I am writing to let you know that this thesis report titled "Study on Issues Impeding the Workflow of a Trader" has been prepared by the student who wears ID and ID has been completed for final evaluation. Abdullah Al Mamun, Associate Professor, Department of Textile Engineering, Daffodil International University, for giving us the opportunity to work on this thesis report and providing us with invaluable guidance throughout the work.

Background of The Study

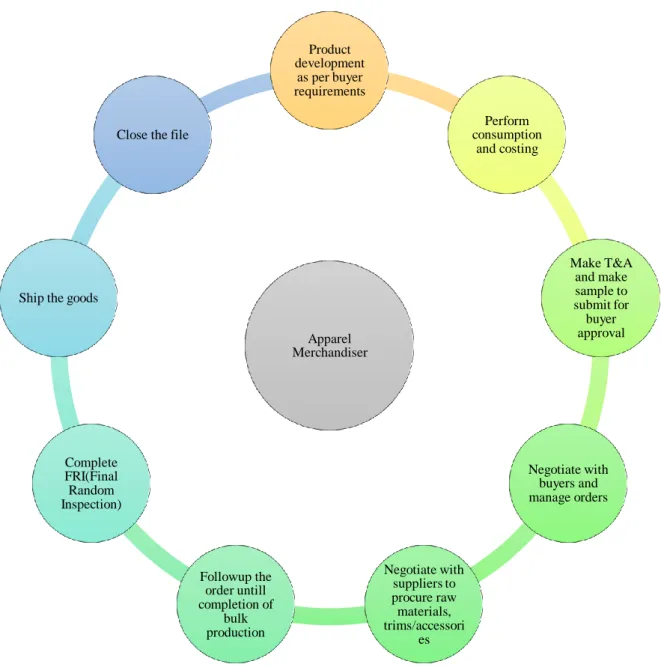

Thus, the apparel merchandising process can be defined as the development, execution and delivery of a product line based on the needs of the target market. The merchandiser is the bridge between the management (or) industry and the buyer in the apparel industry.

Objectives of The Study

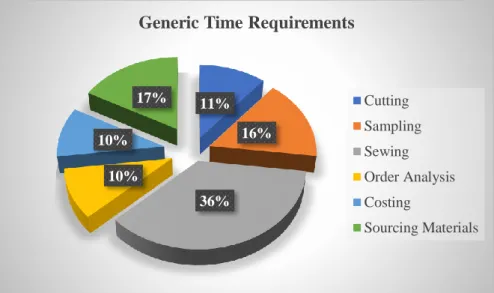

Daffodil International University 13 | P a g e The complex task of developing, executing and delivering product lines based on the needs of a target market is the responsibility of the apparel marketer. The position, responsibilities and authority of the apparel marketer evolved as apparel companies moved from a traditional focus on 'production efficiency' to a more recent focus on 'changing consumer needs.'

Significance of The Study

Limitation of The Study

Previous Works

If the supply chain is not strong, the important subject or department of the company will not deliver the required product on time. Another important point is the distribution of power, so management must distribute it to the right employee.

Merchandising

Merchandising Type

Primary Roles of Merchandiser

Working Flowchart of a Merchandiser

Basic Organogram of a Merchandising Department

Roles of Fashion Merchandiser

But the dealer's role is to coordinate with the designer on the buyer's needs and terms based on his previous experience. Therefore, the retailer's influence on clothing design plays a vital role in the adoption of the developed design.

Role of a Production Merchandiser

Then the seller sends the dyed fabric samples to the buyer for color analysis and approval. Buyer will provide feedback to seller for revision of that sample if necessary.

Retail Merchandising

It is the final process where the garments are packed into boxes and shipped. Daffodil International University 32 | P a g e Promotional Activities: Sales promotion is important for the successful sale of merchandise. Sales Evaluation: The retailer evaluates the sales rate of the product after each selling season.

This includes analyzing sales by product, style, size and color, unsold items, fast sold items, price by line, etc. The general process flow of the retail merchandising process is given below in the figure.

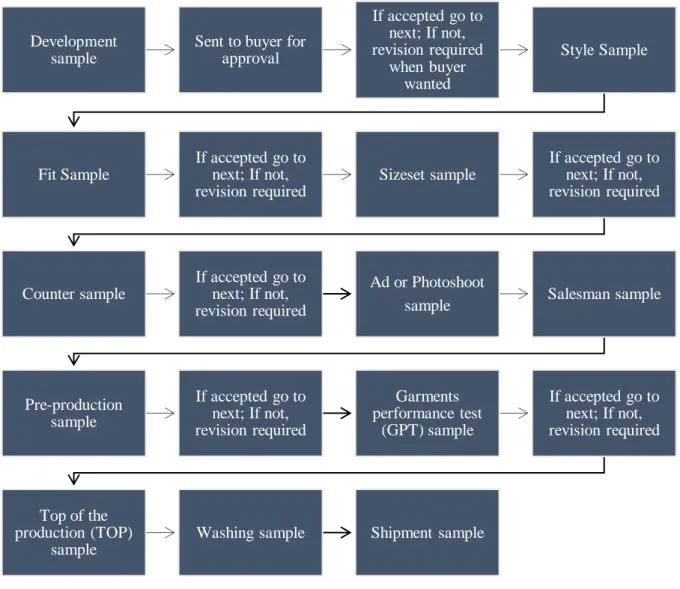

Samples in Apparel Industry

Therefore, the stage exporter should send some additional samples to the buyer in different manufacturing stages depending on the necessity. If the number of sizes is large, the buyer can request a jump size set sample, which skips some measures. As the buyer requires, samples can be made in the sample room or factory floor.

The buyer will issue a purchase order (PO) to the Company based on the counter sample clearance. These samples are only requested if the buyer requires samples to promote their styles in media such as TV commercials, promotional clippings, catalogs, etc. The wax sample is sent to the buyer for approval at the size set stage or PP stage.

In the TOP sample, the buyer tries to evaluate the actual production of the style.

![Table 2.11.1: Samples in the apparel industry [1]](https://thumb-ap.123doks.com/thumbv2/filepdfnet/10931745.0/34.892.110.778.517.1160/table-2-11-1-samples-apparel-industry-1.webp)

Sampling Process

As soon as the first products come off the sewing line, the customer receives a production peak, including comments from the quality assessment department. Some buyers may request shipping samples, which the company must take from the actual cargo and provide. The main purpose of this sample is to assure the buyers about the actual shipment of the shipment.

Quality of a Merchandiser

Merchandiser Interface with Other Departments of an Industry

- Industrial Engineering or Production Planning department

- Sourcing / Purchase Department

- Quality audit Department

- Production Department

- Finance / Accounts Department

- Marketing Department

- Designing Department

- Human Resource (HR.) Department

Based on the information received from the planning department, the merchant advises the purchasing department on the purchase of the necessary raw materials and their quantity. In return, the merchant receives details from the purchasing department. a) Changes in material stocks. After confirming the order with the estimated production start date, the merchant informs the production department about the future order and requirements.

Once the planning and scheduling activities are complete, the merchant consults with the financial manager before instructing the purchasing department. The dealer works closely with the design department in both cases where the Company develops the product or executes the requirement asked from the buyer. In the first case, the trader will be aware of the marketing department's market status and research report.

In the second case, due to his long-term communication with the buyer, the understanding of the buyer is high for the trader.

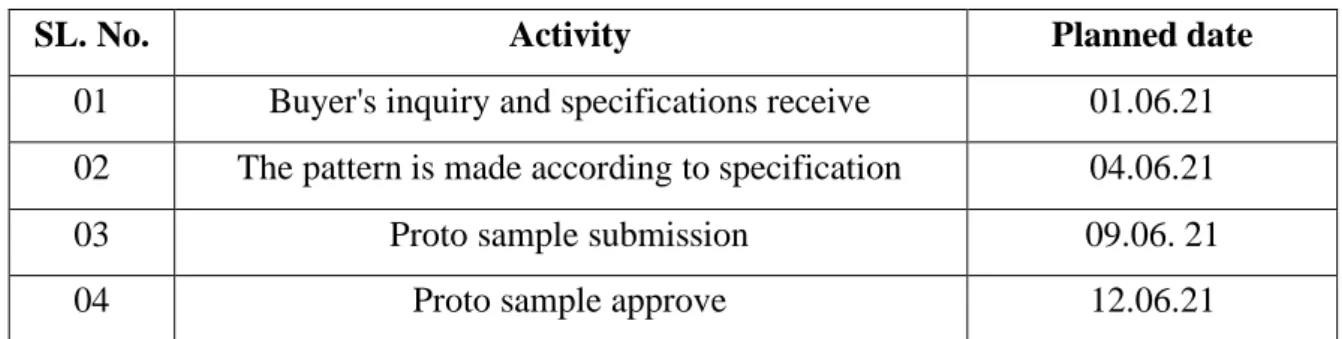

Time and Action Plan

Factors that Considered to Making Time and Action Plan

Since approval from the buyer or his/her Company's top management is necessary after each stage of sampling, unexpected delays in the sampling process make the trader uncomfortable. Therefore, sufficient buffer time should be provided between operations during the preparation of the ANT, based on the experience of the individual. The figure below details the various vital activities that must be performed by a marketer at multiple levels of sample development.

Gantt Chart

The chart will be updated as the project progresses by filling the bars to a length corresponding to the percentage of the task completed. Tasks that have been completed are placed to the left of the line and filled in. If the completed portion of current tasks crosses the line to the left, they are behind schedule; if the completed section stops to the right, they are ahead of schedule.

Therefore, each order has a series of tasks that lead to a specific performance and must be completed in a specific order. A trader must be adaptable and regularly keep their time and action charts up to date. This is dangerous as the dealer may not have a good understanding of how long the task will take.

Alternatively, he or she may not be aware of how long it will take for you to acquire the components you have ordered for a project.

Network Chart

Critical Path Method (CPM)

One of the most important criteria for project management is a reasonable schedule of various activities for the earliest possible completion of the project. The preparation of such a schedule will require information on the duration in which the various activities can be completed. The first step in presenting a network is to understand the interrelationship between the many activities that make up the project.

In this method (CPM), the network diagram is made of symbols such as nodes and arrows. Where a node and an arrow represent the completion of an activity, this represents a task and the sequence of events, as in Figure 3.4. This method calculates the earliest possible start time and the latest possible start time of each activity.

In addition, it will identify critical activities, which can be defined as “Activities, if delayed even for a short time, the entire project will be delayed.

PERT (Program Evaluation and Review Technique)

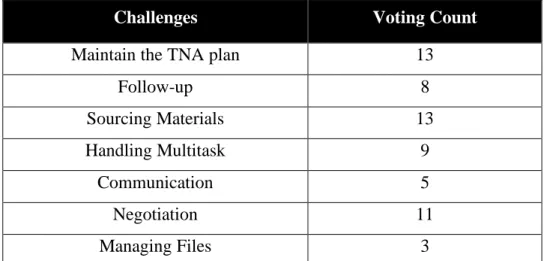

To prioritize work, we performed a Pareto analysis to identify the 20% of challenges that cause the other 80% of data-driven problems. Daffodil International University 55 | Page The Pareto principle (also known as the 80/20 rule) is a phenomenon that states that approximately 80% of the results come from 20% of the causes. So the TNA Maintenance plan gets the most votes at the time of the poll and the number is 13.

So if we can solve the problems "Maintain TNA Plan, Procurement of Materials, Negotiation", the final result of late shipment will change to timely shipment. A TNA consists of several individual jobs, so it is crucial to keep all tasks on time by following up on time with the person responsible for the task/job. So we did a fishbone analysis to solve the problems of maintaining the TNA plan.

There we identified the Supplier, Buyer, Machines and people of the company that have a direct effect on the execution of the ANT on a planned basis.

Sourcing Materials

Negotiation

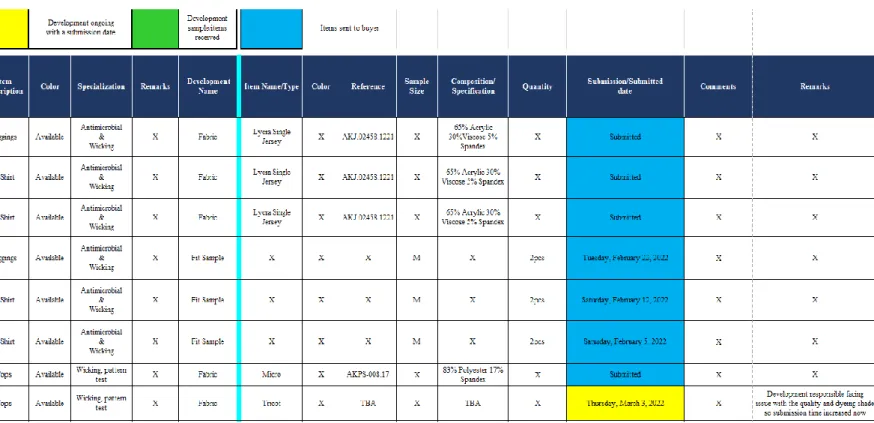

This is the home page for the user when the user enters data on the application. These listed samples are a single task to be developed by the user. Setting up the priority list is also essential because when a buyer first wants a sample, the user can identify that sample and work on it efficiently and submit it on time.

It also has review and revision; This means that the user can set whenever the customer wants a revised sample for any. Without completing the selected task, the user cannot update the status of the one previously set by the user. As Figure 4.1.7 shows, the user can upload any file as an attachment, accessible at any time.

Additionally, the user can make a subtask under this task, and then this task will be displayed as the main task for that subtask.

Sourcing Materials

- Purchasing by Requirement

- Market Purchasing

- Evaluating Supplier Market

- Purchasing for Future Period

- Contractual Purchasing

- Amass Suppliers' information

- Scheduled Purchasing

- Formulate Sourcing Strategy

- Group Purchasing

- Negotiate with Supplier

- Enforce the Sourcing Strategy

- Monitor the Sourcing Plan

This strategy refers to things that are bought only when they are needed and in the necessary quantity. This strategy will be useful if future needs are accurately predicted and purchases are made when market conditions are favorable. The benefits of this strategy include lower purchase prices, higher margins on finished products due to lower material costs, and lower purchasing costs.

However, this strategy has several disadvantages, including potential losses in the event of a misjudgment, concerns about obsolescence, and increased storage costs due to more purchases. Even if the items are acquired in the future, the price and other terms and conditions are fixed in the contract. This strategy can be effective when expected future price increases and material requirements can be adequately predicted.

This strategy provides suppliers with a probable schedule for material requirements, allowing them to plan ahead of time.

Follow-up

- Determination of Need and Scope

- Determination of Roles and Responsibilities

- Gathering Data and Evaluation

- Reporting

- Set a Deadline

- Use Multiple Channels

- Don't Nag

- Multi-Purpose Conversations

Unfortunately, the evaluation of outcomes and results of follow-up is often not carried out, although this analysis should be carried out as it is an essential phase in the process. The evaluation stage of a follow-up program may find that additional steps are needed to manage the problems highlighted. For example, changes to the project's design and operations are made to address issues discovered during follow-up.

In addition, changes to project design, activities, operations, or maintenance operations may be necessary to correct problems identified during monitoring. Brief overview of the project, its location; contact person at the project location (including contact details); and description of project monitoring mechanisms (eg field visit, laboratory test, etc.). The other side's guard will be down by then and will be more responsive to follow-up than if you immediately jumped up and yelled "where is he?".

How you keep your data and how you have followed the responsible task on time.

![Figure 2.1.1: Flowchart of apparel industry [1]](https://thumb-ap.123doks.com/thumbv2/filepdfnet/10931745.0/16.892.138.544.123.988/figure-2-1-1-flowchart-of-apparel-industry.webp)

![Figure 2.3.1: Types of merchandising/merchandiser [1]](https://thumb-ap.123doks.com/thumbv2/filepdfnet/10931745.0/19.892.138.758.871.1099/figure-2-3-1-types-of-merchandising-merchandiser.webp)

![Table 2.9.1: Role of a production merchandiser [1]](https://thumb-ap.123doks.com/thumbv2/filepdfnet/10931745.0/24.892.111.805.345.1064/table-2-9-1-role-production-merchandiser-1.webp)

![Figure 2.10.1: Process flowchart of a retail merchandiser [1]](https://thumb-ap.123doks.com/thumbv2/filepdfnet/10931745.0/33.892.259.622.89.898/figure-2-10-1-process-flowchart-retail-merchandiser.webp)