Lecture Notes in Networks and Systems 42

Isak Karabegović

Editor

New

Technologies,

Development

and

Volume 42

Series editor

The series “Lecture Notes in Networks and Systems” publishes the latest developments in Networks and Systems—quickly, informally and with high quality. Original research reported in proceedings and post-proceedings represents the core of LNNS.

Volumes published in LNNS embrace all aspects and subfields of, as well as new challenges in, Networks and Systems.

The series contains proceedings and edited volumes in systems and networks, spanning the areas of Cyber-Physical Systems, Autonomous Systems, Sensor Networks, Control Systems, Energy Systems, Automotive Systems, Biological Systems, Vehicular Networking and Connected Vehicles, Aerospace Systems, Automation, Manufacturing, Smart Grids, Nonlinear Systems, Power Systems, Robotics, Social Systems, Economic Systems and other. Of particular value to both the contributors and the readership are the short publication timeframe and the world-wide distribution and exposure which enable both a wide and rapid dissemination of research output.

The series covers the theory, applications, and perspectives on the state of the art and future developments relevant to systems and networks, decision making, control, complex processes and related areas, as embedded in thefields of interdisciplinary and applied sciences, engineering, computer science, physics, economics, social, and life sciences, as well as the paradigms and methodologies behind them.

Advisory Board

Fernando Gomide, Department of Computer Engineering and Automation—DCA, School of Electrical and Computer Engineering—FEEC, University of Campinas—UNICAMP, São Paulo, Brazil

e-mail:[email protected]

Okyay Kaynak, Department of Electrical and Electronic Engineering, Bogazici University, Istanbul, Turkey

e-mail:[email protected]

Derong Liu, Department of Electrical and Computer Engineering, University of Illinois at Chicago, Chicago, USA and Institute of Automation, Chinese Academy of Sciences, Beijing, China

e-mail:[email protected]

Witold Pedrycz, Department of Electrical and Computer Engineering, University of Alberta, Alberta, Canada and Systems Research Institute, Polish Academy of Sciences, Warsaw, Poland

e-mail:[email protected]

Marios M. Polycarpou, KIOS Research Center for Intelligent Systems and Networks, Department of Electrical and Computer Engineering, University of Cyprus, Nicosia, Cyprus e-mail:[email protected]

Imre J. Rudas,Óbuda University, Budapest Hungary e-mail: [email protected]

Jun Wang, Department of Computer Science, City University of Hong Kong Kowloon, Hong Kong

e-mail:[email protected]

Isak Karabegović

Editor

New Technologies,

Development

and Application

Editor

Isak Karabegović Technical Faculty Bihać University of Bihać Bihać

Bosnia and Herzegovina

ISSN 2367-3370 ISSN 2367-3389 (electronic) Lecture Notes in Networks and Systems

ISBN 978-3-319-90892-2 ISBN 978-3-319-90893-9 (eBook) https://doi.org/10.1007/978-3-319-90893-9

Library of Congress Control Number: 2018942170

©Springer International Publishing AG, part of Springer Nature 2019

This work is subject to copyright. All rights are reserved by the Publisher, whether the whole or part of the material is concerned, specifically the rights of translation, reprinting, reuse of illustrations, recitation, broadcasting, reproduction on microfilms or in any other physical way, and transmission or information storage and retrieval, electronic adaptation, computer software, or by similar or dissimilar methodology now known or hereafter developed.

The use of general descriptive names, registered names, trademarks, service marks, etc. in this publication does not imply, even in the absence of a specific statement, that such names are exempt from the relevant protective laws and regulations and therefore free for general use.

The publisher, the authors and the editors are safe to assume that the advice and information in this book are believed to be true and accurate at the date of publication. Neither the publisher nor the authors or the editors give a warranty, express or implied, with respect to the material contained herein or for any errors or omissions that may have been made. The publisher remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Printed on acid-free paper

This Springer imprint is published by the registered company Springer International Publishing AG part of Springer Nature

their Development and Application

The content of this book is very interesting and important as it covers a wide range of technologies and technical disciplines including complex systems such as: robotics, mechatronics systems, automation, manufacturing, cyber-physical sys-tems, autonomous syssys-tems, sensor, networks, control syssys-tems, energy syssys-tems, automotive systems, biological systems, vehicular networking and connected vehicles, effectiveness and logistics systems, smart grids, nonlinear systems, power systems, social systems, economic systems and other. The papers included in this content have been presented at the international conference New Technologies, Development and Application, held in Sarajevo, Bosnia and Herzegovina, on 28–30 June 2018. Majority of organized conferences are usually focusing on a narrow part of the issues within a certain discipline while conferences such these are rare. There is a need to hold such conferences. The value of this conference is that various researchers, programmers, engineers and practitioners come to the same place where ideas and latest technology achievements are exchanged. Such events lead to the creation of new ideas, solutions and applications in the manufacturing processes of various technologies. New coexistence is emerging, horizons are expanding, and unexpected changes and analogies arise. Best solutions and applications in technologies are critically evaluated.

Thefirst chapter begins with robots, robotic systems, modelling of compressor systems, mechatronic systems, automation of manufacturing processes and advanced production. Thefirst article offers an analysis of automation of welding processes using industrial robots. The following article in this chapter analyses the modelling of multiphase twin screw machines, commonly used for pumpingfluids which often contain gas, liquid and solid particles, and are of exceptional impor-tance to industry and ecology. The following article in this chapter analyses the influence of injection moulding process parameters on part quality. The last article offers a power and control system of knee and ankle powered above knee prosthesis.

The second chapter is intended to innovative and interdisciplinary applications of advanced technologies (IATs). It is based on the analysis (IoT) of technological tools as an opportunity to use new technologies in the development of society as a whole.

Thefirst article is devoted to the cybersecurity capacity building planning within organizations. Thefinal article offers application of weighted particle swarm opti-mization to imbalanced data in software defect prediction.

The third chapter is intended to transport systems, logistics and intelligent transport systems. Thefirst article gives an analysis of cooperative control in traffic and transportation technology. The second article provides a solution to traffic control in urban areas, while the final article offers the use of unmanned aerial vehicles in logistics processes.

The fourth chapter is intended to electric power systems with different spectrum of topics from turbulence analysis of wind power plants, pico power plants, high energy efficiency to analysis of combustion technologies with the aim of achieving ecological standards.

Thefifth chapter is intended to new methods in agricultural culture of a broad spectrum of topics: modelling the extraction process of sage, effects of sage extract, from occurrence of apple powdery mildew to application of multivariate statistic to classify blueberry fruits, and in addition the detection of heavy metals in hair colours by the atomic absorption spectrophotometry, the content of heavy metals in “PET” bottles of drinking water and its electrical conductivity, microbiological analysis of surface waters and research of antimicrobial resistance of clinical important multiresistant gram-negative bacterial isolates.

The sixth chapter focuses on new technology in civil engineering, education, control quality and other. The first article focuses on nanotechnology in civil engineering. In next article, information about parametric vector analysis of available resources for minimization of project duration is given. The last article in this chapter considers education at universities.

The whole content of this book is intended to a wide range of technical systems; different technical disciplines in order to apply the latest solutions and achievements in technologies and to improve manufacturing processes in all disciplines where systemic thinking has a very important role in the successful understanding and building of human, natural and social systems. We hope this content will be thefirst in a series of publications that are intended to the development and implementation of new technologies in all industries.

New Technologies in Mechanical Engineering, Metallurgy, Mechatronics, Robotics and Embedded Systems

Automation of the Welding Process by Use of Industrial Robots. . . 3 Isak Karabegovićand Riaz Mirza

Modelling of Multiphase Twin Screw Machines. . . 18 Ahmed Kovacevic, Sham Rane, and Nikola Stosic

Influence of Injection Molding Process Parameters on Part Quality . . . 33 Janez Gotlih, Miran Brezočnik, Igor Drstvenšek, Timi Karner,

and Karl Gotlih

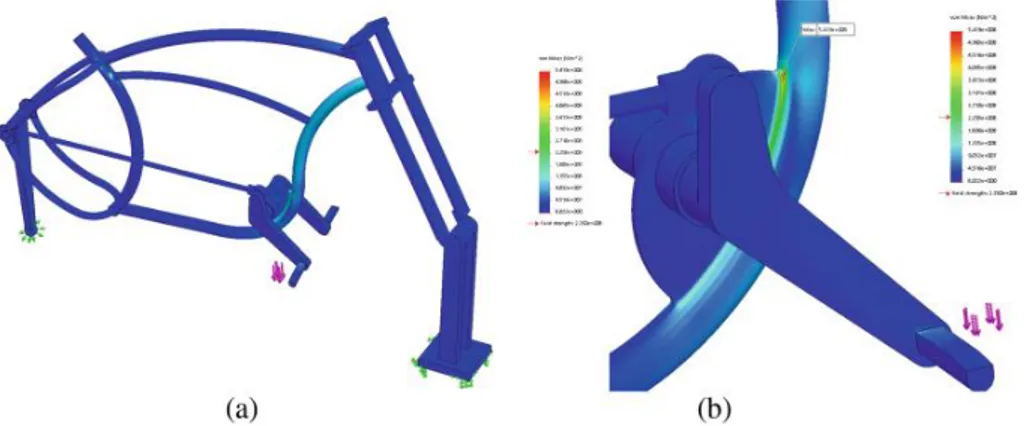

Numerical Analysis of Material Fatigue Impact on Bicycle Frame

Safety in Accordance with EN 14764. . . 41 Nermina Zaimović-Uzunović, Ernad Bešlagić, and Almir Porča

The Influence of the Tool Geometry on the Quality of the Weld

in FSW Process . . . 50 Aleksandra Koprivica, NikolaŠibalić, Milan Vukčević,

and Mirjana Jokanović

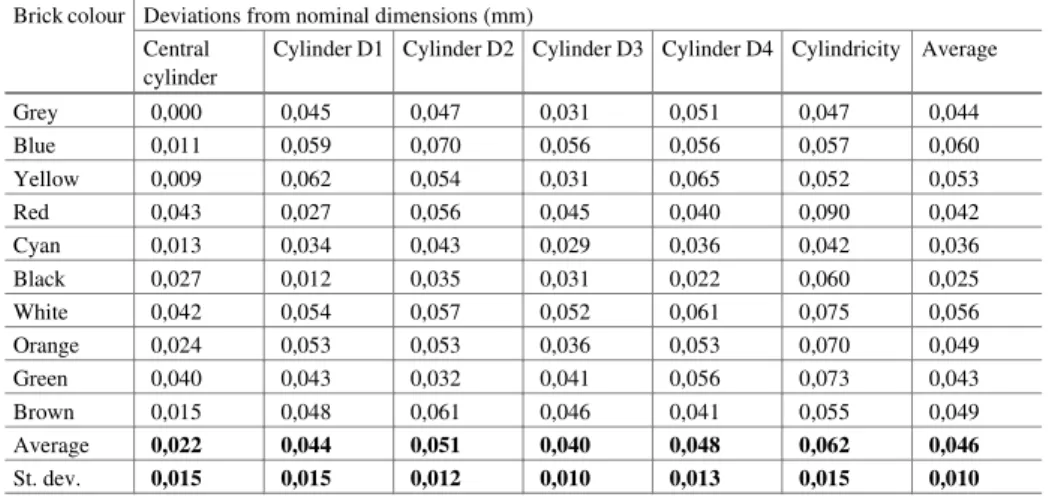

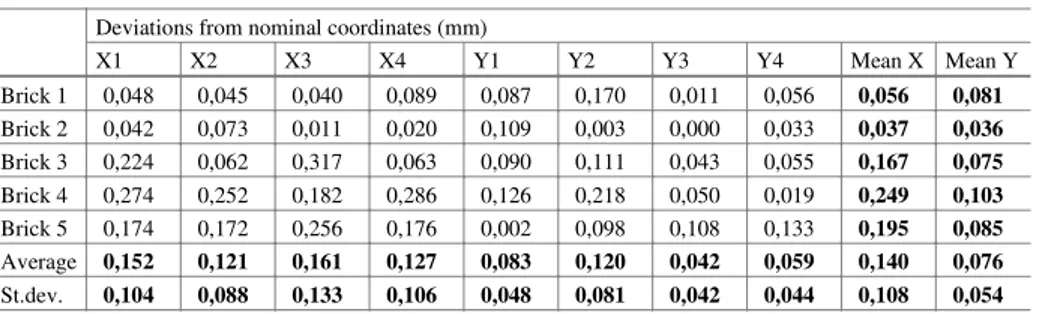

Dimension Measurement of Injection Moulded Toybricks. . . 57 Samir Lemešand Anel Baručija

Wire and Arc Additive Manufacturing (WAAM)–A New Advance

in Manufacturing. . . 65 Nikola Knezovićand Angela Topić

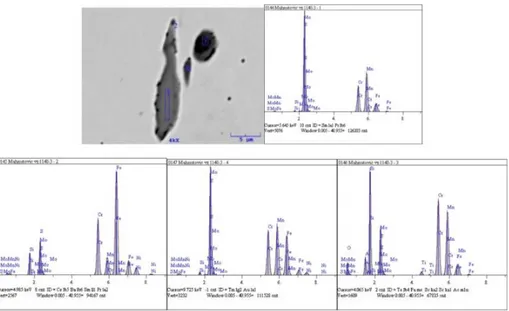

Analysis of the Type and Chemical Content of the Inclusion on SEM

of the Stainless Steel With and Without the Addition of Zr and Te. . . . 72 DervišMujagić, Aida Imamović, Mirsada Oruč,

and Sulejman Muhamedagić

Strength and Deformation Calculation of Flat O-Springs. . . 80 Ivan Balashev, Mariel Penev, Ivan Stoyanov, and Radoslav Balashev

Prototype Apparatus for Calibration Contact Sensors for Measuring

the Temperature of a Solid Surface. . . 86 Edin Terzić, Raif Seferović, and Narcisa Jarović-Bajramović

Automatic Control of Tube Hydroforming Process

in Experimental Conditions . . . 101 Edina Karabegović, EdinŠemić, and Safet Isić

Analysis and Determination of Friction in Hydroforming Process

of Cross Tube. . . 107 Mehmed Mahmić, Edina Karabegović, and Ermin Husak

Science of Metals Through Lens of Microscope. . . 113 Belma Fakić, Adisa Burić, and Edib Horoz

Increase of Performance of Grinding by Plate Circles. . . 121 Tonkonogyi Vladimir, Yakimov Alexey, and Bovnegra Liubov

Analysis of Torsional Vibration of the Engine Connected

with Propeller Through Pair of Gears . . . 128 Ermin Husak and Erzad Haskić

FEM Model of Misaligned Rotational System

with Rotating Looseness. . . 135 Emir Nezirić, Safet Isić, Isak Karabegović, and Avdo Voloder

Application of Explosives in Metal Forming. . . 144 DarkoŠunjićand Stipo Buljan

Application of Iterative Methods to Solve Inverse Kinematics

Problem of Robot. . . 149 Avdo Voloder

Parameter Fitting for Soft Dielectric Elastomer Actuator . . . 156 Timi Karner, Janez Gotlih, Boštjan Razboršek, and Karl Gotlih

Timber Construction and Robots. . . 163 Salah-Eldien Omer

Conceptual Solution of the Robotic Arm/Plotter . . . 170 Milena Djukanovic, Rade Grujicic, Luka Radunovic, and Vuk Boskovic

Robot for Cleaning Ventilation Ducts. . . 180 Milos Bubanja, Marina Mijanovic Markus, Milena Djukanovic,

and Mihailo Vujovic

Cloud Robotics. . . 191 Samir Vojić

Vibration Analysis of Motorcycle Handles. . . 196 Zlata Jelačićand Boran Pikula

Acoustic Diagnostics of Lever Mechanisms with Subsequent

Processing of Data on Neural Networks. . . 202 Sergiy Kovalevskyy, Olena Kovalevska, and Raul Turmanidze

Power and Control System of Knee and Ankle Powered

Above-Knee Prosthesis. . . 211 Miljan Rupar, Zlata Jelačić, Remzo Dedić, and Adisa Vučina

Computer Science, Information and Communication Technologies, e-Business

Cyber Security Capacity Building Planning Within Organisations. . . 219 RamoŠendelj and Ivana Ognjanović

New Method of Sequences Spiral Hybrid Using Machine Learning

Systems and Its Application to Engineering. . . 227 Matej Babič, Isak Karabegović, Sanda IpšičMartinčič, and Gyula Varga

A Multifunctional Platform for Elders’Assisting to Live Alone. . . 238 Blerina Zanaj, Fatjon Shaba, Majlinnda Belegu, and Gerti Boshnjaku

Economic Aspects of the Application of Cloud Computing . . . 247 Mirha BičoĆar, Savo Stupar, and ElvirŠahić

The Role of Hadoop Technology in the Implementation

of Big Data Concept. . . 254 Savo Stupar, Mirha BičoĆar, and ElvirŠahić

Cybernetization of Industrial Product-Service Systems

in Network Environment . . . 262 Elvis Hozdićand Zoran Jurković

Technology-Enhanced Systems in Idiopathic Scoliosis 3D Diagnosis

and Screening. . . 271 Saša M.Ćuković, William R. Taylor, and IonuţG. Ghionea

Contributions to Improve the Sustainability in Services Based

Organizations. . . 279 Mihail Aurel Titu, Bianca Alina Pop, and Stefan Titu

Applying Weighted Particle Swarm Optimization to Imbalanced

Intelligent Transport Systems, Logistics, Traffic Control

Cooperative Systems in Traffic Technology and Transport . . . 299 Sadko Mandžuka

Wireless Sensor Network Based Alarm Detection and Monitoring

of Cyber-Physical System with Mobile Robot Inspection. . . 309 Lejla Banjanovic-Mehmedovic and Mirzet Zukic

Review of Simulation Based Comparison of VANET Protocols . . . 317 Zlatan Jukic and Muhammad Arshad

Ramp Metering on Urban Motorways. . . 332 Martin Gregurić, Sadko Mandžuka, and Edouard Ivanjko

Terminology Extraction to Build an Ontology of Intelligent

Transport Systems . . . 338 PeroŠkorput, Sadko Mandžuka, and Markus Schatten

Cooperative Vehicle Actuated Traffic Control in Urban Areas . . . 345 Miroslav Vujić, Sadko Mandžuka, and Luka Dedić

Application of Mini Computers and RFID Technology

in Automation . . . 354 MalikČabaravdić, SanelaČančar, and Anel Husaković

Application of Unmanned Aerial Vehicles in Logistic Processes. . . 359 Jasmina Pašagić Škrinjar, PeroŠkorput, and Martina Furdić

New Technologies in the Field Energy: Renewable Energy, Power Quality, Advanced Electrical Power Systems

The Turbulence Intensity of the Wind Bora. . . 369 Blago Pehar, Elvir Zlomušica, and Suad Zalihić

Lab-Scale Tests as Support to Selection of Sustainable Coal Combustion Technology - Case Study: Support to Design

of TPP Kakanj Unit 8 - . . . 377 Nihad Hodžić, Sadjit Metović, and Anes Kazagić

Influence of New Technologies on Higher Energy Efficiency

of Hydrostatic Devices and Systems. . . 386 MilutinŽivković, Predrag Dašić, and Zvonko Petrović

Design of Pico Hydropower Plants for Rural Electrification . . . 397 Krsto Batinić, Dušan Golubović, Stojan Simić, and Goran Orašanin

Development of Construction of Mini Hydro Power Plant Model

Based on Pelton Turbine . . . 405 Radoslav Tomović, Aleksandar Tomović, Marko Mumović,

and Vuk Vujošević

Gas Escape from Combustion Chamber to Crankcase, Analysis

of a Set of Parameters Affecting the Blow by. . . 413 Cristiana Delprete, Arian Bisha, and Erjon Selmani

Comb-Based Decimator for Multiples-of-Five Decimation Factors. . . 423 Gordana Jovanovic Dolecek and Isak Karabegovic

The Filter-Compensation Device Applications to the AC 25 kV 50 Hz

AC of Serbian Railways. . . 429 Branislav Gavrilovic and Zoran Bundalo

Optimization of Water Supply System Using Software EPANET 2.0. . . 443 Aleksandar Košarac, Dejan Romić, Goran Orašanin,

and Jovana Blagojević

The Possibilities of the Cadastral Land Use Assessment

by the Methods of Remote Sensing . . . 452 Admir Mulahusić, Jusuf Topoljak, Nedim Tuno, and Karlo Ajvazović

Analysis of the Energy Potential of Organic Bioradable Part

of Municipal Waste . . . 459 Mahmut Jukićand IfetŠišić

New Technologies in Agriculture and Ecology, Chemical Processes

Modeling the Extraction Process of Sage (Salvia OfficinalisL.)

with Supercritical CO2at Different Temperatures. . . 469 Sabina Begić, Vladan Mićić, and Darko Manjenčić

The Effect of Concentration of Methanol as a Solvent on the

Antioxidative Activity of Sage Extract . . . 480 Selma Osmić, Sabina Begić, and Vladan Mićić

Occurrence of Apple Powdery Mildew,Podosphaera Leucotricha (Ellis. & Everh.) E. S. Salmon in North-Western Region of Bosnia

and Herzegovina . . . 491 Zemira Delalić

Application of Multivariate Statistic to Classify Blueberry Fruits . . . 498 Vildana Alibabić, Azra Skender, Melisa Orašćanin, and Ibrahim Mujić

The Effect of Technological Process on Physico-Chemical

and Nutritional Properties of Sour Cherries Products . . . 507 Ramzija Cvrk, Azra Begović, Snježana Marić, and Nils V. Juul

Application of New Technologies in Meat Processing Industry in the Function of Improvement of Total Quality of Products

The Impact of Water on PVC Floor Coverings . . . 522 Mario Krzyk and Darko Drev

Exposure to PM10 Aerosol Particles and Other Aerial Pollutants

in the Capital City of Montenegro. . . 529 Jovana Jovanovic and Svetlana Stevovic

New Technological Procedures for Production of Thioncarbamates

as a Selective Flotation Reagents . . . 542 Milutin M. Milosavljević, Milan M. Milosavljević, MilutinŽivković,

and Ljiljana Pecić

The Content of Heavy Metals in“PET”Bottles of Drinking Water

and Its Electrical Conductivity. . . 552 Ekrem Pehlić, AidaŠapčanin, Husein Nanić, and AdnanĆehajić

Determination of Heavy Metals in Hair Dyes by the Atomic

Absorption Spectrophotometry. . . 561 Ekrem Pehlić, Husein Nanić, Huska Jukić, and Aldina Aldžić

Microbiological Analysis of Surface Waters in the Area

of National Park“Una” . . . 568 Melisa Zulić, Huska Jukić, Asmir Aldžić, and AdnanĆehajić

Research of Antimicrobial Resistance of Clinical Important Multi-resistent Gram Negative Bacterial Isolates

in the Una-Sana Canton Area . . . 575 Asmir Aldžić, Huska Jukić, Kanita Dedić, and Amela Dubinović-Rekić

New Technologies in Civil Engineering, Education, Control Quality

Nanotechnology in Civil Engineering. . . 585 MerimaŠahinagić-Isović, MarkoĆećez, and Fuad Ćatović

Support Parametric Vector Analysis of Available Resources for

Minimisation of Project Duration–Four Varieties of Conditions . . . 590 Omer Kurtanovićand Lejla Dacić

New Technologies in Education at“Džemal Bijedić”University

in Mostar . . . 597 Alim Abazović, Dragi Tiro, and FuadĆatović

Author Index. . . 605

Alim Abazović “Dzemal Bijedic” University of Mostar, Mostar, Bosnia and Herzegovina

Karlo Ajvazović University of Sarajevo, Sarajevo, Bosnia and Herzegovina Aldina Aldžić University of Bihac, Bihać, Bosnia and Herzegovina

Asmir Aldžić University of Bihać, Bihać, Bosnia and Herzegovina

Yakimov Alexey Institute of Industrial Technologies, Design and Management, Odessa National Polytechnic University, Odessa, Ukraine

Vildana Alibabić University of Bihać, Bihać, Bosnia and Herzegovina

Muhammad Arshad University of Engineering and Technology Lahore, Lahore, Pakistan

Matej Babič Jožef Stefan Institute, Ljubljana, Slovenia

Ivan Balashev Technical University of Gabrovo, Gabrovo, Bulgaria

Radoslav Balashev PRONY Engineering Ltd., Gabrovo, Bulgaria

Lejla Banjanovic-Mehmedovic University of Tuzla, Tuzla, Bosnia and Herzegovina

Anel Baručija University of Zenica, Zenica, Bosnia and Herzegovina

Krsto Batinić University of East Sarajevo, East Sarajevo, Bosnia and Herzegovina

Munevera Begić University of Sarajevo, Sarajevo, Bosnia and Herzegovina

Sabina Begić University of Tuzla, Tuzla, Bosnia and Herzegovina; University of East Sarajevo, Zvornik, Bosnia and Herzegovina

Azra Begović Faculty of Technology, University of Tuzla, Tuzla, Bosnia and Herzegovina

Majlinnda Belegu Agricultural University of Tirana, Tirana, Albania

Ernad Bešlagić University of Zenica, Zenica, Bosnia and Herzegovina

Arian Bisha Universiteti Politeknik i Tiranes, Tirana, Albania

Mirha BičoĆar University of Sarajevo, Sarajevo, Bosnia and Herzegovina

Jovana Blagojević University of East Sarajevo, East Sarajevo, Bosnia and Herzegovina

Gerti Boshnjaku New Media Communications, Tirana, Albania

Vuk Boskovic University of Montenegro, Podgorica, Montenegro

Lucija Brezočnik Faculty of Electrical Engineering and Computer Science, University of Maribor, Maribor, Slovenia

Miran Brezočnik University of Maribor, Maribor, Slovenia

Milos Bubanja University of Montenegro, Podgorica, Montenegro

Stipo Buljan Federal Ministry of Energy, Mostar, Bosnia and Herzegovina

Zoran Bundalo Railway College of Vocational Studies, Belgrade, Serbia

Adisa Burić University of Zenica, Metallurgical Institute“Kemal Kapetanović”, Zenica, Bosnia and Herzegovina

MalikČabaravdić University of Zenica, Zenica, Bosnia and Herzegovina

SanelaČančar University of Zenica, Zenica, Bosnia and Herzegovina

Fuad Ćatović “Džemal Bijedić” University of Mostar, Mostar, Bosnia and Herzegovina

Marko Ćećez “Džemal Bijedić” University of Mostar, Mostar, Bosnia and Herzegovina

AdnanĆehajić University of Bihać, Bihać, Bosnia and Herzegovina

Saša M. Ćuković Department of Health Sciences and Technology, Institute for Biomechanics, Swiss Federal Institute of Technology – ETH Zurich, Zurich, Switzerland

Ramzija Cvrk Faculty of Technology, University of Tuzla, Tuzla, Bosnia and Herzegovina

Lejla Dacić University of Travnik, Travnik, Bosnia and Herzegovina

Predrag Dašić High Technical Mechanical School of Professional Studies, Trstenik, Serbia

Kanita Dedić Cantonal Hospital,“Dr. Irfan Ljubijankić”Bihac, Bihac, Bosnia and Herzegovina

Luka Dedić University of Zagreb, Zagreb, Croatia

Remzo Dedić University of Mostar, Mostar, Bosnia and Herzegovina

Zemira Delalić University of Bihać, Bihać, Bosnia and Herzegovina

Cristiana Delprete Politecnico di Torino, Turin, Italy

Milena Djukanovic University of Montenegro, Podgorica, Montenegro

Darko Drev University of Ljubljana, Ljubljana, Slovenia

Igor Drstvenšek University of Maribor, Maribor, Slovenia

Amela Dubinović-Rekić Cantonal Hospital,“Dr. Irfan Ljubijankić”Bihac, Bihac, Bosnia and Herzegovina

Belma Fakić University of Zenica, Metallurgical Institute“Kemal Kapetanović”, Zenica, Bosnia and Herzegovina

Martina Furdić University of Zagreb, Zagreb, Croatia

Amir Ganić University of Sarajevo, Sarajevo, Bosnia and Herzegovina

Branislav Gavrilovic Railway College of Vocational Studies, Belgrade, Serbia

Ionuţ G. Ghionea Faculty of Engineering and Management of Technological Systems, University Politehnica of Bucharest, Bucharest, Romania

Dušan Golubović University of East Sarajevo, East Sarajevo, Bosnia and Herzegovina

Janez Gotlih University of Maribor, Maribor, Slovenia

Karl Gotlih University of Maribor, Maribor, Slovenia

Martin Gregurić University of Zagreb, Zagreb, Croatia

Rade Grujicic University of Montenegro, Podgorica, Montenegro

Erzad Haskić University of Bihać, Bihać, Bosnia and Herzegovina

Nihad Hodžić University of Sarajevo, Sarajevo, Bosnia and Herzegovina

Edib Horoz University of Zenica, Metallurgical Institute“Kemal Kapetanović”, Zenica, Bosnia and Herzegovina

Elvis Hozdić University of Ljubljana, Ljubljana, Slovenia

Ermin Husak University of Bihać, Bihać, Bosnia and Herzegovina

Anel Husaković University of Zenica, Zenica, Bosnia and Herzegovina

Safet Isić Faculty of Mechanical Engineering, University “Džemal Bijedić” Mostar, Mostar, Bosnia and Herzegovina

Edouard Ivanjko University of Zagreb, Zagreb, Croatia

Narcisa Jarović-Bajramović Metallurgical Institute “Kemal Kapetanović”, University of Zenica, Zenica, Bosnia and Herzegovina

Zlata Jelačić University of Sarajevo, Sarajevo, Bosnia and Herzegovina

Mirjana Jokanović University of East Sarajevo, East Sarajevo, Bosnia and Herzegovina

Gordana Jovanovic Dolecek Institute INAOE, Puebla, Mexico

Jovana Jovanovic University Union Nikola Tesla, Belgrade, Serbia

Zlatan Jukic HTL Rankweil & Vienna University of Technology, Vienna, Austria

Huska Jukić University of Bihać, Bihać, Bosnia and Herzegovina

Mahmut Jukić University of Bihac, Bihać, Bosnia and Herzegovina

Zoran Jurković University of Rijeka, Rijeka, Croatia

Nils V. Juul Sør-Trøndelag University College (HiST), Høgskolen i Sør-Trøndelag, Trondheim, Norway

Edina Karabegović Faculty of Technical Engineering Bihać, University of Bihać, Bihać, Bosnia and Herzegovina

Isak Karabegović Technical Faculty, University of Bihać, Bihać, Bosnia and Herzegovina

Enver Karahmet University of Sarajevo, Sarajevo, Bosnia and Herzegovina

Timi Karner University of Maribor, Maribor, Slovenia

Anes Kazagić University of Sarajevo, Sarajevo, Bosnia and Herzegovina

Nikola Knezović University of Mostar, Mostar, Bosnia and Herzegovina

Aleksandra Koprivica University of East Sarajevo, East Sarajevo, Bosnia and Herzegovina

Ahmed Kovacevic Centre for Compressor Technology, City, University of London, London, UK

Olena Kovalevska Department of Machine Building Technology, Donbass State Engineering Academy, Kramatorsk, Ukraine

Sergiy Kovalevskyy Department of Machine Building Technology, Donbass State Engineering Academy, Kramatorsk, Ukraine

Aleksandar Košarac University of East Sarajevo, East Sarajevo, Bosnia and Herzegovina

Mario Krzyk University of Ljubljana, Ljubljana, Slovenia

Omer Kurtanović University of Bihac, Bihać, Bosnia and Herzegovina Samir Lemeš University of Zenica, Zenica, Bosnia and Herzegovina

Bovnegra Liubov Institute of Industrial Technologies, Design and Management, Odessa National Polytechnic University, Odessa, Ukraine

Mehmed Mahmić University of Bihać, Bihać, Bosnia and Herzegovina

Sadko Mandžuka Faculty of Traffic and Transport Sciences, University of Zagreb, Zagreb, Croatia

Darko Manjenčić University of Novi Sad, Novi Sad, Serbia

Snježana Marić Faculty of Technology, University of Tuzla, Tuzla, Bosnia and Herzegovina

Marina Mijanovic Markus University of Montenegro, Podgorica, Montenegro

Sanda IpšičMartinčič University of Rijeka, Rijeka, Croatia

Sadjit Metović University of Sarajevo, Sarajevo, Bosnia and Herzegovina

Milan M. Milosavljević University of Priština, Kosovska Mitrovica, Serbia Milutin M. Milosavljević University of Priština, Kosovska Mitrovica, Serbia

Riaz Mirza University of Engineering & Technology, Lahore, Pakistan

Vladan Mićić University of Tuzla, Tuzla, Bosnia and Herzegovina; University of East Sarajevo, Zvornik, Bosnia and Herzegovina

Sulejman Muhamedagić Institute “Kemal Kapetanović”, University of Zenica, Zenica, Bosnia and Herzegovina

Derviš Mujagić Institute “Kemal Kapetanović”, University of Zenica, Zenica, Bosnia and Herzegovina

Ibrahim Mujić University of Bihać, Bihać, Bosnia and Herzegovina; Colegium Fluminense Polytechnic of Rijeka, Rijeka, Croatia

Admir Mulahusić University of Sarajevo, Sarajevo, Bosnia and Herzegovina Marko Mumović University of Montenegro, Podgorica, Montenegro

Husein Nanić University of Bihac, Bihać, Bosnia and Herzegovina

Ivana Ognjanović University of Donja Gorica, Podgorica, Montenegro

Salah-Eldien Omer SAG CONSULTING d.o.o., Zagreb, Croatia

Goran Orašanin University of East Sarajevo, East Sarajevo, Bosnia and Herzegovina

Melisa Orašćanin University of Bihać, Bihać, Bosnia and Herzegovina

Mirsada Oruč Institute “Kemal Kapetanović”, University of Zenica, Zenica, Bosnia and Herzegovina

Selma Osmić University of Tuzla, Tuzla, Bosnia and Herzegovina

Ljiljana Pecić Bachelor School for Professional Technical Studies, Trstenik, Serbia

Blago Pehar ‘‘Džemal Bijedić’’ University of Mostar, Mostar, Bosnia and Herzegovina

Ekrem Pehlić University of Bihac, Bihać, Bosnia and Herzegovina

Mariel Penev Technical University of Gabrovo, Gabrovo, Bulgaria

Zvonko Petrović High Technical Mechanical School of Professional Studies, Trstenik, Serbia

Boran Pikula University of Sarajevo, Sarajevo, Bosnia and Herzegovina

Vili Podgorelec Faculty of Electrical Engineering and Computer Science, University of Maribor, Maribor, Slovenia

Bianca Alina Pop SC TEHNOCAD SA, Baia Mare, Romania

Almir Porča University of Zenica, Zenica, Bosnia and Herzegovina

Luka Radunovic University of Montenegro, Podgorica, Montenegro

Sham Rane Department of Engineering Science, University of Oxford, Oxford, UK

Boštjan Razboršek University of Maribor, Maribor, Slovenia

Dejan Romić University of East Sarajevo, East Sarajevo, Bosnia and Herzegovina

Miljan Rupar University of Mostar, Mostar, Bosnia and Herzegovina

Markus Schatten University of Zagreb, Zagreb, Croatia

Raif Seferović Metallurgical Institute“Kemal Kapetanović”, University of Zenica, Zenica, Bosnia and Herzegovina

Erjon Selmani Universiteti Politeknik i Tiranes, Tirana, Albania

Fatjon Shaba New Media Communications, Tirana, Albania

Stojan Simić University of East Sarajevo, East Sarajevo, Bosnia and Herzegovina

Azra Skender University of Bihać, Bihać, Bosnia and Herzegovina

Svetlana Stevovic University of Beograd, Belgrade, Serbia

Nikola Stosic Centre for Compressor Technology, City, University of London, London, UK

Ivan Stoyanov Podem Gabrovo Ltd., Gabrovo, Bulgaria

Savo Stupar University of Sarajevo, Sarajevo, Bosnia and Herzegovina

William R. Taylor Department of Health Sciences and Technology, Institute for Biomechanics, Swiss Federal Institute of Technology – ETH Zurich, Zurich, Switzerland

Edin Terzić Metallurgical Institute “Kemal Kapetanović”, University of Zenica, Zenica, Bosnia and Herzegovina

Dragi Tiro “Dzemal Bijedic” University of Mostar, Mostar, Bosnia and Herzegovina

Mihail Aurel Titu Lucian Blaga University of Sibiu, Sibiu, Romania

Stefan Titu The Oncology Institute “Prof. dr. Ion Chiricuță” Cluj Napoca, Cluj-Napoca, Romania

Aleksandar Tomović University of Montenegro, Podgorica, Montenegro Radoslav Tomović University of Montenegro, Podgorica, Montenegro

Angela Topić University of Mostar, Mostar, Bosnia and Herzegovina

Jusuf Topoljak University of Sarajevo, Sarajevo, Bosnia and Herzegovina

Nedim Tuno University of Sarajevo, Sarajevo, Bosnia and Herzegovina

Raul Turmanidze Department of Machine Building Technology, Donbass State Engineering Academy, Kramatorsk, Ukraine

Gyula Varga University of Miskolc, Miskolc, Hungary

Tonkonogyi Vladimir Institute of Industrial Technologies, Design and Management, Odessa National Polytechnic University, Odessa, Ukraine

Samir Vojić Technical Faculty Bihać, University of Bihać, Bihać, Bosnia and Herzegovina

Avdo Voloder Faculty of Mechanical Engineering, University of Sarajevo, Sarajevo, Bosnia and Herzegovina

Mihailo Vujovic University of Montenegro, Podgorica, Montenegro

Vuk Vujošević University of Montenegro, Podgorica, Montenegro

Milan Vukčević University of Montenegro, Podgorica, Montenegro

Nermina Zaimović-Uzunović University of Zenica, Zenica, Bosnia and Herzegovina

Suad Zalihić ‘‘Džemal Bijedić’’ University of Mostar, Mostar, Bosnia and Herzegovina

Blerina Zanaj Agricultural University of Tirana, Tirana, Albania

Elvir Zlomušica ‘‘Džemal Bijedić’’ University of Mostar, Mostar, Bosnia and Herzegovina

Mirzet Zukic University of Tuzla, Tuzla, Bosnia and Herzegovina

Melisa Zulić University of Bihać, Bihać, Bosnia and Herzegovina

Merima Šahinagić-Isović “Džemal Bijedić” University of Mostar, Mostar, Bosnia and Herzegovina

ElvirŠahić University of Sarajevo, Sarajevo, Bosnia and Herzegovina

Aida Šapčanin Faculty of Pharmacy, University of Sarajevo, Sarajevo, Bosnia and Herzegovina

Edin Šemić Faculty of Mechanical Engineering, University “Džemal Bijedić” Mostar, Mostar, Bosnia and Herzegovina

RamoŠendelj University of Donja Gorica, Podgorica, Montenegro

NikolaŠibalić University of Montenegro, Podgorica, Montenegro

IfetŠišić University of Bihac, Bihać, Bosnia and Herzegovina

PeroŠkorput University of Zagreb, Zagreb, Croatia

Jasmina Pašagić Škrinjar University of Zagreb, Zagreb, Croatia

DarkoŠunjić University of Mostar, Mostar, Bosnia and Herzegovina

Milutin Živković High Technical Mechanical School of Professional Studies, Trstenik, Serbia

MilutinŽivković Bachelor School for Professional Technical Studies, Trstenik, Serbia

New Technologies in Mechanical

Engineering, Metallurgy, Mechatronics,

Automation of the Welding Process

by Use of Industrial Robots

Isak Karabegović1(✉) and Riaz Mirza2

1 University of Bihać, 77000 Bihać, Bosnia and Herzegovina [email protected]

2 University of Engineering & Technology, Lahore, Pakistan [email protected]

Abstract. The development of robotic technology, owing to the advancement of digital technology, is evolving each year, resulting in increased representation of industrial robots. We are currently in the fourth industrial revolution, referred to as “Industry 4.0” by the Germans. The implementation of the fourth techno‐ logical revolution depends on a series of new and innovative technological achievements, most of which are applied in robotic technology. Automation of production processes, including automation of the welding process, must include industrial robots. This paper demonstrates the representation of industrial robots in the world continents, and four top countries: China, Japan, North America and Germany. An analysis was conducted of the annual representation of industrial robots in the welding process worldwide and on continents of Asia/Australia, Europe, and Americas, for the period 2010–2016. As it is known that industrial robots are most represented in the automotive industry, a tendency of their repre‐ sentation was depicted in the automotive industry for the same period, as well as the percentage in all industrial branches by 2016. Industrial robots are most widely used in two welding processes: arc welding and spot welding, so an analysis of their representation in these two welding processes for the period 2010–2016 was conducted. A comparative analysis of the annual production of vehicles in four countries was made: China, Japan, USA and Germany, as well as the presence of robots in these countries in the welding processes. The paper also includes the analysis and possibilities of future industrial robot representation in this area. Keywords: Industry · Process · Robot · Welding · Arc welding · Spot welding Application

1

Introduction

The production process in any industry branch is unconceivable without the use of industrial robots. The automation process in the industry started in the 1960s when industrial robots were introduced, and it continues to this day. The process of automation of production process with application of the first-generation industrial robots at that time period was positive because they replaced people in performing difficult and dangerous jobs. This was a rigid and non-flexible automation, because in order to initiate the production of another product in the same manufacturing process, it was necessary

© Springer International Publishing AG, part of Springer Nature 2019 I. Karabegović (Ed.): NT 2018, LNNS 42, pp. 3–17, 2019.

to reprogram each robot with its grips, changing tools, etc., which in return caused long-lasting delays in the production and presented additional production costs. We must also state the fact that industrial robots were enclosed with fences for reasons not to hurt the workers engaged in the production process. With the continuous automation of produc‐ tion processes and their flexibility, as well as demands for constant change in production lines, the function of industrial robot becomes increasingly demanding and complex with the tendency of increasing the use of industrial robots. Every day we have techno‐ logical improvements in terms of flexibility, accuracy, security and simplification of the use of industrial robots. Medium and small businesses will start using flexible automa‐ tion in order to be competitive in the market. The presence of industrial robots is still the largest in the automotive industry in the welding process, but other industries do not lag behind in increasing the use of industrial robots. Industrial robots are ideal for jobs that are considered to be difficult and disadvantageous for people, and jobs that are hazardous to their health, particularly welding. They are used for repetitive jobs that are considered monotonous, as well as for products which require high quality and high productivity, such as automotive industry. Various industrial robots have been designed precisely for a specific type of task. The application of robotic systems in the industry also presents the humanization of work, and the best example is the welding processes in any industry [1–14, 22–24, 29–35]. Industrial robots are used for arc welding, spot welding, laser welding, soldering and other types of welding. The paper presents the analysis of the use of industrial robots in the world, by continents, as well as in the four countries where the automotive industry is the most represented, i.e. in the countries where the most vehicles are produced. In addition, the tendency of representation of industrial robots is presented in two welding processes: arc welding and spot welding, since these two welding processes mostly use industrial robots. When it comes to the transformation of production processes, we are referring to their modernization, with the aim of achieving intelligent production processes. This process is unimaginable without the presence of both industrial and service robots of the new generation. The new generation of robots must be intelligent and autonomous, i.e. to make independent decisions and communicate with people and machines. The application of such industrial and service robots will increase the reliability of the manufacturing process, reduce the time to create the finished product, and enable adapting and precision in performing tasks that exceed human capabilities.

2

The Representation of Industrial Robots

In order to depict the representation of industrial robots in production processes world‐ wide, the data for statistical analysis were taken from the International Federation of Robotics (IFR), the UN Economic Commission for Europe (UNECE) and the Organi‐ zation for Economic Co-operation and Development (OECD) [15–25, 29], as are shown in Fig. 1.

world that reflected the annual presence of industrial robots, so that the lowest repre‐ sentation of only 60.011 industrial robot units was marked in 2009. We can point out that the increase in the number of industrial robots in the world is growing from year to year, so that in 2016 the tendency of use has raised to 259.000 industrial robot units. The reasons for this tendency of representation of industrial robots are many, including the fact that companies want to be competitive in the market and introduce automation into their production processes, which reflects the presence of industrial robots. Other reasons include the development of robotic technology and the fourth digital revolution that simplifies the use of robots in production processes, decreasing price of industrial robots, etc. In order to depict the actual representation of industrial robots in the world, we have to conduct an analysis of their representation on annual and total level by continents, as shown in Fig. 2 [15–29].

0

2010 2011 2012 2013 2014 2015 2016

0

2010 2011 2012 2013 2014 2015 2016 Asia/Australia

Fig. 2. The representation of industrial robots in the automation of production processes in the world on annual and total level for the period 2010–2016

The tendency of representation of industrial robots at the annual level, Fig. 2.a, indi‐ cates that Asia/Australia holds the first place by the presence of industrial robots in the production processes of the industry. We see the continuous increase in the application of robots in production processes from year to year in the period 2010–2016, so that the representation reached about 191.000 industrial robot units in 2016. The second place is held by Europe, that demonstrates a growing tendency, but unlike Asia/Australia, it is a slight increase from year to year. In 2016 it reached the value of about 56.000

0

2009 2010 2011 2012 2013 2014 2015 2016

0

2009 2010 2011 2012 2013 2014 2015 2016 x 1000

Number of units Number of units

259.000 1.828.024

1.020.731

60.011

Fig. 1. The representation of industrial robots in the automation of production processes in the world on annual and total level for the period 2009–2016

industrial robot units, which compared to Asia/Australia is almost four times less. The third place is held by America with a slight increasing tendency, with about 41.000 industrial robot units used in 2016, which is around five times less than Asia/Australia in the same year. In regard to the representation of industrial robots at the overall level, Fig. 2.b, we can see that the tendency in all three continents has a growing character. It is more distinct in Asia/Australia, which holds the first place, and in 2016 the represen‐ tation reached about 1 million industrial robot units. Europe has a slower tendency of representation, which in 2016 reached about 460.000 units, whereas America marked around 300.000 industrial robot units in the same year. There is a far less difference in the representation of industrial robots in Europe and America compared to Asia/ Australia at the overall level than at the annual level. We have to note that the analysis did not include the continent of Africa, because the representation is very small and cannot be compared with other three continents. We have conducted the analysis of the representation of industrial robots in the four developed countries in the world where industrial robots are most widely used. The tendency of presence of industrial robots in these countries is shown in Fig. 3 [15–21].

Number of units

Fig. 3. Annual tendency of representation of industrial robots in the period 2010–2016 in four top countries: China, Japan, USA and Germany

units in 2016. The third place is held by USA, with the similar increasing trend of use of industrial robots in the recent years, which in 2016 amounted to about 31.400 robot units. The fourth place is reserved for Germany, where tendency is constant over the last few years, and in 2016 it reached about 20.000 industrial robot units. Industrial robots are installed on those jobs where they can protect the health of workers, assist them with heavy and monotonous jobs, and gain greater accuracy. The first group of tasks includes all welding processes, because they are harmful for health, and are largely used in the automotive industry where automation of welding processes is advanced [22–28]. For these reasons we have conducted the analysis of the representation of industrial robots in the welding processes.

3

Automation of Welding Production Processes by Use of Industrial

Robots

Welding procedures: spot welding, arc welding, laser welding, and soldering are part of procedures that are dangerous for workers to perform because of the dangerous gases that can damage their health. In addition, these are boring, difficult and monotonous jobs that should be avoided by the workers. Industrial robots must be used instead, except in specific tasks when it is not possible to apply robots. In order to obtain the real illustration of the automation of these jobs in the world, we need to conduct an analysis of the representation of industrial robots in welding processes. The representation of industrial robots in welding processes is shown in Fig. 4. The statistical data on the tendency of representation of industrial robots were obtained from the International Federation of Robotics (IFR), the UN Economic Commission for Europe (UNECE) and the Organi‐ zation for Economic Co-operation development (OECD) [3, 4, 15–21].

Number of units

Fig. 4. Annual tendency of representation of industrial robots in the welding process worldwide and on the continents of Asia/Australia, Europe and North America for the period 2010–2016 [15– 21]

it can be seen that the representation in welding processes is 25%, representing one quarter of used industrial robots in all processes worldwide. The first place by the pres‐ ence of industrial robots in welding processes is held by Asia/Australia with growing tendency each year. In 2016 about 41.400 industrial robot units were used in Asia/ Australia, representing 2/3 of the total industrial robot representation in welding processes in the world. In the period from 2010 to 2016 the continent of Asia/Australia has increased the representation of robots in welding processes with total 23.000 robotic units, i.e. almost 100%. Representation of industrial robots in welding processes is far behind on the continents of America and Europe, while the continent of Africa was eliminated in this analysis due to the fact that the representation is negligible in relation to other three continents. The representation of industrial robots in welding processes in the North America can be considered as constant each year, and in 2016 it was about 13.154 industrial robots units. On the continent of Europe, the illustration of industrial robot representation in welding processes is somewhat different, as the industrial robots’ representation in 2010 and 2011 was higher than in the last five years. It can be said that the representation is constant from year to year (period 2012–2016), and in 2016 there were about 8.186 robot units. Therefore, we can conclude that the tendency of industrial robot application in welding processes is to be expected, when compared to the overall tendency of industrial robot application on the continents, as shown in Fig. 2, and the application of industrial robots by countries, as illustrated in Fig. 3. The reason for this conclusion lies in the fact that China, which is located on the continent of Asia/Australia, is the country with the largest representation of industrial robots in the world, with a tendency of increasing application in the following years. Higher number of industrial robots is installed in the automotive industry where welding processes are represented [29–35]. In order to obtain the real illustration of the tendency of the representation of industrial robots in automotive industry and how many industrial robots were installed in welding production processes, we have conducted an analysis of their representation in this industry in the period 2010–2016, as shown in Fig. 5 [15–21].

Number of units

Fig. 5. Annual tendency of the representation of industrial robots worldwide in the automotive industry and welding processes for the period 2010–2016

we come to the conclusion that about 40% of industrial robots are represented in the automotive industry each year in relation to the total representation of industrial robots in all other production processes. In 2016, around 103.323 robot units were used in the automotive industry, which presents a very high level of representation, while in the same year the representation of robot units in welding processes amounted to about 65.000 units, accounting for 25% of the total number of industrial robots used in other processes worldwide. We can analyze the representation of industrial robots by industry for 2016.

The accurate illustration of the representation of industrial robots in industrial branches can be seen in Fig. 6(a), which indicates the percentage of the representation of industrial robots in 2016. We come to the conclusion that the automotive industry holds the first place with usage of about 39% of industrial robots in 2016, which is reasonable conclusion, followed by the electric/electronic industry with about 34% of industrial robots, metal industry with about 11% of industrial robots, plastic and rubber industry (i.e. chemical) with about 7% of industrial robots, and at the end food industry with about 3% of industrial robot units. Figure 6(b) shows the representation of industrial robots in welding processes in relation to the total representation of industrial robots in the automotive industry in 2016, which is about 103.323 robot units. It is notable that 63% of industrial robots in the automotive industry are used in welding processes, whereas 37% of industrial robots are used in other processes of the automotive industry. The production processes of the automotive industry in which car body products are manufactured use the following welding methods: arc welding, spot welding and laser welding. The first two processes are far more representative in car body production in the automotive industry, and therefore the analysis was conducted of the presence of industrial robots in these processes. So far, the analysis of the representation of industrial robots in laser welding was omitted, due to the fact that industrial robots are far less used than in the other two processes.

a – Representation by industry

b – Representation in welding compared to representation in automotive industry

Fig. 6. Percentage of representation of industrial robots in 2016 in industrial branches and welding processes compared to other processes in the automotive industry in 2016 [15]

we analyze the presence of industrial robots in the arc welding process, we can see that the representation of robots is smaller compared to the spot welding process. In 2016 the representation of industrial robots in this welding process was around 2.415 units in the world. In order to obtain a ratio of representation of industrial robots in all welding processes in the world, we have analyzed the percentage of industrial robots in 2016, as shown in Fig. 8.

Number of units

Welding pprocess

Arc Spot we

welding elding

65.004

25.415 34.056

Fig. 7. The tendency of annual representation of industrial robots in welding processes in the world and representation of arc welding and spot welding in the period 2010–2016 [7, 15–21]

Numbe

Fig. 9. The tendency of annual vehicle production worldwide and in four countries with the largest vehicle production in the period 2010–2016 [11–14]

The tendency of vehicle production in the world (Fig. 9.a) is growing on annual basis, and in 2016 94.997.000 units of vehicles were produced. The analysis of vehicle produc‐ tion in the countries with highest vehicles production in the world (Fig. 9.b), namely: China, USA, Japan and Germany (these countries were selected because of the highest representation of industrial robots, Fig. 3), has established that China is the world’s leader in vehicle production with around 28.431.000 cars units produced in 2016. China is in the first place in the world by application of industrial robots. The second place, according to the vehicles production in the world, is held by the USA, with annual increasing tendency in production that in 2016 reached 18.293.000 produced vehicle units. Japan’s vehicle production positions it in the third place with annual growth, which in 2016 amounted to 13.237.000 vehicle units produced. Based on Fig. 3, we have noted that Japan is the second in the world by the representation of industrial robots, followed the USA in the third place, whereas in the vehicles production the situation is reverse. The reason is that more industrial robots are installed in the electronic and electric industry compared to the automotive industry in Japan. The fourth place in world production of vehicles is held by Germany with continuous tendency, so that in 2016 around 6.062.000 units of industrial robots were produced. As we have stated, the largest representation of industrial robots is in two welding processes, namely arc welding and spot welding processes. In order to obtain an overview of the presence of industrial robots in these two welding processes in the world, an analysis was conducted of their representation on the continents, as shown in Fig. 10 [15–21].

that the sudden trend of annual increase of application of industrial robots in Asia/ Australia in 2016 reached about 20.621 robot units, which is extremely high in relation to other countries when it comes to industrial robots and vehicle production. This is a consequence of Chinese technological development strategy named “Made in China 2025”. The second place is held by North America with increasing representation of industrial robots in the spot welding process, that in 2016 amounted to about 8.932 industrial robot units, which is two times more than in arc welding process. Europe is in the third place with the declining tendency of representation of industrial robots in the spot welding process, which in 2016 reached 1.564 industrial robot units. The reason for this reduced representation of industrial robots in spot welding process are manifold, one of which being that the automotive companies are transferring their production processes outside of Europe. The representation of industrial robots in arc welding and spot welding processes in the countries of China, USA, Japan and Germany is shown in Fig. 11 [8–21].

Fig. 11. The tendency of annual representation of industrial robots in the automation of two welding processes: arc welding and spot welding in China, North America, Japan and Germany in the period 2010–2016

As shown in Fig. 11(a), China demonstrates growing tendency of use of industrial robots in the process of arc welding during the period 2010–2016, with a decline in the representation in the last two years compared to 2014. In 2016 the representation amounted to 8.088 industrial robot units. With the far less presence of industrial robots compared to China, USA holds the second place with a slight rising trend that in 2016 reached 3.948 units of industrial robots, which is two times less than in China in the same year. The third place is held by Japan with almost the same trend as the USA, which in 2016 reached value of 3.687 industrial robot units. The fourth place by the representation of industrial robots in the arc welding process is held by Germany, whose tendency is almost constant in the period 2010–2016, and in 2016 amounted to 1.157 units. Trends of the representation of industrial robots in the process of spot welding are different in relation to the trends of representation of industrial robots in arc welding process, as shown in Fig. 11(b). By 2013, the order of application of industrial robots per country was as follows: USA, China, Japan, and finally Germany. Since 2013, China holds the first place in the application of robots in the spot welding process with a growing tendency in the period 2010–2016, so that in 2016 representation of industrial robots in China reached 10.772 units of industrial robots, which is almost 2,500 more robots used than in the arc welding process in the same year. USA holds the second place with increasing annual trend of representation, that in 2016 amounted to 8.362 robot units, which is two times more than in the arc welding process. Japan is holding the third place with a slight oscillating annual tendency of representation which in 2016 reached about 2.854 industrial robot units in the process of spot welding. The last place is held by Germany that in 2010 and 2011 held the first place. The representation of industrial robots in Germany has begun to decline since 2011, so that in 2016 it amounted to about 673 industrial robot units. In 2010 and 2011, Germany was in the first place in the tendency of representation of industrial robots in the process of spot welding, but in the last five years the trend has declined, so that in 2016 it reached its lowest value. There are many reasons for this tendency [28–35]. One reason is that vehicle manufacturers and vehicle suppliers in Germany are increasingly investing in electric and hybrid vehi‐ cles, another reason is that automotive companies are organizing production in other countries around the world, etc.

4

Conclusion

Based on the analysis of the automation of the welding production processes by use of industrial robots worldwide, and countries with the largest vehicle production, we can make the following conclusions:

• The tendency of application of industrial robots in the automation of production processes in the world is continually increasing on an annual and total level, so that in 2016 annual level reached about 259.000 industrial robot units, whereas overall level reached about 1.8 million industrial robot units, as shown in the diagrams in Fig. 1(a), and (b).

is growing from year to year in the period 2010–2016. The first place is held by Asia/ Australia, followed by America and lastly Europe. However, when considering the tendency of automation of production processes at the overall level of installed industrial robots, it can be noted that the order is somewhat different. Again, the first place is held by Asia/Australia, followed by Europe and finally America. Continent of Asia/Australia has a far greater automation of production processes than Europe and America.

• In regard to the representation of industrial robots in the automation of production processes in four top countries, we can conclude that the tendency is constantly increasing, with China in the first place, followed by Japan, USA and Germany. Compared to other three countries, China is far more advanced, since it installed around 82.000 industrial robot units in 2016, like all three countries together. • The tendency of the automation of welding production processes worldwide is

increasing annually, with continent of Asia/Australia being in the first place, as indi‐ cated by the diagram in Fig. 4. The second place is held by America, followed by Europe. We have to state that around 65.000 robot units were used in welding processes in 2016 worldwide, of which 2/3 are related to Asia/Australia.

• The highest representation and application of industrial robots in the world is in the automotive industry, particularly in the welding processes of the automotive industry, as indicated in the Fig. 5.

• In regard to the automation of production process in 2016, we can see that the auto‐ motive industry is in the first place with 39% of industrial robots, followed by elec‐ trical/electronic industry with 34%, metal industry with 11%, rubber and plastic industry with 7% and finally food industry with 3% of overall representation of industrial robots in the world.

• The highest number of industrial robots is installed in production processes of arc welding and spot welding, as shown in Fig. 7. The first place is held by spot welding, followed by arc welding, both indicating growing tendency in the representation of industrial robots.

• Analysis of Fig. 8 shows that in 2016 the representation of industrial robots in spot welding process was 52%, followed by arc welding with 39%, soldering process with 4% and finally laser welding with 1%.

• Knowing that the automation of welding processes is mostly used in the automotive industry, an analysis was conducted on the vehicle production in the world and in the four top countries where industrial robots were represented the most: China, USA; Japan and Germany, as indicated in Fig. 9. The tendency of vehicle production has a growing nature. The first place is held by China with the highest vehicle production in the past six years. China is also in the first place in terms of number of industrial robots installed in the automation processes in the industry. The second place is held by USA, followed by Japan and Germany.

• The tendency of annual representation of industrial robots in the automation of two welding processes: arc welding and spot welding in China, North America, Japan and Germany for the period 2010–2016 is shown in Fig. 11. Based on this Figure we see that China holds the first place and differs from other three countries. In addition, it was shows that the tendency of representation of industrial robots in spot welding is decreasing the Germany.

• Finally, we can conclude that the tendency of automation of welding production processes will have a growing character in the future, in all manufacturing processes. Such a conclusion is driven by the fact that the world at the moment is in the fourth industrial revolution that the Germans refer to as “Industry 4.0”. Its implementation in production processes and in the robotic technology itself will enable new gener‐ ation of industrial robots that can securely work together with man and machine, without setting up the fences between them. Robots will gain or adapt new skills through learning processes, and become smarter robots using a great deal of data and collective learning. They will have simplified applications. Continuous quality improvement requires sophisticated high-tech robotic systems. Robots improve the quality of work by taking dangerous, painful, and dirty jobs that are not possible or safe for people to perform.

References

1. Doleček, V., Karabegović, I.: Robots in the industry. Technical Faculty of Bihac, Bihac, Bosnia and Herzegovina (2008)

2. Doleček, V., Karabegović, I: Robotics. Technical Faculty of Bihac, Bihac, Bosnia and Herzegovina (2002)

3. Karabegović, I.: Role of industrial robots in the development of automotive industry in China. Int. J. Eng. Works 3(12), 92–97 (2016). ISSN 2349-6495, www.kwpublisher.com/? paper=1-114-The-Role-of-Industrial-Robots-in-the-Development-of-Automotive-Industry-in-China#Author

4. Karabegović, I., Husak, E.: China as a leading country in the world in automation of automotive industry manufacturing processes. In: IV International Congress Motor Vehicles & Motors 2016, MVM-2016, 06–08 October 2016, Kragujevac, Serbia (2016)

5. Karabegović, I., Doleček, V.: The tendency of application of industrial robots in the automotive, electrical engineering and metal industries worldwide. In: 3rd International Scientific Conference, COMETa 2016, 07–09 December 2016. University of East Sarajevo, Bosnia and Herzegovina (2016)

6. Kalpakjian, S., Schmid, S.: Manufacturing Processes for Engineering Materials, 5th edn., pp. 125–150. Amazon, USA (2007). ISBN-13:978-0132272711

7. Sulavik, C., Portnoy, M., Waller, T.: How a new generation of robots is transforming manufacturing. Manufacturing Institute USA, September 2014, Gaithersburg, USA, pp. 1– 13 (2014)

8. de Luca, A.: Industrijal Robotics. Sapienze, University of Roma, Roma, Italia (2016) 9. McKerrow, P.J.: Introduction to Robotics. Addison-Wesley Publishing Company, Sydney

(1991)

10. Wolka, D.W.: Roboter sisteme. Technishe Universität des Saarlandes im Stadtwald, Deutschland (1992)

11. Good Jobs in the Age of Automation. BSR-The Business af a Better World, New York, USA, pp. 1–28 (2015)

12. Verband Deutscher Verkehrsunternehmen VDV: Jahresbericht 2015/2016, Koln, Deutschland 13. Friis, D.: Editorial, Universal Robots, Editorial_WR_Industrial_Robots_2016. www.ifr.org/

news/ifr-press-release/world-robotics-report-2016-832/

14. Bunse, B., Kagermann, H., Wahlster, W.: Industrie 4.0, Smart Manufacturing for the Future, Germany Trade and Invest, 2016, Berlin, Germany (2016). www.gtai.com

15. World Robotics 2016 (2016). United Nations, New York and Geneva 16. World Robotics 2015 (2015). United Nations, New York and Geneva 17. World Robotics 2014 (2014). United Nations, New York and Geneva 18. World Robotics 2012 (2012). United Nations, New York and Geneva 19. World Robotics 2011 (2011). United Nations, New York and Geneva 20. World Robotics 2010 (2010). United Nations, New York and Geneva 21. World Robotics 2009 (2009). United Nations, New York and Geneva

22. Karabegović, I., Husak, E.: Significance of industrial robots in development of automobile industry in Europe and the World. J. Mob. Veh. 40(1), 7–16 (2014). University of Kragujevac, Faculty of Engineering, Kragujevac, Serbia (2014). ISSN 1450-5304

23. Makowieckaja, O.: Industrial robots on the market of means of production automation, pp. 22–27. Biuletyn Instytute Spawalnictwa, No. 2. Gliwice, Czechoslovak (2015). ISSN 0867-583X

24. Karabegović, I., Karabegović, E., Husak, E.: Application analyses of industrial robot in World automobile industry in 2010. J. Int. Sci. Pub. Mater. Methods Technol. 5(2), 336–345 (2011). ISSN 1313-2539

25. Institute for Public Policy Research: Technology, Globalization, and the Future of Work in Europe: Essays on Employment in a Digitized Economy (2015). http://

www.oxfordmartin.ox.ac.uk/downloads/academic/technology-globalisation-future-ofwork_Mar2015.pdf

26. Mannan, B., Khurana, S.: Enablers and barriers for introduction of robotics as an AMT in the Indian industrie. Int. J. Comput. Appl. 19–24 (2012). https://www.researchgate.net/ publication/267450380, https://doi.org/10.13140/2.1.2625.5368

27. Ray, J., Atha, K., Francis, E., Dependahl, C., Mulvenon, J., Alderman, D.: China’s industrial and military robotics development. Research Report Prepared on Behalf of the U.S.-China Economic and Security Review, Commission, Center for Intelligence Research and Analysis (CIRA), October 2016, Vienna, Austria, pp. 78–84 (2016)

28. Holdren, J.: National Science and Technology Council Washington, D.C. 20502, 15 February 2012, Washington, USA, pp. 4–27 (2012)

29. Kozul-Wright, R.: Robots and industrialization in developing countries, UNCTAD/ PRESS/PB/2016/6 (No. 50), United Nations Conference on Trade And Development UNCATD, Geneva, Switzerland, pp. 1–4 (2015). www.unctad.org

30. Paper, W.: Robots fuel the next wave of U.S. productivity and job growth. Association for Advancing Automation, October 2015, Michigen, USA, pp. 11–19 (2015). www.a3automate.org

31. Robotics 2020 Strategic Research Agenda for Robotics in Europe, Produced by euRobotics aisbl, Draft 0v42 11/10/2013, pp. 25–43. http://www.eurobotics-project.eu

32. Yang, G.-Z.: The Next Robotic Industrial Revolution, Manufacturing Robotics, Robotics and Autonomous Systems (RAS). UK-RAS Manufacturing Review 2015–2016, pp. 2–17 (2016). ISSN 2398-4422, www.ukras.org

34. Asia in Tomorrows World: Technology Unveilsa New Paradigm, 30th Anniversary Issue, Asia Today International, pp. 1–4, October/November 2013. www.asiatodayinternational.com 35. Roehricht, K.: Study on emerging markets, with special focus on Asia. Robotics Coordination

Action for Europe, KU Leuven, pp. 1–14 (2016)

Ahmed Kovacevic1(&), Sham Rane2, and Nikola Stosic1 1

Centre for Compressor Technology, City, University of London, London EC1V 0HB, UK

2 Department of Engineering Science, University of Oxford, Oxford, UK

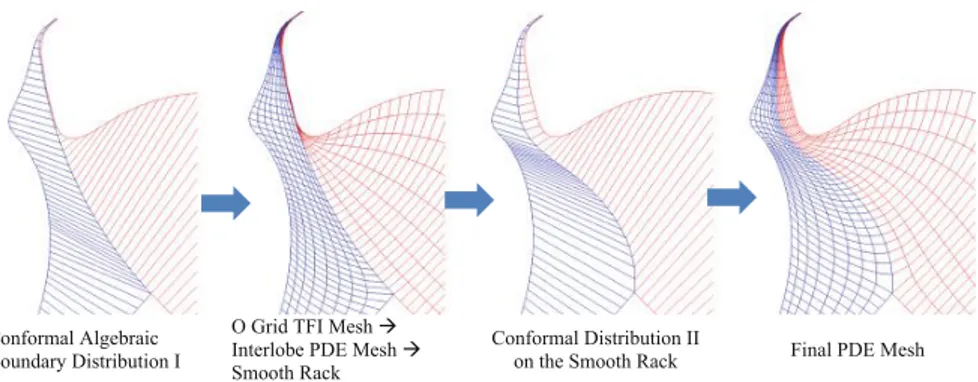

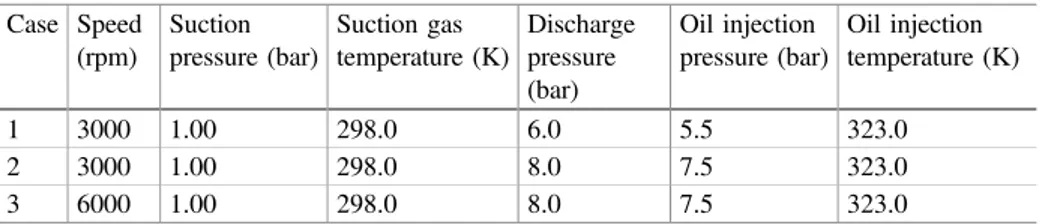

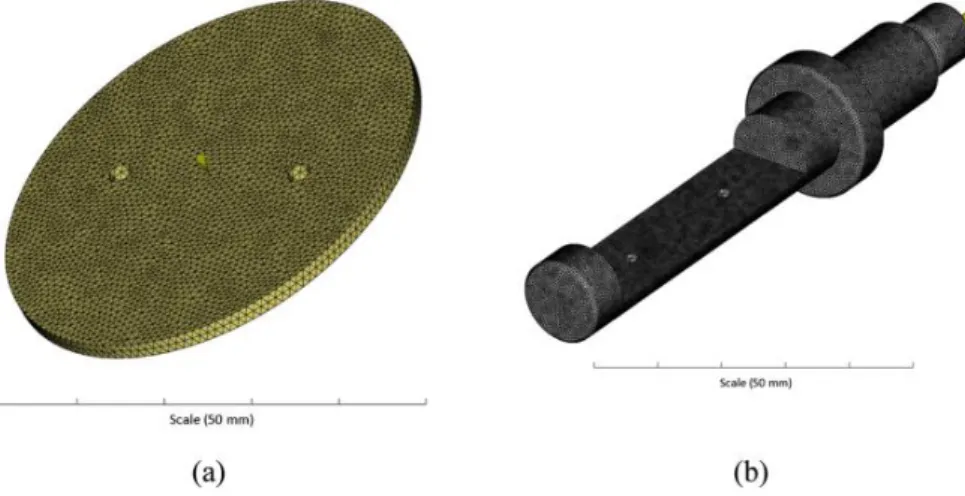

Abstract. Twin screw compressors used in refrigeration, gas and air com-pression represent approximately 80% of the millions of industrial positive displacement compressors produced globally each year. More than 95% of these are oil injected. Oil injected twin screw compressor is just one type of multi-phase screw machines. Other include twin screw expanders, multimulti-phase pumps and motors. Multiphase twin screw machines are traditionally analysed and designed by use of chamber thermodynamic models. However for further improvement of efficiency and reliability it is necessary to use more advanced modelling techniques such as 3D Computational Fluid Dynamics (CFD). In order to obtain fast and accurate solution of multiphase screw machines using CFD, it is important that a numerical grid of the highest quality is generated quickly and reliably. For that purpose, a deforming grid of a twin screw machine is generated using algebraic transfinite interpolation upon which an elliptic partial differential equations (PDE) of the Poisson’s form are solved numerically to produce smoothfinal computational mesh. This paper gives a review of the current state of art in the application of CFD in modelling of multiphase twin screw machines including compressors, expanders and pumps. Future chal-lenges and development trends in application of CFD for multiphase twin screw machines are also shown in the paper.

Keywords: Screw compressor

Computational Fluid Dynamics Grid generation

Conformal grid

1 Introduction

Compressors are used to compress air, refrigerants and various gases in many different industrial sectors. It is estimated that they consume more than 17% energy produced in developed countries [19]. This pollutes the environment with more than 3000 MtCO2 per year, while energy costs exceed €275 billion per year [4]. Based on the same source, it is forecasted that the global CO2emission will increase by 28% from 2015 to 2030. On the other side, the latest EU targets [5] for 2020 are to reduce the CO2 emissions by 20% from the levels recorded in 1990. This requires at least 20% of energy to be produced by renewable sources and the increase in energy efficiency of

![Table 4. Influence of variables on flap part quality S. M. [%] Vol. S.[%] D. E. X[%] D. E](https://thumb-ap.123doks.com/thumbv2/123dok/3860772.1842107/57.659.128.552.697.854/table-influence-variables-flap-quality-s-m-vol.webp)

![Fig. 2. Frame: fatigue test with pedalling forces [ 2 ] (Key: R w -height of rigid mount and](https://thumb-ap.123doks.com/thumbv2/123dok/3860772.1842107/63.659.140.554.435.641/fig-frame-fatigue-pedalling-forces-height-rigid-mount.webp)