ABSTRACT

ABSTRAK

DEDICATION

ACKNOWLEDGEMENT

2.6 EDM Machining Characteristics 13

2.6.1 Electrode Wear Rate 13-14

2.6.2 Material Removal Rate 14

2.7 Design of Experiment (DOE) 14-15 3.3 Step 2: Identify the Machining Parameter and Response Variable 26

3.3.1 Variable Machining Parameter 26

3.3.2 Constant Machining Parameter 27

3.4 Step 3: Preparation of the Experiment 27

3.7 Step 6: Define the Optimal Setting of Experimental Parameters 35

3.8 Step 7: Confirmation Run 35

3.9 Step 8: Make Conclusion for Project 35

4. RESULTS AND DISCUSSION 36

4.2 Analysis of Material Removal Rate 37-38

5. CONCLUSION AND RECOMMENDATIONS 64

CHAPTER 1

INTRODUCTION

This chapter is introduces the micro EDM process and problem statement. Besides that, this chapter also includes the objective, scope, importance of study and expected result for the project.

1.1 Introduction

Rapid advances in technology require further development in the manufacturing of micro parts and micro-electromechanical system components. Increasing demand for micro-parts made micro-machining processes more focused and investigated among the front end of the technology in recent years. Micro-machining is the basic manufacturing technology of the miniaturized and smaller parts having size of millimeter down to micrometer.

The basic physical characteristics of the micro EDM process is essentially similar to that of the conventional EDM process but the main difference is the size of the electrode that used. Electrical discharge machining is widely used in machining of dies and for produce of unusually shaped or size production work. Example for EDM products are fuel injector valves, parts and components for medical devices, fiber optic connectors, micro mold making, stamping tools and micro electronic parts.

There are many manufacturing techniques to drill micro holes and micro parts beside micro-EDM. The recently developed methods are Wire Electric Discharge Grinding (WEDG), Micro-Electrochemical Machining (MECM), Laser-Beam Machining (LBM), Focused Ion Machining (FIM), Micro milling, Micro Ultrasonic Machining (MUSM), Electrochemical Discharge Machining (ECDM) and Micro punching. Performances of these methods are unique, because they have different machining mechanisms. For example, LBM can be used to drill a hole under diameter of 4 μm, however, it causes deterioration and micro cracks on the machined surface. Besides that, ECDM can improve the material removal rate to 1.5 mm/min and surface roughness to 0.08 μm. However, the walls of the micro-holes are over etched (Yan et al, 2002).

Micro EDM is suitable for these and similar applications because its low discharges energy generate smooth surfaces and that have no physical contact between the tool electrode and the work piece so the process works efficiently. However, micro EDM face two significant challenges that is high electrode wear and low Material Removal Rate (MRR). Electrode wear which results from each discharge removing some material from the electrode, degrades the geometric accuracy of machined features.

1.2 Problem Statement

In micro EDM process, the pulse on time, peak current and flushing are very important machining parameter because it can control material remove rate and electrode wear rate. However, there are difficulties to determine the optimum machining parameter to increase the material remove rate and reduce the electrode wear rate. The unsuitable pulse duration and peak current will increase the cost of production. Besides that, adding the dielectric fluid flushing process will increase the material remove rate.

In this study, that were determined the optimum machining parameter to increase material remove rate and reduce the electrode wear rate.

1.3 Objective

The objectives of this experiment are to:

1. Analysis the material remove rate and electrode wear rate for the process by using the different machining parameter sure as peak current, pulse on time and the flushing process.

2. Determine the optimum machining parameter to increase material remove rate and reduce the electrode wear rate.

1.4 Scope

1.5 Important of Study

This project were defined the suitable EDM machining parameter such as peak current, pulse on time and the flushing process to get more material remove rate and less of the electrode wear rate. Besides that, this study was bringing benefit for industry to minimize the costs when using the EDM machining to process the tungsten carbide.

1.6 Expected Result

CHAPTER 2

LITERATURE REVIEW

This chapter discuss about the principle of EDM, electrode, material (tungsten carbide), dielectric fluid, flushing process, machining parameter, and EDM machining characteristics. Besides that, summary of the previous journal is included at the end of this chapter.

2.1 Principle of EDM

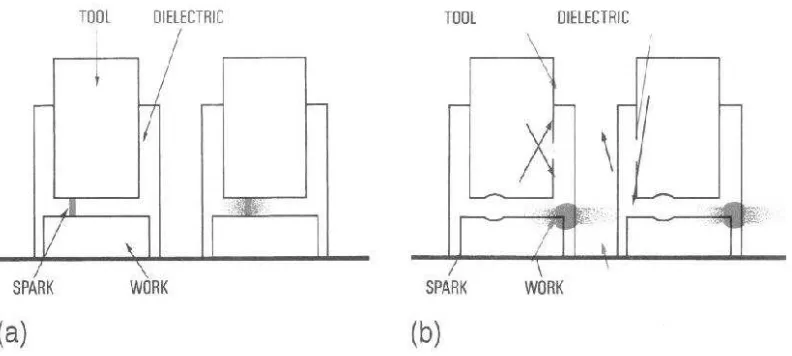

during the off-cycle of the pulse and assists in dissipating the heat caused by the spark. (Steve et al, 2005)

Figure 2.1: a) A controlled spark remove metal during electrical discharge machining (EDM); b) basic element of an electrical discharge system.

Figure 2.2: Stages of single spark

Electrode Servo

Work piece

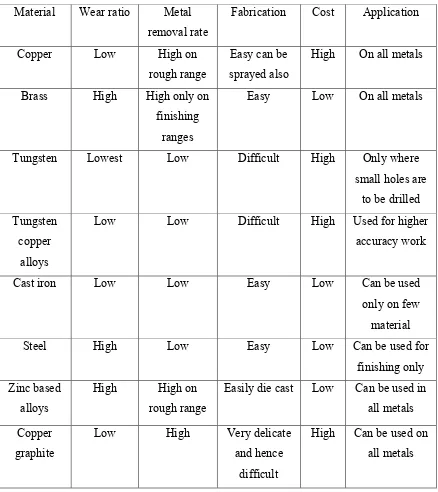

2.2 The Electrode

The electrode in die sinking EDM is formed to the shape of the cavity desired. As in conventional machining, some materials have better cutting and wearing qualities than others. Therefore, electrode must have the following characteristics:

Be good conductors of electricity and heat. Be easily machined to shape at a reasonable cost Produce efficient metal removal from the work piece Resist deformation during the erosion process

Exhibit low electrode (tool) wear rates