type F 100 mesh were unavailable on this project, and the intended used chainat rice because the high amylose content and in Thailand chainat rice is used as traditional Korat noodle, moreover the high farming of chainat rice then it can use to produce commercial of rice noodle. The advisor of this research was Dr.Tatsawan Tipvarakarnkoon. The research objective was to investigate the use of various rice flour sources and effect of milling to the characteristic on the noodle being made, and in order to know the result needed in investigating the rice flour as the main raw material to make the noodle.

3.2.Background of Research 3.2.1.Rice Noodle

Rice is a staple food of over a half in the worlds population, mostly in Asia being widely used in human nutrition as a source of energy due to its high starch level, next to wheat (Frei, Sidhuraju and Becker, 2003). While, the major rice growing countries are Thailand, India, Bangladesh, Burma, Vietnam, Japan and Philippines. They are the biggest rice exporter countries, but in the utilization of rice is narrow compared with others such as wheat in other parts of the world, and this is one of the problems being faced by Thailand and the product develompment technic of rice is needed and rice noodles are one of the solutions in the utilization of rice. Rice noodle is products made

from rice flour and rice flour derived rice grain. Rice noodles have a very smooth

texture, soft mouth feel and are white in colour, it is reported that adequate functional

(Chen et al. 2003; Cui 2005; Purwani et al.2006). Rice has been shown to vary widely

in it is cooking and eating quality, depending on variety and type of rice, amylose

content and gelatinization behaviour (Halick and Kelly 1959, Juliano et al 1965, Perez

and Juliano 1979, Williams et al, 1958). Therefor rice varieties are classified according

to reviews their use, low amylose (9 – 20%) rice are preferred for processing crackers and biscuits, intermediate amylose (20 – 25%) rice is used for making extruded (dried) pasta and high amylose (>25%) rice are favoured for parboiled rice, rice bread and

noodles (Juliano and Perdon, 1975).

Figure 5. Thai Rice Noodle (shesimmers.com/2011/06/pad-thai-rice-noodle)

3.2.2.Dry Milling and Wet Milling

10

However, dry-milled rice flour shows many differences in terms of chemical composition and physicochemical properties compared with the wet-milled rice flour (Chen et al., 1999, Chaing and Yeh, 2002, Yoenyongbuddhagal and Noomhorm, 2002, Suksomboon et al., 2005). The sample used to determine physicochemical properties of the flour is sample C1, C2, D1, D2, E1, E2 and F1. The difference type of type 1 and type 2, sample type 1 with dry milling treatment and 2 with wet milling treatment. Thus sample from dry and wet milling method is being analyzed about the color, light microscopic examination of the granule, RVA analysis, moisture content, swelling power, amylose content. The process of grinding in making rice flour affects the physico-chemical characteristics by changing the particle size and creating differences in particle size distribution pattern (Nishita and Bean, 1982), and the milling yield the most important criteria to control the quality of rice flour-based products, and the milling yield depend of types and degree of milling (Kang et al. 2003).

3.2.3.Modified Starch

Modified starches are common ingredients in food and industrial products. Modification does not alter the appearance of the starch but can improve the desired properties of the starch. The purposes of this modification are to enhance its properties particularly in specific applications such as to improve the increase in water holding capacity, heat resistant behavior, reinforce its binding, minimized syneresis of starch and improved thickening (Adzahan, 2002; Miyazaki et al., 2006). On this research, the modified starch that used are Succinic Anhydride (SA), Octenyl Succinic Acid (OSA) and Acetylated (AC).

3.2.3.1.Succinic Anhydride

Succinic anhydride, also called dihydro-2,5-furandione, is an organic compound with the molecular formula C4H4O3. This colorless solid is the acid anhydride of succinic

3.2.3.2.Octenyl Succinic Acid

A common modification of starch is esterfication with anhydrous octenyl succinic acid (OSA). The properties of the OSA starch make it interesting for used in egg yolk protein stabilized food emulsions, such as mayonnaise. The interactions between different components in a product have a great impact on factors such as texture and stability (De Kruif and Turnier, 2001). OSA can increased viscosity and decreased gelatinization temperature (Bao et al, 2003). OSA starch may give heat- (He et al, 2008) and freeze-thaw stability (Song et al, 2006), and may also be used as a partial replacement for fat, as it may give a sense of fattiness (BeMiller and Whistler, 1997).

3.2.3.3.Acetylated

Acetylated starches are commercially produced byacetylation with acetic acid, acetic anhydride, ketene, vinylacetate, or a combination of these reagents. According to Rutenberg and Solarek (1984), introduction of these acetyl groups reduces the bond strength between starch molecules and thereby alters the properties. Normally, the resultant acetylated starch will possess good stability at low temperatures and exhibit improved resistance to retrogradation, and clarity.

3.3.Research Schedule

Table 1. Research Project Schedule

January February March April May Note

4 5 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 5 Week(s) Reference

searching In the process

12 4. RESEARCH METODOLOGY

Steps to get rice flour, treatment that used, and analysis conducted in the research can be seen in figure 6 .

Figure 6. Analysis Method ofRice Noodle

Note: C = whole grain rice (long storage) D = ½ whole grain rice ½ broken grain rice E = 2/3 whole grain rice 1/3 broken grain rice F = whole grain rice (new storage)

Modified Starch, Succinate Anhydride Modified Starch,Octenyl Succinic Anhydride Modified Starch.

4.1.Color Measurement (Rachel Thomas, 2014) 4.1.1.Materials and Tools

Rice flour, Colorimeter, petridish 25 g.

4.1.2.Methods

First the tools were being set and the USB was plugged into the laptop. Then the sample were prepared, as 1 cup of the sample (rice flour) 25 gram was placed into the petridish, then the petridish was placed into the colorimeter. The colorimeter was standardized at room temperature, D65 light source, then the test was done through the colorimeter software for 5 times in 5 different points (parts) of the petridish (middle, top, left, bottom, right).

Figure 7. Five different part of the Petridish.

4.2.Light Microscope Examination of Granule (Kasetsart,2006) 4.2.1.Materials and tools

Glass slide, cover slide, pipette, microscope, micrometer eye piece (Dino capture version 2.0), dino capture software, stirring stick, distilled water, iodine, rice flour.

4.2.2.Methods

14

pictures each sample) were taken using Dino Capture Software, approximately 10 granules were selected randomly. These step were repeated but without iodine.

4.3.Rapid Visco Analyser (Brabender RVA) 4.3.1.Materials and Tools

RVA machine, digital scale, distilled water, rice flour, and modified starch.

4.3.2.Methods

First switch on the RVA machine, and allow 30 minutes warm up. Switch on associated computer, run the RVA control software. Measure distilled water + 25 gram and sample +3 gram, its depend on the moisture content of sample. Place a paddle into the canister and vigorously jog the blade through the sample up and down 10 minutes. If any lumps remain on the water surface or adhere to the paddle then repeat the jogging action. Place the paddle into the canister and insert the canister into the insturment. Initiate the measurent cycle by depressing the motor tower of the instrument. Remove canister and completion of test and discard. From the pasting curve, the pasting temperature, peak viscosity, time to peak, breakdown, minimum viscosity, setback and final viscosity.

4.4.Moisture Content (Mccabe and Smith, 1993) 4.4.1.Material and Tools

Aluminium can, oven, desiccator, electric scale, rice flour.

4.4.2.Methods

First, the empty alumium can and the lid were dried in the oven at 105℃ for 1 hours and transferred to the desicator for 15 minutes to cool. The dried alumium can and lid then weighed. After that about 3 grams of sample (4 digits) was weighed to the alumium can the put in the oven for 3 hours at 105℃. After drying, the alumium can with partially covered lid was transferred to the desiccators for 15 minutes to cool. Then the dish was reweighed again. To measure the moisture (%) we use the formula:

%Moisture content = (𝑊𝑡.𝑜𝑓𝑓𝑙𝑜𝑢𝑟𝑏𝑒𝑓𝑜𝑟𝑒𝑑𝑟𝑦𝑖𝑛𝑔 − 𝑊𝑡.𝑜𝑓𝑓𝑙𝑜𝑢𝑟𝑎𝑓𝑡𝑒𝑟𝑑𝑟𝑦𝑖𝑛𝑔)

𝑊𝑡.𝑜𝑓𝑓𝑙𝑜𝑢𝑟𝑏𝑒𝑓𝑜𝑟𝑒𝑑𝑟𝑦𝑖𝑛𝑔 𝑥 100

4.5.Swelling Power (Jangchud K, 2004) 4.5.1.Material and Tools

Aluminium can, centrifuge tube, water bath, oven, electric scale, distilled water, rice flour.

4.5.2.Methods

First, the empty alumium can and the lid were dried in the oven at 105℃ for 1 hours and transferred to the desicator for 15 minutes to cool. The dried alumium can and lid then weighed. After that about 0,5 grams of sample (4 digits) was weighed to centrifuge tube, add 15 ml distilled water and heat in water bath at 80oC for 30 minutes. After heating, keep the centrifuge tube for 15 minutes to cool and centrifuged at 4000 rpm for 20 minutes. Then pour the supernatan into aluminium can and dried in the oven for 3 hours at 105℃, and for the sediment in the centrifuged tube was weighed. After drying, the alumium can with partially covered lid was transferred to the desiccators for 15 minutes to cool. Then the dish was reweighed again.To measure the swelling power (%) we use the formula:

Swelling Power = 𝑤𝑒𝑖𝑔𝑡𝑜𝑓𝑠𝑒𝑑𝑖𝑚𝑒𝑛𝑡

𝑤𝑒𝑖𝑔𝑡𝑜𝑓𝑓𝑙𝑜𝑢𝑟 − 𝑤𝑒𝑖𝑔𝑡𝑜𝑓𝑑𝑟𝑖𝑒𝑑𝑠𝑜𝑙𝑖𝑑𝑠𝑖𝑛𝑠𝑢𝑝𝑒𝑟𝑛𝑎𝑡𝑎𝑛𝑡

4.6.Amylose Content (Juliano, 1990-modified) 4.6.1.Material and Tools

Volumetric flask, aluminium foil, pilleus pump, spectrophotometer (620nm), NaOH 1N, 95% etanol, distilled water, acetic acid 1N, iodine, rice flour.

4.6.2.Methods

16

17 5.1.1.Color Analysis

The superficial appearance and color of food are the first parameters of quality

evaluated by consumers, and are thus critical factors for acceptance of the food item by the consumer. Although there are different color spaces, the most used of these in the measuring of color in food is the L*, a*, b* color space due to the uniform distribution of colors, and because it is very close to human perception of color. Sample that used are rice flour type C, D, E with dry-wet milling treatment no sieve and F with dry milling treatment no sieve because to measure color of sample, particle size did not affect the result of color analysis. Brightness very important for rice flour, because brigthness is one of the aspects which determine the quality of rice flour, and Nishita& Bean (1982) said that the finest flour would be brighter and whiter.

Table 2. Color measurement result of sample

Type Dry Milling Wet Milling

C L: 63,488

This result was the average of total 35 data each sample. See Table 2.1. – 2.2. (Attached) Note: C = whole grain rice (long storage)

D = ½ whole grain rice ½ broken grain rice E = 2/3 whole grain rice 1/3 broken grain rice F = whole grain rice (new storage)

18

more refined. It can be seen from the table that the value of L* for rice flour with treatment wet milling more higher than rice flour with dry milling.

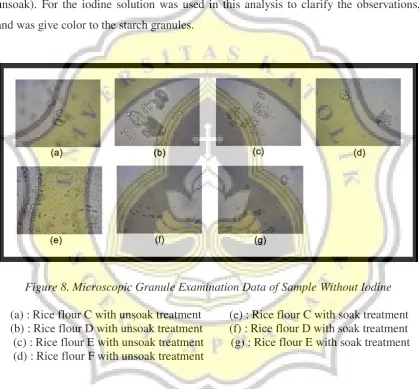

5.1.2.Microscopic Granule Examination Analysis

Lens that used in microscopic analysis is 40x objective lens, while sample that used are rice flour type C, D, E with dry-wet milling treatment and F with dry milling treatment no sieve, because this analysis to compare the treatment effect of rice flour (soak and unsoak). For the iodine solution was used in this analysis to clarify the observations, and was give color to the starch granules.

Figure 8. Microscopic Granule Examination Data of Sample Without Iodine

(a) : Rice flour C with unsoak treatment (e) : Rice flour C with soak treatment (b) : Rice flour D with unsoak treatment (f) : Rice flour D with soak treatment (c) : Rice flour E with unsoak treatment (g) : Rice flour E with soak treatment (d) : Rice flour F with unsoak treatment

Figure 9. Microscopic Granule Examination Data of Sample With Iodine

(a) : Rice flour C with unsoak treatment (e) : Rice flour C with soak treatment (b) : Rice flour D with unsoak treatment (f) : Rice flour D with soak treatment (c) : Rice flour E with unsoak treatment (g) : Rice flour E with soak treatment (d) : Rice flour F with unsoak treatment

From figure 9, obtained data of microscopic of rice flour with treatment wet milling and dry milling with iodine solution. The addition of iodine can resulted in bluish discoloration after added a solution of iodine, it does showed that rice flour contain amylose while rice flour with amylocpectin will give brownish (Zulaidah, 2011).

20

5.1.3.RVA Analysis

Rapid Visco-Analyzer (RVA) was used to determine the pasting behavior of the starch extracted and flour from rice flour. Parameters recorded were pasting temperature, peak viscosity, hot paste viscosity (minimum viscosity at 95 °C), cool paste viscosity (final viscosity at 50 °C), breakdown viscosity. The pasting behaviour and visco-elastic properties of the rice floursare mainly determined by the differences in the amylose content. The pasting propertiesare also influenced by granule size, starch molecule characteristic and the thermalprocess involved in gelatinization of the starch (Lai 2001). Sample that used are rice flour type C, D, E with dry-wet milling treatment (80 mesh and 100 mesh) and F with dry milling treatment (80 mesh), and this analysis used 3 types modified starch (AC, SA, and OSA).

Figure 10. RVA graph parameter

Table 3. Data of Rapid Visco Analyzer

Sample Peak 1 Trough 1 Breakdown Final Viscosity Setback Peak Time Pasting Temp

C1 80 mesh 1972,33 1662 310,333 3473,333333 1811,33 5,6 86,65

D1 80 mesh 1906,67 1650,67 256 3506 1855,33 5,64444 87,73333333

E1 80 mesh 1990,67 1557,67 433 3492,666667 1935 5,57778 86,31666667

F1 80 mesh 576,333 550 26,3333 862,6666667 312,667 7 92,36666667

F1 100 mesh 709,667 697,333 12,3333 1107 409,667 6,11111 89,98333333

AC 2612,33 1017,33 1595 1505 487,667 4,06667 72,03333333

SA 6001,67 5087,33 914,333 6263,666667 1176,33 4,33333 71,73333333

OSA 7492,67 3465,67 4027 4452 986,333 4,17778 69,26666667

F1-80-AC 5% 618,333 601 17,3333 881,3333333 280,333 6,31111 93,16666667

F1-80-AC 10% 700,667 656,667 44 957 300,333 6,31111 94

F1-80-AC 15% 759,667 704,667 55 976 271,333 6,44444 94,6

F1-80-OSA 5% 837,667 795,667 42 1272,333333 476,667 6,93333 92,05

F1-80-OSA 10% 1116,33 1027,33 89 1709 681,667 6,95556 89,1

F1-80-OSA 15% 1450 1390,33 59,6667 2156,333333 766 6,75556 80,88333333

F1-80-SA 5% 740,333 700,667 39,6667 1305 604,333 7 91,06666667

F1-80-SA 10% 1007 944 63 1938,333333 994,333 7 88,05

F1-80-SA 15% 1206,67 1141,33 65,3333 2512 1370,67 7 81,41666667

This result was the average of total 35 data each sample. See Table 3.1. (Attached)

Note: C = whole grain rice (long storage) AC = Acetylated Modified Starch

22

From the table 3, obtained significant value and for the final viscosity of the modified starch obtained results with the highest value is Succinate Anhydride Modified Starch than Acetylated and Octenyl Succinic Anhydride Modified Starch while the highest final viscosity value for rice flour is rice flour type D1 80 mesh, and for rice flour mixed with modified starch data was showed that the more modified starch is added will produce the final viscosity increasing. From data of RVA anaylsis, was showed that the addition of modified starch will has an impact on the characteristics of rice flour and succinate anhydride modified starch has the highest final viscosity value, low peak time value, medium breakdown value, and high setback value while acetylated modified starch has the lowest value for final viscosity,setback, high breakdown and medium peak time. The low setback value make acetylated as the best modified starch although the final viscosity value is low, because setback indicates the quality of the noodle. The higher setback value, tend to prone syneresis (Budijanto 2012, Newport Scientific 1998). While the low viscosity value indicates that a high amylose content in flour, but high viscosity value indicated that a high amylopectin content in flour (Sang et al.,

2008). For the high breakdown value indicates that the flour is not resistant to heat, and

peak time value indicated the time it takes flour to increasing the viscosity. Amylose will inhibited starch granules development by forming a complex fat, which resulted in the low peak viscosity at high pasting temperatures. Asides of high amylose content in flour is due to the low water binding capability which is characterized by low power

swelling, that affect the value of the viscosity and peak time were low. From the results

of RVA analysis showed that the addition of modified starch, especially acetylated will

give higher viscosity value compared with rice flour sample (F type) and is not followed

5.2.Chemical Analysis

5.2.1.Moisture Content Analysis

The water content or moisture of the flours is very important not only for their shelf life but also for determining the solid content. Water controls important rheological characteristics such as hardness, cohesiveness and adhesiveness, which are of considerable importance in masa processing, as it influences the quality of the final product (Quintanar-Guzm´an et al., 2009). Flour that have moisture content 12% or below is the most needed because moisture values over 15% restrict the shelf life. As what Prasad, et al., (2012) said that the method used in making rice flour greatly affect the final result, such as heating the starch in the oven overnight would reduce the moisture content in the starch then got a smaller data every time kept the rice flour on the oven. It had been studied about the sorption characteristics of rice flour in a temperature range of 10 to 40°C, in a water activity range excluded elevated water activities. Sample that used are rice flour type C, D, E with dry-wet milling treatment and F with dry milling treatment no sieve, because this analysis to compare the treatment effect (soak and unsoak) against moisture content of rice flour.

Table 4. Data of Moisture Content Rice flour

Treatment Flour Type % Moisture

Dry Milling C 10,58

This result was the average of total 6 data each sample. See Table 4.1. (Attached) Note: C = whole grain rice (long storage)

D = ½ whole grain rice ½ broken grain rice E = 2/3 whole grain rice 1/3 broken grain rice F = whole grain rice (new storage)

24

weighting the rice flour the sample is stayed open on the environment and it may cause the rice flour absorb the moisture in the environment.

5.2.2.Swelling Power Analysis

Swelling power is a measure of the hydration capacity of starch and is expressed as the weight of centrifuged swollen granules, divided by the weight of the original dry starch used to make the paste. The swelling power test is one test very simple as anindicator of noodle quality. Sample that used are rice flour type C, D, E with dry-wet milling treatment (80 mesh and 100 mesh) and F with dry milling treatment (80 mesh).

Table 5. Data of Swelling Power Rice flour

Size Mesh Type Dry Milling Wet Milling

This result was the average of total 6 data each sample. See Table 5.1. (Attached) Note: C = whole grain rice (long storage)

D = ½ whole grain rice ½ broken grain rice E = 2/3 whole grain rice 1/3 broken grain rice F = whole grain rice (new storage)

contains broken grain rice that has the ability to absorb water faster than whole grains rice. As for rice type C has a high value because rice type C has a longer shelf life in comparison with other types of rice so that the rice has a great ability to absorb water as well (Saleh, 2006).

5.2.3.Amylose Content Analysis

Amylose content greatly influences the chacteristics of rice-based food,and high amylose of rice flour its good gel forming property that is suitable for rice noodle making. (Suwannaporn et al., 2007), and from low amylose rice has no potential for making usable rice noodles (Jayakody and Hoover, 2008; Jobling, 2004). Sample that used are rice flour type C, D, E with dry-wet milling treatment (80 mesh and 100 mesh) and F with dry milling treatment (80 mesh). The equation from amylose standart curve is y = 4,209x - 0.065, then can be used to calculate the amylose content contained in rice flour.

Table 6. Data of % Amylose Rice flour

Size Mesh Type Dry Milling Wet Milling

This result was the average of total 6 data each sample. See Table 6.1. (Attached) Note: C = whole grain rice (long storage)

D = ½ whole grain rice ½ broken grain rice E = 2/3 whole grain rice 1/3 broken grain rice F = whole grain rice (new storage)

26

content. The result show that 80 mesh have a higher amylose content than 100 mesh, and rice flour with dry milling treatment have a higher value than rice flour with wet milling treatment it because amylose soluble in water, water will bind amylose and take it out of rice. As known that milling will damage the physic of rice by changing the particle size, and by sieving process will cause some components will be retained in accordance with the size of the mesh, such as amylose and amylopectin. Amylose have

a particle size greater than amylopectin which will produce rice flour with a size of 80

27

28 7. REFERENCES

Adzahan, N. M. (2002). Modification on wheat, sago and tapioca starches by irradiation and its effect on the physical properties of fish cracker (keropok). Food Technology. Selangor, University of Putra Malaysia. Master of Science: 222

Bao: J.; Xing; J : Philips ; D.L and Corke, H., Physical Properties of Octenyl Succinic Anhydride Modified Rice, Wheat and Potato Starches, Journal of Agriculture and Food Chemistry 51

Chen Schols, Z.H.A., & Voragen, A.G.J.(2003). Starch Granule Size Strongly Determines Starch Noodle Processing and Noodle Quality. Journal of Food Science, 68 (5), 1584-1589.

Chen, J.J., S. Lu and C.Y. Lii.(1999). Effects of milling on the physicochemical characteristics of waxy rice in Taiwan. Cereal Chem. 76: 796-799.

Chiang, P.Y. and A.I. Yeh.(2002). Effect of soaking on wet-milling of rice. J. Cereal Sci. 35:85- 94.

Cui,S. W. 2005. Food Carbohidrates Chemistry, Physycal Properties, and Aplication. CRC Press, Boca Raton, London, New York, Singapore

De Kruif, C.G and Tuinier, R. Polysaccharide Protein Interactions, Food Hydrocolloids 15 (2001) 555-563

Epriliati, I., (2002), Isolasi dan Karakterisasi Sifat Fisik, Kimia, dan Fungsional Pati Gayam (Inocarpus edulis Forst.), Tesis, Program Pascasarjana Institut Pertanian Bogor, Bogor, Indonesia.

Frei, M., Siddhuraju, P. And Becker, K. (2003). Studies on The In Vitro Starch Digestibility and The Glycemic Index of Six Different Indigenous Rice Cultivars From The Phillippines. Food Chemistry 83 : 395-402.

Halick, J.V and Kelly, V.J.(1959). Gelatinization and Pasting Characteristic of Rice Varieties as Related to Cooking Behavior. Cereal Chem 36 : 91.

Heacock, P.M.; Hertzler, S.R. and Wolf, B., The Glycemic, Insulemic, and Breath Hydrogen Responses in Humans to a Food Starch Esterfied by 1-octenyl succinic anhydride, Nutrition Research 24 (2004) 581-592.

Jangchud K, Boonthrapong M and Prinyawiwatkul W. Kasetsart Journal (2004); 38:247 – 254

Juliano, B.O. dan P.A. Hicks. (1990). Utilization of rice functional properties to

produce rice food products with modern processing technologies. International Rice Commission Newsletter. 39: 163-178.

J.W. BeMiller and W.Lafayette, “Starch Modification:Challenges and Prospects,”

Starch, vol.49, no.4, pp 127-131,(1997).

Kasetsart. J (2006). Effect of Dry-Wet Milling Processes on Chemical, Physicochemical Properties and Starch Molecular Structures of Rice Starches. 40 (suppl) : 125 – 134.

Kang, H.J., Hwang, I.K., Kim, K.S. and Choi, H.C. (2003). Comparative structure andphysicochemical properties of Ilpumbyeo, a high-quality japonica rice, and its mutant, Suweon 464. J. Agric. Food. Chem. 51(22): 6598 – 6603.

Lai, H.M. (2001). Effects of Hydrothermal Treatment on The Physicochemical Properties of Pregelatinized Rice Flour. Food Chemistry 72 : 455-463.

Marshall, W.E. (1992). Effect of Degreeof Milling of Brown Rice and Particle Size Milled Rice on Starch Gelatinization. Cereal Chemistry 69 (6): 632-636.

McCabe, W.L., Smith, J.C and P. Harriott.(1993). Unit Operations of Chemical Engineering, 5th Ed. McGraw-Hill International Editions, Singapore. 1130 p.

Miyazaki, M. R., Hung, P. V., Maeda, T., & Morita, N. (2006). Recent advances in application of modified starches for breadmaking. Trends in Food Science & Technology, 17(2006): 591-599.

Morrison, W. R., Tester, R. F., Snape, C. N., Law, R., and Gidley, M. J. (1993). Swelling and gelatinization of cereal starches. IV. Some effects of lipid-complexed amylose and free amylose in waxy and normal barley starches. Cereal Chem. 70:385-391.

M. W, Rutenberg and D.Solajek., “Starch derivatives :production and uses,” in starch :

Chemistry and Technology Vol.1. London “ :Academic Press, (1984), pp : 312 - 388

Newport Scientific. (1998). Operation Manual for The Series 4 Rapid Visco Analyzer.Newport Scientific Pty, Ltd. Australia.

Nishita, K.D. and Bean M.M. (1982). Grinding methods: Their impact on rice flour properties. Cereal Chemistry 59(1): 46 – 49.

Perdon, A.A., and Juliano, B.O (1975). Amylose Content of Rice and Quality of Fermented Cake. Staerke 27:196

30 Characteristics of Pusa 1121 Rice Flour. J. Trop. Agric. and Fd. Sc. 40(2)(2012): 193– 201

Quintanar-Guzm´an, A., Jaramillo-Flores, M.E., Mora-Escobedo, R., Chel-Guerrero, L. And Solorza-Feria, J. (2009). Changes on the structure, consistency, physicochemical and viscolastic properties of corn (Zea mays sp.) under di_erent nixtamalization conditions. Carbohydrate Polymers 78, 908-916.

Rachel Thomas, et al.(2014). Quality Evaluation of Flat Rice Noodle (Kway Teow) Prepared From Bario and Basmati Rice. Sains Malaysiana. 43(3) (2014) : 339-347. Sang Y, Bean S, Seib PA, Pedersen J, and Shi YC. 2008. Structure and functional properties of sorghum starches differing in amylase content. J. Agric. Food Chem. 56: 6680-6685

Saleh, M.I. (2006). On the role of rice constituents toward cooked rice texture and rice flour pasting properties. PhD dissertation. University of Arkansas.

Slamet Budijanto, Yuliyanti (2012). Study of Preparation Sorghum Flour

and Application for Analogues Rice Production. Department of Food Science and Technology - Faculty of Agriculture - Agricultural Institute of Bogor

. Vol. 13 No. 3 [December 2012] 177-186

Suksomboon, A., O. Naivikul and B.R.Hamaker.(2005). Comparison of chemical, physicochemical properties and starch molecular structures in dry- and wet-milled rice flours, pp. 247-252. In Proceeding ofStarch Updated 2005 The 3rd Conferenceon Starch Technology, National Center of Genertic Engineer and Biotechnology, Bangkok, Thailand.

Suksomboon, A. and Naivikul,O. (2006). Effect of Dry- and Wet-Milling Processes on Chemical, Physicochemical Properties and Starch Molecular Structures of Rice Starches. 125 - 134 (2006).

Tester, R.F. and Morrison, W.R. (1990). Swelling and gelatinization of cereal starches I. Effects of amylopectin, amylase and lipids. Cereal Chemistry, 67:551-557.

Wang, L., and Seib, P. A. (1996). Australian salt-noodle flours and their starches compared to U.S. wheat flours and their starches. Cereal Chem. 73:167-175.

Williams, V.R. WU, W-T, Tsai. H. Y. And Bates, H.G (1958). Varietal Differences in Amylose Content of Rice Starch. J. Agric. Food Chem 6:47

Yoenyongbuddhagal, S., &A. Noomhorm. (2002). Effect of physicochemical properties of high amylose Thai rice flours. Cer. Chem., 79(4): 481–485.

32 8. APPENDICES

8.1.Color measurement

Table 2.1. Color measurement result of sample type 1

Code L a* b*

Table 2.2. Color measurement result of sample type 2

8.2.RVA Data

Tabel 3.1. Data of RVA Rice Flour

RVA

Raw data : C, E, F (80 mesh, 100 mesh), Modified Starch (OSA, SA, AC) Date: 16-Februari-2015

objective :

Sample Peak 1 Trough 1 Breakdown Final

Viscositas

Setback Peak Time Pasting

Temperature

C1 80 mesh 57,01169 59,92495 11,01514 55,94938189 6,806859 0,06667 0,086602540

E1 80 mesh 54,04936 33,56089 20,80865 83,34466590 49,78956 0,03849 0,448144322

F1 80 mesh 5,859465 7,211103 1,527525 6,429100507 1,154701 0 0,028867513

F1 100 mesh 4,618802 6,110101 2,309410 4,582575695 9,291573 0,10184 0,028867513

AC 36,47373 4,509250 39,88734 17,52141547 22,03028 0,06667 0,875119040

SA 31,21431 86,00194 58,04596 128,5081061 125,5959 0 0,505799697

OSA 141,1536 52,15681 132,6612 95,77055915 43,75310 0,10184 0,448144322

F1-AC 5% 9,504385 11,00000 1,527250 15,04437880 7,094599 0,13878 0,901849951

F1-AC 10% 17,67295 15,04428 2,645751 25,35744467 11,06044 0,07698 0

F1-AC 15% 32,65476 29,28026 3,605551 49,38623290 31,01250 0,15396 0,589491306

F1-SA 5% 8,386497 11,23981 3,785939 35,67912555 24,44040 0 0,505799697

F1-SA 10% 42,29657 50,26927 8,888194 85,50048733 35,34591 0 0,909670270

F1-OSA 5% 19,34770 14,29452 13,22876 17,89785834 16,50253 0,06667 0,433012702

F1-OSA 10% 6,027714 27,97022 33,04542 28,58321186 12,50333 0,03849 1,385640646

34

Figure 11. RVA graph of sample rice flour

Figure 12. RVA graph of Modified Starch

Figure 14. RVA graph of F1 80 mesh – OSA

36

8.3.Moisture Content

Tabel 4.1. Data of Moisture Content Rice Flour C,D,E,F

% Moisture Content

Date: 8-Februari-2015

Data of D1

Aluminum can Aluminium can weight

Sample weight Weight after oven

Aluminium can Aluminium can weight

Sample weight Weight after oven

Aluminium can Aluminium can weight

38

Data of E2

Aluminium can Aluminium can weight

Sample weight Weight after oven

Sample weight after oven

Moisture loss %Moisture Content

1 15,8915 3,0001 18,6812 2,6611 0,3390 11,300

2 16,3937 3,0001 19,1967 2,6583 0,3418 22,393

3 17,0809 3,0005 19,8672 2,6578 0,3427 11,421

4 16,7321 3,0001 19,5312 2,6586 0,3415 11,383

Average 11,374

Data of F1

Aluminium can Aluminium can weight

Sample weight Weight after oven

Sample weight after oven

Moisture loss %Moisture Content

1 17,1963 3,0173 19,9329 2,7366 0,2807 9,303

2 15,9185 3,0005 18,6455 2,7270 0,2735 9,115

3 16,7778 3,0068 19,5175 2,7397 0,2671 8,883

4 16,3693 3,0105 19,0906 2,7213 0,2892 9,606

8.4.Swelling Power Data

Tabel 5.1. Data of Swelling Power Rice Flour C,D,E,F (80 mesh, 100 mesh)

% Swelling Power

Date : 18-Februari-2015

objective : to measure percent of swelling power in rice flour Data of C1-80 mesh

Sample Centrifuge Tube Aluminium Can Sample Weight Sediment Weight Dried Solid in Supernatant

40

Data of D1-80 mesh

Sample Centrifuge Tube Aluminium Can Sample Weight Sediment Weight Dried Solid in Supernatant

Sample Centrifuge Tube Aluminium Can Sample Weight Sediment Weight Dried Solid in Supernatant

Data of E2-80 mesh

Sample Centrifuge Tube Aluminium Can Sample Weight Sediment Weight Dried Solid in Supernatant

Sample Centrifuge Tube Aluminium Can Sample Weight Sediment Weight Dried Solid in Supernatant

42

Data of D1-100 mesh

Sample Centrifuge Tube Aluminium Can Sample Weight Sediment Weight Dried Solid in Supernatant

Sample Centrifuge Tube Aluminium Can Sample Weight Sediment Weight Dried Solid in Supernatant

8.5.Amylose Data

Tabel 6.1. Data of Amylose Rice Flour C,D,E,F (80 mesh, 100 mesh)

% Amylose

Date: 24-Februari-2015

objective : to measure percent of amylose in rice flour Data of C1 80 mesh

Sample Sample weight (gr) Absorbance 1 Absorbance 2 Sample 1 (mg/L) Sample 2 (mg/L) % Amylose

1 0,5001 1,435 1,645 17,9339 20,5583 19,2461

2 0,5003 1,647 1,439 20,5751 17,9767 19,2759

3 0,5000 1,638 1,567 20,4750 19,5875 20,0312

4 0,5003 1,378 1,451 17,2146 18,1266 17,6706

Average Data of C2 80 mesh

Sample Sample weight (gr) Absorbance 1 Absorbance 2 Sample 1 (mg/L) Sample 2 (mg/L) % Amylose

1 0,5001 1,272 1,317 15,8968 16,4592 16,1780

2 0,5001 1,004 1,069 12,5474 13,3598 12,9536

3 0,5001 1,348 1,253 16,8466 15,6593 16,2529

4 0,5003 1,161 1,140 14,5037 14,2414 14,3726

44

Data of D1 80 mesh

Sample Sample weight (gr) Absorbance 1 Absorbance 2 Sample 1 (mg/L) Sample 2 (mg/L) % Amylose

1 0,5008 1,766 1,788 22,0397 22,3142 22,1770

2 0,5002 1,769 1,798 22,1036 22,4660 22,2848

3 0,5004 1,794 1,964 22,4070 24,5303 23,4687

4 0,5000 1,123 1,121 14,0375 14,0125 14,0250

Average 20,4888 Data of D2 80 mesh

Sample Sample weight (gr) Absorbance 1 Absorbance 2 Sample 1 (mg/L) Sample 2 (mg/L) % Amylose

1 0,5000 1,550 1,556 19,3750 19,4500 19,4125

2 0,5000 0,878 1,073 10,9750 13,4125 12,1937

3 0,5003 1,450 1,437 18,1141 17,9517 18,0329

4 0,5001 1,408 1,452 17,5964 18,1463 17,8714

Average 16,8776 Data of E1 80 mesh

Sample Sample weight (gr) Absorbance 1 Absorbance 2 Sample 1 (mg/L) Sample 2 (mg/L) % Amylose

1 0,5002 1,747 1,777 21,8287 22,2036 22,0161

2 0,5006 1,347 1,315 16,8173 16,4177 16,6175

3 0,5005 1,728 1,656 21,5784 20,6793 21,1288

4 0,5008 1,4800 1,406 18,4704 17,5469 18,0086

Data of E2 80 mesh

Sample Sample weight (gr) Absorbance 1 Absorbance 2 Sample 1 (mg/L) Sample 2 (mg/L) % Amylose

1 0,5003 1,713 1,653 21,3996 20,6501 21,0248

2 0,5004 1,532 1,522 19,1346 19,0097 19,0722

3 0,5003 1,124 1,125 14,0415 14,0540 14,0478

4 0,5001 1,378 1,376 17,2215 17,1965 17,2090

Average 17,8385 Data of F1 80 mesh

Sample Sample weight (gr) Absorbance 1 Absorbance 2 Sample 1 (mg/L) Sample 2 (mg/L) % Amylose

1 0,5003 1,382 1,473 17,2646 18,4014 17,8330

2 0,5004 1,811 1,793 22,6194 22,3945 22,5069

3 0,5002 1,383 1,403 17,2805 17,5304 17,4055

4 0,5008 1,957 1,974 24,4234 24,6455 24,5295

Average 20,5687

Data of C1 100 mesh

Sample Sample weight (gr) Absorbance 1 Absorbance 2 Sample 1 (mg/L) Sample 2 (mg/L) % Amylose

1 0,5005 0,939 0,863 11,7257 10,7767 11,2512

2 0,5005 0,931 0,980 11,6258 12,2377 11,9318

3 0,5008 1,283 1,280 16,0118 15,9744 15,9931

4 0,5007 1,500 1,382 18,7237 17,2508 17,9873

46

Data of D1 100 mesh

Sample Sample weight (gr) Absorbance 1 Absorbance 2 Sample 1 (mg/L) Sample 2 (mg/L) % Amylose

1 0,5001 1,386 1,317 17,3215 16,4592 16,8903

2 0,5005 1,022 0,918 12,7622 11,4635 12,1128

3 0,5004 1,227 1,067 15,3252 13,3268 14,3260

4 0,5008 1,288 1,351 16,0742 16,8605 16,4674

Average 14,9491

Data of E1 100 mesh

Sample Sample weight (gr) Absorbance 1 Absorbance 2 Sample 1 (mg/L) Sample 2 (mg/L) % Amylose

1 0,5005 0,918 0,840 11,4635 10,4895 10,9765

2 0,5002 0,855 0,783 10,6832 9,7835 10,2334

3 0,5005 1,105 1,141 13,7987 14,2482 14,0234

4 0,5002 1,303 1,311 16,2809 16,3809 16,3309

Average 12,8910

Data of F1 100 mesh

Sample Sample weight (gr) Absorbance 1 Absorbance 2 Sample 1 (mg/L) Sample 2 (mg/L) % Amylose

1 0,5006 1,399 1,480 17,4665 18,4778 17,9721

2 0,5009 1,051 1,086 13,1139 13,5506 13,3322

3 0,5007 1,005 1,052 12,5449 13,1316 12,8382

4 0,5004 1,769 1,696 22,0948 21,1830 21,6389

Figure 16. Standart Curve Rice Flour

y = 4.2094x - 0.0657 R² = 0.9937

-0.5 0 0.5 1 1.5 2 2.5

0 0.1 0.2 0.3 0.4 0.5 0.6

Series1