Endit for the help, knowledge sharing and assistance during my internship period in PT. SAD : The sales administration department is a department that takes care of the order of the customer in PT. Mane Indonesia, which verifies the product before the product is shipped.

Mane Indonesia, which ensures to ensure the quality of the products in accordance with GMP, Halal qualification, FSSC 22000 and ISO 9001.

INTRODUCTION

- Problem Background

- Problem Statement

- Objective

- Scope

- Assumptions

- Research Outline

The main process of this study is to standardize the spice production area using the 5S concept and methodology to improve the safety, awareness and hygiene of the production area. The data used in the research is the current state of the PT spice production area. The implementation of the 5S methodology will be more focused on raising awareness among workers through standardization in the work area.

This chapter consists of the background of the study, the purpose of the study, the scope of the study and the assumption used in the study.

STUDY LITERATURE

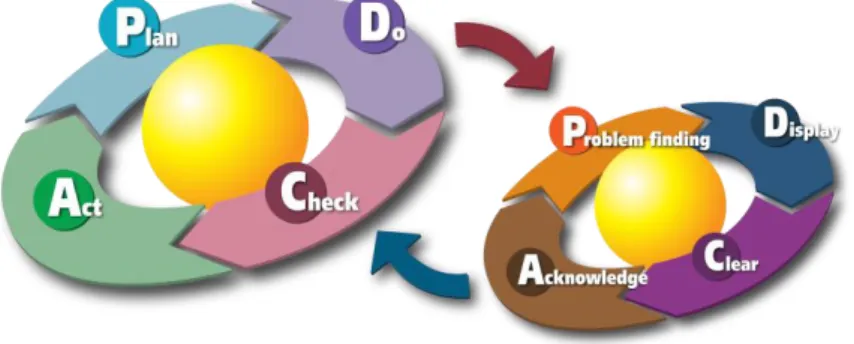

Kaizen Methodology

When used in a business sense and applied to the workplace, kaizen refers to activities that continuously improve all functions, involving all employees from the CEO to the assembly line workers. The word refers to any improvement, one-time or continuous, large or small, in the same sense as the English word "improvement". However, given the common practice in Japan of labeling industrial or business improvement techniques with the word "kaizen" (in the absence of a specific Japanese word meaning "continuous improvement" or "improvement philosophy"), especially in the case of often-imitated practices with Toyota in the lead, the word Kaizen in English is typically used for measures to implement continuous improvement, or even understood as a "Japanese philosophy" thereof.

6 focuses on such interpretations of the word as are often used in modern management discussions. Overall, the process suggests a humanized approach to workers and to increasing productivity: "The idea is to nurture the company's human resources as much as it is to praise and encourage participation in kaizen activities." Successful implementation requires "employee participation in the improvement." People at all levels of an organization participate in kaizen, from the CEO down to the janitorial staff, as well as external stakeholders when appropriate. Although the origins of the 5S method are in manufacturing, it can also be applied to knowledge economy work with information, software or media instead of physical product.

In the day-to-day work of a company, routines that maintain organization and order are essential for a smooth and efficient flow of activities. A typical 5S implementation would result in significant reductions in the square footage of space required for existing operations. It would also result in the organization of tools and materials in labeled and color-coded storage locations, and in "kits" containing only what is needed to complete a task.

A red tag is placed on all items that are not important to the operation or are not in the correct location or quantity. Once the first three 5S's have been implemented, the next pillar is to standardize the best practices in the work area.

Fishbone Diagram

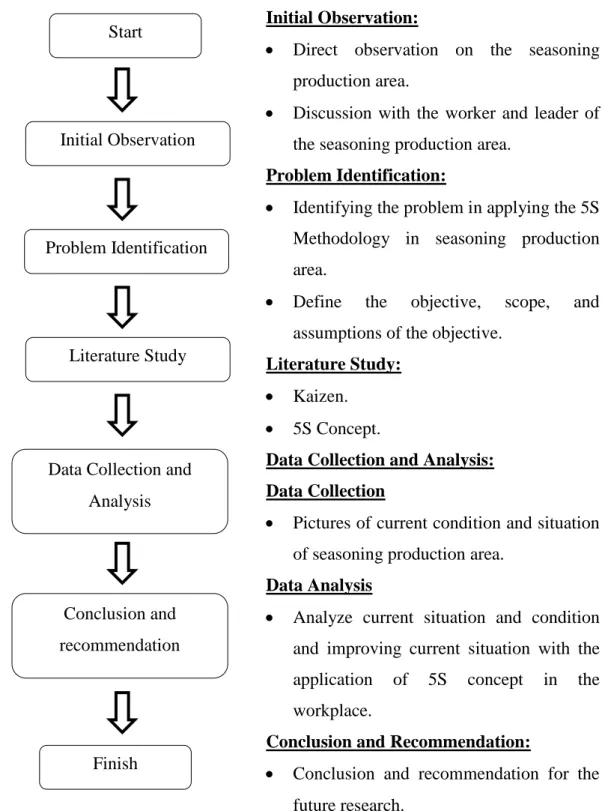

RESEARCH METHODOLOGY

Initial Observation

Problem Identification

Literature Study

Data Collection and Analysis

Conclusion and Recommendation

COMPANY PROFILE AND PROJECT

Company Profile

- Company History

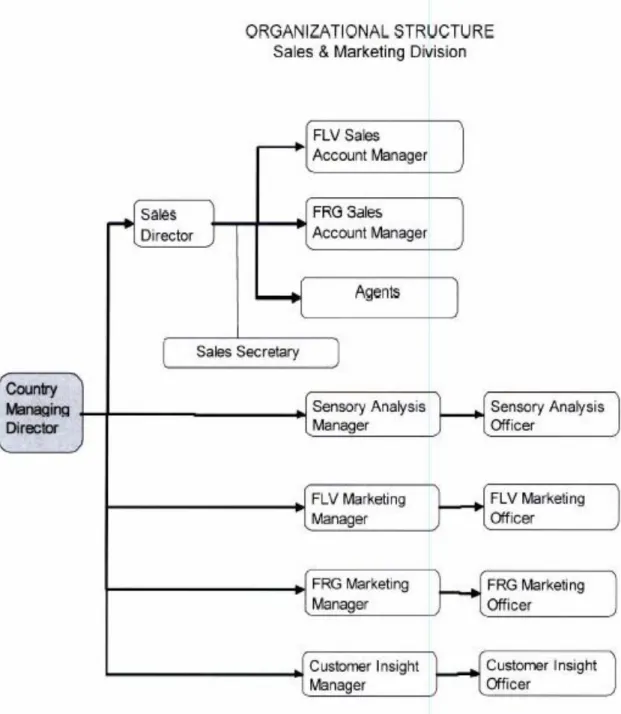

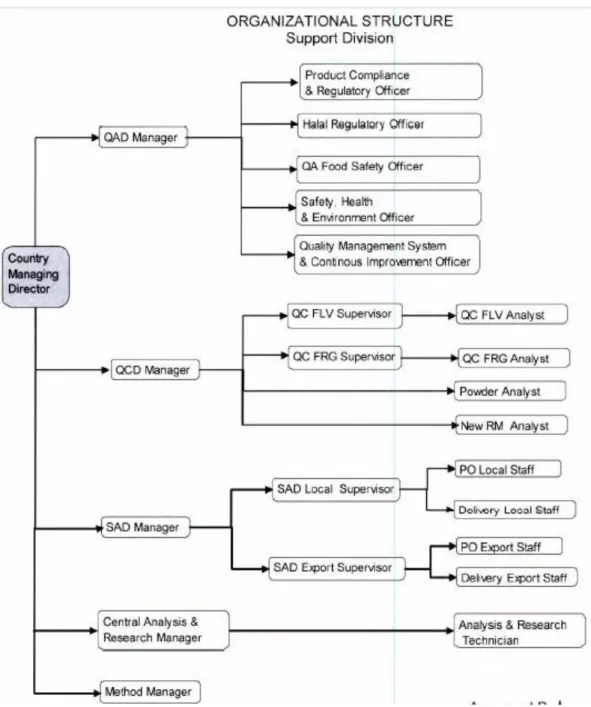

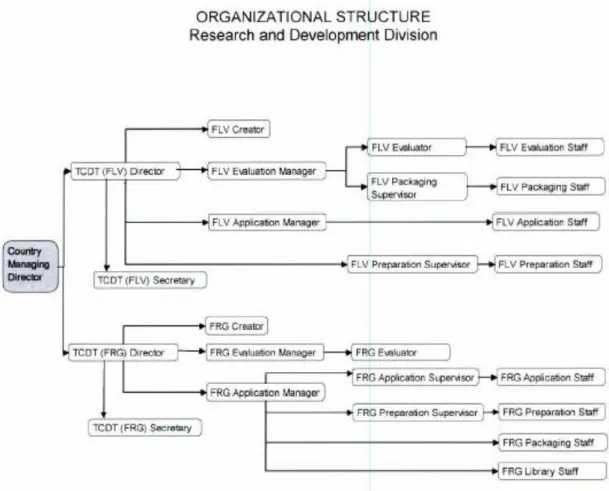

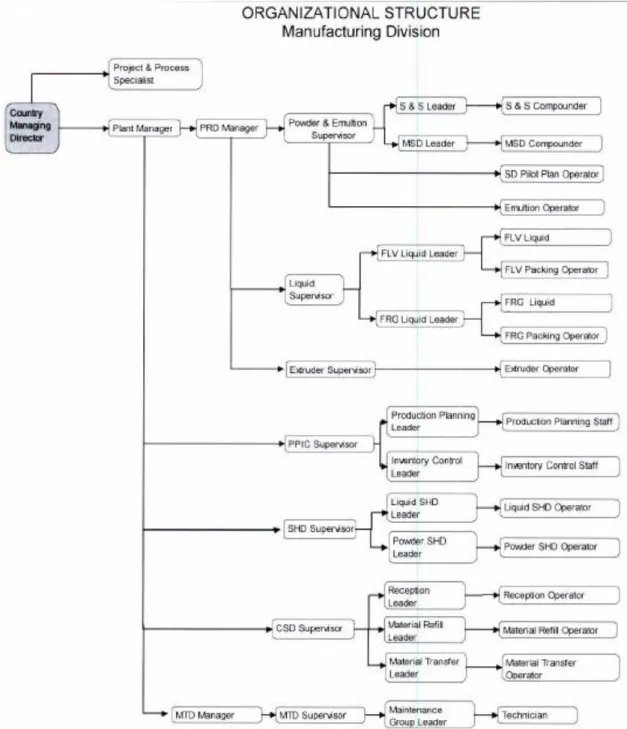

- Organizational Structure

- Company Policy

Since then, the small distillery, which has successfully grown into one of the leading Flavors and Fragrances companies in the world, has been continuously run by the MANE family. Inspired, because the company is independent, they have developed a genuine entrepreneurial spirit, so a freedom to think outside the box. The ISO 9001 certification is a quality management certification, which means that the quality of the company that has already obtained the ISO 9001 certificate meets the requirements of the International Standardize Organization.

24 From the point of view of the Sales and Marketing Division (shown in Figure 4.2), the Country Managing Director is in charge of the Sales Director, the Sensory Analysis Manager, the Flavor Marketing Manager, the Fragrance Marketing Manager and the Customer Insight Manager , in which each manager is assisted by their officers or staffs. Mane Indonesia which sells fragrances and flavors by handling and managing customer complaints, ensuring product quality and production processes in order to maintain quality in line with standard requirements and customer requirements. The new flavor and aroma that is produced by the Research and Development Division may come from the improvement of the old or existing product or come from a brand new product (product which has never existed before).

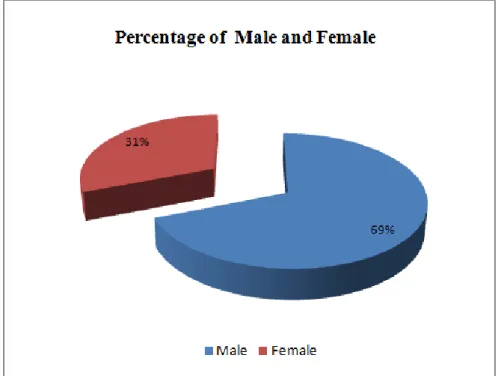

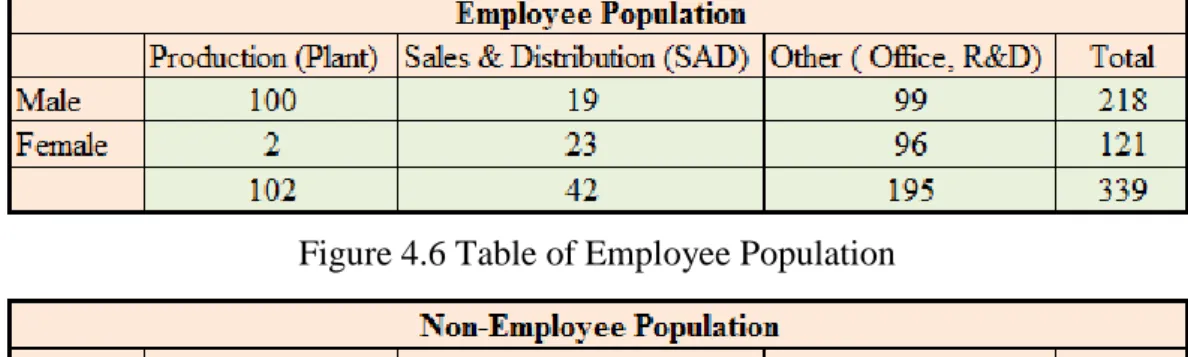

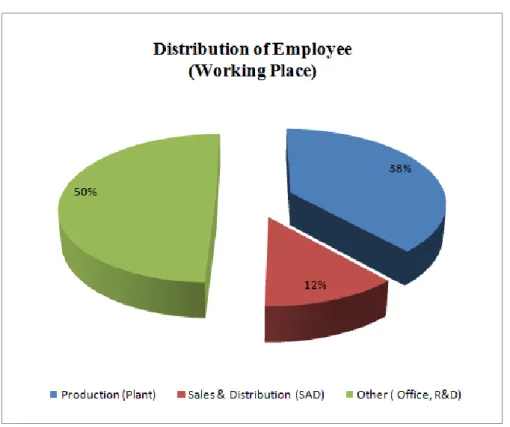

Mane Indonesia, while the non-employee group consists of the temporary workers who work for PT. And the distribution of the workers is 161 persons work in the Production Area, 51 persons work in the Sales and Distribution Area, 208 persons work in the office as Research and Development, and other supporting department member; such as member of the Information Technology Department, member of the Quality Assurance Department, member of the Accounting Department, member of the Maintenance Department and member of the Human Resources Department. Mane Indonesia as a large multinational company has the main policy and concern for the quality of its product as the heart of the company policy.

Criteria and methodology are established to ensure the efficiency of operation and process control. Food safety risks that may occur in products within the scope of the system are identified, evaluated and controlled so that products do not harm consumers, either directly or indirectly.

Production System and Product

- Production System

- Products

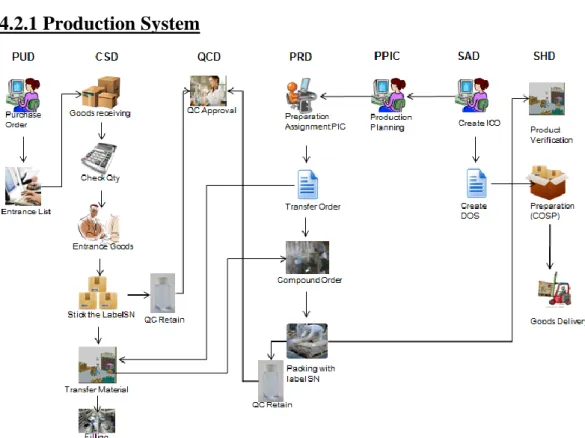

According to the standard, the materials are either transferred to the central storage or placed in the raw material drums on the production floor. After all materials are obtained and ready for use, the PPIC department transfers the production schedule to the production department in the form of a composite order. The compound order itself is a list of products that must be made within a certain time frame, in this case within one day.

After the production process is completed, some samples of the product are taken and given to the Quality Control (QC) department for checking, while at the same time the product is packaged and assigned a serial number (SN). When the quality control process is completed, the accepted product is transferred to the shipping department (SHD). After the product is ready to ship, the shipping department ships the product based on the schedule created by the Sales Administration (SAD) department.

Mane Indonesia as one of the biggest flavor houses in Indonesia has two products which are Flavor and Fragrance. For the shape of each product, it requires a certain type of machine which is different for one type of shape to another. Mana Indonesia are in the form of fine powder (capable of passing through certain mesh sizes).

Oil-soluble is a category of liquid whose base is oil and can dissolve in oil, while water-soluble is a category of liquid whose base is water and can dissolve in water. The paste category consists of liquid products that have a high density and are almost solid-like in appearance.

Project

DATA COLLECTION AND ANALYSIS

Data Collection and Analysis

The research began with initial direct observation in the spice production area; which from this observation the current conditions and situations of the spice production area are obtained. From the discussion with the operators and manager of the spice area, the routine of the workers during the working hours can be predicted and known verbatim. From the initial observation in the spice production area, it is known that some applications of 5S methodology have been implemented in the spice area, for example, in the spice area, some places are already being marked to give identification to the area. (for example the staging area) and labeling in the storage or placement of containers, the purpose of this labeling is to provide identification in storage so as to facilitate workers finding and storing the containers they intend to use, although the processes of marking and identification that have been done are not yet completed (compared to the 5S methodology and concept).

After consultation and finding out the limitations of 5S implementation, various observations, assessments and checks are made to implement 5S concepts. Through observations in the spice production floor, the situation, habit and daily routine of the. Despite marking and identifying areas and utensils, in order to successfully apply the 5S concept and methodology, the awareness of the employees must also be built, because if there is no awareness of the employees to maintain their workplace and worry about their workplace, the result of the 5S implementation will not last long, and the implementation of 5S can not be called a success.

The tool problem in this problem concerns the physical application of 5S methodology such as completeness of equipment, arrangement of materials, comprehensive marking and identification process, while the man problem concerns the mental changes of the workers such as the awareness, knowledge, understanding, willingness and the commitment of the workers as the main subject of the 5S implementation process. While the rearrangement process takes place only in the utensil drawers and cutlery caused by the carelessness of the worker in that area. And the cleaning processes were done on the outside of the workbench dust collector and the dust collector.

When changes are made during this study, a final image of the final state of the seasoning area is taken, shown in Figure 5.7 below. In order to increase the awareness of the workers, two steps are taken. Mane Indonesia, there are two main problems that this company has to overcome, such as physical changes and mental changes of the work space and workers.

The physical changes relate to the completeness of equipment, the arrangement of materials, the comprehensive marking and the comprehensive identification process, while the mental changes relate to the awareness, knowledge, understanding, willingness and dedication of the workers as the main topic of the 5S implementation process.

CONCLUSIONS AND RECOMMENDATIONS