The work associated with the development of a biogas stove was carried out in two parts. The second part of the study was devoted to the development of a naturally aspirated domestic biogas cooker with a PRB.

Nomenclature

ELU Environmental Loading Unit FCC Free Flame Combustion HCV High Calorific Value ICS Improved Cookstove LCA Life Cycle Assessment LCV Low Calorific Value. VMV Porous medium burner PMC Porous medium combustion PRB Porous radiant burner ppm part per million ppi Pores per inch ppc Pores per inch.

Contents

Development and Testing of Commercially Viable LPG Cook-stove with Porous Radiant Burner

85 4.2 Working principle of Self-aspirated LPG Cookstove with PRB 86 4.3 Procedures of Thermal Efficiency and Emission Measurement 86 4.4 Development of Self-aspirated LPG Cookstove with PRB for.

Waste Cooking Oil (WCO) Operated Domestic Cook-stove with PRB

Details of pan size and mass of water for Water Boiling Test (WBT)

List of Tables

Introduction

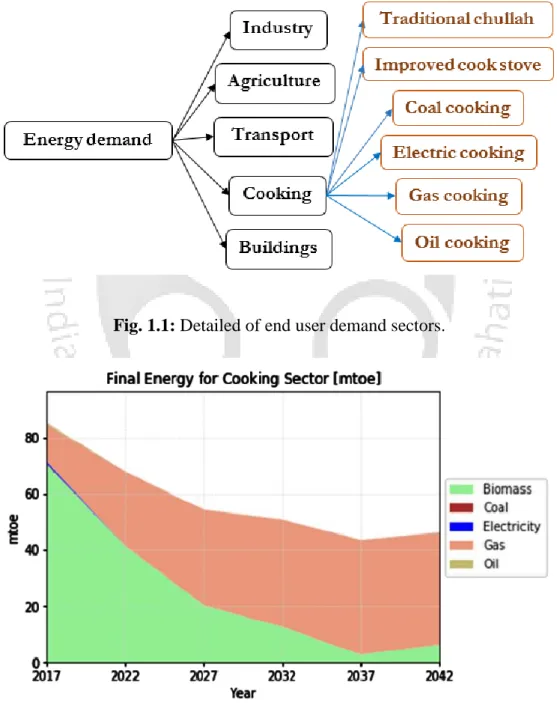

Overview of India’s Energy Situation

- Fuel usage trend in Indian household

- Current status of cooking technology

- Lesson learned and way forward

- Heat transfer mechanism in PMC

- Combustion stability in PMC

- Materials used in PMC

- Advantages of PMC

- Applications of PMC

However, in urban areas, most households used LPG as the primary energy source for cooking. Some of the heat produced in the flame zone is transferred to the solid matrix via convective heat transfer.

Motivation of the Thesis Work

Similarly, for kerosene application, porous radiant combustion cookstoves developed by Sinha (2017), showed maximum thermal efficiency improvement of ~16%. It is also observed that no researcher has studied the use of PMC for the development of cookstoves that run on biogas and waste cooking oil.

Organization of thesis

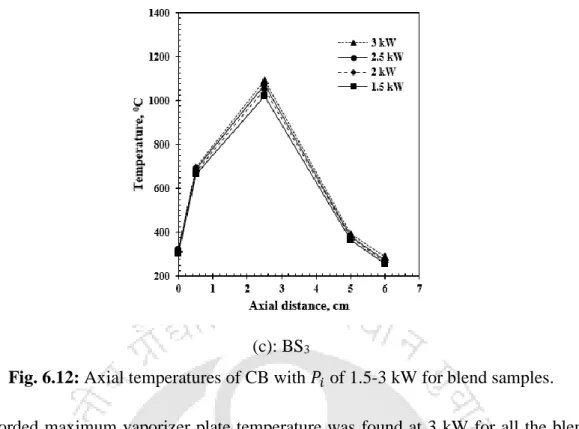

This study is also dedicated to investigate the use of biogas and waste cooking oil especially for domestic cooking applications. The combustion behavior inside the burner was studied using the temperature distribution at different positions of the burner.

State-of-the-Art

History of porous media combustion (PMC)

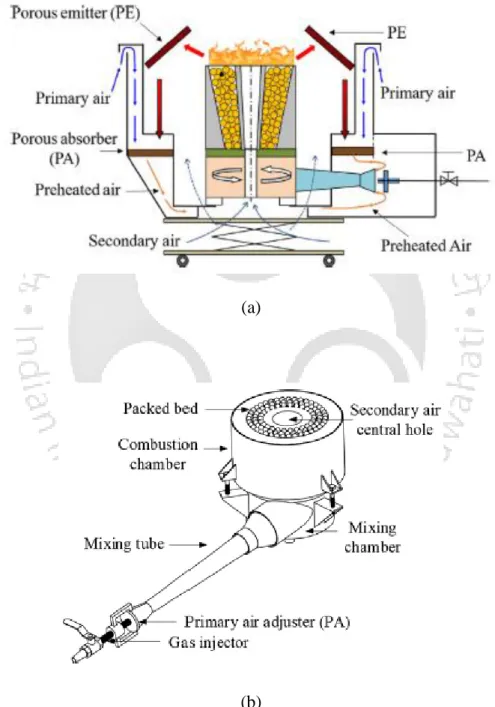

Mujeebu et al., 2009a, 2009b, 2010) presented state-of-the-art materials, configurations and performance of PRBs operating on various liquid and gaseous fuels, etc. We can see that until 2010 there was a good track of various developments in PMC technologies.

State of Art on LPG Cook-stove with Porous Radiant Burner (PRB)

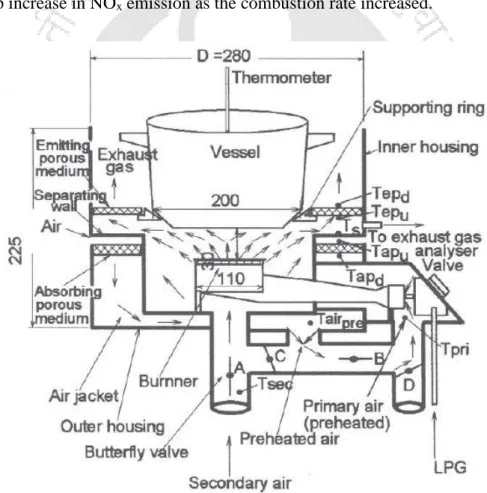

Another notable observation regarding the influence of ambient temperature on the thermal efficiency of PRB was also made by Muthukumar et al. They also observed that the loading height (i.e. the distance between the top of the PRB and the ship) of 30 mm is optimal.

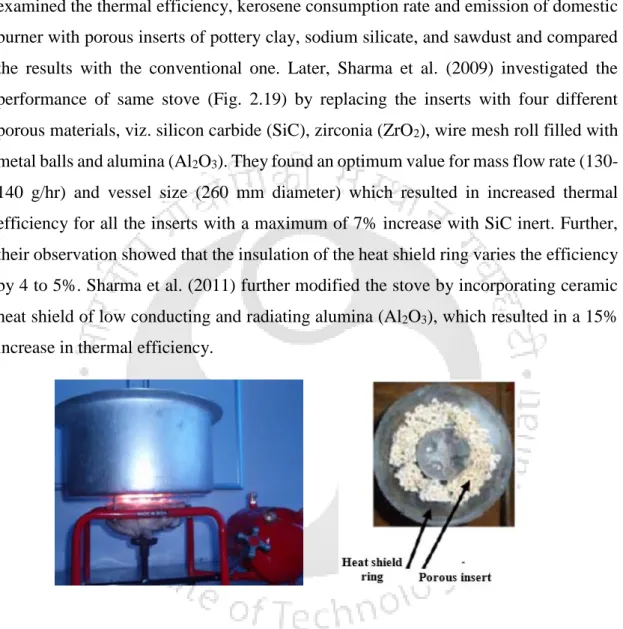

State of art on pressurized kerosene cook-stove with Porous Radiant Burner (PRB)

They studied the variation of operation depending on the shape of the burner, i.e. round and square shape. In the same burner, Sharma et al studied the effect of burner diameter on thermal efficiency, emission and temperature distribution at different air and fuel flow rates.

State of the art on biogas cook-stove developments

The results of these works are summarized in the respective sections of the development of biogas and vegetable oil stoves. 2014) developed a biogas burner for domestic use and found thermal efficiency with water boiling test (WBT) and rice cooking. Using CFD simulation, Decker (2017) optimized the flame port geometry and found maximum thermal efficiency of 56.8% compared to 53% of the available.

State of the art on plant oil cook-stove developments

With cottonseed oil and kerosene blended fuel, the thermal efficiency reported by Murthy et al. 2015) compared the performance of similar stove used by Murthy et al. bean cooking oil and kerosene blend. With Neem and Pongamia oil, Arvind and Bekal (2018) found that the decrease in calorific value and increase in viscosity (reduced fuel mobility and preheating) led to low thermal efficiency of the pressure cookers.

Literature Closure

Objectives of the Thesis

Performance Assessment of Self-aspirated LPG Cook- stoves with Porous Radiant Burner

Control Cooking Test of LPG operated domestic cook-stove with PRB

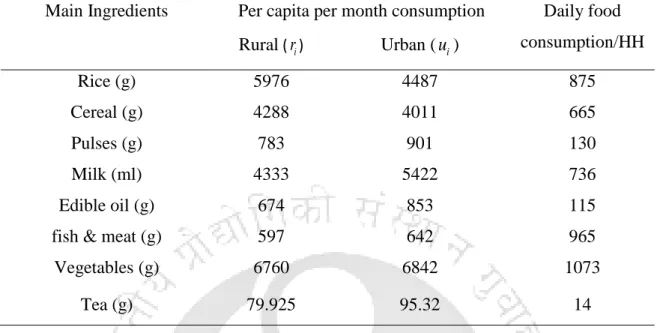

Based on the average daily intake of food type and quantity reported by NSC (2011-12) as given in Table 3.2, different dishes were cooked in both LPG stove using PRB and LPG conventional cooking stove. Three menus (A, B and C, Table 3.3) were prepared after a small inquiry was made in the families of a rural and urban household. For the preparation of menu-A, given in Table 3.3, the conventional stove consumed 296.76 g of LPG, while stove with PRB used only 203.49 g.

Life Cycle Assessment (LCA) of LPG Operated Cook-stoves with PRB

- System boundary and life cycle inventory for LPG

- LCA of medium scale cook-stove with PRB

- LCA of domestic scale cook-stove with PRB

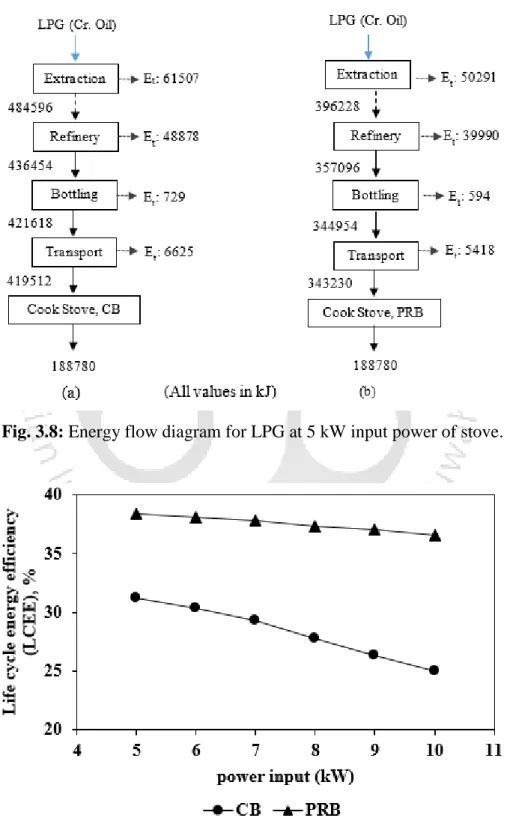

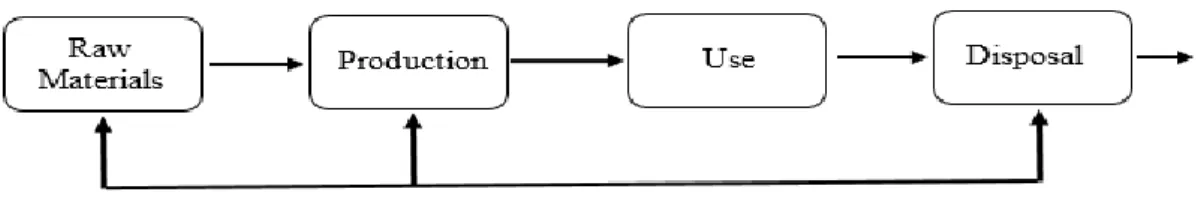

3.6, while for one specific complete LPG life cycle used in the present study, shown in Fig. Through road trucks, LPG cylinders are delivered to the retailers and then distributed to the customers for domestic/commercial cooking application, completing the life cycle of LPG. 3.8 (others are given in Appendix II) depicting the impact of burner efficiency on the life cycle energy flow stream of cooking fuels.

- Techno-economic Assessment (TEA) of medium scale PRB

- Techno-economic Assessment (TEA) of domestic scale PRB

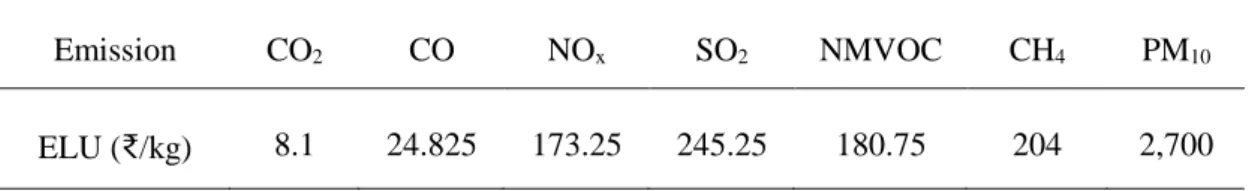

Emissions from stoves on an annual basis are calculated from Eq. D) Life Cycle Costing (CLS); which is the sum of the actual construction costs (𝐶 . 𝐿𝑠), the operating costs (𝐶𝑂𝑃) and the 𝐶𝑒𝑚𝑖𝑠𝑠𝑖𝑜𝑛cooker emission costs, where the lifetime of the oven is (years.𝐿) It should be noted that the same functional unit has been considered for all power inputs, and therefore the annual operating costs of the conventional burner are the same for all power inputs. Using an inflation rate of 5% and an interest rate of 8%, the cumulative present value of the annual savings over the life of the PRB furnace has been found to be ₹ 3,44,991.

Summary

Similarly, for domestic cooking stove comparative study of conventional and PRB based cooking stoves was carried out by the following CCT method. The CCT method gives a closer estimate of the performance of a cooking stove as it is based on the realistic consideration of cooking environment. Life cycle economic assessment shows annual savings of ₹2204 and the estimated cumulative present value of the annual savings for 10 years of life of the cookstove is ₹18036.

Development and Testing of Commercially Viable LPG Cook-stove with Porous Radiant Burner

Scope of Modification in Self-aspirated PRB for Medium Scale Cooking Application

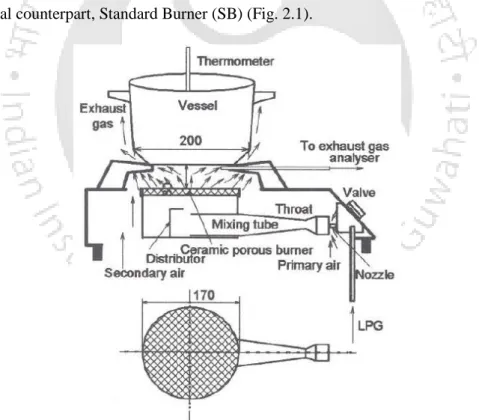

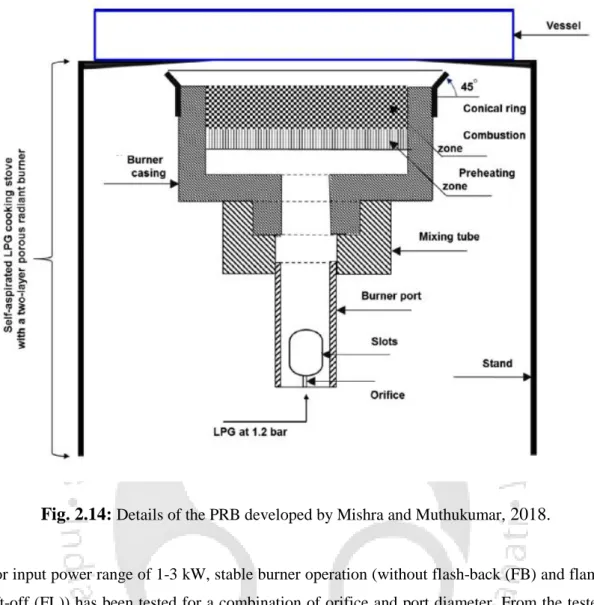

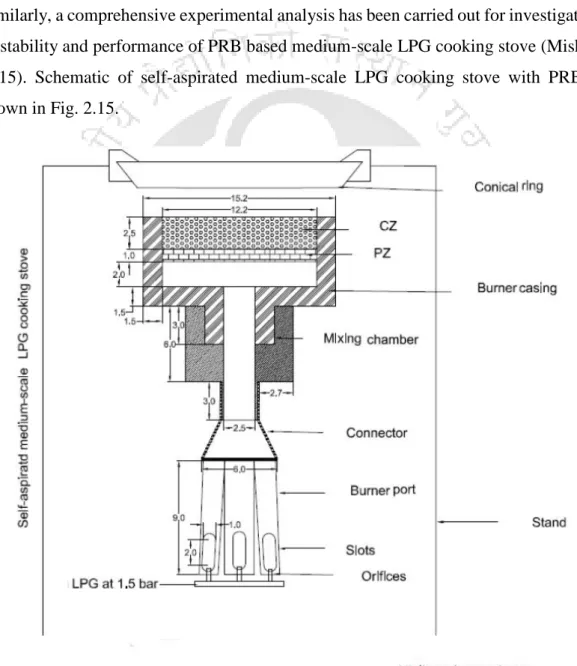

Due to the venturi effect, the high velocity LPG jet creates a low static pressure near the burner port and this causes suction of primary air through the two primary air slots. Air and gas move via burner port through a mixing chamber and reach the burner casing. Once the burner has reached a stable state, performance viz. thermal efficiency and emissions estimated.

Procedures of Thermal Efficiency and Emission Measurement

Flashback occurs when the flame moves upstream into the mixing chamber, whereas detachment of the flame from the burner surface involves blowdown. The burner is ignited and after the burner has reached its steady state, the container is held over the burner. The hood was placed over the burner along with the container and the portable flue gas analyzer probe was placed in the first sampling hole.

Development of Self–aspirated LPG Cook-stove with PRB for Medium-scale Cooking Application

- Result and Discussion

- Summary

Within the input power range of 5–7 kW, the thermal efficiency and emission variations are shown in Figs. The performance in terms of temperature distribution, thermal efficiency and CO and NOx emissions of the stove have been investigated experimentally. This mode of operation results in higher thermal efficiency and also showed more uniform temperature over the burner surface.

Bio-gas Operated Domestic Cook-stove with PRB

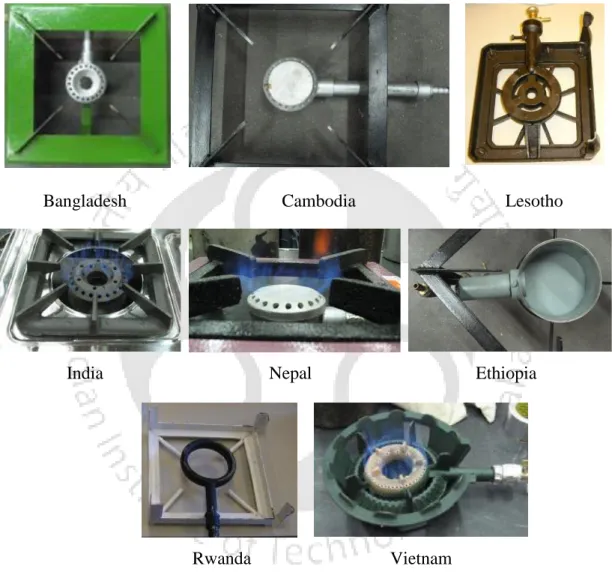

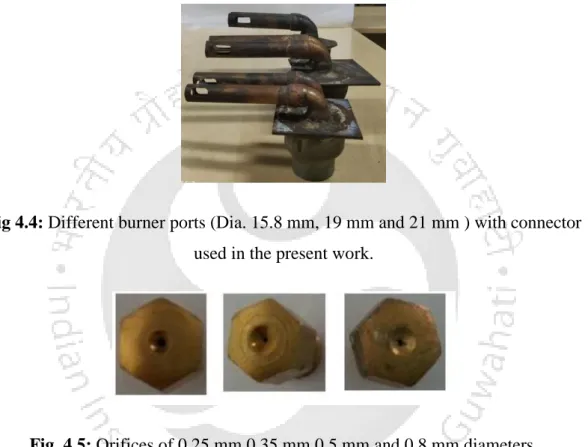

Performance Assessment of Domestic Scale Conventional Biogas Cook-stove Different types of domestic biogas cook-stove available in the Indian market are shown

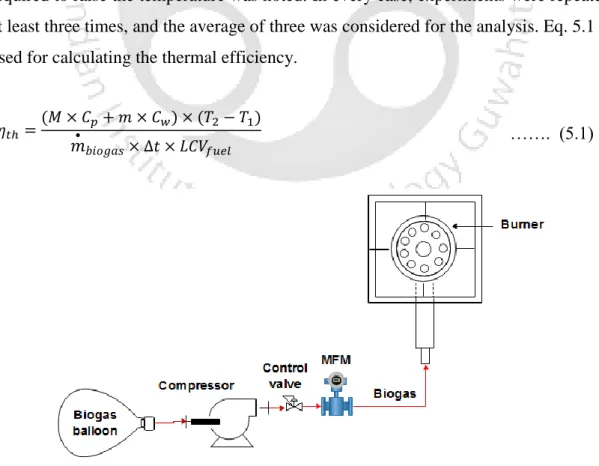

The compressed biogas from the biogas balloon was fed into the hotplate and the flow rate was measured with a Coriolis mass flow meter (MFM). The thermal efficiency of a conventional biogas stove was evaluated for a flow range of 177 to 530 l/h (1-3 kW) and was found to be in the range of 43 to 52%. As conventional biogas burners are designed to burn fuel, incomplete combustion in a conventional stove results in high CO emissions.

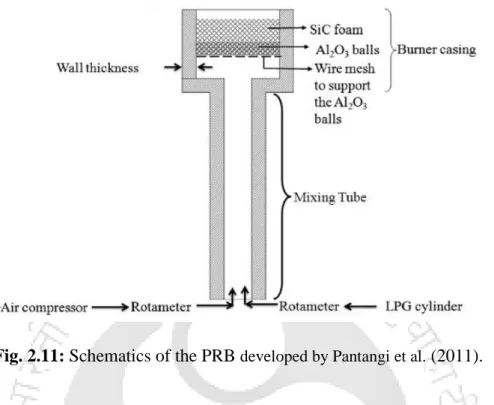

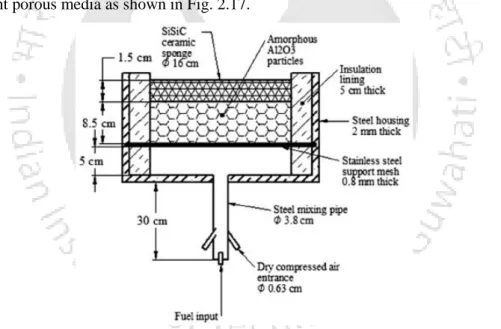

Investigation of PRB Performance with Forced Air Supply

- Experimental procedure and performance indicators

- Result and discussion

The schematic of the experimental setup used to characterize biogas combustion is shown in the figure. The schematic of the experimental setup used for thermal efficiency and emission measurements is shown in Fig. maximum surface temperature of PRB.

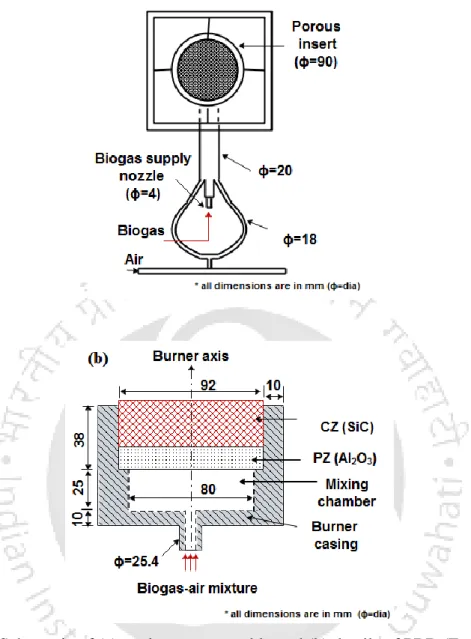

Development of Self–aspirated Biogas Cook-stove with PRB

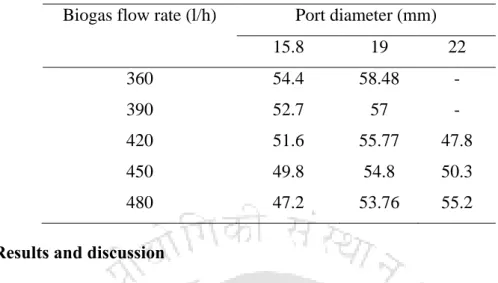

The specifications of self-aspirating domestic biogas stoves with PRB are shown in Fig. The comparative thermal efficiency of the self-priming PRB and the conventional biogas cookstove within the operating biogas flow rate range of 360 l/h to 480 l/h is shown in Fig. The overall performance of the self-priming PRB indicates that it is perfectly suited for domestic cooking applications.

Summary

For the operational biogas flow rate range from 360 l/h to 480 l/h, the radial and axial temperature distributions are shown in Fig. Both the radial and axial temperature distributions found for self-priming PRB also follow similar trends to those of the forced-air supply PRB.

Waste cooking oil (WCO) Operated Domestic Cook- stove with PRB

Thermo-physical properties of blend samples of waste cooking oil (WCO) and kerosene

Design and fabrication of WCO/kerosene blend operated PRB

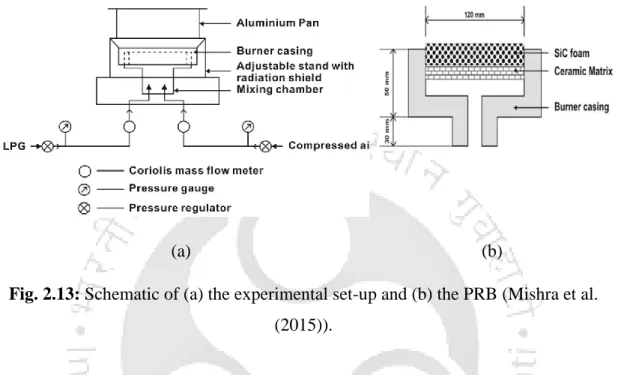

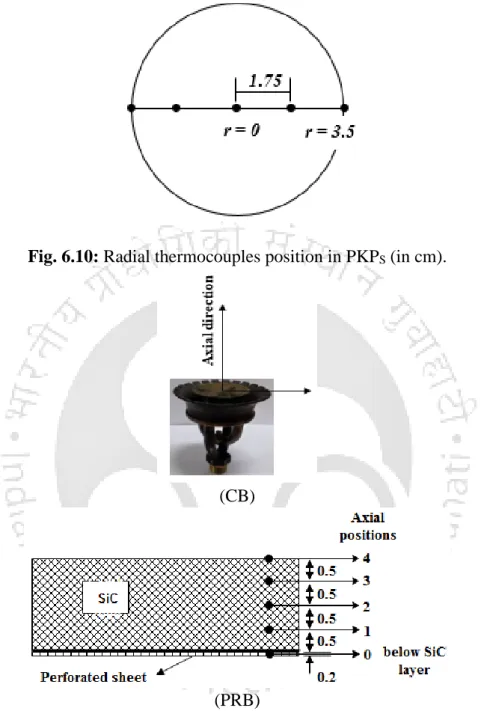

Detailed specifications of the heater, nozzle, CB and porous insert used in the study can be found in Table 6.2. The initiation of the combustion process in both burners is quite similar, but the combustion principle is different. Figure 6.9 shows a schematic representation of the experimental setup used for thermal efficiency and emission measurements.

Experimental procedure and performance indicators

- Temperature mapping

- Radiation efficiency

- Thermal efficiency

- Emissions

- Control Cooking Test (CCT) and Techno-economic Assessment (TEA) As discussed earlier (Chapter 3), t he feasibility testing of developed cook-stove needs

Therefore, a suitable consistent value of the ambient temperature (27C) was taken into account to calculate the radiation efficiency. Where 𝑚𝑝 is the mass of the vessel with lid and stirrer (kg), 𝑚𝑤 is the mass of water in the pan (kg), 𝐶 is the specific heat (p: pan and w: water), 𝑇2 and 𝑇1 are the final and initial water temperatures. The average value of the consumed fuel shows the daily need for thermal energy per household, which was further used for the technical-economic assessment (TEA).

Results and discussion

- Axial and radial temperature distribution

- Thermal efficiency

- Emissions

- Empirical correlation for PKPs thermal efficiency (𝜼 𝒕𝒉 )

- Techno-economic Assessment (TEA)

Due to the collective effects of conductive and radiative heat transfer in the highly emissive porous material, for all tests, PKPS showed higher thermal efficiency than CKPS. The vessels and details of time and amount of fuel required for cooking are given in Table 6.6 and Table 6.7, respectively. Compared to the life of the cooking stove (10 years), the payback period is also very small.

Summary

Conclusions and Future Work

Conclusions

In the first part, with external air supply, the stability range of the burner was identified and then the burner dimensions have been determined for use in the home power range. For stable combination, detailed performance studies have been carried out and also compared with that of forced air supply to see its working equivalence ratio (self-aspiration capability). In the last phase of the work, studies have been carried out to demonstrate WCO as an alternative option for fuel preparation.

Scopes for future work

From CCT it has been shown that PRB on a daily basis results in 49 minutes and.

Min D.K., Shin H.D., (1991), Laminar premixed flame stabilized within ceramic honeycomb International Journal of Heat and Mass Transfer, vol. Mujeebu M.A., Abdullah M.Z., Zuber M., (2013), Experiment and simulation for the development of a clean porous medium surface combustor using LPG, Journal of Thermal Science & Technology, vol. Panigrahy S., Mishra N.K., Mishra S.C., Muthukumar P., (2016a), Numerical and Experimental Analyzes of LPG (Liquefied Petroleum Gas) Combustion in a Porous Radiant Burner Domestic Stove.

APPENDIX – I

Properties of Fuels

APPENDIX – II

Life Cycle energy inventory (energy and emission) of LPG

Life cycle environmental impact distribution of LPG with CB at 5 kW operating power input. Life cycle environmental impact distribution of LPG with CB at 6 kW operating power input. Life cycle environmental impact distribution of LPG with CB at 10 kW operating power input.

APPENDIX – III

Uncertainty Analysis

APPENDIX – IV

Details of pan size and mass of water for Water Boiling Test (WBT)

APPENDIX – V

Technical Specifications of the Instruments Used in the Experiments

Pressure gauge

Pressure regulators

Compressor

Weighing balance

Thermocouples

Mass flow meters

Portable gas analyzer

Data Acquisition Unit (DAQ)