The Department of Science and Technology (DOST) strives to inoculate in all its agencies and institutes the drive to keep our "Bosses", the Filipino people, at the heart of everything we do. Our National Metrology Laboratory or NML, also the National Metrology Institute of the Philippines or NMI, ended 2013 with the acceptance of the country's calibration and measurement capabilities (CMC) in the field of mass. While the lechon used in the study was from Leyte, the results can be replicated or used as a reference for further studies on pork lechon in other areas of the country.

The project was implemented to determine the level at which migration, if any significant migration present, would occur between LDPE film and food simulants when exposed to an artificial light source that closely mimics natural daylight. The test results generated from the study would benefit MSMEs in assessing the appropriate inventory of LDPE packaging material used in applications that may be exposed to direct sunlight or during storage or transit and use this material later for food packaging. Decision makers such as managers or general food retailers whose LDPE packaging is in frequent exposure to sunlight may find the results useful in resolving issues involving a trade-off between packaging material availability and product safety. food.

LDPE is the polymer or plastic commonly used in food packaging because it is cheap and readily available. While recycling is recommended, some food safety issues should not be overlooked as UV rays from the sun can react with the polymer from the LDPE bags producing some products or by-products that will migrate into the food when in contact with the bag. Effect of simulated sunlight on the migration characteristics of low density polyethylene (LDPE) packaging film.

A biomass steam boiler was designed and built, which can be used to boil and concentrate coconut water as an intermediate material for the production of coconut drink. A ratio of one (1) part concentrated coconut water to thirteen (13) parts pre-boiled water is required to achieve the original sweetness (5°Brix) of fresh coconut water. Construction of a biomass steam boiler for the production of concentrated coconut water as an intermediate material for coconut drink.

It can also be used to process excess coconut water that is only wasted due to a lack of appropriate equipment and processing knowledge. The biomass fired steam boiler is a simple open type evaporator pan, suitable for concentrating coconut water in small farms. Based on field trials, the minimum amount of coconut water for cooking per batch is 60 kg and the maximum amount of coconut water is 75 kg.

With this kettle and the developed processing method, coconut water can be treated more efficiently, its shelf life extended and preserved, leaving no room for waste. The cooking time to concentrate the coconut water was set at 6-7 hours per batch, while the rate of evaporation of coconut water per kg per hour is higher (11.83 kg/hour) at 30 psi (134°C). Additional filtration is necessary to remove the sediments. Adherence to Good Manufacturing Practices (GMP) is a must to avoid contamination during the processing of concentrated coconut water. The field test results were inconclusive, so more field trials should be conducted to obtain reproducible results.

The results showed an improved yellow color on the product and no immediate degradation of the color was observed during processing. To improve the study, other methods of analysis such as UV-Vis spectrometry and HPLC should be performed on the extracted pigments to get more details about their identities and of other compounds that may have been co-extracted. In addition, other extraction techniques such as supercritical fluid extraction (SFE) and ultrasonically assisted extraction (USE) should be studied to develop more efficient and greener standardized procedures in the production of natural food coloring from Tiesa.

Development of restructured steak

The results of the analyzes showed that the oil from the Kalumpang seeds is rich in linoleic acid (48.09%) and palmitic acid (35.64%). Based on the results, kalumpang seed may be a suitable raw material for the production of biodiesel and other oleochemicals. Analyzes have shown that the oil is a viable replacement for diesel based on PNS ASTM biodiesel standards.

Extraction of seed oil using hexane was done after grinding and preheating at 60 oC. The oil was then analyzed for acid value, saponification value, iodine value, density, kinematic viscosity and gas chromatography. Trans-esterification was performed to produce calumpang seed oil methyl ester (CSOME) using the optimized parameters for coconut and Jathropa curcas oil.

Fuels / Biofuels

Calumpang seeds, Sterculia foetida, were studied to determine their characteristics as a potential source of biofuels and other oleochemicals.

Environment

Development of the ITDI Hazardous Waste Management Manual

Development of electrospun cellulose acetate/

Nanotechnology

TECHNICAL SERVICES

Tests & Standards

One of the MiC project initiatives during the year is to conduct Proficiency Testing (PT) services for contaminants in food and metals in water. Currently, the MiC program is conducting PT on samples of benzoic acid in mango juice and metals in water.

Establishment of ADMATEL - Phase 2 (Operation)

ADMATEL

Metrology

NML's Thermometry Standards Laboratories were also awarded their ISO 17025 accreditation by Germany's leading accreditation body Deutsche Akkreditierungsstelle GmbH (DAkkS) following an oversight visit last October, while the Thermometry Standards Section (LIGT, DT and IPRT) maintained Success Section of Thermometry Standards (LIGT, DT and IPRT) of NMLDAkS. . Both the technical capability of the Thermometry Section and the quality system of NML were evaluated in accordance with ISO by Dr. Erich Tegeler, former Head of the Thermometry Laboratory of the PTB (German National Institute of Metrology), who although retired from the PTB still works as a technical assessor. for DAkkS in Germany and around the globe.

He thoroughly assessed the Laboratory's quality system and then evaluated the technical competence of the Thermometry Laboratory. Despite some minor deviations issued on the technical side, none were critical and therefore have no significant effect on the quality of calibration service provided by the Thermometry Department to its customers. Similarly, the Printing Department also underwent a laboratory surveillance visit in November 2013. Knowledge Translation or KT is now increasing in importance in Science and Technology, especially in the field of research and development (R&D) by moving the results of research work from the laboratory to the hands of people and organizations that may have the potential to adopt them. good use.

KT initiatives are implemented in the form of technology forum, social marketing, technical services, training and consulting leading to eventual commercialization and subsequent business ventures.

Social Marketing

Knowledge Translation

Technology forum

Knowledge Products

Intellectual property

Jollibee Foods Corporation, 5/F Jollibee Plaza, Ortigas Center, Pasig City Detergent Powder (Use of ITDI facilities for trial production of detergent powder for perfume testing based on client's formulation). Arnulfo Singca, Mica By the Sea, 609 Sirloin St., FTI, Taguig City Production of bottled sardines in oil. Umali, Las Pinas Doctor's Hospital, Las Pinas City Trial Production of Activated Carbon from Coco Peat & Carbonized Coco Shell Powder Mr.

28 Fruit processing 29 Bioreactor technology 30 Introduction to metrology 31 Calibration of electronic balances 32 Testing of commercial balances. Diffun, Quirino NMD, ITDI FPD, ITDI NMD, ITDI FPD, ITDI FPD, ITDI NMD, ITDI FPD, ITDI NMD, ITDI NMD, ITDI FPD, ITDI FPD, ITDI. 7 Processing Bottled Fishery Products 8 Making Ceramic Pot Filters 9 Processing Vinegar Using the ITDI Acetator 10 Processing Vinegar Using the ITDI Acetator Kit 11 Processing Calamansi.

15 Installation/Training on operation of vinegar acetator kit and wine kit 16 Operation and maintenance of bioreactor and plastic shredder. 18 Manufacture of ceramic filters (baking and application of anti-microbial agent) 19 Installation/Training on operation of vinegar acetator kit and wine kit 20 Fabrication/Operation of portable biogas digester. 43 Installation/Operational Training of Vinegar Acetator Kit Technology 44 Energy Management and Audit Processes with Practicum.

Kamuning, Quezon City Munisipaliteit van Pamplona, Negros Oriental First Philippine Scales, Inc., Potrero, Malabon.

QUALITY

HEALTHCARE

Dietary antioxidants from plants

Health Products

RESEARCH &

DEVELOPMENT

Production of dome - type ceramic water filter

S&T DISASTER PREPAREDNESS

Ready-to-Eat (RTE) chicken arroz caldo

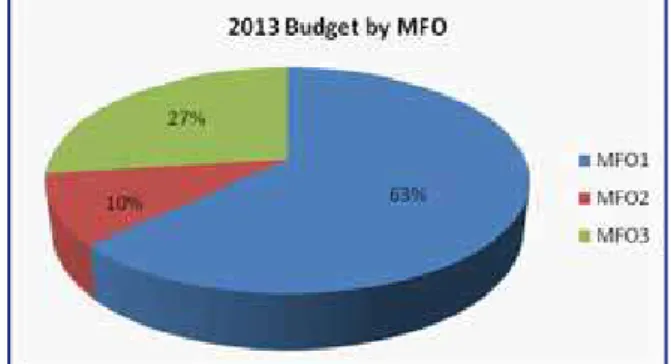

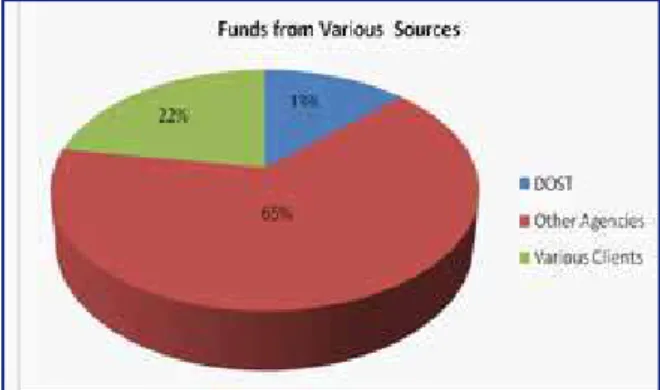

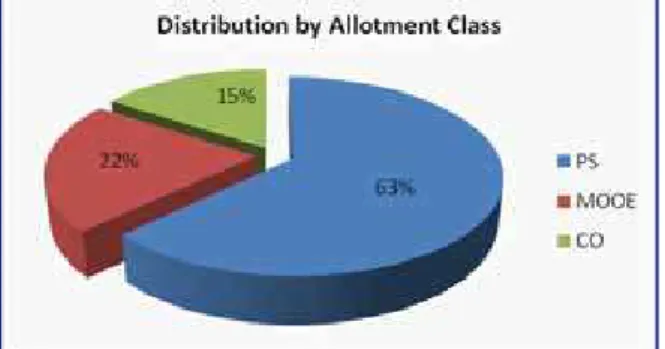

Financial Management

Human Resource Development

Manpower Profile

Awards

2013 DOST International Publication Awards (IPA)

The award ceremony was held at the Traders Hotel Manila on December 12, 2013. The DOST IPA Awards are presented annually by the National Academy of Science and Technology (NAST), Philippines (NAST Phil), this time under the theme of "Evaluating" and Improving Research Publication and IP Productivity for the DOST R&D institutes.

Best R&D Paper, PCAARRD

S&T Networks

Effect of alkaline treatment of Eicchorinia crassipes fibers on the properties of Eicchornia crasipes/HDPE biocomposite - MSD. Adsorption properties of bentonite and activated carbon in the treatment of oil-seawater emulsion - oral presentation (MSD). Development of VCO-based personal care products for hair and skin (PCHRD). Improved technology for slow release fertilizers.

Development of fatty acid grafted coconut dust as oil spill adsorbing dietary antioxidants from plants. Removal and Decomposition of Water Soluble Diesel Oil Fraction by TI02 Photocatalysis Development of Calcium Carbonate Chitosan Composites from Waste for Spill Treatment. Comparative study on the effect of the use of different additives in the market on the oxobiodegradation of polyethylene plastic bags.

Food safety assessment of the sodium content of the cornice fabrication produced in place of the biomass fired steam boiler for the production of concentrated coconut water as an intermediate material for coconut beverages. Development of Silver Filled Epoxy (SFE) / Halloysite Nanotube (HNT) Nanocomposites as Bonding Material in Semiconductor Devices. Effect of storage time and temperature on the properties of selected flexible materials Effect of simulated sunlight on the safety of low density polyethylene (LDPE) as food packaging film.

Development of Packaging Technology for Pork Lechon (Regular to GIA) Effects of Slots on the Compressive Strength of Corrugated Sheet Panels.

Organizational Chart

Key Officials

INDUSTRIAL TECHNOLOGY DEVELOPMENT INSTITUTE