LIFE

CYCLE

ANALYSIS

LCA merupakan suatu metode analisis lingkungan dan

dampak lingkungan yang berhubungan dengan suatu

produk, proses, atau jasa; dengan jalan melakukan

inventori input enerji dan material, serta limbahnya yang

dibuang ke lingkungan; analisis dampak lingkungan dari

input dan limbah, serta interpretasi hasil-hasilnya untuk

digunakan dalam pengambilan keputusan.

Ketersediaan perangkat lunak (software) mempermudah

pelaksanaan LCA yang membutuhkan basis data yang

besar.

Life Cycle Asessment merupakan satu pendekatan “Cradle to

Grave” dimulai dari pengambilan bahan mentah dari lingkungan

untuk membuat produk dan berakhir pada pembuangan limbah ke

lingkungan.

Esensi dari Life Cycle Assessment adalah evaluasi dampak

teknologi, ekonomi dan lingkungan, yang relevan dengan bahan

mentah (material), proses dan/atau produk, sepanjang siklus

hidup mulai dari pembuatannya hingga menjadi limbah.

LCA = LIFE-CYCLE AANALYSIS

Analisis Siklus Hidup.

A

life-cycle assessment

(

LCA

, also known as

life-cycle

analysis

,

ecobalance

, and

cradle-to-grave analysis

) is a

technique to assess environmental impacts associated with

all the stages of a product's life from-cradle-to-grave (i.e.,

from raw material extraction through materials processing,

manufacture, distribution, use, repair and maintenance,

and disposal or recycling).

LCAs can help avoid a narrow outlook on environmental

concerns by:

1. Compiling an inventory of relevant energy and material inputs

and environmental releases;

2. Evaluating the potential impacts associated with identified

inputs and releases;

3. Interpreting the results to help make a more informed decision.

GOALS AND PURPOSE

The goal of LCA is to compare the full range of environmental effects assignable to products and services in order to improve processes,

support policy and provide a sound basis for informed decisions. The term life cycle refers to the notion that a fair, holistic assessment

requires the assessment of raw-material production, manufacture,

distribution, use and disposal including all intervening transportation steps necessary or caused by the product's existence.

There are two main types of LCA.

Attributional LCAs seek to establish the burdens associated with the production and use of a product, or with a specific service or process, at a

point in time (typically the recent past).

Consequential LCAs seek to identify the environmental consequences of a decision or a proposed change in a system under study (oriented to the future), which means that market and economic implications of a decision

may have to be taken into account.

Social LCA is a different approach to life cycle thinking intended to assess social implications or potential impacts. Social LCA should be considered

as an approach that is complementary to environmental LCA.

The procedures of life cycle assessment (LCA) are part of the ISO 14000

environmental management standards: in ISO 14040:2006 and 14044:2006. (ISO 14044 replaced earlier versions of ISO 14041 to ISO

14043.)

1. Thomas,J.A.G., ed: Energy Analysis, ipc science and technology press & Westview Press, 1977, ISBN 0-902852-60-4 or ISBN 0-89158-813-2

Empat tahapan Utama

According to the ISO 14040[4] and 14044[5] standards, a Life Cycle

Assessment is carried out in four distinct phases as illustrated in the figure shown to the right. The phases are often interdependent in that the results

of one phase will inform how other phases are completed.

LCA = LIFE-CYCLE ASSESSMENT

4.ISO 14040 (2006): Environmental management – Life cycle assessment – Principles and framework, International Organisation for Standardisation (ISO), Geneve

5.ISO 14044 (2006): Environmental management – Life cycle assessment – Requirements and guidelines, International Organisation for Standardisation (ISO), Geneve

INTERPRETASI

ANALISIS

INVENTORY

PENDUGAAN

DAMPAK

Goal and scope

An LCA starts with an explicit statement of the goal and scope of

the study, which sets out the context of the study and explains

how and to whom the results are to be communicated. This is a

key step and the ISO standards require that the goal and scope of

an LCA be clearly defined and consistent with the intended

application. The goal and scope document therefore includes

technical details that guide subsequent work:

1. The functional unit, which defines what precisely is being

studied and quantifies the service delivered by the product

system, providing a reference to which the inputs and outputs

can be related. Further, the functional unit is an important

basis that enables alternative goods, or services, to be

compared and analyzed.

[6]2. The system boundaries;

3. Any assumptions and limitations;

4. The allocation methods used to partition the environmental

load of a process when several products or functions share

the same process; and

5. The impact categories chosen.

6. Rebitzer, G. et al. (2004). Life cycle assessment Part 1: Framework, goal and scope

definition, inventory analysis,and applications. Environment International. 30(2004), 701-720.

Life cycle inventory

Life Cycle Inventory (LCI) analysis involves creating an inventory of flows from and to nature for a product system. Inventory flows include inputs of water, energy, and raw materials, and releases to air, land, and water. To develop the inventory, a flow model of the technical system is constructed

using data on inputs and outputs.

The flow model is typically illustrated with a flow chart that includes the activities that are going to be assessed in the relevant supply chain and

gives a clear picture of the technical system boundaries. The input and output data needed for the construction of the model are collected for all

activities within the system boundary, including from the supply chain (referred to as inputs from the techno-sphere).

The data must be related to the functional unit defined in the goal and scope definition. Data can be presented in tables and some

interpretations can be made already at this stage. The results of the inventory is an LCI which provides information about all inputs and outputs in the form of elementary flow to and from the environment from

all the unit processes involved in the study.

7. Steinbach, V. and Wellmer, F. (May 2010). “Review: Consumption and Use of Non-Renewable Mineral and Energy Raw Materials from an Economic Geology Point of View.” Sustainability. 2(5), pgs. 1408-1430. Retrieved from <http://www.mdpi.com/2071-1050/2/5/1408

Life cycle inventory

Inventory flows can number in the hundreds depending on the system boundary. For product LCAs at either the generic (i.e., representative industry averages) or brand-specific level, that data is typically collected through survey questionnaires. At an industry level, care has to be taken to ensure that questionnaires are completed by a representative sample

of producers, leaning toward neither the best nor the worst, and fully representing any regional differences due to energy use, material sourcing

or other factors. The questionnaires cover the full range of inputs and outputs, typically aiming to account for 99% of the mass of a product, 99%

of the energy used in its production and any environmentally sensitive flows, even if they fall within the 1% level of inputs.

One area where data access is likely to be difficult is flows from the techno-sphere. The technosphere is more simply defined as the man-made world. Considered by geologists as secondary resources, these resources are in theory 100% recyclable; however, in a practical sense the

primary goal is salvage. [7]

For an LCI, these technosphere products (supply chain products) are those that have been produced by man and unfortunately those completing a questionnaire about a process which uses man-made product as a means to an end will be able to specify how much of a given

input they use. Typically, they will not have access to data concerning inputs and outputs for previous production processes of the product. The entity undertaking the LCA must then turn to secondary sources if it does

not already have that data from its own previous studies. National databases or data sets that come with LCA-practitioner tools, or that can be readily accessed, are the usual sources for that information. Care must

then be taken to ensure that the secondary data source properly reflects regional or national conditions.

7. Steinbach, V. and Wellmer, F. (May 2010). “Review: Consumption and Use of Non-Renewable

Inventory analysis is followed by impact assessment. This phase of LCA is aimed at evaluating the significance of potential environmental impacts

based on the LCI flow results. Classical life cycle impact assessment (LCIA) consists of the following mandatory elements:

selection of impact categories, category indicators, and characterization models;

the classification stage, where the inventory parameters are sorted and assigned to specific impact categories; and

impact measurement, where the categorized LCI flows are characterized, using one of many possible LCIA methodologies, into common

equivalence units that are then summed to provide an overall impact category total.

In many LCAs, characterization concludes the LCIA analysis; this is also the last compulsory stage according to ISO 14044:2006. However, in addition to the above mandatory LCIA steps, other optional LCIA elements

– normalization, grouping, and weighting – may be conducted depending on the goal and scope of the LCA study. In normalization, the results of the impact categories from the study are usually compared with the total impacts in the region of interest, the U.S. for example. Grouping consists

of sorting and possibly ranking the impact categories. During weighting, the different environmental impacts are weighted relative to each other so

that they can then be summed to get a single number for the total environmental impact.

ISO 14044:2006 generally advises against weighting, stating that “weighting, shall not be used in LCA studies intended to be used in comparative assertions intended to be disclosed to the public”. This advice is often ignored, resulting in comparisons that can reflect a high

degree of subjectivity as a result of weighting.

LCIA =

Interpretation

Life Cycle Interpretation is a systematic technique to identify, quantify, check, and evaluate information from the results of the life cycle inventory

and/or the life cycle impact assessment. The results from the inventory analysis and impact assessment are summarized during the interpretation

phase.

The outcome of the interpretation phase is a set of conclusions and recommendations for the study. According to ISO 14040:2006, the

interpretation should include:

1. Identification of significant issues based on the results of the LCI and LCIA phases of an LCA;

2. Evaluation of the study considering completeness, sensitivity and consistency checks; and

3. Conclusions, limitations and recommendations.

A key purpose of performing life cycle interpretation is to determine the level of confidence in the final results and communicate them in a fair, complete, and accurate manner. Interpreting the results of an LCA is not as simple as "3 is better than 2, therefore Alternative A is the best choice"!

Interpreting the results of an LCA starts with understanding the accuracy of the results, and ensuring they meet the goal of the study. This is accomplished by identifying the data elements that contribute significantly to each impact category, evaluating the sensitivity of these significant data elements, assessing the completeness and consistency of the study, and

drawing conclusions and recommendations based on a clear understanding of how the LCA was conducted and the results were

developed.

Reference test

More specifically, the best alternative is the one that the

LCA shows to have the least cradle-to-grave environmental

negative impact on land, sea, and air resources.

[8]8. Curran, Mary Ann. "Life Cycle Analysis: Priciples and Practice". Scientific Applications International Corporation. Retrieved 24 October 2011.

LCA = LIFE-CYCLE ASSESSMENT

LCA estimates the impacts or costs of resources associated with a project from ‘cradle to grave’ – including extraction, processing, use, and disposal. The technique is often used to compare options for a project, informing a selection that is less environmentally

LCA uses

Based on a survey of LCA practitioners carried out in 2006[9] LCA is mostly

used to support business strategy (18%) and R&D (18%), as input to product or process design (15%), in education (13%) and for labeling or product declarations (11%). LCA will be continuously integrated into the built environment as tools such as the European ENSLIC Building project

guidelines for buildings or developed and implemented, which provide practitioners guidance on methods to implement LCI data into the

planning and design process.[10]

Major corporations all over the world are either undertaking LCA in house or commissioning studies, while governments support the development of

national databases to support LCA. Of particular note is the growing use of LCA for ISO Type III labels called Environmental Product Declarations,

defined as "quantified environmental data for a product with pre-set categories of parameters based on the ISO 14040 series of standards, but

not excluding additional environmental information".[11][12] These third-party

certified LCA-based labels provide an increasingly important basis for assessing the relative environmental merits of competing products.

Third-party certification plays a major role in today's industry. Independent certification can show a company's dedication to safer and environmental

friendlier products to customers and NGOs.[13]

LCA also has major roles in environmental impact assessment, integrated waste management and pollution studies.

9. Cooper, J.S.; Fava, J. (2006). "Life Cycle Assessment Practitioner Survey: Summary of Results". Journal of Industrial Ecology.

10. Malmqvist, T; Glaumann, M; Scarpellini, S; Zabalza, I; Aranda, A (April 2011).

"Life cycle assessment in buildings: The ENSLIC simplified method and guidelines". Energy

36 (4): 1900-1907. Retrieved October 31, 2012.

11. S. Singh, B. R. Bakshi (2009). "Eco-LCA: A Tool for Quantifying the Role of Ecological

Resources in LCA". International Symposium on Sustainable Systems and Technology: 1–6.

doi:10.1109/ISSST.2009.5156770. ISBN978-1-4244-4324-6.

Data analysis

A life cycle analysis is only as valid as its data; therefore, it is crucial that data used for the completion of a life cycle analysis are accurate and current. When comparing different life cycle analyses with one another, it is crucial that equivalent data are available for both products or processes in question. If one product has a much higher availability of data, it cannot

be justly compared to another product which has less detailed data.[14]

There are two basic types of LCA data – unit process data and environmental input-output data (EIO), where the latter is based on national economic input-output data.[15] Unit process data are derived from

direct surveys of companies or plants producing the product of interest, carried out at a unit process level defined by the system boundaries for

the study.

Data validity is an ongoing concern for life cycle analyses. Due to globalization and the rapid pace of research and development, new materials and manufacturing methods are continually being introduced to the market. This makes it both very important and very difficult to use up-to-date information when performing an LCA. If an LCA’s conclusions are to be valid, the data must be recent; however, the data-gathering process

takes time. If a product and its related processes have not undergone significant revisions since the last LCA data was collected, data validity is

not a problem. However, consumer electronics such as cell phones can be redesigned as often as every 9 to 12 months,[16] creating a need for

ongoing data collection.

14.Scientific Applications International Corporation (May).

"Life cycle assessment: principles and practice". p. 88.

15."How Does GREET Work?". Argonne National Laboratory. 2010-09-03. Retrieved 2011-02-28. 16.Choney, Suzanne (24 February 2009). "Planned obsolescence: cell phone models". MSNBC.

Retrieved 28 October 2011.

Data analysis

The life cycle considered usually consists of a number of stages including: materials extraction, processing and manufacturing, product use, and product disposal. If the

most environmentally harmful of these stages can be determined, then impact on the environment can be efficiently reduced by focusing on making changes for that

particular phase.

For example, the most energy-intensive life phase of an airplane or car is during use due to fuel consumption. One of the most effective ways to increase fuel efficiency is to decrease vehicle weight, and thus, car and airplane manufacturers can decrease

environmental impact in a significant way by replacing aluminum with lighter materials such as carbon fiber reinforced fibers. The reduction during the use phase

should be more than enough to balance additional raw material or manufacturing cost.

14.Scientific Applications International Corporation (May).

"Life cycle assessment: principles and practice". p. 88.

15."How Does GREET Work?". Argonne National Laboratory. 2010-09-03. Retrieved 2011-02-28. 16.Choney, Suzanne (24 February 2009). "Planned obsolescence: cell phone models". MSNBC.

Retrieved 28 October 2011.

Economic input–output life cycle assessment

Economic input–output LCA (EIOLCA) involves use of aggregate sector-level data on how much environmental impact can be attributed to each sector of the economy and how much each sector purchases from other

sectors.[24]

Such analysis can account for long chains (for example, building an automobile requires energy, but producing energy requires vehicles, and building those vehicles requires energy, etc.), which somewhat alleviates the scoping problem of process LCA; however, EIOLCA relies on

sector-level averages that may or may not be representative of the specific subset of the sector relevant to a particular product and therefore is not suitable for evaluating the environmental impacts of products. Additionally

the translation of economic quantities into environmental impacts is not validated.[25]

24. Hendrickson, C. T., Lave, L. B., and Matthews, H. S. (2005). Environmental Life Cycle Assessment of Goods and Services: An Input–Output Approach, Resources for the Future Press ISBN 1-933115-24-6.

25.Limitations of the EIO-LCA Method and Models

Ecologically based LCA

While a conventional LCA uses many of the same approaches and strategies as an Eco-LCA, the latter considers a much broader range of

ecological impacts. It was designed to provide a guide to wise

management of human activities by understanding the direct and indirect impacts on ecological resources and surrounding ecosystems.

Eco-LCA is developed by Ohio State University Center for resilience, a methodology that quantitatively takes into account regulating and supporting services during the life cycle of economic goods and products. In this approach services are categorized in four main groups: supporting,

regulating provisioning and cultural services.[11]

11. S. Singh, B. R. Bakshi (2009). "Eco-LCA: A Tool for Quantifying the Role of Ecological Resources in LCA". International Symposium on Sustainable Systems and Technology: 1–6. doi:10.1109/ISSST.2009.5156770. ISBN 978-1-4244-4324-6.

LCEA = Life cycle energy analysis

Life cycle energy analysis (LCEA) is an approach in which all energy

inputs to a product are accounted for, not only direct energy inputs during manufacture, but also all energy inputs needed to produce components,

materials and services needed for the manufacturing process. An earlier term for the approach was energy analysis. With LCEA, the total life cycle energy input is established.

Diunduh dari: http://en.wikipedia.org/wiki/Life-cycle_assessment……. 5/1/2013

LCA = LIFE-CYCLE ASSESSMENT

Life Cycle Energy Assessment (LCEA) of Building Construction

Life Cycle Energy Assessment (LCEA) of building construction covers a range of the issues relevant to sustainable building development. LCEA includes the entire life cycle

of the product, process or activity, encompassing extracting and processing materials; manufacturing, transportation and distribution; use, reuse, maintenance; recycling and final disposal. Promoting LCEA of buildings would arouse attention to environmentally

friendly building designs, including energy efficient building design and selection of materials and construction methods that would incur lower impacts on the global, local

Energy production

It is recognized that much energy is lost in the production of energy commodities themselves, such as nuclear energy, photovoltaic electricity

or high-quality petroleum products. Net energy content is the energy content of the product minus energy input used during extraction and

conversion, directly or indirectly. A controversial early result of LCEA claimed that manufacturing solar cells requires more energy than can be

recovered in using the solar cell.

The result was refuted.[26] Another new concept that flows from life cycle

assessments is Energy Cannibalism. Energy Cannibalism refers to an effect where rapid growth of an entire energy-intensive industry creates a

need for energy that uses (or cannibalizes) the energy of existing power plants. Thus during rapid growth the industry as a whole produces no energy because new energy is used to fuel the embodied energy of future

power plants. Work has been undertaken in the UK to determine the life cycle energy (alongside full LCA) impacts of a number of renewable

technologies.[27][28]

26. David MacKay Sustainable Energy 24 February 2010 p. 41

27. McManus, M (2010). "Life cycle impacts of waste wood biomass heating systems: A case study of three UK based systems". Energy 35 (10): 4064–4070. doi:

10.1016/j.energy.2010.06.014.

28. Allen, S.R., G.P. Hammond, H. Harajli, C.I. Jones, M.C. McManus and A.B. Winnett (2008). Integrated appraisal of micro-generators: methods and applications. 161. pp. 73–86. doi:

10.1680/ener.2008.1+61.2.73

ENERGY RECOVERY

If materials are incinerated during the disposal process, the energy released during burning can be harnessed and used for electricity production. This provides a low-impact energy source, especially when compared with coal and natural gas[29] While incineration produces more

greenhouse gas emissions than landfilling, the waste plants are well-fitted with filters to minimize this negative impact.

A recent study comparing energy consumption and greenhouse gas emissions from landfilling (without energy recovery) against incineration (with energy recovery) found incineration to be superior in all cases except

for when landfill gas is recovered for electricity production.[30]

29. Damgaard, A, et. al. Life-cycle-assessment of the historical development of air pollution

control and energy recovery in waste incineration. Waste Management 30 (2010) 1244–1250. 30 Liamsanguan, C., Gheewala, S.H., LCA: A decision support tool for environmental

assessment of MSW management systems. Jour. of Environ. Mgmt. 87 (2009) 132–138.

Critiques

Life cycle assessment is a powerful tool for analyzing commensurable aspects of quantifiable systems. Not every factor, however, can be reduced to a number and inserted into a model. Rigid system boundaries

make accounting for changes in the system difficult. This is sometimes referred to as the boundary critique to systems thinking.

The accuracy and availability of data can also contribute to inaccuracy. For instance, data from generic processes may be based on averages,

unrepresentative sampling, or outdated results.[34]

Additionally, social implications of products are generally lacking in LCAs. Comparative life-cycle analysis is often used to determine a better process or product to use. However, because of aspects like differing system boundaries, different statistical information, different product uses,

etc., these studies can easily be swayed in favor of one product or process over another in one study and the opposite in another study

based on varying parameters and different available data.[35]

There are guidelines to help reduce such conflicts in results but the method still provides a lot of room for the researcher to decide what is

important, how the product is typically manufactured, and how it is typically used.

34.Malin, Nadav, Life-cycle assessment for buildings: Seeking the Holy Grail. Building Green, 2010.

35. Linda Gaines and Frank Stodolsky Life-Cycle Analysis: Uses and Pitfalls. Argonne National Laboratory. Transportation Technology R&D Center

36. National Council for Air and Stream Improvement Special Report No: 04-03. Ncasi.org. Retrieved on 2011-12-14.

37.FPInnovations

2010 A Synthesis of Research on Wood Products and Greenhouse Gas Impacts 2nd Edition p age 40

. (PDF) . Retrieved on 2011-12-14.

38. Bland, W.L. and Bell, M.M. (2007). "A holon approach to agroecology". International Journal of

Critiques

An in-depth review of 13 LCA studies of wood and paper products[36] found

[37] a lack of consistency in the methods and assumptions used to track

carbon during the product life cycle. A wide variety of methods and assumptions were used, leading to different and potentially contrary

conclusions – particularly with regard to carbon sequestration and methane generation in landfills and with carbon accounting during forest

growth and product use.

The Agroecology tool "agroecosystem analysis" offers a framework to incorporate incommensurable aspects of the life cycle of a product (such

as social impacts, and soil and water implications).[38]

This tool is specifically useful in the analysis of a product made from agricultural materials such as corn ethanol or soybean biodiesel because it can account for an ecology of contexts interacting and changing through

time. This analysis tool should not be used instead of life-cycle analysis, but rather, in conjunction with life-cycle analysis to produce a well-rounded

assessment.

34.Malin, Nadav, Life-cycle assessment for buildings: Seeking the Holy Grail. Building Green, 2010.

35. Linda Gaines and Frank Stodolsky Life-Cycle Analysis: Uses and Pitfalls. Argonne National Laboratory. Transportation Technology R&D Center

36. National Council for Air and Stream Improvement Special Report No: 04-03. Ncasi.org. Retrieved on 2011-12-14.

37.FPInnovations

2010 A Synthesis of Research on Wood Products and Greenhouse Gas Impacts 2nd Edition p age 40

. (PDF) . Retrieved on 2011-12-14.

38. Bland, W.L. and Bell, M.M. (2007). "A holon approach to agroecology". International Journal of Agricultural Sustainability 5 (4): 280–294.

LIFE CYCLE

ANALYSIS

Analysis of Environmental, Financial and

Social Impacts throughout the Life-cycle of

• The Concept of Environmental LCA

• Methodology of Environmental LCA;

• Goal and Scope

• Inventory Analysis

• Impact Assessment

• Interpretation

• Extending the scope of Environmental LCA;

• Economic LCA

• Social LCA

LCA

Diunduh dari:

http://www.scielo.org.za/scielo.php?pid=S1816-A life-cycle assessment (LChttp://www.scielo.org.za/scielo.php?pid=S1816-A) is a comprehensive environmental management tool used to investigate the environmental impacts of products, services and activities by taking a 'cradleto-grave' approach. The assessment scope includes the extraction and processing

•

Products do no pollute, but their production,

use and disposal do!

•

Product systems are composed of

interrelated processes

Life Cycle of Product Systems (Source: USEPA, 2006. Life Cycle Assessment: Principles and

Practice, Cincinnati, Ohio report no. 45268

Some products have a dominating

environmental load in production, some in

use, some in disposal:

Examples: books, furniture,

art etc.

Examples:

cars, television, airco etc.

Examples: Ni-Cd batteries,

household

chemicals, fireworks etc.

•

Environmental LCA is the quantitative

assessment of environmental impacts of

products or processes over their life cycle.

LCA is the analysis of the contribution of lifecycle

stages, product parts or processes to

environmental burden.

LCA is often used to compare between products

or design alternatives.

•

Applications of LCA:

Product improvement

Support for strategic choices

Benchmarking

External communication

•

LCA is a

model

of a complex reality!

•

…of an average lifecycle of a mass

product

•

…of the effect of all impacts that

occur

•

…of their interaction.

•

Any model is a simplification of

reality: If you make a model, you

must specify the goal and scope

describing why you want to make the

model.

1. Goal and Scope definition

- Public policy making - Marketing Life cycle assessment frameworkQuestions:

•

What is the intended application of the

LCA?

•

How much effort do you want to invest?

•

Who are interested parties?

•

What methodology will you use?

Why is a goal and scope definition

important?

–

guidance in data collection phase

–

communication base for data providers

–

reference for data quality management.

–

afterwards, to explain how choices have been made

during the various LCA phases.

•

Definition of functional unit, initial system

boundaries and procedural aspects

Functional unit

:

comparison of products on the

basis of

equivalent function

, for example:

comparison of 2 packaging systems for 1000

litres of milk by (a) 1000 disposable cartons or

(b) 100 reusable bottles; instead of

comparison of 1 carton and 1 bottle.

Functional unit is basis for comparison

=

?

“Compare

environmental

impacts of

packaging of

1000

litres milk

in carton

packages or glass

bottles”

Definition of functional unit, initial system

boundaries and procedural aspects

1. System boundaries:

definition of processes that

are included in the investigation, e.g. material

extraction, processing and transport; energy

production; disposal processes. Production of

capital goods (equipment used for production

and transportation) are often excluded from the

system. System boundaries are further defined

during the inventory process.

2. Procedural aspects:

organizational

arrangements such as a critical review to

guarantee consistency, scientific validity,

transparency of the final report and how various

stakeholders will be involved in the process (LCA

is a participatory process)

1. Also referred to as Life Cycle Inventory (LCI)

phase

2. Compiling and quantifying of inputs and

outputs

3. Collecting of data, determination of total

emissions and resource use

4. Detailed defining of product system and

economy-environment boundary. Only data

collection for processes that are controlled by

human beings (economic processes).

Examples: coal mining, electricity production,

controlled dumping of solid waste etc.

5. Visualizing connected processes in product

system

6. Scaling of available technical data (e.g. from

data libraries) to functional unit

7. Aggregating the inputs and outputs in

Inventory Table

Example of Product system and Inventory

Difficulties:

•

Data availability and quality

Data rarely available, usually special data

gathering studies needed

Measurement procedures rarely standardized

•

Geographic variations

quality of raw materials/energy sources

production methods

relevant environmental impacts

•

Technology

Which type of electricity production?

Salt Electrolysis with Mercury or Membrane

process?

Oldest, average or modern Waste Incineration

Plant?

Difficulties:

•

Allocation

of environmental interventions in case of

multiple output processes

;

Many processes are ‘multifunctional’ (e.g.

co-production, combined waste treatment.) and

interventions can be allocated to more outputs:

•

Recycling and reuse

•

Allocation determined by number of reuse times

•

Also referred to as Life Cycle Impact Assessment

(LCIA)

•

Linkage (long) list of LCI results to environmental

•

Steps: Characterization, Classification and

Normalization:

Determine which LCI results contribute to which impact

category, e.g. CO2 and CH4 to climate change

Multiply environmental interventions (resources,

emissions etc.) from LCI with a characterisation factor to

get indicator results

Normalize to understand the relative magnitude of the

indicator results and to get dimensionless score (useful

for comparison)

Cat. Indicator result (kg CO2 equivalent)

METODOLOGI LCA:

Effect

Category indicators are quantifiable representations of

impact categories (ISO) and are defined according

standards, such as CML-IA, Eco indicator 99, Impact

2002+ etc.)

•

A ‘high’ contribution to a certain impact category (a

high normalized score) does not automatically mean

an ‘important’ contribution

weighing of results is

needed

•

Weighing is a valuation of results and thus a

normative process, depending on preferences of

researcher; which environmental impact is most

important?

•

Procedure of LCIA according to ISO:

-

Classification and characterisation are an

obligatory step.

-

Normalisation is an optional step.

-

Weighing is only permitted for internal decision

making, and not for comparison of products to the

public.

•

“Phase of life cycle assessment in which

the findings of either the inventory

analysis or the impact assessment, or

both, are combined consistent with the

defined goal and scope in order to reach

conclusions and recommendations” (ISO)

•

To interpret an LCA, you must check the

goal and scope:

Are the the general assumptions

reasonable?

Is the functional unit well chosen?

Are ISO standards applied?

Has a peer review been conducted?

•

Conduct a sensitivity analysis: analyze the

impact of important choices or

assumptions

What if other allocations are applied.

What if other boundaries are applied.

What if other impact assessment

method is used

.

•

By recalculating the LCA with other

assumptions, we can verify how the

conclusions connect with the

assumptions.

1. LCA is often associated with

environmental impacts, but scope can be

extended to include economic and social

impacts.

2. Financial LCA = Life Cycle Costing

(LCC);

Analysis of life cycle costs

3. Social LCA

Social impacts throughout life cycle of

products and processes

•

What are the costs and revenues

incured during the life cycle of a

product or process?

•

R&D

•

Production

•

Marketing

•

Sales

•

Etc.

•

Sometimes external costs included as

well (costs that are ‘imposed’ on

society or the environment):

•

Monetary valuation of environmental LCI

and LCIA results…but is it possible to

monetise all environmental services?

•

Social LCA analyses social impacts, such

as employment and health:

Job quality

Quality physical health

Quality social health

Earthly possessions

•

Challenging to model social life cycle

impacts, because social conditions do

change more rapidly

impacts from changes in employment conditions

may dissipate

emotions resulting from changes disappear with

time

diseases get cured

people who are laid off may find new jobs)

LCA

METHODS

AND

METHODOLOGY

Introduction

Definitions of LCA

According to the ISO DIS standards, LCA is

defined as a method for analysing and

determining the environmental impact along

the product chain of (technical) systems.

It includes the various types of technical

conversions that occur in the manufacturing

process.

These consist of:

- change of material chemistry (chemical

conversion), material formulation, or material

structure;

- the removal of material resulting in an

increase of (primary) outputs over the inputs;

- joining and assembly of materials resulting

in a decrease of (primary) outputs over the

inputs.

Sumber: LCA methods and methodology. Ireneusz Zbicinski; Lodz, Technical

According to ISO 14040, the formal

definition of LCA is as follows:

“LCA is a technique for assessing the environmental

aspects

and potential impacts associated with a product by:

• Compiling an inventory of relevant inputs and

outputs of

a product system.

• Evaluating the potential environmental impacts

associated

with those inputs and outputs.

• Interpreting the results of the inventory analysis and

impact assessment phases in relation to the objectives

of the study.”

The Goals and Applications of

LCA

LCA assess the environmental effects of a product

or service

or, more commonly, the effects of a change in the

production

or design of a product or service.

The goals and applications of LCA range over a

scale from

short to long term. It includes:

• Short-term process engineering.

• Design and optimization in a life cycle

• Product comparisons including product design

and product

improvement.

• Eco-labelling in the medium and long term

• Long-term strategic planning

Sumber: LCA methods and methodology. Ireneusz Zbicinski; Lodz, Technical

The Qualitative

(approximate) LCA

The Red Flag Method

Qualitative LCA methods do not use

systematic computational

procedures to assess the environmental

profile of the system

under study. They analyse the life cycle of

a product in environmental terms directly

on the basis of emissions released

and the consumption of raw materials.

Assessing the seriousness of the impacts

directly from the impact table requires

thorough training and extensive

knowledge. A decisive role is played by

relevant experiences of the expert

carrying out the evaluation

The red flag method (RFM) may serve as

an example of a

qualitative method. There are a number

of companies working

with RFM, for instance Philips. The first

step is preparing an impact table. This

gathers all emissions and material

consumption during the whole life cycle

of a product.

Then, the items which are harmful to the

environment are flagged. The

red-flagged process or product should be

given special attention and if possible

excluded from the life cycle of the

product.

The red flags many times are placed in

nearly each process

or life stage without, any distinction

between small and large

The MET Matrix

(materials, energy

and toxicity).

A MET analysis consists of five stages:

•

a discussion of the social relevance of

the product’s functions.

•

the life cycle of the product under study

is determined and all the relevant data is

gathered.

•

next the data is used in which is the

core of the MET matrix method:

completing the matrix

•

the processes in the life cycle are

entered in

the matrix divided into three categories:

material consumption, energy

consumption, and emissions of toxic

substances.

As in the case of Red Flag Method,

completion of the MET matrix can be done

only with an aid of environmental experts.

•

when the most significant

environmental problems are

identified, possible steps to improvement

of the product or service should be

outlined.

5.3 Quantitative LCA

Methods

The Components of Quantitative Methods

There are a number of different

quantitative LCA techniques.

These are in practice applied as a group

of methods which use

classification, characterisation,

normalisation and weighting.

The most important are:

• Eco-points

• Eco-indicator

• EPS system

• MIPS concept

The methodological framework of all the

LCA techniques

is based on ISO standards 14040-43.

A complete LCA consistent with ISO standards

consists of

four interrelated phases (compare with the

definition of LCA

given by ISO):

1. Goal definition and scope.

2. Inventory analysis.

3. Impact assessment with four sub-phases:

classification,

characterisation, normalisation, weighting.

4. Improvement assessment.

Interrelations among the LCA phases make LCA

an iterative

process

Interrelation of LCA phases [Hillary, 1995].

Sumber: LCA methods and methodology. Ireneusz Zbicinski; Lodz, Technical

The calculation and evaluation procedure is repeated

until the analysis reaches the required level of detail and

reliability.

The first step in an LCA is a raw assessment to

determine

critical points in the life cycle and find directions for

further

studies. Such a quick analysis is called

screening

.

Sometimes it is enough to answer all the questions

asked in the goal definition.

Goal definition and scope

is crucial for all the other

phases.

These include gathering data, that is building a model of

the

life cycle, choosing appropriate environmental effects to

consider (local, global?), and drawing conclusions to

answer the questions asked at the beginning of the

project.

The last step, the

improvement assessment phase

, is

performed in accordance with the goal of the study and

on the basis of results from the impact assessment

phase. This is achieved by applying the computational

procedure to the data in the inventory table.

In the goal definition and scope phase the

unambiguous and

clear description of the goal of the study and its

scope must be

developed.

The product (or service) to be assessed is defined,

a functional basis for comparison in case of

comparative analysis is chosen and, in general, the

questions to be answered are established.

The scope of the study sets requirements to the

desirable level of detail. The main issues to

consider in this stage are:

• Purpose of the study: Why is the analysis being

performed?

What is the end use of the LCA? To whom are the

results addressed?

• Specify the product to be investigated (functional

unit).

• Scope of the study: depth and breadth (system

boundaries).

Sumber: LCA methods and methodology. Ireneusz Zbicinski; Lodz, Technical

As far as the LCA end use is concerned there are

several basic possibilities:

1. Product or process improvement.

2. Product or process design.

3. Publication of information on the product.

4. Granting of an eco-label.

5. Exclusion or admission of products from or to the

market.

6. Formulation of company policy (purchasing, waste

management, product range, how to invest the

money).

An LCA of a product must have clearly specified

functions to be assessed.

If, for instance, the product is a washing machine, it

is important to describe its performance

characteristics.

That is, it is important to define a function of a

product rather than a product itself. The measure of

performance which the system delivers is called a

functional unit.

The functional unit provides a reasonable point of

reference when comparing different products.

Sumber: LCA methods and methodology. Ireneusz Zbicinski; Lodz, Technical

1. Two products, A and B, may have different

performance characteristics even though they

fulfil the same function.

2. An illustrative example is the comparison of

different kinds of milk packaging. Two

possible alternatives are: a milk carton and a

returnable glass bottle.

3. A glass bottle can be used ten or more times,

whereas a milk carton can be used only once.

On the other hand, a milk carton does not

need washing and additional transportation.

4. When comparing one carton and one bottle

we could conclude that carton is the

environmentally best choice. If the functional

unit of the two packages is established,

however, the analysis are not distorted by

unfair assumptions.

The next vital task in the goal and scope

definition step is to define system boundaries.

The necessity of defining system boundaries

results from the fact that the main technique

applied in any LCA is modelling. A function

fulfilled by the product is represented by a

model of the complex technical system.

This consists of subsequent processes required

to produce, transport, use and dispose of a

product. The model is graphically illustrated by

a process tree.

Moreover, models of environmental

mechanisms are created to translate inflows

and outflows from the life cycle into the

environmental impacts they may contribute to.

Sumber: LCA methods and methodology. Ireneusz Zbicinski; Lodz, Technical

The typical question when defining the system

boundaries is whether to include the

production of capital goods or not.

In a majority of LCAs capital goods, e.g.

equipment of a workshop, are neglected. This

assumption does not lead to important

distortions of the final LCA outcome.

In some cases, however, neglecting capital

goods significantly underestimates

environmental burdens. This applies to, for

example, electricity production. It has been

shown, that the production of capital goods

constitutes about 30% of the total

environmental impact resulting from an

average generation of electricity.

Another common problem is presented by

agricultural areas, which can be seen as a part

of nature or as a part of the production

system.

Sumber: LCA methods and methodology. Ireneusz Zbicinski; Lodz, Technical

To narrow down the system boundaries, one

uses cut-off rules. Thus if the mass or

economic value of the inflow is lower than a

certain percentage (a previously set threshold)

of the total inflow it is excluded from further

analysis.

The same applies when the contribution from

an inflow to the environmental load is below a

certain percentage of the total inflow. Carefully

and properly specified goals and scope help to

develop the model of the product in such a way

that the simplifications and thus distortions

have only an insignificant influence on the

results.

This is vital for getting reliable answers from an

LCA. This challenging task undoubtedly

depends to some degree on subjective

decisions and requires a lot of experience.

The inventory phase is the core of an LCA and is

a common feature of any LCA. During this phase

all the material flows, the energy flows and all

the waste streams released to the environment

over the whole life cycle of the system under

study are identified and quantified.

The final result of the inventory analysis is an

inventory table. The inventory phase has four

separate sub-stages:

1. Constructing a process flow chart (so-called

process tree).

2. Collecting the data.

3. Relating the data to a chosen functional unit

(allocation).

4. Developing an overall energy and material

balance (all inputs and outputs from the

entire life cycle) – an inventory table.

Sumber: LCA methods and methodology. Ireneusz Zbicinski; Lodz, Technical

Very often a process fulfils two or more

functions or gives two or several of usable

outputs.

They are multi-output processes.

Then we have to determine which part of the

total emissions and material consumption

should be attributed to each specific product.

The same applies to multi-input processes.

An example of a multi-input process is a plastic

bag.

When performing an LCA for a plastic bag, we

assume that at the end of its life cycle it is

incinerated. However, there are many other

products incinerated at one time. To what extent

is the bag responsible for chemicals emitted

from the incineration plant?

The problem of how to divide emissions and

material consumption between several product

or processes is called allocation.

Sumber: LCA methods and methodology. Ireneusz Zbicinski; Lodz, Technical

Several methods have been developed to deal

with allocation

LCIA = Life Cycle Impact

Assessment

The Components of Impact Assessment

A typical Life Cycle Assessment inventory table

consists of a

few hundred or more items. They might be grouped

into categories: raw materials, emissions to air, water,

soil, solid emissions, non-material emissions (noise,

radiation, land use) etc.

An inventory table is a basis for the next step of LCA –

impact

assessment.

On the condition that an inventory table contains

relatively few items, an environmental expert can

assess the life cycle without applying any

mathematical procedures. In practice, however, such a

situation hardly ever obtains.

The data from an inventory table has to be processed

to attain a higher level of aggregation.

Ideally the aggregation process results in a meaningful

single score. To achieve this, the ISO standards advise

a four-step procedure :

1. Compulsory steps:

1. Classification - Klasifikasi

2. Characterisation - Karakterisasi.

2. Optional steps:

1. Normalisation - Normalisasi

The first step to higher aggregation of the data is

classification.

Inflows and outflows from the life cycle are

gathered in a number of groups representing the

chosen impact categories.

The inventory table is rearranged in such a way

that under each impact category, all the relevant

emissions or material consumption are listed

(qualitatively and quantitatively).

This procedure is illustrated in Figure

Sumber: LCA methods and methodology. Ireneusz Zbicinski; Lodz, Technical

The common source of uncertainty here is the

lack of a universally accepted appropriate

official list of environmental impacts to

consider. Nevertheless, as a result of numerous

already performed LCAs, a “standard”, a list of

environmental impacts that should be treated

does exists.

These are all broadly recognised environmental

problems such as resource depletion, toxicity,

global warming, ozone depletion,

eutrophication, acidification, etc.

The choice of impact categories is subjective.

In the previous step, substances contributing to

the impact categories were taken from an

inventory table and ascribed to a certain group.

However, different substances among one group

contribute differently to the impact category.

During the characterisation step the relative

strength of the unwanted emission is evaluated

and contributions to each environmental

problem are quantified. What is needed here is a

single number for each category.

Sumber: LCA methods and methodology. Ireneusz Zbicinski; Lodz, Technical

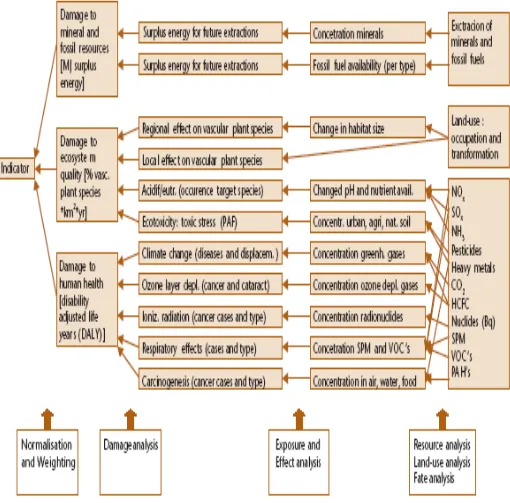

Relations between emissions and impact categories.

To the left are raw materials used (top) and pollutants

emitted (bottom) during the life cycle of a product.

To the right are the impact categories to which these

emissions contribute.

The figure illustrates that one emission may

contribute to several impacts, and that several

The final result of the characterisation step is a

list of potential environmental impacts.

This list of effect scores, one for each category,

is called the environmental profile of the

product or service.

Sumber: LCA methods and methodology. Ireneusz Zbicinski; Lodz, Technical

Environmental profiles.

The impact of a life cycle may be expressed as the

sum of each kind of impact summed over the entire

life cycle (above), or as the impact expressed

separately for each life stage (below).

In this life cycle four impacts are considered

(resource depletion; global warming; acidification;

and stratospheric ozone depletion), and four life

stages (disposal (wasting); transportation; use; and

manufacture) [Hillary, 1995].

Equivalence factors for environmental impacts.

The contribution to an environmental impact is

calculated for any substance if an equivalence

factor is available.

Sumber: LCA methods and methodology. Ireneusz Zbicinski; Lodz, Technical

The results from the characterisation step

cannot be compared since they are usually

presented in different units (CO2eq., SO2eq.,

CFC-11eq, etc.). A procedure to allow us to

compare impact categories among themselves

is therefore carried out.

This is called normalisation.

Normalisation is performed to make the effect

scores of the environmental profile comparable.

The normalised effect score is the percentage

of a given product’s annual contribution to that

effect in a certain area:

Normalised Effects

The principle of a normalisation is illustrated by the diagram below. It shows a computational procedure for an

environmental profile of a coffee machine in Belgium. The entire life cycle of the coffee machine results in the following emissions: 6.1 kg of equivalent CO2 (for global warming), 56.2 g of equivalent SO2 (for acidification), 2.88.

Sumber: LCA methods and methodology. Ireneusz Zbicinski; Lodz, Technical University. Molo, EMS Conference, 28th June-2 nd July 2006

MENGHITUNG

PROFIL LINGKUNGAN

A LCA is a mapping (inventory) and allocation / calculation of environmental impacts for a product system. Starting with the product and its manufacturing then backwards upstream along the supply chain until you reach base reosurces used. All emissions to

air, water and ground for this chain will be gathered and summarised to a total sum. Same is done downstream, at product usage and at waste phase. But these latter parts

must be build on scenarios as we do not in detail know the fate of the sold product. Totally you then get a sort of a model for total environmental impact from the products

Comparing Impact Categories

In order to obtain a single score

representing the environmental impact of

a product, we need further aggregation of

the data.

Weighting (valuation) is the step in which

the different impacts categories are

weighted so that they can be compared

among themselves, i.e. the relative

importance of the effects is assessed.

In comparative analysis the prime goal is

to find out which one of the products

fulfilling the same function is the best

option for the environment.

Sumber: LCA methods and methodology. Ireneusz Zbicinski; Lodz, Technical

Comparing impacts of life cycles from different

products.

Four impacts from three different products,

called A, B and C expressed as relative values.

How to establish such a set of preferences and

priorities?

This is a still subjective process although

much effort has been spent in recent years to

work out a scientific basis for weighting, i.e.

weighting principles.

Ranking impact categories in terms of their

environmental impact makes clear distinction

between the weighting and all of the previous

phases. The latter use empirical knowledge of

environmental effects and their mechanisms,

while the weighting relies mainly on

preferences and social values.

In practice, weighting is performed by

multiplying a normalised environmental profile

by a set of weighting factors, which reflect the

seriousness of a given effect.

Sumber: LCA methods and methodology. Ireneusz Zbicinski; Lodz, Technical

One of the ready-made methods,

Eco-indicator 95, can serve an example of

a defined set of weighting factors

(Table).

Weighting factors used in Eco-indicator 95

A Panel of experts can provide a qualitative

analysis which uses weighting without

weighting factors. Instead of applying the

computational procedure the rating is

performed by the panel of experts.

The major disadvantage of this approach is its

poor reproducibility – the results will often

remain controversial and open to discussion .

Sumber: LCA methods and methodology. Ireneusz Zbicinski; Lodz, Technical

![Figure 1. Life-cycle assessment framework [18].](https://thumb-ap.123doks.com/thumbv2/123dok/3875474.1845624/149.540.25.483.303.591/figure-life-cycle-assessment-framework.webp)