IRSAN ALIPRAJA

GRADUATE SCHOOL

BOGOR AGRICULTURE UNIVERSITY

BOGOR

DECLARATION

I declare that this thesis titled Influence of Cutting Tool Wear on the Quality of Poplar Veneers is my own work with the direction of the supervising committee and has not been submitted in any form for any college except in ENGREF, France (required by Double Degree Program). Information and quotes from journals and books have been acknowledge and mentioned in the thesis where they appear. All complete references are given at the end of the paper.

I understand that my thesis will become part of the collection of Bogor Agriculture University. My signature below give the copyright of my thesis to Bogor Agriculture University.

Bogor, October 2012

Irsan Alipraja

IRSAN ALIPRAJA. Influence of Cutting Tool Wear on the Quality of Poplar Veneers. Under direction of WAYAN DARMAWAN and REMY MARCHAL.

Poplar wood is well known as a potential raw material for veneer industry. However, its proportion of tension wood often cause problems on the veneer quality. Therefore, optimization of machining process is required to improve the quality of veneer. This study aims to examine the role of machining factors, especially cutting tool wear on the quality of poplar veneer. The plan of experiments was done by using the Taguchi method with six machining parameter. Peeling process was performed by using the micro lathe. The results showed that cutting tool wear, pressure bar, and temperature of wood give significance influence on surface roughness while pressure bar and cutting speed were important factors on lathe check formation.

SUMMARY

IRSAN ALIPRAJA. Influence of Cutting Tool Wear on the Quality of Poplar Veneers. Guide by WAYAN DARMAWAN and REMY MARCHAL.

As a fast growing species, poplar wood (Populus spp) has become potential raw material for veneer industry, especially in temperate regions such as in Europe. In France, a total of 1,422,523 m3 timber was harvested in 2008 and 64.3% were used for rotary-cut veneer (lightweight packaging, plywood and export). Currently, there are more than 140 clone cultivable poplar in Europe that can make industry has more choice for its raw material. However, due to its proportion of tension wood, this species often produces poor surface quality. One way to improve the quality of veneer is by optimization of cutting parameter. The rate of cutting tool wear is also a factor that must be considered in order to obtain the best quality of surface. The purpose of this study is to examine the role of machining factors, especially cutting tool wear, on the quality of veneer product.

Experimental design was conducted using Taguchi method to make the research more efficient in time and material. Factors control that used in this study were cutting tool wear, cutting speed, pressure bar, type of bar, cultivar and temperature of wood. Peeling process was conducted by using microlathe machine to obtain veneer with thickness of 3 mm. Evaluation of veneer consisted of cutting force, surface roughness and lathe check. Surface roughness has been evaluated by using Surfascan SOMICRONIC S-M3 device while lathe checks have been measured by using SMOF device and its software.

The result from this study showed that cutting tool wear is the factor that most affect the quality of veneer. In this study, the lowest force on the knife is obtained at the level of 0 µm cutting tool wear, 0% of pressure bar, cultivar I214 and at room temperature, while 0% of pressure bar, cultivar I214 and with angular bar sharpened tends to generate optimum force on the bar. The best surface quality (Ra) is found when peeling wood with 0 µm wear level of the knife, 10% of pressure bar, cultivar lambro and at room temperature, whereas the optimum of lathe check was produced by using cutting speed 0.1 m/s with 10% of pressure bar.

© Copyright IPB, 2012

Copyright Reserved by Law

Prohibited quoting part or all of this paper without mentioning or citing the sources. Quotation is only for educational purposes, research, writing papers, preparing reports, writing criticism, or review of an issue, and the citations will not harm the interests of IPB

INFLUENCE OF CUTTING TOOL WEAR ON THE QUALITY

OF POPLAR VENEERS

IRSAN ALIPRAJA

E251100081

Thesis

In partial fulfillment of the requirements for the degree of Master of Science

At Bogor Agriculture University

GRADUATE SCHOOL

BOGOR AGRICULTURE UNIVERSITY

BOGOR

Title : Influence of Cutting Tool Wear on the Quality of Poplars Veneers Name : Irsan Alipraja

NIM : E251100081

Approved, Co-Major Professors,

Prof. Dr. Ir. I Wayan Darmawan, M.Sc. NIP. 19660212 199103 1 002

Prof. Rémy Marchal

Head of the Department of Forest Product Technology

Prof. Dr. Ir. I Wayan Darmawan, M.Sc. NIP. 19660212 199103 1 002

Dean of the Graduate School

Dr. Ir. Dahrul Syah, M.Sc.Agr NIP. 19621026 198803 1 001

FOREWORD

All praise and gratitude to Allah SWT so that the author could finish this scientific work entitled Influence of Cutting Tool Wear on the Quality of Poplars Veneers. The results of this study hopefully can contribute and give useful information in the development of science and technology of wood processing in particular in veneer manufacturing.

First of all, I would like to convey my gratitude to Ministry of National Education (DIKNAS) that give the opportunity to continue my study in master program through the program of double degree Indonesia-France. I would like also to thank Prof. Dr. Ir. Wayan Darmawan M. Sc. and Prof. Rémy Marchal as the supervisors who have given a lot of suggestions during the research. High appreciation for all the teachers, staff and technician LaboBois ENSAM for excellent reception, warm atmosphere and also for their support during the research. Thanks also to my father, my mother, my brothers and the whole family, for all the prayers and love. Finally, I would like to thank all master student of Forest Product Technology especially to Rentry Augusti Nurbaity, Vera Junita Sitanggang, Novitri Hastuti, Sonia Somadona and Meylida Nurrachmania for their desires to share both difficulty and happiness when we lived in France.

The author recognizes that this research is still far from perfect. Therefore, suggestions and constructive criticism are expected to improve this work.

Bogor, October 2012

TABLE OF CONTENTS

Cultivar Selection and Preparation of Disk ... 11

LIST OF TABLE

No. Page 1. Determination levels of control factors ... 10 2. Experiment matrix ... 11 3. Experimental results for surface roughness, lathe check, and cutting force

LIST OF FIGURES

No. Page

1. Poplars and their implementation... 4

2. Mechanical properties of poplar wood ... 5

3. Principe of peeling process ... 5

4. Cracking formation during the production of veneer with different pressure level of the bar ... 8

5. Discs for micro lathe from three types of poplar cultivar ... 11

6. Microlathe ... 12

7. Decompositions of the resulting cutting force Fc ... 13

8. Filtering process using Labview software... 14

9. Evaluation of lathe check ... 14

10. Surfacescan device ... 15

11. Surface roughness profile ... 15

12. Chart S/N for cutting force ... 17

13. Cutting force in peeling wood with knots ... 19

14. The optimum is minimum S / N graph for surface roughness ... 20

15. Influence cutting tool wear on surface roughness ... 21

16. The optimum is a minimum S / N graph for cracks ... 22

LIST OF APPENDIX

No. Page

1 Matrix experimental L27 ... 30

2 Response table for average S/N Ratio for cutting force factors ... 31

3 Results of analysis of variance for the efforts ... 32

4 Response table for average S/N Ratio for surface roughness factors ... 33

5 Results of analysis of variance for roughness ... 34

6 Response table for average S/N Ratio for lathe check factors ... 35

7 Results of analysis of variance for cracks ... 36

INTRODUCTION

Background

Plywood, laminated veneer lumber (LVL) and laminated veneer panels (LVP) are structural wood products that using veneer as its raw material. The quality of those products are then could determined from the quality of veneer and production process. Parameters commonly used to assess the quality of veneer i.e. lathe check, surface roughness and thickness variation. Research on the effect of these parameters on the quality of product (such as plywood and LVL) has been widely done (Neese JL, 1997; DeVallance, 2003; Daoui A et al., 2011; Piirlaid et al., 2012). Similarly, factors that affect the quality of veneer (Corder SE and Atherton GH, 1963; Lutz JF et al., 1967; Bakar ES, 2004; Aydin et al., 2006; Tanritanir E et al. 2006; Dundar et al., 2008a) and methods used to evaluate the veneer has been widely known (Blomme et al., 2010; Palubicki et al. 2010; Denaud et al., 2012). However, because of the natures of wood are complex that often give different responses, performing research on veneer quality is still interesting to do.

As a fast growing species, poplars has become potential raw material for veneer industry, especially in temperate regions such as in Europe. In Europe, total production of poplar wood is approximately 8 million m3 per year and about 40% of this volume is intended for veneer and plywood industry while 31% is used for sawmill industry (Nervo et al., 2011). In France, a total of 1,422,523 m3 timber was harvested in 2008 and 64.3% used for rotary-cut veneer (lightweight packaging, plywood, and export).

by perform the optimization of machining process. Optimization process in peeling of wood can be done by changing the cutting parameters such as cutting speed, bar pressure, cutting temperature or clearance angle.

Knife has an important role in peeling process. Its maintenance costs are relatively high. The high rate of knife wear can also affect the level of productivity of veneer. On the other hand, research on the effect of cutting tool wear in peeling process is very little published. Based on this problem, it takes a study that observe the contribution of cutting tool wear on the quality of veneer, especially on poplar wood.

Formulation

Poplar is a fast growing species that has long been used as raw material for plywood and veneer industry. The main constraint that are frequently encountered in machining process of poplar wood is the presence of tension wood with various proportions. The presence of tension wood often causes problems in wood machining processes primarily related to the quality of resulting veneer surface. One way to solve these problems is by optimize the conditions or cutting parameters. Another parameter that also important in this process is the knife. Knife in peeling process should be as sharp as possible to avoid the adhesion of tension wood fibers on the surface of the knife. Knife wear can also be an obstacle to produce high quality of veneer and to reduce energy consumption. Problems to be addressed in this research is how cutting tool wear influence on the cutting force that occurs and the quality of veneer surface? and how large the contribution of cutting tool wear compared with other peeling parameters?

Objectives

Benefit

The study is expected to provide scientific information on the role of cutting tool wear on cutting force, surface quality and lathe check of veneer as well as on the characteristics of poplar wood in peeling process.

Hypotheses

STUDY LITERATURE

Poplar Wood

Poplar, also known as the scientific name Populus spp., is an angiosperms plant that comes from family Salicaceae. It comes from temperate zones and the northern hemisphere. This species is classified as a fast-growing species, has homogeneous wood with a high level of productivity (up to 35-40 m3/ha per year) (O Pichard et al., 1997). The volumetric composition of poplar wood is compiled by high proportion of fibers (53-60%), followed by vascular elements (28-34%), medullary ray (11-14%), and a significant proportion of axial parenchyma (0.1-0.3%) (Panshin and de Zeeuw, 1980 in Balatinecz DD and DE Kretschmann, 2001). The chemical composition of poplar wood is dominated by high proportion of polysaccharides (up to 80% holocellulose, which varies among clones and stations) and low proportion in lignin (about 20%).

The hybrid poplar have already produced many species. There are currently at least 145 registered cultivars and cultivable poplar in Europe. The process of vegetative propagation is usually very easy, by cuttings and plants capable of producing the same quality. Poplar wood is generally white, sometimes reddish or pink, easy to be worked (Figure 1) and can be nailed without splitting (Pichard O et al., 1997).

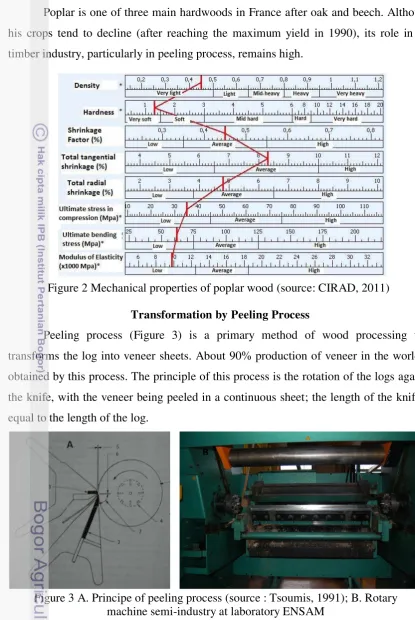

Poplar wood has an average density of 0,45 (at the level of moisture content 12%) with the shrinking value in tangential section 8,3%, and in the radial 4,8%. Mechanical properties and durability of poplar wood are generally low and it has good aptitude for peeling and slicing process (Figure 2). Poplar wood can be used for interior plywood, packing, match, current furniture, lightweight frame, pulp, fiberboard and particle board.

Poplar is one of three main hardwoods in France after oak and beech. Although his crops tend to decline (after reaching the maximum yield in 1990), its role in the timber industry, particularly in peeling process, remains high.

Transformation by Peeling Process

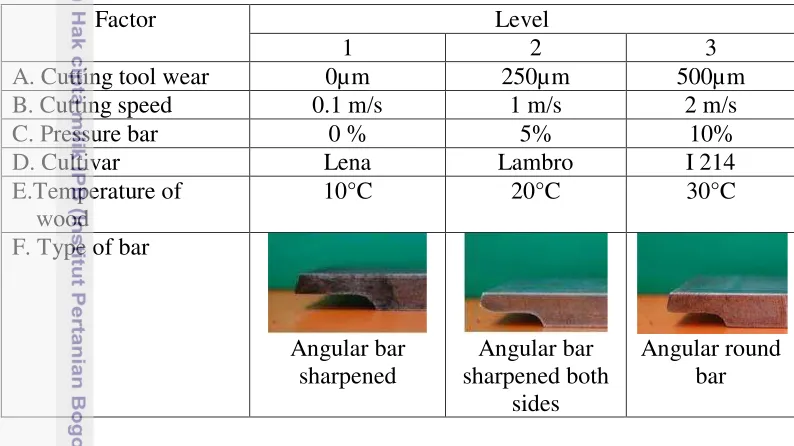

Peeling process (Figure 3) is a primary method of wood processing that transforms the log into veneer sheets. About 90% production of veneer in the world is obtained by this process. The principle of this process is the rotation of the logs against the knife, with the veneer being peeled in a continuous sheet; the length of the knife is equal to the length of the log.

Pressure bar

Knife Cutting direction

Chuck Horizontal opening

Vertical opening

Cutting angle

Figure 3 A. Principe of peeling process (source : Tsoumis, 1991); B. Rotary machine semi-industry at laboratory ENSAM

B

Veneer peeling lathe (veneer rotary lathe) is equipped with a pressure bar (or often named nosebar) which is placed ahead of the knife and has equal length. Its role is to prevent or minimize the appearance of cracks on veneer and also to control the thickness and smoothness of veneer. The nosebar and knife carriage will then move slowly towards the log, give the pressure in accordance with a veneer thick.As veneer comes from the lathe, it is received by a conveyor, reel or table. Nosebar adjustment must be done every turn of the new knife, knife sharpening, changes thick of veneer peeled or when peeling different wood species. In addition, it requires a fairly high accuracy in determining the position and pressure levels of the bar to produce high quality of veneer. If the pressure bar is too big, it will crush the wood while if it is too low it will produce a lot of crack on the veneer surface (Forest Product Laboratory, 1962; Tsoumis, 1991; Bakar ES and Marchal R, 2001).

There are mainly two types of pressure bars i.e. fixed pressure bar and roller pressure bar. The fixed bar is the simplest, cheap and most commonly used. It is normally used on veneer slicers and also for cutting hardwood on a rotary-lathe. The fixed bar has generally a bevel angle between 74-78°. Other than fixed bars, roller bar is one of the bars that often used. Compared to fixed bar, utilization roller bar could reduce cutting force that occurs. However this type of bar cannot cut veneer of any thickness like fixed bar. Lutz (1978) states that roller bar with diameter 15.9 mm cannot be used to cut veneer which is thinner than 1.6 mm.

Knife represents the largest maintenance cost in veneer industry thus required good knowledge in the use of the knife (grinding and setting) to keep the knife remains in good conditions. The knife is generally low alloy steel with a low sharpness angle, between 18 and 23 °. Normally, the smaller the angle, the less the veneer is bent when it is cut thus produce tighter veneer. Otherwise, the larger the sharpness angle, the stiffer the knife thus the better the knife edge withstand impact. Grinding process for a small angle knife must be done more carefully than the knife with larger angle. Veneer knife should has Rockwell hardness of 56-58 on the C scale for rotary-lathe and 58-60 for veneer slicers. A Rockwell hardness 60-62 may even be used when cutting low density wood.

cutting thin veneer, thinner knife can be used as long as it properly supported (Lutz JF, 1978). The knife working in the manner of penetration, cuts wood and often cause cracks on veneer product.

Quality of Veneer

Veneer quality is an important parameter that determines the success rate of plywood or LVL production. It is depend on the quality of raw materials used, skill of the operator, condition of the lathe and cutting parameters used (FPL, 1962; Bakar ES, 1996). The quality of veneer is generally evaluated based on the variation of thickness, surface roughness and lathe check (frequency and depth). In addition, radius curl of veneer is also sometimes used as an indicator to assess veneer quality since the curved veneer is difficult to be worked than flat veneer. For some uses such as face veneer, color is also one of parameters that need to be considered (Lutz, 1971; Bakar ES, 1996; Marchal R, 1996; Wang J et al., 2001; Daoui et al., 2011). A good quality of veneer will certainly be a uniform in thickness, flat, smooth and slightly cracking.

Roughness can be defined as an irregularity on a periodic basis (other than defects) on the surface of a material generated by the production process. Surface roughness plays an important role, especially on bonding quality and finishing treatments. Control of surface roughness in veneer production is substantial to maintain adhesive quality between veneer on the plywood/LVL or between veneer and other wood based panel. The surface quality of veneer which is not good (rough) will produce a weak bonding and reduces the mechanical properties of composite panels produced (DeVallance 2003; Unsal et al., 2005; Korkut S M and Akgul, 2007; Dundar et al., 2008b). Rough surface of veneer can also causes excessive resin use and may lead resin-bleed through the face veneer. On the face veneer, roughness can be reduced by sanding process. Nevertheless, the veneer which is too rough requires much more sanding process than "smooth" veneer, resulting in reduced material thickness.

(Ayrilmis et al. 2006). Furthermore, Sandak J and Martino (2005) added that wood porosity and moisture content also gives effect to the formation of surface quality.

Similar with roughness, cracking (lathe check) is also an important criteria and has long time been used as an indicator of veneer quality (Figure 4). In almost all veneer manufacturing process, lathe checks are present at different level. These cracks occur during machining process. Lathe check in veneer showed weak zone and cause excessive penetration of adhesive.

Typically, lathe check is strongly influenced by the level of pressure and also by cutting speed and geometry of the knife. Lathe checks frequent but shallow are preferable to less frequent but deep, especially when the appearance of plywood or LVL is required as in face veneer.

Figure 4 Cracking formation during the production of veneer with different pressure level of the bar.

MATERIALS AND METHODS

Location and Period of Research

This research was carried out at Laboratory of Wood (Laboratoire Bourguignon des Matériaux et Procédés), Ecole Nationale Supérieur d’Arts et Métiers (ENSAM), Cluny, France. The study lasted for six months, starting from February 2012 to July 2012.

Tools and Materials

Materials used in this study were three 15-20 year old clones of poplar wood (I214, Lambro and Lena) in a form of disk with a thickness of 30 mm. Tool used to produce samples of veneer were Microlathe ENSAM, wood peeling knives, and nosebar. Peeling knives used were three pieces with different levels of wear (0 μm, 250 μm, and 500 μm) but has the same sharpness angle (20°). The knives are low alloy steel with a composition of 0.6% C, 1.8% Si, 0.7% Mn, 0.3% Cr, 0.5% Mo, 0.2% V with hardness value of 55-56 HRC. Evaluation of veneer quality was performed by using piezoelectric system installed on the microlathe and its software developed by ENSAM Lab to scan cutting force; System Measurement Opening of Fissure (SMOF) devices and its software to measure lathe check; and Surfascan SOMICRONIC S-M3 with its stylus with a tip radius of 2 μm to evaluate surface quality.

Some of the other tools that used to support this research including "storage tubs", infrared gun, ruler, calipers (caliper), grinding machine, planer machine, band saw and drilling machine. Data processing is performed by using LABVIEW 2011 software and STATISTICA 2011.

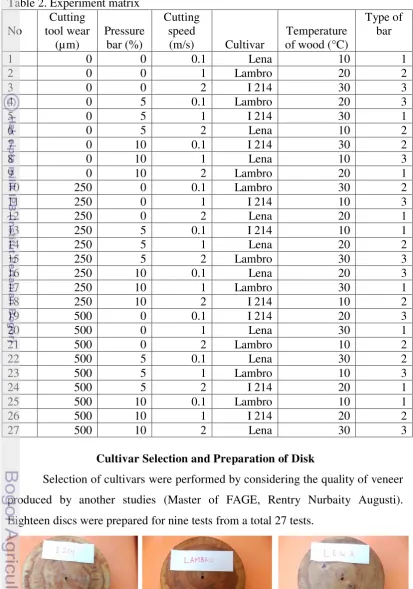

Taguchi Method

In Taguchi method, it is necessary to select control factors (Main factors that will be evaluated on their effects on the results of the experiment) and variation levels to minimize the sensitivity of the response on the experimental noise. These factors are cutting tool wear, cutting speed, pressure bar, cultivar, temperature of the wood, and type of bar (Table 1).

Table 1. Determination levels of control factors

Factor Level

The experimental matrix chosen is type L27 with 27 rows and 7 columns. The parameters to be studied are placed in columns. Thus, a total of 27 tests were performed (Table 2).

Taguchi method approach introduces “signal-to-noise” ratio (S/N ratio) to study the influence of noise on the variations that occur. Generally, there are three performance categories in the analysis of the S / N ratio, i.e. optimum is nominal, optimum is a minimum and optimum is maximum. In this study, to obtain optimum machining performance, conditions optimum is minimum for surface roughness, lathe check and cutting force should be taken to achieve the highest quality veneer. The formula used to calculate SNR in the case where the optimum is a minimum are:

∑ ,

Table 2. Experiment matrix

Selection of cultivars were performed by considering the quality of veneer produced by another studies (Master of FAGE, Rentry Nurbaity Augusti). Eighteen discs were prepared for nine tests from a total 27 tests.

Three cultivars selected were I214, Lambro and Lena (Figure 5). Veneer of good quality is represented by the discs I214 with a diameter of ± 360 mm while the average quality is represented by Lambro with a diameter of 280 mm and the poor quality represented by Lena with a diameter of 300 mm.

The preparation of discs was done by bandsaw to get constant disc thickness of 30 mm. They were then stored in water to prevent fungal attack. Before peeling process, each sample was placed in three different temperatures for 24 hours depending on research model. Storage temperature used were 6 ° C, 20 ° C (room temperature) and 40 ° C.

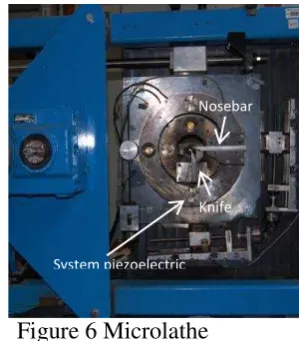

Experiments on micro-lathe

The micro-lathe was developed by Jean-Claude BUTAUD (Butaud et al. 1995). This machine is specially developed for research purpose and it can be used to study the mechanism complete of peeling process from disks samples. Knife and nosebar lies in two different rings that are connected and form a piezoelectric system and can be moved through the main "computer".

Micro-lathe ENSAM can peel wood with cutting speeds up to 3m/s, and clearance angle up to 40°. Sample should be in the form of disks with a thickness 5-30 mm and diameter between 25-500 mm. This machine can produce peeled veneer with a thickness of 0.1-5 mm.

In this study, each sample was peeled five rounds for each modality and repeated several times. Peeling process was performed with 3 mm thick veneer and various machining conditions contained in the experimental design.

The veneer samples obtained were then divided into several parts: the length of the samples taken for measurements of the roughness (SR) and lathe check (SMOF) are respectively 5 cm and 45 cm.

Figure 6 Microlathe

Nosebar

Knife

Evaluation of Veneer

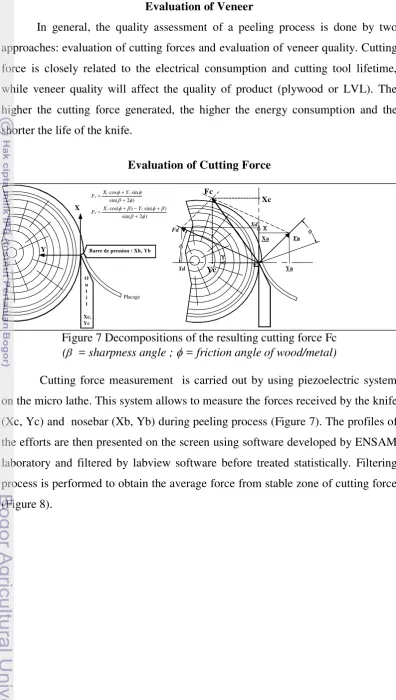

In general, the quality assessment of a peeling process is done by two approaches: evaluation of cutting forces and evaluation of veneer quality. Cutting force is closely related to the electrical consumption and cutting tool lifetime, while veneer quality will affect the quality of product (plywood or LVL). The higher the cutting force generated, the higher the energy consumption and the shorter the life of the knife.

Evaluation of Cutting Force

Figure 7 Decompositions of the resulting cutting force Fc ( = sharpness angle ; = friction angle of wood/metal)

Evaluation of veneer quality Lathe check measurement

Veneer lathe check was measured by a specific measurement device and its associated software (SMOF): this set can measure the frequency and the depth of the cracking of veneer.The measurement technique is based on the opening of cracks occurring at the time of passage of veneer through the pulley (Figure 9a). Concerning the nature of veneer which is very fragile, then the success of measurement is strongly influenced by the choice of pulley diameter. When diameter of the pulley is too small, the measurement process will lead to cracking and increase the depth of fissure thus the measure is not reliable. Otherwise, if diameter of pulley is too large, veneer cracks can not be opened so it is difficult to be detected by the camera.

Determination pulley diameter is generally done on an experimental basis. In this study, the observed thick veneer is 3 mm, so that the diameter of pulley that used is equal to 65 mm or in accordance with the recommendations of the research performed by Palubicki et al. (2010) (Figure 9c). Measurement process Figure 9 Evaluation of lathe check; (a) Devices of SMOF (b) determining the depth

of lathe check, (c) Recommendations of pulley diameter by Palubicki (2010)

Veneer place

Bending pulley LVDT sensor

a b

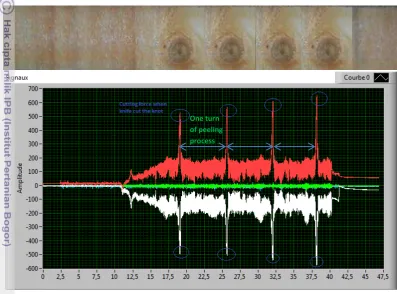

Figure 8 Filtering process using Labview software

begins when veneer through LVDT sensor. This sensor will measure the thickness of veneer. Then the moment veneer passed pulley, lathe check formed on the loose side will be opened and at the same time the camera which is placed on the back of device will start scanning the side (thickness) of the veneer. The images obtained are then analyzed its depth (percentage) manually using software of SMOF.

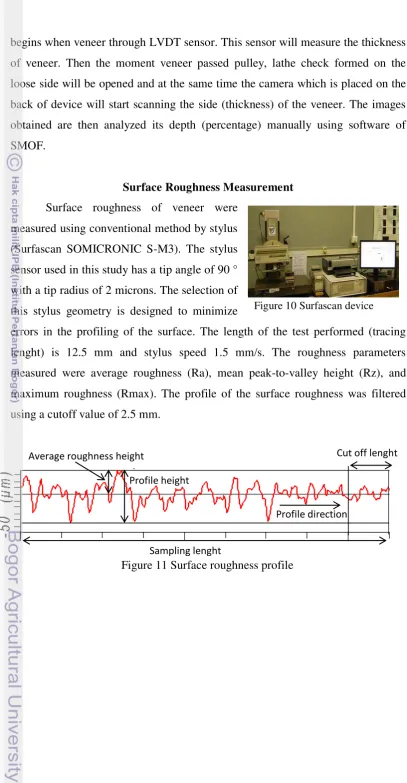

Surface Roughness Measurement

Surface roughness of veneer were measured using conventional method by stylus (Surfascan SOMICRONIC S-M3). The stylus sensor used in this study has a tip angle of 90 ° with a tip radius of 2 microns. The selection of this stylus geometry is designed to minimize

errors in the profiling of the surface. The length of the test performed (tracing lenght) is 12.5 mm and stylus speed 1.5 mm/s. The roughness parameters measured were average roughness (Ra), mean peak-to-valley height (Rz), and maximum roughness (Rmax). The profile of the surface roughness was filtered using a cutoff value of 2.5 mm.

Devices of stylus

Figure 10 Surfascan device

Sampling lenght Profile height

Cut off lenght Average roughness height

Profile direction

RESULTS AND DISCUSSION

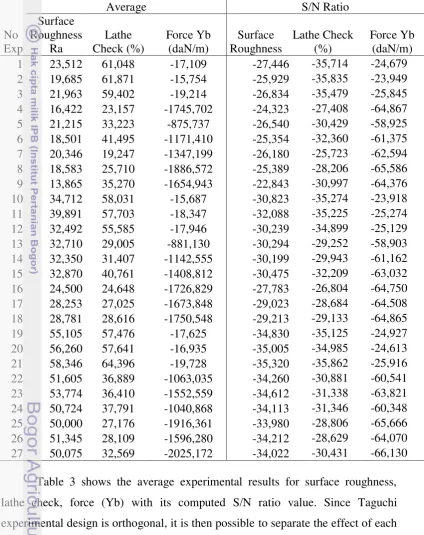

Analysis of S/N Ratio (SNR)

for experiment 1-9, 10-18, 19-27, respectively. The mean S/N ratio for each level of cutting condition is then summarized in tabular form called the mean S/N ratio response table or a chart that can be used to predict the influence of parameter observed, as in the further discussion.

Cutting force

Cutting force plays an important role in wood machining processes, especially related to energy consumption and cutting tool life. Figure 12 shows that cutting tool wear has a huge influence on the force exerted on the knife (Xc and Yc), while the pressure of the bar has a significant influence on the force bar (Xb and Yb ).

The results in figure 12 correspond to the previous research which states that tool wear has a parallel relationship with the cutting force (Aknouche et al. 2009). Mankova (2002) states that cutting force is generally used as an indirect method to identify the level of tool wear. In general, the average signal force increases as the level of wear increases.

Generally, the cutting force increases with increasing cutting speeds. Results of research conducted by Darmawan and Tanaka (2004) showed a linear Figure 12 Chart S/N for cutting force (from left to right: cutting tool wear, cutting

speed, pressure bar, cultivar, temperature, type of bar)

Xc Yc

relationship between the cutting force and cutting speed on turning test. However in this study, the same trend is only can be observed from cutting force on the horizontal bar (Yb) where the optimum force is obtained at the cutting speed 2 m/s. The opposite result also found on the research conducted by Quentin B and Marchal R (2007) who reported cutting force fluctuations in peeling process with cutting speed between 0.5-4 m/s. This phenomenon can be caused due to the cutting speeds used in peeling process is still relatively low when compared to cutting speed of other wood machining process, thus causing the different between cutting force is not very significant.

Based on Figure 12, it can be also seen that type of cultivar had significant influence on the knife cutting force. Lambro cultivar tends to generate greater force, while cultivar of I214 tend to produces smaller force. These differences can be attributed to differences in density between cultivars. The result of research conducted by Eyma et al. (2004) showed linear correlation between wood density and cutting force on fourteen species of tropical wood. It appears that cutting force increases with increasing density. Wood with a higher density will be more difficult to be cut due to have fewer cell cavities and thicker cell wall.

The cutting force tends to decrease with increasing storage temperature. These results are similar with the results obtained by Marchal R (1996) which showed that increased storage temperature of oak from 45 ° C to 80 ° C tended to reduce cutting force that occurs. Similarly, Daoui et al. (2007) reported that increasing storage temperature could decreased all cutting force on the knife and nosebar. It is logic since given the wet heating causes the wood tends to be softer, make it more plastic and pliable so it can more easily deformed before defect is present. Increasing storage temperature before logging can also reduce the resistance of wood so that the peeling process can be carried out under conditions of lower stress wood. Fronczak FJ and Patzer RA (1982) state that heated wood generate less force on the pressure bar due to decreased friction at the pressure bar.

normal cutting force. A report on cutting force by Lutz JF and Patzer RA (1976) also showed that when cut the knots, cutting force increased 1-3 times the force needed to cut clear wood. Knot in wood represents changes in density and cells orientation from wood surrounding it. Knots generally more dense than other wood parts and cell orientation is perpendicular to the knife so it takes a greater force when cutting the knots.

Surface Roughness

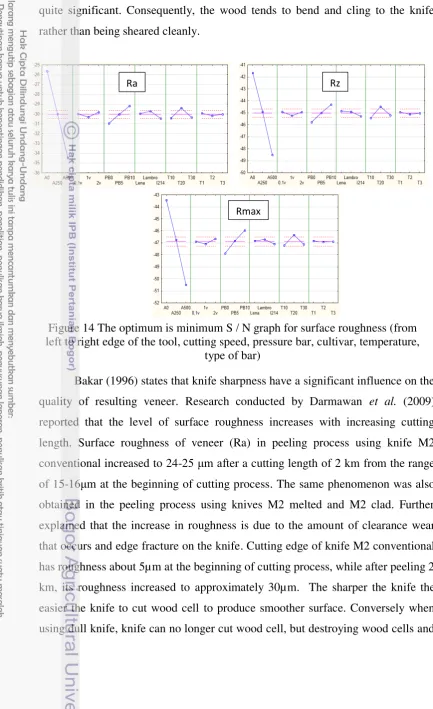

In almost machining process including peeling process, roughness is one of the most important parameters that can describe the success rate of cutting performance. The average of S/N ratio for the roughness Ra, Rz, and Rmax is shown in Figure 14. Figure 14 shows that cutting tool wear, pressure bar and temperature of wood are the most important factors. The highest pressure of the bar with better honed knife seems to be the best choice to get the optimum value for roughness. In general, in the peeling process of poplar, it is important to keep the knife sharp. This is due to the percentage of tension wood in poplar which is

Figure 13 Cutting force in peeling wood with knots and its illustration (up) One turn

quite significant. Consequently, the wood tends to bend and cling to the knife rather than being sheared cleanly.

Bakar (1996) states that knife sharpness have a significant influence on the quality of resulting veneer. Research conducted by Darmawan et al. (2009) reported that the level of surface roughness increases with increasing cutting length. Surface roughness of veneer (Ra) in peeling process using knife M2 conventional increased to 24-25 μm after a cutting length of 2 km from the range of 15-16μm at the beginning of cutting process. The same phenomenon was also obtained in the peeling process using knives M2 melted and M2 clad. Further explained that the increase in roughness is due to the amount of clearance wear that occurs and edge fracture on the knife. Cutting edge of knife M2 conventional has roughness about 5µm at the beginning of cutting process, while after peeling 2 km, its roughness increased to approximately 30µm. The sharper the knife the easier the knife to cut wood cell to produce smoother surface. Conversely when using dull knife, knife can no longer cut wood cell, but destroying wood cells and

Figure 14 The optimum is minimum S / N graph for surface roughness (from left to right edge of the tool, cutting speed, pressure bar, cultivar, temperature,

type of bar) Rmax

separate them from surrounding cells. It is then resulted in rough veneer and tends to fuzz.

According to Lutz JF (1974) cutting speed does not seem to be a critical controlling factor for the production of veneer. However, he recommends using a moderately slow speed if the tightness of veneer and quality of surface are important. Another study performed by Dundar et al. (2008) showed that increasing cutting speed decreased significantly the average roughness. Cutting speed should be as fast as possible to obtain smooth veneer. In this study, increasing cutting speed from 0.1 m/s to 1 m/s increased the value of roughness, whereas when cutting speed was increased to 2 m/s tend to decreased the value of roughness. This phenomenon may be caused by the knife and bar setting process that is not always exactly the same or can be caused by the presence of knots. The presence of the knots in cutting process by using slow to moderate cutting speed allows the vibration which can lead to poor quality of surface. These vibration may caused by variation in wood density between the knots and wood surrounding it. By increasing cutting speed, the vibration that occurs can be reduced because the knife has enough force to cut the knots.

Based on Figure 14, it can be seen that the provision of pressure bar could reduce surface roughness value of veneer. Dundar et al. (2008) state that in rotary-cut veneer manufacturing, wood tends to split along the grain during rotary-cutting process. This splitting causes the formation of vertical cracks (lathe checks) and produce rough veneer. Utilization pressure bar could keep cutting process remains on track and avoid wood to split. However, proper adjustment process is required to obtain the smoothness veneer. The excessive compression of bar may lead

rough surface and cause high cost of energy due to extreme friction during cutting process. In this study the best results for surface roughness were obtain from pressure bar 10%.

In contrast to the results obtained on the cutting forces, cultivar Lambro produced the best surface quality while I214 tends to produce the worst. Bakar (1996) states that a good cutting process occurs when knife success to cut wood cells on its cutting track. In general, at the same cutting conditions, wood with higher density will result in better quality of cuts. This is due to wood with high density have thicker cell walls so that it strong enough to withstand pressure during cutting process. This allows the knife to split the cell so that it can be produced either a uniform thickness and better surface quality because there is no cell or wood fibers is torn. Increasing and lowering temperatures tend to degrade the quality of the surface while the type of bar does not significantly affect the surface finish since the measurement is made on the loose side.

Lathe Check (Depth)

The main effects for each level of parameter on lathe check are shown in Figure 16. Based on S/N ratio, the best choice for lathe check depth is obtained at condition as followed; at 0µm tool wear, low cutting speed, high pressure bar, cultivar I214, room temperature, and with angular round bar.

Based on Figure 16, it can be seen that the value of S/N ratio for pressure bar increase dramatically from PB0 (-35,378) into PB5 (-30,574), and then follow to PB10 (-28,602). These value means that pressure bar changes effect

significantly on the lathe check depth, and the same trend (with reverse value) can also be observed on the cutting speed parameter for each level.

Generally lathe check may be caused during peeling process by a tensile stress field at the front of the cutting edge. It was explained by Corder SE and Atherton GH (1963) that pressure bar in peeling process creates a field of antagonist compression that tend to counteract the tensile bending stress on the tight side of veneer. The greatest pressure of the bar is given, the shallowest crack that appears on the veneer and vice versa. These compressive force also plays a role in reducing or limiting splitting wood ahead of the knife edge. However, it should be noted that giving too much pressure will lead to wood failure and increase roughness on the veneer tight side. In this study, giving a pressure of 10% generate the most optimal result for lathe check depth (Figure 16, 17).

At the level of cutting tool wear, a sharp knife has a small edge radius so that the blade can cut well, but in the case of a dull knife, the edge radius of the knife becomes larger which induces a poor quality of surface and deep cracks. Conditions will worsen if we cut with a dull knife and using a high speed cutting. It appears that it is difficult to obtain continuous veneers with using a dull knife. Using a high speed cutting with a dull knife making it almost impossible to obtain a continuous veneer. Increasing cutting velocity on the lathe tend to increase the depth of lathe check. It can be caused by the risk of wood splitting during peeling process with high cutting speed is higher than when cut the wood with slow cutting velocity. Cade et al. (1969) in DeVallance (2003) reported that an increase Figure 17 Lathe check at different level of pressure (A: without bar; B: pressure

5%; C: pressure 10%)

A

B

cutting speed causes in weaker veneer with deeper lathe checks. This phenomenon due to an increase cutting speed tend to decrease the level of pressure bar so that resulting more severe lathe check formation.

CONCLUSION

Based on the results of this studies, using the Taguchi method is proved to be suitable to analyze the optimal conditions in a wood machining process. It is found that the parameter design in taguchi method provides a simple, cheap, systematic and efficient methodology for the optimization of the cutting parameters in manufacturing of veneer.

REFERENCE

Aknouche H, Outahyon A, Nouveau C, Marchal R, Zerizer A, et Butaud JC. 2009. Tool Wear Effect on Cutting Force: in Routing Process of Aleppo Pine Wood. Journal of Materials Processing Technology 209: 2918-2922.

Ayrilmis N, Korkut S, Tanritanir E, Winandy JC, Hiziroglu S. 2006. Effect of Various Fire Retardants on Surface Roughness of Plywood. Journal of Building and Environment 41:887-892.

Aydin I, Colakoglu G, Hirizoglu S. 2006. Surface Characteristics of Spruce Veneers and Shear Strength of Plywood as a Function of Log Temperature in Peeling Process. International Journal of Solids and Structures 43: 6140-6147.

Bakar ES. 1996. The Affecting Factors of Veneer Quality. Jurnal Teknologi Hasil Hutan 9(2): 14-23.

Bakar ES and Marchal R. 2001. Automatic Setting Veneer Lathe: a challenge and opportunity. Jurnal Tekhnologi Hasil Hutan 16(1): 24-31.

Bakar ES. 2004. Study on the Influence of Nosebar Setting of a Peeler on the Compressive Forces and Cutting Quality of Veneer. Jurnal Ilmu dan Teknologi Kayu Tropis 2(2).

Butaud JC, Decés-Petit C, and Marchal R. 1995. An Experimental Device for the Study of Wood Cutting Mechanisms: Microlathe. IWMS 12, Kyoto.

Balatinecz JJ et Kretschmann. 2001. Properties and Utilization of Poplar Wood. Poplar Culture in North America. Ottawa: NRC Reseach Press.

Blomme E, Bulcaen D, Cool T, Declercq F, Lust P. 2010. Air-coupled Ultrasonic Assessment of Wood Veneer. Journal of Ultrasonics 50: 180-187.

Corder SE and Atherton GH. 1963. Effect of Peeling Temperatures on Douglas Fir Veneer. FPL, Forest Service. U.S., 34p.

Daoui A, Douzet J, Marchal R, Zerizer A. 2007. Valorisation du Bois de Pin d’Alep par

Déroulage : Optimisation de son Etuvage. Bois et Forêts des Tropiques 294(4): 51-63.

Daoui A, Descamps C, Marchal R, Zerifer A. 2011. Influence of Veneer Quality on Beech LVL Mechanical Properties. Maderas. Ciencia y technologia 13(1): 69-83.

Darmawan W, Quesada J, Rossi F, Marchal R, Machi F, Usuki H. 2009. Performance of Laser-Treated AISI-M2 Cutting Tools for Peeling Beech. Eur. Journal Wood Prod 67: 247-255.

DeVallance DB. 2003. Influence of Veneer Roughness, Lathe Check, and Annual Ring Characteristics on Glue Bond Performance of Douglas-pir Plywood. Master Thesis. Oregon State University, 233p.

Denaud LE, Bléron L, Eyma F, Marchal R. 2012. Wood Peeling Process Monitoring: a Comparison of Signal Processing Methods to Estimate Veneer Average Lathe Check Frequency. Eur. Journal Wood Prod 70: 253-261.

Dundar T, As N, Korkut S, et Unsal O. 2008. The Effect of Boiling Time on the Surface Roughness of Rotary-cut Veneers from Oriental Beech (Fagus orientalis L.). Journal of Materials Processing Technology 199: 119-123.

Dundar T, Akbulut T, Korkut S. 2008. The Effects of Some Manufacturing Factors on Surface Roughness of Sliced Makoré (Tieghemella heckelii Pierre Ex A. Chev.) and Rotary-Cut Beech (Fagus orientalis L.) Veneers. Journal of Building and Environment 43: 469-474.

Eyma F, Méausoone PJ, Martin P. 2004. Study of the Properties of Thirteen Tropical Wood Species to Improve the Prediction of Cutting Forces in Mode B. Ann. For. Sci 61: 55-64.

Forest Product Laboratory. 1961. Veneer Cutting and Drying Properties. Report No. 1766-16. FPL, Forest Service. U.S.D.A., 7p.

Forest Product Laboratory, 1962. The Manufactured of Veneer. Report No. 285. Armed Services Technical Information Agency, Virginia.

Fronczak FJ and Patzer RA. 1982. Influence of Chuck Design on Spin-Out Torque in Softwood Veneer Peeling Blocks. FPL, Forest Service. U.S.D.A., 17p.

Huda A, Koubaa A, Cloutier A, Hernandez R, Fortin Y. 2011. Quality of Hybrid Poplar Wood: Effect of Site, Clone, and Age on Anatomical, physical and Mechanical Properties of the Tree. Info-RLQ 8(2), 5p.

Izekor DN, Fuwape JA, Oluyege AO. 2010. Effects of Density on Variations in the Mechanical Properties of Plantation Grown Tectona grandis Wood. Archives of Applied Science Research 2(6): 113-120.

Korkut S et Akgul M. 2007. Effect of Drying Temperature on Surface Roughness of Oak (Quercus petraea ssp. iberica (Steven ex Bieb) Krassiln) Veneer. Journal of Building and Environment 42: 1931-1935.

Lutz JF. 1971. Wood and Log Characteristics Affecting Veneer Production. FPL, U.S.D.A., 35p.

Lutz JF. 1974. Techniques for peeling process, slicing, drying veneer. FPL, Forest Service. U.S.D.A., p 228

Lutz JF, Patzer RA. 1976. Spin-Out of Veneer Blocks during Rotary Cutting of Veneer. Research paper. FPL, U.S.D.A., 26p. ilex L., Quercus pubescens Willd.). Forêt Méditerranéenne 17(1): 3-12.

Neese JL. 1997. Charaterizing Veneer Roughness and Glue-bond Performance in Douglas-fir Plywood. Master Thesis. Oregon State University, 75p.

Nervo G, Coaloa D, Vietto L, Giorcelli A, Allergo G. 2011. Current Situation and Prospects for European Poplar Culture: The Role of Italian Research. Tercer Congreso Internacional de Salicàceas en Argentina.

Palubicki B, Marchal R, Butaud J-C, Denaud L-E, Bléron L, Collet R, Kowaluk G. 2010. A Method of Lathe Check Measurement; SMOF Device and Its Software. Eur. Journal Wood Prod 68: 151-159.

Pichard O, Clinovschi L, Lantheaume F, Clinovschi F, Grange B, Pillon S, Clinovschi F, Pichard F . 1997. L'homme et le Bois. http: www.prog-perception.com/IMG/pdf/hombois.pdf

Piirlaid M, Matsi M, Kers J, Rohumaa A, Meier P. 2012. Effect of Birch Veneer Processing Factors on Adhesive Bond Shear Strength. 8th International

DAAM Baltic Conference “Industrial Engineering”.

Quentin B and Marchal R. 2007. Optimisation et Maîtrise Globale du Déroulage du Pin

d’Alep. Report Project, ENSAM, Cluny. 39p.

Sandak J and Martino N. 2005. Wood Surface Roughness.

http://www.boku.ac.at/physik/coste35/rosenheim/article/art_Sandak_COST_ E35_Rosenheim_2005.pdf

Tsoumis G. 1991. Science and Technology of Wood. Structure, Properties, Utilization. New York : Van Nostrand Reinhold.

Unsal O, Atrilmis N, Korkut S. 2005. Effect of Drying Temperature on Surface Roughness of Beech (Fagus orientalis Lipsky L.) Veneer. 9th International IUFRO Wood Drying Conference.

Appendix 2 Response table for average S/N Ratio for cutting force factors

Parameter Average S/N ratio Important

Appendix 3 Results of analysis of variance for the efforts

Pressure bar 5303,031 2 2651,515 489,7017 1,104E-13 96,524

Cultivar 29,576 2 14,788 2,7312 0,099662 0,538

Pressure bar 8789,233 2 4394,617 5957,171 3,068E-21 99,461

Cultivar 11,448 2 5,724 7,759 0,005398 0,130

Temperature of wood 2,002 2 1,001 1,357 0,289265 0,023

Type of bar 20,165 2 10,082 13,667 0,000511 0,228

Error 10,328 14 0,738 0,117

Appendix 4 Response table for average S/N Ratio for surface roughness factors

Parameter Average S/N ratio Important

Level 1 Level 2 Level 3 Max Min

Max-min

Ra

Cutting tool wear -25,649 -30,015 -34,484 -25,649 -34,484 8,835 1

Cutting speed -29,991 -30,333 -29,824 -29,824 -30,333 0,509 5

Pressure bar -30,946 -30,019 -29,183 -29,183 -30,946 1,763 2

Cultivar -29,966 -29,703 -30,478 -29,703 -30,478 0,775 4

Temperature of wood -30,410 -29,386 -30,351 -29,386 -30,410 1,025 3

Type of bar -29,942 -30,166 -30,039 -29,942 -30,166 0,223 6

Rz

Cutting tool wear -41,662 -44,923 -48,507 -41,662 -48,507 6,845 1

Cutting speed -44,915 -45,238 -44,940 -44,915 -45,238 0,323 5

Pressure bar -45,799 -44,994 -44,300 -44,300 -45,799 1,499 2

Cultivar -44,858 -44,928 -45,306 -44,858 -45,306 0,447 4

Temperature of wood -45,426 -44,470 -45,196 -44,470 -45,426 0,957 3

Type of bar -44,936 -45,127 -45,029 -44,936 -45,127 0,190 6

Rmax

Cutting tool wear -43,432 -46,737 -50,475 -43,432 -50,475 7,043 1

Cutting speed -46,882 -47,097 -46,666 -46,666 -47,097 0,431 4

Pressure bar -47,867 -46,824 -45,953 -45,953 -47,867 1,914 2

Cultivar -46,842 -46,705 -47,098 -46,705 -47,098 0,393 5

Temperature of wood -47,213 -46,322 -47,110 -46,322 -47,213 0,892 3

Appendix 6 Response table for average S/N Ratio for lathe check factors

Parameter Average S/N ratio Importance

Level 1 Level 2 Level 3 Max Min Max-min

Cutting tool wear -31,350 -31,269 -31,934 -31,269 -31,934 0,664 4

Cutting speed -30,554 -31,475 -32,524 -30,554 -32,524 1,970 2

Pressure bar -35,378 -30,574 -28,602 -28,602 -35,378 6,776 1

Cultivar -31,580 -31,824 -31,149 -31,149 -31,824 0,675 3

Temperature of wood -31,766 -31,221 -31,566 -31,221 -31,766 0,545 5

Appendix 7 Results of analysis of variance for cracks

Factor SS DDL VAR F-Ratio P-Value

Contribution (%)

Cutting tool wear 2,365 2 1,183 0,936 0,415229 0,909

Cutting speed 17,488 2 8,744 6,924 0,008115 6,723

Pressure bar 218,648 2 109,324 86,572 1,31E-08 84,058

Cultivar 2,101 2 1,051 0,832 0,455577 0,808

Temperature of wood 1,371 2 0,685 0,543 0,592945 0,527

Type of bar 0,463 2 0,232 0,183 0,834468 0,178

Error 17,679 14 1,263 6,797