The review of the third edition by eminent reviewers prompted me to revise the book to bring out this edition. I would be grateful for any constructive criticism for improvements in the future edition of the book.

GREEK

INTRODUCTION

ENERGY CONVERSION

Another advantage of the reciprocating internal combustion engine over the other two types is that all its components operate at an average temperature that is much below the maximum temperature of the working fluid in the cycle. This is because the high temperature of the working fluid in the cycle only lasts for a very small fraction of the cycle time.

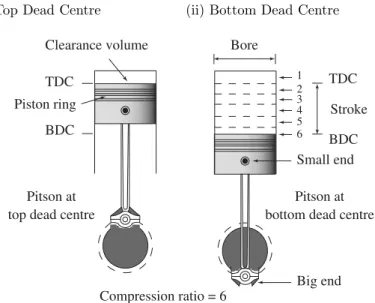

BASIC ENGINE COMPONENTS AND NOMENCLATURE

At the end of the expansion stroke, the exhaust valve opens momentarily and the inlet valve remains closed, Fig.1.4(d). The two-stroke engine was developed to get higher output from the same engine size.

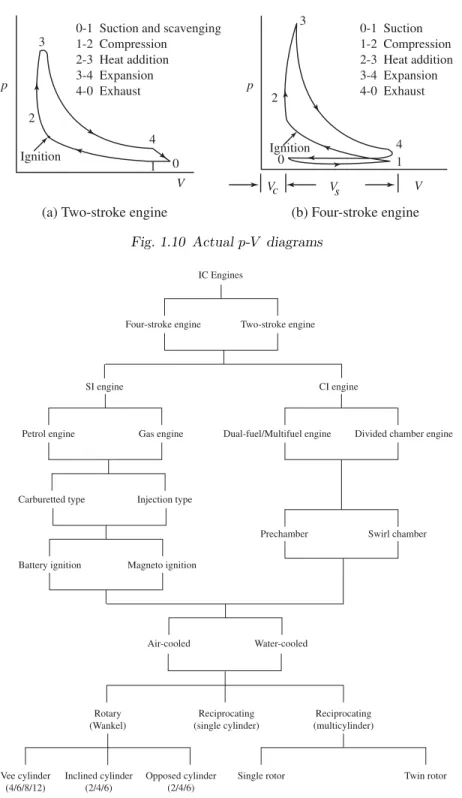

ACTUAL ENGINES

The other disadvantage of two-stroke engine is the lack of flexibility, viz. the capacity to operate with the same efficiency at all speeds. The two-stroke diesel engine is quite widely used in many high-output engines operating on this cycle.

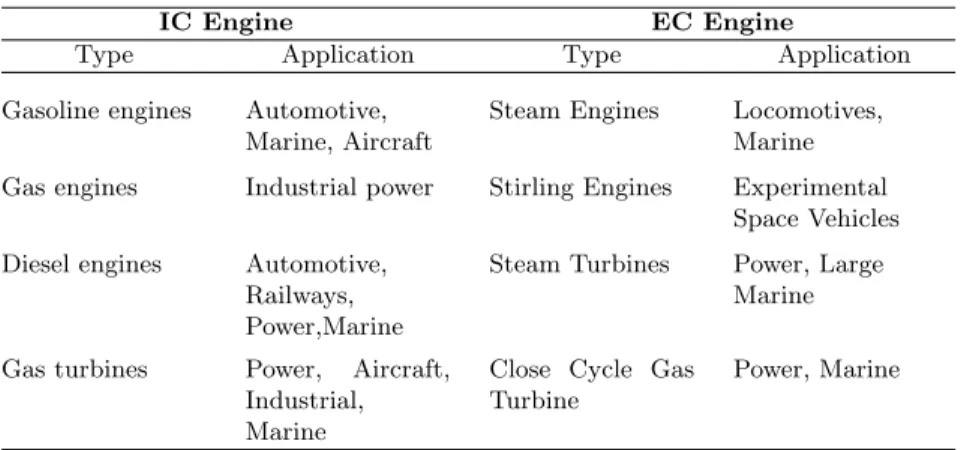

CLASSIFICATION OF IC ENGINES

Due to relatively higher weight and complicated valve mechanism, the initial cost of the engine is higher. Due to light weight and simplicity due to the absence of valve actuation mechanism, the initial cost of the engine is less.

APPLICATION OF IC ENGINES

Small diesel engines are used in pump sets, construction machinery, air compressors, drilling equipment and many different applications. Diesel engines are used both for mobile and stationary electric generating plants with different capacities.

THE FIRST LAW ANALYSIS OF ENGINE CYCLE

Earthmoving machines use diesel engines with a compressor with a power of 200 to 400 kW. Marine applications, from fishing boats to ocean liners, use diesel engines from 100 to 35000 kW.

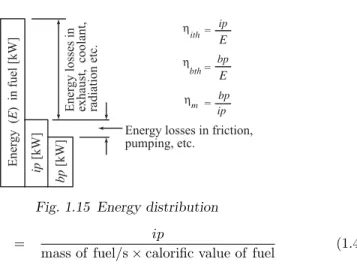

ENGINE PERFORMANCE PARAMETERS

The specific power can be shown to be proportional to the product of the mean effective pressure and the mean velocity of the piston. It is inversely proportional to the thermal efficiency of the motor. sfc = Fuel consumption per unit time.

DESIGN AND PERFORMANCE DATA

Assuming that the friction force is constant with load, what will be the mechanical efficiency at 60% of the load. Calculate the cubic capacity of the engine and the clearance volume of each cylinder. Find the friction force of the engine if the engine is an over-square engine with an over-square ratio of 0.8.

AIR-STANDARD CYCLES AND THEIR

ANALYSIS

INTRODUCTION

These assumptions make the analysis too simplistic and the results do not match the actual engine results. The operating power, maximum pressure, maximum temperature and thermal efficiency based on air standard cycles will be the maximum achievable and will vary considerably from those of the actual engine. In this chapter we will review various cycles and also derive equations for work efficiency, mean effective pressure, efficiency, etc.

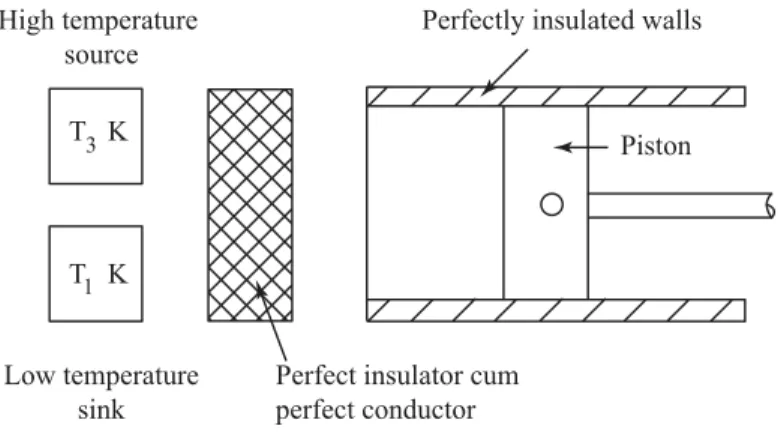

THE CARNOT CYCLE

Thus, the increase in thermal efficiency can only be achieved by increasing the source temperature. Despite this advantage, the Carnot cycle does not provide a suitable basis for the operation of an engine using a gaseous working fluid, because the work output of this cycle will be quite low. Mean effective pressure, pm, is defined as the hypothetical constant pressure acting on the piston during its expansion stroke and producing the same work output as that of the actual cycle.

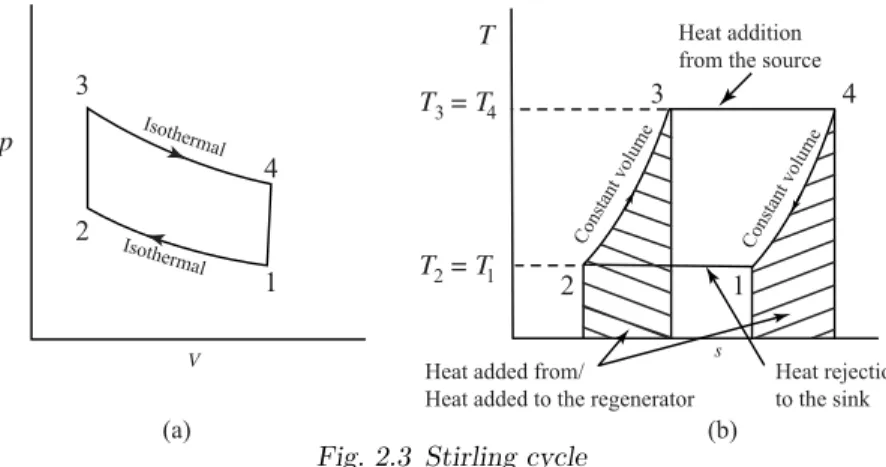

THE STIRLING CYCLE

The Stirling cycle was previously used for hot air engines and became obsolete when Otto and Diesel cycles came into use. But with developments in metallurgy and intensive research into this type of engine, the Stirling engine has staged a comeback in practicality. Therefore, the Stirling cycle efficiency will be less than the Carnot efficiency and can be written as.

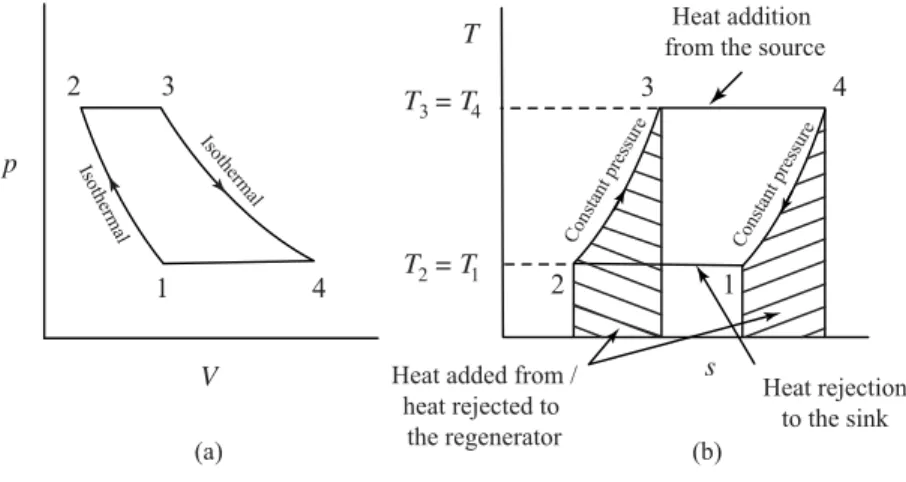

THE ERICSSON CYCLE

The design of Stirling engine involves a major problem in the design and construction of heat exchanger to operate continuously at very high temperatures. Since the process 2→3 and 3→4 are parallel to each other on the T-s diagram, the net effect is that the heat only needs to be added at constant temperature T3 =T4 and rejected at constant temperature T1=T2. The advantage of the Ericsson cycle over the Carnot and Stirling cycles is its smaller pressure ratio for a given ratio of maximum to minimum specific volume with higher mean effective pressure.

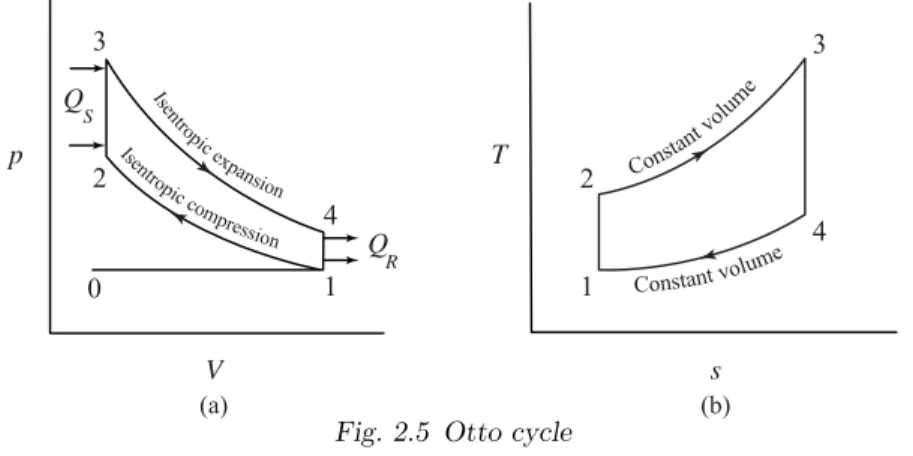

THE OTTO CYCLE

Note that the thermal efficiency of the Otto cycle is a function of the compression ratio and the ratio of specific heats, γ. The average effective pressure, which is an indicator of the internal work, increases with the pressure ratio at a fixed value of the compression ratio and the ratio of specific heats. In the Otto cycle, an increase in the compression ratio leads to an increase in mean effective pressure and thermal efficiency.

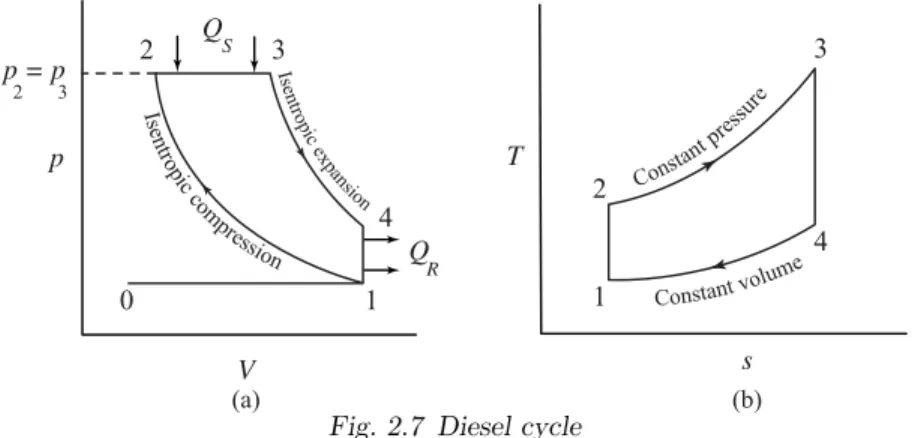

THE DIESEL CYCLE

It can be observed that the efficiency of the Diesel cycle is different from that of the Otto cycle only in the bracketed factor. Therefore, unlike the Otto cycle, the standard air efficiency of the Diesel cycle depends on output. The higher efficiency of the Otto cycle compared to the Diesel cycle for the same compression ratio is of no practical importance.

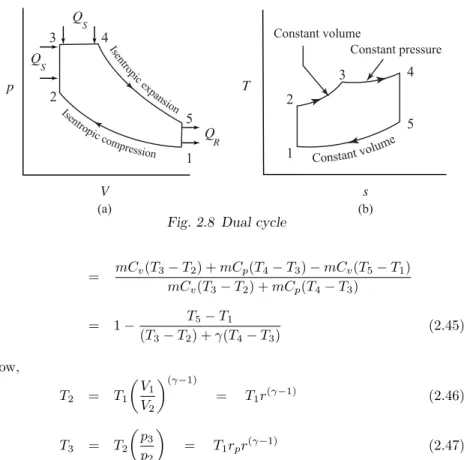

THE DUAL CYCLE

The efficiency of Double Cycle therefore lies between that of the Otto cycle and the Diesel cycle with the same compression ratio.

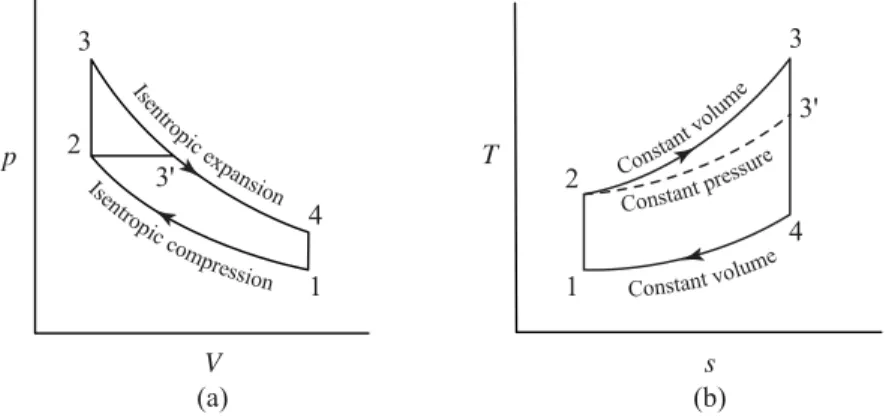

COMPARISON OF THE OTTO, DIESEL AND DUAL CYCLES The important variable factors which are used as the basis for comparison of

Therefore, it is clear that the efficiency of the Otto cycle is greater than the efficiency of the Diesel cycle for a given compression ratio and heat rejection. Therefore, diesel cycle is more efficient than Otto cycle for the same maximum pressure and heat input condition. It is clear that the heat rejection for Otto cycle is more than for Diesel cycle.

THE ATKINSON CYCLE

THE BRAYTON CYCLE

The air temperature at the start of compression is 60◦C and the compression ratio used is 14:1. Calculate the efficiency of the cycle, the required rate of heat addition, the mean effective pressure, and the maximum temperature of the cycle. Calculate for the cycle (i) the maximum pressure developed (ii) the compression ratio assuming adiabatic compression and (iii) the efficiency of the cycle.

A semi-diesel engine operates on a dual combustion cycle. and temperature at the beginning of the compression is 1 bar and 27. C respectively and the compression ratio is 12. Calculate the parameters at the characteristic points of the cycle and the thermal efficiency, if the working fluid is air.

FUEL–AIR CYCLES AND THEIR ANALYSIS

INTRODUCTION

FUEL–AIR CYCLES AND THEIR SIGNIFICANCE

The analysis of the fuel-air cycle takes into account the following: i) The actual composition of the gases in the cylinder: The gases in the cylinder contain fuel, air, water vapor and gas residues. A good estimate of the power that can be expected from an actual engine can be made by analyzing the fuel-air cycle. Thus, the effects of many variables on engine performance can be better understood by analyzing the fuel-air cycle.

COMPOSITION OF CYLINDER GASES

VARIABLE SPECIFIC HEATS

The magnitude of the temperature drop is proportional to the decrease in the value of the ratio of specific heat. The magnitude of the difference between 4 and 4 is proportional to the reduction in the value of γ. 3.8) Decreasing the value of k due to variable specific heat results in an increase in temperature from T4 to T4.

DISSOCIATION

The effect of separation on power output is shown in Fig.3.3 for a typical four-stroke spark-ignition engine operating at constant speed. As the mixture becomes richer, the dissociation effect tends to decrease due to incomplete combustion. Comparing with the ideal 3→4 expansion, it is observed that the effect of dissociation is to lower the temperature and thus the pressure at the beginning of the expansion stroke.

EFFECT OF NUMBER OF MOLES

Although during recombination heat is returned, it is too late to contribute to a convincing positive increase in engine power. This has a direct effect on the amount of work the cylinder gases can do on the piston.

COMPARISON OF AIR–STANDARD AND FUEL–AIR CYCLES In this section reasons for difference between air-standard cycles and fuel-air

Therefore, it would appear that thermal efficiency will increase as the mixture is made leaner. This gives rise to combustion loop, as shown in Fig.3.6 which can be drawn for different mixture strengths for an engine operating at constant speed and at a constant throttle setting. This loop gives an idea about the effect of mixture strength on the specific fuel consumption.

EFFECT OF OPERATING VARIABLES

So the efficiency is actually higher and closer to the air cycle efficiency as the fuel-air ratio is reduced as shown in Fig.3.10. However, fuel-air cycle analysis cannot exactly mimic the experimental curve due to several simplifying assumptions made. If the fuel-air mixture is 19.05% rich and the maximum pressure developed is 115.26 bar, then evaluate the composition of the mixture (in percent by weight).

ACTUAL CYCLES AND THEIR ANALYSIS

- INTRODUCTION

- COMPARISON OF AIR-STANDARD AND ACTUAL CYCLES The actual cycles for internal combustion engines differ from air-standard

- TIME LOSS FACTOR

- HEAT LOSS FACTOR

- EXHAUST BLOWDOWN

- LOSS DUE TO RUBBING FRICTION

- ACTUAL AND FUEL-AIR CYCLES OF CI ENGINES

If the exhaust valve is opened too early, part of the expansion stroke is lost. Volumetric efficiency is affected by many variables. Some of the most important are: i) The density of the new cargo. The ratio of actual efficiency to fuel air cycle efficiency for CI engines is approx.

CONVENTIONAL FUELS

- INTRODUCTION

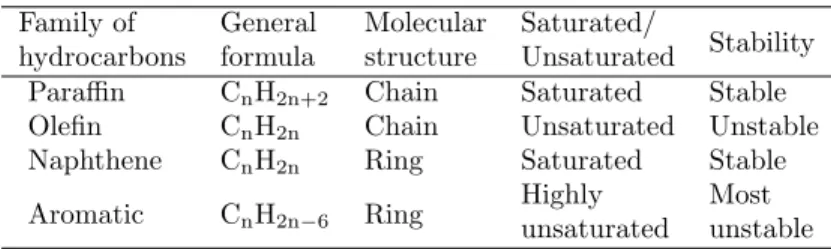

- CHEMICAL STRUCTURE OF PETROLEUM

- PETROLEUM REFINING PROCESS

- IMPORTANT QUALITIES OF ENGINE FUELS

- RATING OF FUELS

Since gasoline is a mixture of different hydrocarbons, the volatility depends on the fractional composition of the fuel. The compression ratio of the engine is gradually changed until the stroke meter reading is the same as the previous run (standard stroke). A good spark-ignition engine fuel should have (a) a high octane number. b) very high cetane number (c) short ignition delay (d) all of the above.

ALTERNATE FUELS

INTRODUCTION

Another problem with alternative fuels is the lack of distribution points (gas stations) where the fuel is available to the public. The public will be reluctant to buy a car unless there is a large network of gas stations available where fuel for that car can be purchased. Some cities have started a few distribution points for some of these fuels, such as propane, natural gas, LPG and methanol.

POSSIBLE ALTERNATIVES

On the other hand, it is difficult to justify building a network of these service stations until there are enough cars to make them profitable. Transferring from one primary fuel type to another will be a slow, costly and sometimes painful process.

SOLID FUELS