Conference Proceedings

December 2013

Hong Kong

HKI CEAS

EECS

International Conference on Electrical Engineering and Computer Sciences

ISBN:978-986-88450-3-9

Contents

General Information for Participants ... 6

Conference Organization ... 8

Conference Schedule ... 12

Conference Venue Information ... 16

Oral Session ... 18

Electrical and Electronics Engineering I/ Photonics and Optoelectronics ...18

EECS-730 ...20

EECS-747 ...27

EECS-711 ...34

EECS-716 ...38

EECS-700 ...44

EECS-818 ...46

Fundamental and Applied Sciences I...47

HKICEAS-622...49

HKICEAS-877...55

HKICEAS-884...61

HKICEAS-632...68

HKICEAS-783...72

HKICEAS-909...77

HKICEAS-819...83

Natural Science Keynote Speech ...89

Civil Engineering I...91

HKICEAS-857... 100

Computer Science and Information Engineering I ... 138

HKICEAS-743... 139

HKICEAS-903... 147

EECS-721 ... 153

EECS-722 ... 160

Environmental Science I... 169

HKICEAS-788... 171

Biomedical Engineering I/ Civil Engineering ... 218

HKICEAS-657... 220

Biomedical Engineering II ... 280

HKICEAS-771... 282

Material Science and Engineering I ... 333

HKICEAS-908... 335

Computer Science and Information Engineering II ... 393

EECS-740 ... 395

Environmental Science II/ Civil Engineering II ... 446

HKICEAS-800... 486

Chemical Engineering ... 492

HKICEAS-770... 494

Computer Science and Information Engineering III/ Wireless or Mobile Communication & Computing ... 524

EECS-748 ... 526

Material Science and Engineering II ... 565

HKICEAS-569... 567

HKICEAS-851... 575

HKICEAS-852... 581

HKICEAS-853... 589

HKICEAS-854... 596

Electrical and Electronic Engineering II ... 602

HKICEAS-718... 604

Fundamental and Applied Sciences II ... 648

HKICEAS-821... 649

HKICEAS-665... 658

HKICEAS-906... 665

HKICEAS-764... 670

HKICEAS-904... 688

Mechanical Engineering ... 694

HKICEAS-580... 696

Material Science and Engineering III... 733

HKICEAS-860... 735

Material Science and Engineering ... 749

HKICEAS-717... 752

HKICEAS-556... 759

HKICEAS-861... 763

HKICEAS-733... 769

HKICEAS-680... 781

Electrical and Electronic Engineering... 823

HKICEAS-876... 824

HKICEAS-939... 828

Biomedical Engineering I/ Biomedical Electronics and Bioinformatics ... 837

HKICEAS-650... 842

Civil Engineering ... 896

HKICEAS-735... 898

HKICEAS-542... 906

HKICEAS-672... 919

HKICEAS-667... 920

HKICEAS-889... 927

Mechanical Engineering ... 930

HKICEAS-744... 931

HKICEAS-652... 938

HKICEAS-782... 946

Chemical Engineering ... 951

HKICEAS-663... 952

HKICEAS-559... 956

HKICEAS-552... 972

Wireless or Mobile Communication & Computing/ Nano-Electro-Mechanical System, Networking ... 973

EECS-670 ... 974

EECS-735 ... 981

Fundamental and Applied Sciences ... 982

HKICEAS-836... 984

HKICEAS-837... 985

HKICEAS-607... 986

HKICEAS-891... 987

HKICEAS-893... 989

Electrical and Electronic Engineering/Photonics and Optoelectronics ... 990

EECS-736 ... 993

EECS-701 ... 999

EECS-713 ... 1007

EECS-718 ... 1015

EECS-743 ... 1021

EECS-761 ... 1028

EECS-809 ... 1034

EECS-799 ... 1043

EECS-717 ... 1050

Computer Science and Information Engineering/ Environmental Science .... 1051

HKICEAS-673... 1053

HKICEAS-773... 1058

HKICEAS-711... 1065

EECS-712 ... 1066

EECS-731 ... 1071

EECS-738 ... 1078

EECS-746 ... 1085

HKICEAS-887... 1086

General Information for Participants

Information and Registration

The Registration and Information Desk will be situated in the below time and location at Regal

Airport Hotel:

2F, December 19, 2013 (15:00-17:00)

B1, December 20, 2013 (08:15-16:00)

B1, December 21, 2013 (08:15-16:00)

Parallel Sessions

Parallel Sessions will run on December 20 and 21. Sessions are usually 90 minutes in length.

Presentations and Equipment

All presentation rooms are equipped with a screen, an LCD projector, and a laptop computer

installed with PowerPoint software. You will be able to insert your USB flash drive into the

computer and double click on your presentation to open it in PowerPoint. We recommend that

you bring two copies of your presentation in case of one fails. You may also link your own

laptop computer to the projector cable, however if you use your own Mac please ensure you

have the requisite connector.

A Polite Request to All Participants

Participants are requested to arrive in a timely fashion for all addresses, whether to their own,

or to those of other presenters. Presenters are reminded that the time slots should be divided

fairly and equally between the number of presentations, and that they should not overrun. The

session chair is asked to assume this timekeeping role.

6

Poster Sessions & Poster Requirements

Materials Provided by the Conference Organizer:

1. X-frame display & Base Fabric Canvases (60cm×160cm)

2. Adhesive Tapes or Clamps

Materials Prepared by the Presenters:

1. Home-made Poster(s)

Requirement for the Posters:

1. Material: not limited, can be posted on the canvases

A 60cm*160cm Poster Illustrates the research findings.

1.Wider than 60cm (left)

2.Copy of PowerPoint Slides in A4 papers (right)

Conference Organization

HKICEAS Committee Board

Linda Osman-Schlegel Deakin University (Geelong Waterfront Campus)

Khalid M. Mosalam University of California, Berkeley

Chueerat Jaruskulchai Kasetsart University

M. Cheralathan SRM University

J N Bandyopadhyay Indian Institute of Technology Kharagpur

S. Dhar University of Calcutta

Poongothai Shankar Annamalai University

Amit Agrawal Indian Institute of Technology Bombay

Cheng Li The Hong Kong Polytechnic University

T.M. Indra Mahlia University of Malaya

Kunal Ghosh Indian Institute of Technology Kanpur

Narayanan Kulathuramaiyer University of Sarawak Malaysia

Arup K. Sarma Indian Institute of Technology Guwahati

Suresh K Bhargava School of Applied Sciences

Banerji P Indian Institute of Technology Kharagpur

P.K. Ghosh Indian Institute of Technology Poorkee

E George Dharma Prakash Raj Bharathidasan University

R.P.Bhatnagar Birla Institute of Technology

V. Vijayagopal Annamalai University

Amit Awekar Indian Institute of Technology Guwahati

Gustavo Carneiro University of Adelaide

Pui-In Mak University of Macau

E, Rathakrishnan Indian Institute of Technology Kanpur

Bassim H. Hameed University of Science Malaysia

Sudhirkumar Barai Indian Institute of Technology Kharagpur

S. N. Sarkar Calcutta University

Samit Bhattacharya Indian Institute of Technology Kanpur

A. P. Shashikala Birla Institute of Technology

RM. Senthamarai Annamalai University

Arnab Bhattacharya Indian Institute of Technology Kanpur

Zbigniew Michalewicz University of Adelaide

B. Bhattacharya Indian Institute of Technology Kharagpur

Amin Heidarpour Monash University

Faizal Mustapha Universiti Putra Malaysia

Susanta Banerjee Indian Institute of Technology Kharagpur

M.V.L.R Anjaneyalu Birla Institute of Technology

P. Balasubramanian Universiti Teknologi PETRONAS

Hui Tong Chua University of Western Australia

Andrew Whyte Curtin University

Johnson Agbinya La Trobe University

Yuen Ka Veng University of Macau

ShahNor Basri Universiti Putra Malaysia

T. V. Gopal SRM University

Surendra Kumar Indian Institute of Technology Poorkee

K. K. Saju Cochin University of Science and Technology

HKICEAS-906

Percentage of Free Fatty Acid and Characteristics of Biodiesel Fuel in Waste

Coconut Oil (WCO)

N M. Suanitia, I W. B. Adnyanab

a

Chemistry Department, Faculty of Mathematic and Natural Sciences, Udayana University, Bali

b

Mechanical Engineering, Faculty of Engineering, Udayana University, Bali E-mail: suanitisr@yahoo.com

Abstract

Various commercial product in tropical regions has a wide impact in many field. Coconut as one of the export scale product often processed becoming coconut oil to fulfill daily life matter. Coconut oil usually be used as a media to fry foodsttufs such as chicken and residual oil during frying process named Waste Coconut Oil (WCO). Over the past year WCO serve as a waste product and known less advantage. Nowdays, WCO be treated become biodiesel as an alternative fuel of diesel engine to reduce utilization fosil fuels. The aims of this study were to analyze some characteristics as biodiesel from WCO which undergo esterification or transesterification process. Esterification process obtained a specific purpose to convert fatty acid in coconut oil that is consisting with lauric

acid. Esterification process to produce methyl ester from WCO using catalyst H2SO4 and Toluene

sulfonate where upon the yield of esterification process subsequently analyzed contents of free fatty acid (FFA) from acid value. Synthesis of biodiesel from fatty acid methyl ester (FAME) from WCO ester ongoing process of frying chicken during chicken 1, 3, 5, and 7 hours. Percentage (%) of FFA

has a variation under the influence both of catalyst H2SO4 and Toluene sulfonate and lengthy of

frying at oil. % FFA with H2SO4 catalyst obtained each 1.01 to 2.02 % and with toluene-sulfanote

catalyst produced each 0.68 to 1.02 %. Characteristics of biodiesel fuel analyzed of density,

viscosity, and flash point value were 1.91 to 2.03, 6.43 to 17.25, 38 to 46 respectively with H2SO4

catalyst and 1.94 to 2.00, 10.73 to 12.97, 35 to 60 respectively with toluene-sulfonate catalyst. WCO obtained after frying during 5 and 7 hours eligible as a Biodiesel because as avaluable result.

Determination of flash point has been done under temperature 50oC which and the oil should not

use for frying again some values of density and viscosity were getting high. Keyword: Fatty acid, Biodiesel, WCO

1.Introduction

Coconut oil especially used in frying can undergo an oxidation process because of the high temperature, that condition can reduce the quality of oil such as physic-chemical properties, odor and resulting rancidity of coconut oil which reported as one of the toxic substance that can promote a serious malignant disease. Coconut oil heated for every different duration of time at present can produce a renewable product namely biodiesel and the process called esterification where the fatty acid from coconut oil reacted with methanol to produce ester with the side product like glycerol as known still have a high economical value.

The development of human civilization along with advances in technology demand a large scale of energy sources from time to time. Enhancement needs of energy sources caused the depletion of petroleum energy sources. According to the Department of Energy and mineral resources, reserve petroleum in Indonesia estimated as a fosil fuel which can’t refurbished with the result that an average production rate around 500 million barrels per year will run out in 18 years due to increased fuel consumption.

One of the fuel energy sources that are not derived from petroleum is coconut oil, more than that used cooking oil can be used as a biodiesel. WCO can be processed into biodiesel that environmentally friendly form and usually obtained by esterification and transesterification process.

Esterification method according to IUPAC (1987) often used these two methods than the other, namely Christie and Laureles to produce methyl esters from Virgin Coconut Oil (VCO). This Process undergo some step consist with added n-hexane, vortex the oil, and added 1.5 mL NaOH (Pontoh and Makasoe, 2011). Esterification is a reaction between ester and methanol with an acid catalyst, whereas ester transesterification obtained in the esterification reaction which methanol is reacted again but using a base catalyst. This result known as esterification and transesterification of Fatty Acid Methyl Ester (FAME). In principle, all strong inorganic acids catalyst can be used such as sulfuric acid, phosphoric acid, hydrochloric acid or organic acids such as catalyst toluene- sulfonate (Hamelinck, et al., 2007).

Based on the background above, the series of conducted research has been done to analyze the characterization of biodiesel made from waste coconut oil (WCO) after frying chicken during 1, 3, 5, and 7 hours.

2.Materials and Method

Waste Coconut Oil after frying chicken 1, 3, 5, and 7 hours, n-hexane, 95-98% sulfuric acid (E.

Merck), followed by toluene sulfonic acid, NaOH, methanol p.a 99%, and anhydrous CaCl2.

Esterification: first of all methanol added to WCO, followed by hexane, and stirred to 5 minutes and

then added H2SO4 catalyst or toluene sulfonate catalyst, solution with a mixture of heated 1 hour.

Transesterification: the cold solution added Na methoxide and hexane, then heated at temperature

55oC and stirred for 2.5 hours which placed into a separating funnel. Process of separating begun

when the top layer of solution washed with distilled water until the washing water distillation clear.

Solution added CaCl2 anhydrous, filtered, collected a number of biodiesel and analyzed.

3.Results and Discussion

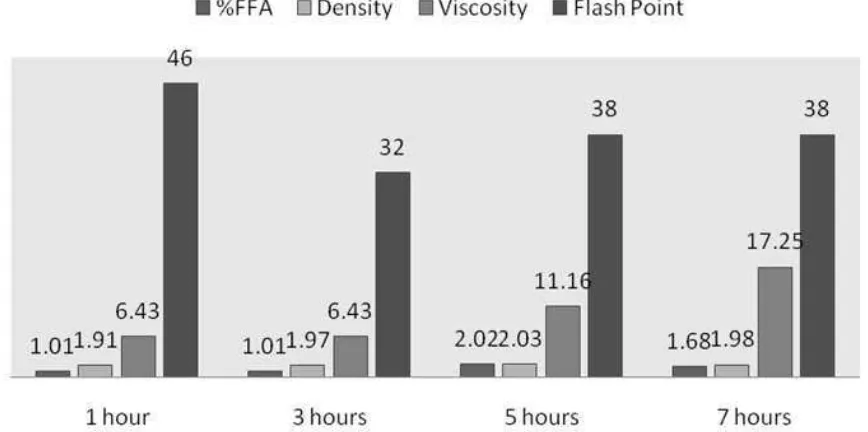

Percentages of free fatty acids (% FFA), density, viscosity, and flash point in Figure 1 described bellow with sulfuric acid catalyst and Figure 2 with toluene sulfonat catalyst. %FFA, in this research the maximum result obtained after frying chicken during 5 hours and still have high value after 7 hours of frying. However %FFA decreased after heating at frying chicken for 1 and 3 hours. Subsequently after heating at 5 and 7 hours the value of % FFA and acid number increased, it indicates that pure coconut oil needs to be heated to reduce free fatty acids content in the oil, but when the heating of the used oil did continuously until 7 hours there was a slight increased value of fatty acids. It can occur after process of frying chicken without skin obviously produce fatty acids and increased %FFA, moreover the diffferent result obtained from the frying process of other chicken part like skin, viscera, and so on. This study can be used as a reference in the field of health, because high fatty acid content is not good for health. Therefore we recommended utilization of cooking oil more than 5 hours after frying chicken, it must be used to be a fuel, and it can not be used for processing food furthermore but can be used to supply needs of motor vehicles.

Figure 1: %FFA, density, viscosity, and flash point values of FAME with sulfuric acid catalyst

Measurements of density, viscosity, and flash point of FAME have been done using Ostwald method as shown in Figure 1 above. Density value ranged from 1.91 to 2.03 (5 hours) and then decrese to 1.98 (7 hours). The viscosity of FAME ranged from 6.43 to 17.25, and flash point ranged from 32 to 46 (1 hour). The European biodiesel quality standard (EN 14214) ranged from 0.86 to 0.90 and the Indonesian National Standard (SNI: 04-7182 -2006), ranged from 0.850 to 0.890. Density of FAME in this research is still higher than Indonesia standard and European, after all it needs to be optimized in the process manufacturing of oil mixture.

Figure 2: %FFA, density, viscosity, and flash point values of FAME with toluene-Sulfonate catalyst

Measurements of % FFA has been done were 0.68 to 1.01 as shown in Figure 2 above, value also accomplished with the same method, while value of density, viscosity, and flash point of FAME wth the density ranged around 1.96 to 2 (5 hours) and decreased until 1.97 (7 hours). The viscosity of FAME ranged from 12.97 to 17.06, and flash point ranged from 35 to 60 (3 hours). The European biodiesel quality standard (EN 14214) ranged from 0.86 to 0.90 and the Indonesian National Standard (SNI: 04-7182 -2006), ranged around 0.850 to 0.890. Density at FAME is still higher than the standard Indonesian and European, eventually it needs to be optimized in the process manufacturing of oil mixture. Viscosity FAME with toluene-sulfonate catalyst obtained high value compared with sulfuric acid, this suggests that sulfuric acid catalyst is still better.

% FFA obtainable around ≤ 2 according to the research Yuliani et al., There high fatty acid content

(> 2), represent the impact of catalyst alkaline in the transesterification because the fatty acid reacts with the catalyst to form soap through a saponification reaction. This resulted ineffective catalyst role because the catalyst reacts with the fatty acids that can degrade ester formed and separation process more difficult to be solved.

Density values according to the standards of Indonesian biodiesel (SNI) :04-7182-2006 (Supardan,

et al., 2011) indicating the value of used cooking oil viscosity at 5 and 7 hours with sulfuric acid and toluene sulfonate catalyst however still high so it needs to be reviewed for the optimum conditions of fat in the process of mixing oil with alcohol while flash point value has been reached fulfill as biodiesel.

4.Conclusion

Percentages of FFA (% FFA) were obtained from 1.01 to 2.02 with H2SO4 catalyst, and 0.68 to 1.02

with toluene-sulfonate catalyst. Characteristics determination of biodiesel such as density, viscosity,

and flash point were 1.91 to 2.03, 6.43 to 17.25, 38 to 46 respectively with H2SO4 catalyst and 1.94

to 2.00, 10.73 to 12.97, 35 to 60 respectively with toluene-sulfonate catalyst. WCO after frying 5 and 7 hours with sulfuric acid catalyst because a developed good result as Fuel. Flash point under

50oC has been done and analyzed for further processing like frying it should be discontinued by

reason of some values of density and viscosity were getting high.

Acknowledgement

Authors express their gratitude and appreciation to the Directorate General of Higher Education (DIKTI) for the opportunity to conduct the process of research in a laboratory scale gradually. Thanks as well given to LPPM Udayana University and all those who helped this study achieved success.

References

[1] Hamelinck, C., Schober, S., Mittelbach, M., Verolet, J., dehue, B., Bioscopes, Fatty acid

Ethyl Ester. Ecofys Uni Craz, 2007, 3-5

[2] Pontoh, J., makasoe, L., Comparison of several methods of making the analysis of methyl

esters of fatty acids of Virgin Coconut Oil ( VCO ) . Scientific journal Science , Chemistry courses F.MIPA Univ . Sam Ratulangi Manado, 2011. 11, 241-247

[3] Suirta, IW. Preparation of Biodiesel from Palm Oil Jelantah . Journal of Chemistry

F.MIPA Unud , 2009, 3 , 1 , 1-6 . Bukit Jimbaran . Badung . Bali . ISSN 1907-9850

[4] Supardan, M.D. Use of Ultrasonic for Used Cooking Oil Transesterification .

Journal of Chemical and Environmental Engineering , 2011, 8 , 1 . 11-16 . Department of Chemical Engineering , FT . Syah Kuala University . Banda Aceh . ISSN 1412-5064 .

[5] Yuliani, F., Primasari, M., Rachmaniah, O., Rachimoellah, M., Effect of acid catalyst (

H2SO4) and reaction temperature on the esterification reaction Seed Oil rubber (Hevea

brasiliensis) into Biodiesel. Biomass and energy laboratory ITS Surabaya , 2003