lnternational Journal of Engineering & Technology IJET-UENS

vol;

1l

No; 04PROVIDING VEGETABLE

STEARIC

ACID

SUPER

V

1895 S FROIVI

HYDROGENATED

OF

CRUDE

VEGETABLE

STEARIC

ACID HCV

1895

SWITH A

SINGLE

FRACTIONAL DISTILI-ATION COLUMN

Muhammad

yusuf.

Ritongal

l,Chemical Engineering Department, Faculty of Engineering, University of Sumatera Utara, Jl. Almamater Kampus USU, Medan 20155, Indonesia

E-mail : yu s ufrit @ gmail. com

Abstract

ln 2005 stearic acid

V

1895 S is manufactured for l*ttime in Indonesia base on the natural vegetable oil, Crude palm Cil to apply Twin Rivers's demand. One of it specific quality (iodine value 0.15 gll00 g maximum) is very influence to,re purifying steps, one

of

the steps is purifying of hydrogenated crudeV

1895 S (HCV 1895 S) feed by a single :olumnof

fractional distillationto

produceV

1895 S with the lowest possibleof

it

iodine value, lower than thenaximum value. The results of application and small adjustments of determination operating conditions of the single ;olumn priority based on the feed composition, product composition of

V

1895 S andit

pressure drop character are ;ompared based onit

quality standards. This is the method used in this research to provideV

1895 S and conducted in ihe plant scale of PT.XXX

factory with production yield 88-

89 Vo of 0.90mtHCV

1895 S, unsarurated content is ioiver than 0"15 g/100 g and higher than 98 7o wtw Cl8 purity. In general the specific quality standards ofV

1895 S can be met"Keywords: quality standards, fractionation, composition, unsaturated contenl, adjustments

1.

Introduction

Fany acid

ofV

1895 Sis meansuperfatty

acidbasedonnatural

vegetableoilslfotswith

stearic

acid C17I{35COOHor

C1s compositionisminimw 95

Vowlw. Ithas been never manufactured at

all,

although oleo chemical industryhad been growth in Indonesia inthe

period

1989-2004.This fatty

acid had

beenproduced in America and Europeto consume for:one of the consumption asthe raw material

of

the cosmetic manufacturing that have the lowest skin effect, for exampleto manufacturethe

premium

shampoo Pantene.Thts stearic acidhasvery

low

unsaturated content.Sincethe beginning of the year 2005,South East Asia's begunto see as aV

1895 S producer. In October 2005Twin Riversas a buyer gave an idea, a standardquality that had

to

be

followed and

produceit

according

to

the

process sequenceswhich

were determined and doby

PT.XXX

alone(Figure 1), acompany

that had

beenexist

in

operation inoleo chemical industry, since the lastof

the year 1998.Quality of

V

1895 S produced had to meet the quality standard which is shownin

Table 2 below (settled by Twin Rivers).The same quality standard which wasproduced

in

America and Europe by the method wasdifferent at all.This was because of the different raw material and the used technology"

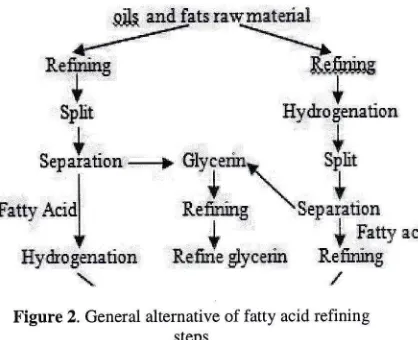

In

this research is useda natural vegetableoil,

Crude Palm Oil (CPO) as raw material for the manufacturingand refining of stearic acid super

V

I 895 S as shown in Figure lbelow. Manufacturing and refining technique of CPO to produce stearic acid superV

1895 S (Figurel)is

so

different compare tothe general alternative manufacturing and refining techrique of fatty acid in Figwe 2 below [12]. Figure 2 is modified to be FigureI

to produceV

1895 S to apply Twin Rivers's demand with the lowest possibleit

unsaturated content, as thefirst technique in the world. Refining

of

raw material onleft

sideof

Figure land Figure2

can be done by degummingonly

and/or

combined together with bleaching andor

deodorization process alternatively according to raw material used, product quality have to be met and equipment capability. Refining of fatty acid on theleft

sideof

the both figures can be proceed through distillation and./or combinedwith

fractional distillation alternatively, againit's

very depend on theI 10404-3737 IJE'I-IJENS (d Augusr 2011 I.lflNS

lntemational Journal of Engineering & Technology IJET-IJENS Vol: 11 No: 04

raw material specs, product quality have to be met and

present equipment capability.

oils and fats ra$'meterial

;-

-=\_-r

Returing

Br.Eflat

+t

$plit

Hvdrogenationr+

S.pJrtior,

+

Gl1'ceru:ra

t{rt

I

r*uu

e.,al

R.t*s \*.,*Luo'

+

J

{Fanv

Hy&ogenation

Refineglycerin

Refimng\/

---*CPo'.-+-

\-*

Refrning

eqfiu$g{+

Split

HvdrogenauonSepaiation

-r

Glycerin,*

Sil,,r*tty

roal

R,***

\*rri*r.,,

+

+

{Fauvaud

H1'drogenahon Refine

glvcenn

Refitting H1'drogenahon Refineglvcenn

RefinurgHytuse-

I

+pfllcLfilUl

I

Hydrogenated fattv acicflfr\4

{

Distillahon

Frttyrdd

tyrcid

I

I

_l

_l

1850

I

L+

ResldueFnctiopation

-|

pl"lmid.q acid

{J

flv

1$9J S [image:2.612.385.594.115.285.2]Table 1 .Thespecific quality of CPO to provide

V

1 895 SFigure 2. General alternative of fatty acid refining

steps

Palm

oil is

one

of

the

sourceof

stearic acid (CrzH:aCOOH) or Crs also as a source of unsaturatedfatty

acid oleic acid

(CtrHgsCOOH)or

C1s-1 andlinoleic acid (CrzHgzCOOH)

or

C1s-2 that could be hydrogenatedto

be

stearicacid

as also stated byt7ltl0lll5l

till

the total amount of Crs is around 50 7ow/w. See the raw material quality CPO that used in this study. The

fatty

acid distillate whichis

obtained of splittedCPOis

called fatty acid 1850[7]. Crude Palm Oil has the highest C1s content than the others natural vegetableoils

such as: crude palm kerneloil

andcoconut oil. This's the reason the raw material CPO is

used in this research.

ecid

iuci;issfrf

-

,I

Fractiohation---* \'1895S

I

ll,

S.awrrai+rial

A\tr

SY E?Ocru

c14 8tr6 *13

f,!&-X

C:8-!

c]0

"u-Ilkcro

?.6

101:

0:9

0.:1.1 43.l

,1.439.1

10.3 0.4 0.8io rrcg ." F?ora $4Xg1f4 C*emirudo,J

0fi

{-qLS-:,

AV= aeidvrlue;

SV =saponificationvelue;I];ftri=unkno*ncomponenUmsterialRefining steps that are started from CPO refinery

till

distillation stepin

FigureI

above are intended to separatethe

impurities of CPO(gum,

trace metals), reduce of ; pigments, odors, short carbon chain of C6till

C14 fatty acid (as the experience CPO contain trace C6-10 in the light end product of distillation process), Fractional distillationIn this manuscript is discussed priority the results of this study'in the end step of the refining Hydrogenated Crude

V

1895 S (HCV 1895 S) to produce stearic acid superV

1895 S through a single fractional distillation columnin

Figure 3whichis

equippeda

packed of structured packing and fallingfilm

reboiler [6]. The using this column rvill be obtained the better saving ofaldehydes, ketones,

iodine value

(through hydrogenation and distillation) to provide of fatty acid feed quality(HCv

1895S in

Table2

below) that refined in the end step, in a single fractional distillation column (Figurel).

Each step affect to the each others, agreed also by the researcher [8].energy

consumption, equipment, operating cost, flexible and product quality compared to the using oftwo

fractional distillation columnsthat utilized trays andlive

steam (Figure4)

tl3l.

This technology in Figure 4 was mostly used in Indonesia since 1989, in oleo chemical industries.I 10.104--i7J7 IJDT-IJENS {!) Augast 20ll UENS

ITN

[image:2.612.147.361.145.455.2]--lntemational Journal of Engineering & Technology UET-UENS Vol: I

I

No: 04\recuum rystem Cl6purge rslight end

V 1895 S asside product

Frsn* akier of

Sottorepro*mt

orresid*e

[image:3.612.46.240.113.268.2]D

Figure 3. The refining of HCV 1895 S by a single fractional distillation column

Please compare this new technology in Figure 3 above

with

the

old

onein

Figure4

below. Refining of blended fatty acid that contentof

at leasttwo

mainfatty

acid

componentswasusually used

twofractionation columns.

The

l't

colurnnis

used to separate light end and 2od colurnn is used to separatethe top product with bottom product. Light end contain any substances

or

impurities which have the lower boiling point than boi-ling point of the main product in 2'o column (the side or bottom product). The bottom product has the higher boiling point than the boilingpoint

of

the

side

productin

the

same column. Separationof

the light endin I't

column and bottom productin

2od column affect much better to the main products quality..[ehlCJ" Quality of feed

]ICV

1E95 SVacuum pressure fractional distillation

is

applied in this study as done for distillation because of fatty acid included unsaturated bond inside are so sensitive for oxidationtl3ltl4l

(whichis so influence into the bed of fatty acid color and odor). This is also according tothe reseachers

tl-3lt9l.

Unsaturated bond in fatty acid is more sensitive. Ifunsaturated bond is higher in fatty acid,it's easier to oxidize [10]. Prevention of fatty acid oxidationis mean to prevent the increment of fatty acid iodine value or unsaturated content, colors and odors.It

is mean also control closely fatty acid quality which is made"In

this

researchwasV

1895S

quality" A researcher explainedin

his disertasion: reduction of bottom temperature of column can reduce stearic acid iodine value or unsaturated content or vice versa [18]. Fractional distillationis

shownin

Figure3

above is intended to reduce unsaturated content of stearic acidC16" Separation

of

oleic acid Cls-1in

the residue of single fractional distillation columnwill

reduce oleic acid (C1s.1) content in stearic acid Clsas a side product"It

is

mean the lower color and odorsin

stearic acid ClsorV

1895 S. Reduction of fattyacid

iodine value,color

and

odors

is

not only

can

be

done by hydrogenation priority, but can be done also through fractional distillation processto

achievethe

lower point. How it can be done?Tab!* fu Quality :*aadsrd o f *gg{i$ ecid. s up e* V I B 9 5 $

FattS' o*id comy o s itioa,

$i'+-Jw)

Arr]lrditr'rane*

< ctr4

clf

c:6-t

c1?

c!8

cl8-I

C}8.]

C:O

0;5

lorrimus

I0.0 msriuurr9fi.{ luinillu.m

s,44

artlmuu

cI0-l

fiqgs6; flo I o fi fir[ilfl $:andu da, J 005 Figure 4. The refining of blended fatty acid through 2

fractionation columns

Met*iaX(ltl

C14 CI6 q:8

Clg-l

C30

Seh

Remark*

Qualityrtatus

Status-$qur*E;

fforo

$flslIs

C*aml *da,261 5Unsaturated content of HCV 1895 S is higher than the maximum standard (see Table 3 above), because ofit value is over than O.l5 Vo. So

it

has to be reducedtill

meet the standard, Reduction of C1s-lamountin

C1s is also decrease of arachidic acid (C26) composition and the others impurities that have the same or higher thanstearic acid C18 boiling

point

whichis

so positive influenceto

theV

1895 S iodine value, unsaturated content, color and odors,to

be lower. Thiswill

beinfluence to the lower production yield

of

V

1895 Sabsolutely, but hopefully with the better quality

V

1895Check tl.e troruogenous feed tank

sample; GC, !\r and rclor

Appliad tlle main caemting co*&trs** t* *.:in5!e tellmr::o:erd remallised om 8O 96 cf Y 1895 S

gm&xt*teis de.ters*red

Ttre rtain oPer=iing cenditia* are detemine* and Fredict ba3€d on tl.e ccmPo:iticn (GC) of feed. pu.ge, side and bottamProdircts

*e Pr*dicted

Dislillate a' 189f $ PuitY conttol

Reduce side stream &aw off rste

Stored as ttrc in rpe* V 1895 S in fhe fiael

lntemational Journal of Engineering & Technology IJET-IJENS Vo1:

1l

No: 04S

thanHCV

1895S will

be

achieved' The above question is answered'Operating conditions

of

single fractional distillati,on co'lumnias

tobe determined and predict carefully beforeby Roult's Law [5][16]. Oleic acid content.Cls-thadtoie

a main considerationin

this study'It

is so sensitiveto

the oxidation and heating' Increment of unsaturatedcontent

or

iodine value

should

beprotected, should be lower in

V

1895 S' The predictionLf

the single fractional distillation column operating conditionsis done base on the capacity and column characters (the pressure drop on the top, bottom.and feed tray locationof

the column), feed compostuonHCv

friSS S, product compositionof

V

1895 S and residueproduit

compositionis

predicted'-.{ctual applicationof

this predictionwill

change alittle

bit depend on the actual product qualityis

made' The2" Method

Semi

trial

and error methodis

usedin

this researctr'Operating conditions are determined, predict first-and uppty

to-*".t

V

1895 S specs' The glalClnC.is fone u'"lorOlng to the actualtetoltt

V

1895 Sis

obtained' basedoi

it

quality standard (priorityit

composition'changing

have

to

be

predictedand

make better;;ft"?

to the quality standard' The understanding of fru.iionuf distillation, physical and chemical properties oi th" tobrtur.e, e*pJti"nc" in this process and fillingt"urr-ftur"

the big conffibution to do the changing oftfr"

operating conditions

tl{'

The-. operati^ng "orOl,iont arJ determined

and predict

1" for

807oproJr"ri",

yield ofV

1895 S according to the specs- ofV

rasS S composition to getin

specs and the higher reflux ratein

ihe

single column, accordingto

C13-1ptop.tti"t

that so sensitive to theoxidation and heating'it.'trigt

reflux rate hasto

be made asit

value is;;hi";."d

on the actual 807o productionleld

of V 1895S or higher, that's limited by

V

1895-S composttion'

*rut*u',"4'"ontent,

colorar; achieved on the actual operating conditions are applied., to^ get the higher yield. What are the suitable conditions?unsaturated content) and production yield' See Figure 5

b"lo,". Proc"dure of anaiysis refers to AOCS Ce l3e-Oiana

fg

l-64 to do iodine value analysis of fatty acid"f."

eO6S

1-62 to do fatty acid compositionanalysis t4t.

Product:V1895S Ilurit]' : 90 i'b minirrum

C:s-t : fi,15 0,6maximum Crc : 1O -qio maxirctr'

Figor.

s=u.ti;;uto#

"or

and qualityv

1895 s as it standardIntemational Journal of Engineering & Technology IJET-UENS

vol:

II

No: 043.

Results and Discussions

T-r_rPp

,l

intended to separate stearicacid (C1s) superuV

1895 Sandfarty acid residue C1s_2s of the feedUiV

1895 S to reduce unsaturated contentof

V

lg95

S. lhere is no light end draw off in this study because of color (not shown here), C16 and C1s of HCV 1g95 S isin

specs. The final qualityof

V

1895 Sis

shown in Table 4 below. The off specs oneV

1895 S in the final storage tank is caused of by production yield increment over than 87 Vo (see Table 5 and Figure 7 below).1S

I+h}fl.*" Unsaturated content o f HCV I I 9 5 S and.

\r

1 895 S (96:*rsr)9S,06 \r1s95

S

0.s9

1"12

!S

.Qgs.r.;5g;

f'lora

$mCr{s S&fil{n{dg, .?00iThe results of,

this

research show that unsaturated contentin

this step came down to beaverageof

0.19Vo(based on Twin River's analysis) or iodine value of

\/

1895 S came down ro be average of 0.12gr l2fi00

g. Comparison

of

unsaturated contentClg-l

of HCV 1895 S andV

1895 S can be seen in Table 4 above"Actual color of

V

1895 S is in specs, but not shown in Table 4 above, discussionis centered to the unsaturatediEl-l

rrra,

34.r-r45

i$

F€€d"

HgV

1895 SCI4

O,cl6

?",6

fl.?6cI

I 980.5

98.S9ci&l

].-l

0-11c:0

9,:

0.9?total 999.7

l{0.0

iliii

iir*

*t*

:63-X64:9.

trB-t

>ff,

tr$-1. C30 are .lPees Feedcl8-1

> C18-l iscontent which is off specs. See inTable 3 and Table 4 above.

The operating conditions are determined and predict,

can bee seen in Figure 6 below.This prediction is made base

on

the fatty acid

compositiononly. please, compare this one with the actual operating conditions in Table 6, in discussion 3.3.eoffdsrr:rer

Li_Eht Eud

lnol

rs'ei-e]rt1',) e

35f

184

c14

0.{0

cx6

]..05ct

E

0.4_iC,.0S

76.S0 3fl.08

total

1,,50to0.0s

ri.r

l895

S ?i,f*ad]s.8 x9 98.S4I s.s4 o,30

totstr

?99.?6

I00.0tl

cI6

6_55cl8

?!1.}0

cl8-r

ff.33c30

*.53

cls

c!3

ct8-1

ct0

o 18s.86

I.9S ?.6$

s.g5 95.03

x.ffo

3_ E3

tot,sl

EgS.4O

IflS.8Figure 6.The operating conditions design forthe providing

ofHCV

1895 S by a single fractional distillationcolumnIl{)40.+-3737 tJEl,ltUNS @ Augusr20II IJENS

[image:5.612.60.524.375.687.2]lnternational Joumal of Engineering & Technology UET-IJENS Vol: 11 No: 04

3.1.

How

to

minimize unsaturated

content

in

V1895

S?10

Based on Table 5 and Figure 7 below no doubt at all that

Cl8

purityis over than 95 7o, althoughv 1895 Sproduction yield are (80.0 - 95'0 %). This is caused by

bt6

feed is lower thanI

Va (Table4

above).If C16 amountin

the feedHCV

1895 Sis

kept asis

in

V 1895 S feed and nolight

end draw offor total reflux in this system./study, ClS puritywill

not be lower than90 7o wlw. This

also affect

to

the

bigger C16concentration

in V

1895

S

that can

minimize unsaturated(Cl8-1)

contentin

V

1895 S, the others components too, C20 and unknown (Unk) (in Table 5)' The higher S production yield ofV

1895 affect to the smaller C16 content and the higher C20 and unknown relatively.It

affectedto

the

off

specs unsaturated contentin

V

1895 S.It

can't be allowed. Please, seealso

both

figures, Figure7

and Figure8

below's7

0,35

99,.131.1

5

9?,580,16

0,11 0,f s111:

0s-1.0 6.8-0-9

In *pecs

3rr specs

$ff

sprcr0"04

0,0:CIJ6

oJ3

8?"0

s3$

s*foh+Eff.ectof,*B*if,:oati:omgreductitr:,xi€K*]s#wr,ra{a.ratesccnlerr1oflxlEEs$99

fl

ss.:E99

:

3 91"5@

96.J

4

fl"39

1,Xl

97 Sawqe: F/ara Sqrtt'ifsC]e*ind+. lS$J

100

99"J

9d

95"5

0.11 95

off

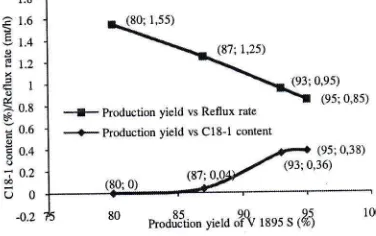

[image:6.612.389.577.516.634.2]The influence of the reduction of

V

1895 S production yield on C18-l content inV

1895 S and reflux rate in Figure7

can be used as the evidenceto

support to state; reductionof

V

1895S

production yieldwill

reduce unsaturated contentin

the

main

product' Reduction ofV

1895 S production yield is cause of theincreasing

of

reflux

rate which reduced theBT

of fractionation column(in

Figure9

at discussion 3.4)"The same thing that had been done by a researcher to reduce stearic acid iodine value or unsaturated content in stearic acid distillate; by reducing BT of distillation column

[18].

The

reductionof

BT

affect

to

the reductionof

evaporation rateof

unsaturated content, reduceit

amountinto

V

1895 S,of

course also the other components. This is according to the distillation principlest5ltl llt17l.

Figure 8. The influence of

V

1895 S production yieldon C18-lcontent in

V

1895 S and reflux rate*o rbditryfifd tJ lti [!gJE $ii

Figure 7. The influence

ofV

1895 S production yieldon C18 purity in

V

1895 SSeparation of amount C18 into fatty acid residue (see

Figure 5 above) affect to the lower amount ofV 1895 S.

Reduction the production yield

of

V

1895 S. This is cause of C16 amount ratio to the total amount of side productV

1895 S is bigger. Finally although without iight end draw off, color ofV

1895 S met the quality standard (not shown in discussion). So the decision not to draw off light end is the exact consideration in the beginning of this study, one technique to minimize the unsaturated content or not reach 0.15 Vo. The ratio canbe

changed dependon

the changingof

V

1895 Sproduction yield. So in this study reduction of

V

1895S production yield is also the other technique to control or reduce unsaturated (C18-1) content as

it

specs (seeFigure 8).

1.8

? 1.6

c

cl

> 0.8

:

0.6E 0.4

UO

-0.2 91.J8)

*.l* Production yield vs Reflux rale

---*- Production yield vs C18-l conrcnt

p.od,iJtion yi"ro ,li$ rsss s i&i)

I I 0 104--1737 Ll U I''lJ IjNS (cl,\u gu sl l0 I I IJ E^-S

@

International Journal of Engineering & Technology IJET-IJENS Vol: I 1 No: 04

-1,i.

Prediction

versus

actual

V

1895 Sproduction yield

;::-:uon

ofV

18955 unsaturated content was done in,: . ,:.rdy.Theproduction yield of

V

1895 S is tried firstr.

'-:

asthe design and predictionof

the operating. ,::::rons(Figure 5 above). ReJlux rate is also made so

.:-,

rgh

in the beginning, on the intervall5OO-

1600.;

-,- Thisreflux rate

is

intendedto

suppress the:

.:,:iation rateof

unsaturated component as low as:..,::le

becauseof

the boiling pointof

unsaturated.

-.

.cid Cls-1is lower than C1s boiling point[16]. This-:

l-r

rate is made also because of the amount of C1s-1:

---: feed HCV 1895 S is so small (0.23 7o in Table 4-:,-,:r.

also the other components (Table 4). On the -'::

reflux rate,it's

moredifficult to

be separated:-l

,rnto the bottom productor

residue (Figure 5-;.,r3). Of course the amount of Cra

will

be bigger in--.

::sidue.It's

a riskof

a high reflux rate. The feed --.:,sried first

onl.000 kg/hr. These predictions are.::

accordingto

the experiencein

thefatty

acid'

.:..ation and fractionation in the previous"'-.

:roduction yieldof

V

1895 Sis

then increased:ii-)'(as

shownin

Table5

above) after fractional -.:-iation

conditions

werestablefor

80.0

7or-:,:jction

yield. This simulation is done for knowing--.

.;rfluenceof

the incrementof

V

1895S

on the-::.ment

of

unsaturated contentin

V

1895 S. The':,

-.:s rvithin Table 5 proved the prediction above. See..

Figure8

below.The higher possible production..:

can be achieved but at the same time unsaturated- t:,3nt is closer to the maximum point of unsaturated : --,ent and finally of specs on

9l

Vo,93 % and 95 Vo:: -,:.rction

yield

(Table

5

aboveand

Figure

8:t.:.r').The in specs one ofV 1895 S should be made in ,-

:

research.How

many

percentthe maximum:::'r.rction

yield

hasto

be

achieved?How

many:r::ent

the safest production yield?It

has to be met.-::

rendin

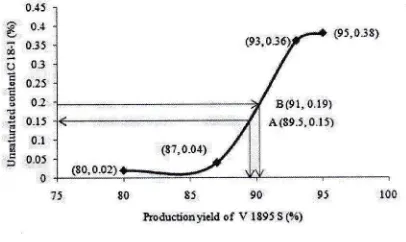

this Figure 9 can be used to predict the,

--"ble production yield ofV

1895 S to provide.:.

rodine value and unsaturated content ofV

1895 S -- Table 5 above) came up to be higher. This is cause:.

*nsaturated component is evaporated more together, :.

\/

1895 S as the impactof

the incrementof

V-.::

S production yield and/or decreasingof

reflux:r,:

see Figure 8 above). The compositionof

C20 is: :-ler

also, causedof

the

same reasons.This

is .: - :rding to the distillation principles t5l t I 1l I171.i.3.

Actual

versus

predicted operating conditions

-:.:

reduction ofV

1895 S production yield mean the-:

:3mperature of the fractionation column is adjusted.-.rer.

This

temperaturecould

be

determined and::::rct

practicallybyRoult's

Law but

haveto

be:

=l-red actually through this research. The predicted11

The

off

specs one stearic acidV

1895 Sin

Table 5 [image:7.612.299.502.415.536.2]above is sent back the other feed tank as described in Figure 5 above to avoid the higher unsaturated content in the same feed tank and in the next

V

1895 S will be produced.Based on data in this table,it

is so clear the influence of the higher production yieldV

1895 S tothe higher it unsaturated content. See Figure 8 below, Base

on

this figure,V

1895S

production yield is predicted 89.5 Voto

achieveO.l5

7o unsaturatedcontent

in V

1895S

(point

A).

So the

safestproduction yield should be under 89.5 Vo. Based on this

predictionv

1895S

productionyield

should be adjusted to be lower than 89.5 % (see Figure 9 below).It

could be 88 Vo or 89 Vo. Whyit can be happened?It

has to be considered strongly the unsaturated content should be achieved first lower than 0.15 Vo.lt

is very importantto

meet the specsfirst.

If

the production yield is kept constantly as is (89.5 Vo), therc is a big possibility thatV

1895 S will be off specs.Beside

this

reasonthe

stabilityof

this

process is considered strongly.It is

not

guaranteedall

the instru:mentationshave

the

straightline

response,according to the experience it's normally has the small fluctuate on the same amplitude.

,5, 80 *5 90 9' t00

lro&rtionyi{d of Y lS95 S G6)

Figure 9. The influence of

V

1895 S production yield on unsaturated content inV

1895 SThe actual average production yield is achieved 85.0

Vo. Why is it different? The production yields in Table 5 are not straight since the increment is done, It is done slowly, step by step.It so logic the actual production yield is lower than the predicted one.

one

is

used as a main guide and very important to conduct this research. This prediction was limited by unsaturated contentor

double bondof

C13-1in

the quality standard.If

the consideration was based only of C18 purity (see Table 3 above),V

1895 S can be draw0.45

3 0.1

; 0 35

6

o.r6 0?5

6 ^-i n r{

:

0.r5

o.o5B (91, 0.19 !

a{s9.i,0.ri)

lnternirtional Journal of Engineering & Technology IJET-IJENS Vol: I

I

No: 04 t2off 98 Vo or

it

production yield 98 70 asit

composition in the feed but actually unsaturated content is off specswhen

it

production yield achieved 93 7o and95 Vo. Soit

must belower becauseof

timitedby

unsaturated contentin

the quality standard.It's

mean also theactual operating conditions

are

differentwith

the predicted operating conditions. See Table 6 until Table9 below.

The average conditions for the production yields 80 7o,

87 Vo and 93 Va (Table

6)

were the averageof

thesimulation data on the same yields from Table 7 below. The data for 93 7o and 95 Vo production yield didn't take more because

of

the

conditions wereup

setalready.

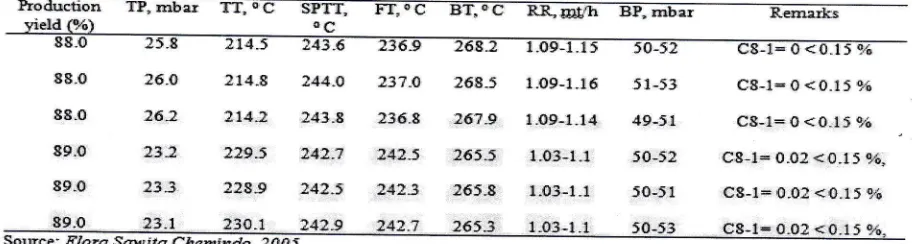

The average conditions for the production yields 88 7o,

89 Vo

in

Table 10 were the average of the simulationdata on the same yields from Table 11 below.

Table 6. The actual operating conditions to produce V 1895 S of l't test

IJroductron TP"

mbar

TT. {C

SPTT.

FT, oC

BT, oC

RR,U:t&

E},mbar

Remarksv'ipld l9,ir\ o fl

80.0

19.3

.I3X.S

l4j{.4 231"4 ?66"6 1.1-1.1 50-J4

Cg-1<015 9',;sl-o

:J.8

ll4-i

t43"S 136.8 :6S.0 1.09-1.1

50_Jf93.0

27.2 :03"8 ?45.1 138-9 t?4.0 0.Sl-0.9

50-51c8-1< 0-15 f.i C8-l> 0"15 o;';

fl8-1> 0"15 o]$

95-0

?5.5 lBl,I ?44.: ?t8.9

I?-1.$

0.7S,0"S3

50"0Source:

ffara {6g;ffi

C*s#i11&" JOUj

Notes: TP

:

top PreB$uE; TT = top temperatlue;SITT:

aide product tlsy temFerature;FT:

f*ed temperstue;ET:

fo1t1g;g1 tenlperature; RR

-

reflus mte ; BP:

bottom pres$ureTable 7. The actual simulation ofthe operating conditions to produce

V

1895 S ofl't

testProduction

TP,mbar

TT,DC

SPTT,

FI,{C

BT,sC

}-R,E*r,h

Bp,mh4rIroduction TP,mbar TT,DC SPTT, FI,{C BT,sC RR,E*iih BP,mhar

Remzrksyietlf"..t) ,..

oc80.0 l9J

t32_S

:44.4 :3?.4

256"6

1.1-11 5g:54

Cts-l< 015 0/6s0-0 80,0

The actual operating conditions on 80.0 7o production yield has a small different than the predicted one (see

Figure 5). The actual suitable prediction of production

yield

was 89.5 Vo (discussion3.2

above).It's

sodifferent also than the prediction was done only base

on the C18 composition in the feed. Feed temperature can't be reached because of the limitation Oil Thermal Heater system capacity

(on

850-900 kgs/trour feed rate), to conduct heatingin

a heater and a reboiler of fractionation column.Reducing of TT and SPTT trends that almost constant are according

to

the simulationof

Roult's Law (not shown here)I5l.

SPTT trendas

is

due

to

Cl8

concentrationis

almost constant around 98 Vo on the same pressure27

mbat. Reducingof TT is

due to increasingCl6

or

reducing C18 compositionin

thec.8-1{O-t5 9d

c.8-1{8-15 9/a

cB-:{

*-15 9t *8-:{0-1"5 *6 c*-14 0.1,J % c8-1> 0-15 $6cg-1> 0"15 BL

tr8-1> 0.15

}t

total reflux of light end on the same pressure, around 25 mbar, as affect

of

V

1895S

production yield incrementor

decreasingof

total reflux into

the column,This

incrementis

causeof

reducing C15 composition inV

1895 S that is added major from light end and also C18 composition increment that is added major from bottom product. This incrementis

also cause of the increment of BT that is effect to the higher C18 evaporation soit

compositionis

higherat

the productionyield

87

Vo (see Figure8 in

the next discussion 3.4). [ncrement of production yield (priority 93 Vo and 95 Vo) is cause of the increment of BT that is so effectto

the higher contentof

Cl8-1,

C20 andunknown components, unsaturated content is off specs

(0.36 and 0.38 Vo). This is also so affect to the lower C18 content in

V

1895 S. That is why both the last 2actual operating conditions in Table 6 can't be applied

19"5

]]J

-0 344,2 13?.6 ?67.0 1-1-1.:

51_5419-1 23t.6 :.{.1.6 ?3?3 266.2 1.1-1.19

49-5487,0

25.8 ?14.5 f,43.6 :36.S 268"0 i.g9_1"1

5S-53s7.0

21"6

X14-7

?44.0 J37.0

?68..+

1.0S-1.11

51_51B?"0

?6.0 214-3 t4t.I 236.6 ?67.6 1.09,1.1

49-5293,0

:?.:

203.$ 145.1 :38"9

2?4-1

0.8.1_0.9

50_5193,0

27.25 ?03"7 :44.9 :38.9

??3.9

0.8$_0"39

50-519t"0

ts.l

:04-5 J44-5 :38"9

]?i

.83

50-51Soruce: SIora SqU*;g SftS4i*f{k 3

I'{ote: IP

-

top prersurs;TT:

tcp t€nlperaturB; SPTT = side pro'duct ua}'trr.$erertue;r-I:

feed iemperaft$e;ET:

Itltgm

terRperature ; RR = r,eflux ret* ; BF = boitorn pre*:,r:reInternational Journal of Engineering & Technology UET-IJENS 11 No: 04

,he next test, but the higher yield should be pointed

.,

shown as discussion 3.2, based on Figure 7. The:

,"iuction yield 88 and 89 Vo are met graphically and89.0 ?3

J6

:1?- ?44-

246_ll& 145

24"7the

operating conditionsRoult's Law, next

hascompared how precise it.

have

to

be

predicted byto

be

tested actually, and-

":le

8. The predicted operating conditions to produce V lg95 S of l,ttestion

TP,mbar

TT, oC

SPTT,BT,{C

RR,,

mbar

Rr{d*lT)

==

..

,

,

oc

ss.0 2336 217-

?44118 ?45 ?47

264 9t (beee onligure

9of

I st tes$ C8-1= 0.14 +6

{

CI"15flo, (base on Frgule

I

?s3-

:.01-1.s.1+ 264cflsttest

\ote:T}=tgpPr*sure;TT:toFtempi[etue;S}T:=*i*uperEtue;BT=

hSffnS

tenper*true

; RR = reflti:r rate ; EP = bottompre:ssire ;;

base on the highest agtual 1.ecu11111Irregflrrel:ble

9" The predicted ofV

I 895 S quality on l,t tesr-i

c:6

18-1

C?S Reflux rate, ductio* yield s.

?

0,76

99.6? 0,06

0"32

0.30* -

1.0I-1.04+

89$

In

specsTable 10. The actual operating conditions to produce

V

1895 S of 2nd testProduction

TP,mbar

TT,oC

SPTT,

m

rield (Va)

25.8

214.5 243.6

236.9

268.2

LOg_Lts C8-1= 0 < 0.15 7p (baseon Table 12)

23.2

229.5 242.7

242.5

265.5

1.03-1.1 CS-l= 0.02 <0.15 Vo,base on Table 12

\ote: TP = top pressure ; TT = toP temperature; SPTT = side product tray temperature ; FT = feed temperature; BT = bottom temperature; RR = reflux rate ; Bp = bottom pressure

Table I L The actual simulation of the operating conditions to produce

v

1 g95 S of 2nd test 5A-5250-52

16-0

t14-S :44-0 :37,O :69-5

1.09_1-ld

51-5316l

I14.2 243.8 :36,8 t6?.9

1.O9-1,14

49-i1

88.0 83.0

89.O

89.0 s9.0

?3-l

iJ .J

C8-1:0

<0.15 9.5C8-1:O<O.15li)

2?9.i Xtr3-7 342"5 265,5

t-O3-1"1 50-it

CB_l:

O"0-?<fi_l5

9.6.:t$.g f4"?-: 24?"3 :65.8

t-03-1,l

50-11

CS-t:

0-01 < 0.15 9.a?3fr-1

t41"92.7 t65-3

1"03-J0-t3

CS-1: O.01 < 0-15 9nSouree; Floro fi4ggiitg "G&emUgdg ,OOJ

Note: ?P

:

toP Pre$u.re; TT:

top ternperehne; $PTT:

side product tra!' ternperature;FI:

fe.ed ternperature; BT:

l:ottomtemuer*ttre: RtrL: Teflux rete :}lp

: hcttomorsr.*.|

S ource: F lo ra S awit aChemindo, 2 00 5

1 I 0r10.+^J737 UEI'-IJENS @ Augusr 201 I LIE^-S

@

l3

50*

Remarks 88.0

89.0

vield

(%,)

o C [image:9.612.52.508.552.674.2]International Journal of Engineering & Technoiogy IJET-IJENS Vol: 1

I

No: 04Table 12. The acrual V 1895 S quality of 2nd test

cls

rate,1.09-1"15

TS

9S"9,7 1,CI3-1"I3'4' Mechanism of

the

changing of

the

main temperature in

the

manufacturing of

V

1g95 SC1

Ifuk

89 CI$0

0,ff1

180

,2

ztaEE

260t-E

250is

:ro t c 2i0T* rrn .e e :10

1 E roi:

ig

rco-

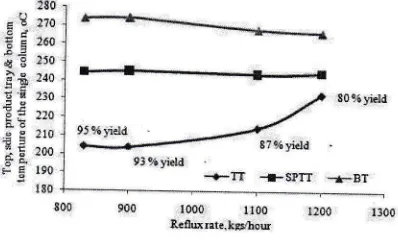

lsoThe changing of the top, side product hay and bottom temperatwe

versus

reflux

rate

in the

single fractionation column (in this research) can be seen-in [image:10.612.118.566.140.192.2]8qs

9*0

100& u!9

,!a00

13oo Reflq ntekE/hfl(Figure 10. Mechanism of the changing of the main temperature to produce

V

lg95 S in a singlefractionation column

4. Conclusions

Unsaturated content of

V

1895 S is higher than0.l5 Vo 11"_aft"

producrion yield ofV

l89ts

is higher than 90 Vo.Based on the actual operating conditions to meet the safest unsaturated content (lower than O.l5 Vo)

in

y

1895 S finally is found graphically on g9.5 Zo V iB95 S

production yield. Practically is found gg _ g9 Vo

V

lg95S production yield. The light end has to be total reflux and unsaturated content of

V

lg95 S is controlled by the adjustmenrof

V

1895 S production yield on rhefound practical or actual operating conditio;s

4.

Suggestions

[image:10.612.117.316.285.409.2]It's

suggested strongly to improve the OTHS capacity tg q:ttlg

higher FT/capacity andV

1895 S production yield. The incrementof

FTwill

be causeof

tfre Rn incrementthat

can

reducethe lower

unsaturated content.Figure

l0

below. The changing temperature above happen whtle total reflux of lisht endin

the single fractionation column as Figure 3 above.Reducing ofreflux rate or increment ofthe production yield

V

1895 S is causeof

the top temperature (TT) decreasing, relatively no changing of the side product ffay temperature (SPTT) and the bottom temperature(BT)

incrementof

the single column,on

the sameheating in the reboiler.

This mechanism

is

so different with the temperature mechanismoffatty

acid blended fractional disiillationas

Figure4

above. Accordingto

the

experience practically, the total reflux of light end is cauje of TT and BT decreasingin

lst column and the increment of productionleld

distillate productin

2nd column is causeof TT

and BT incrementin

2nd column on thesame heating in the reboiler. This is according also to

the reference

Il

l].

The actual operating conditions are found atTp (23.2 _ 25.8 mbar

), TT

(214.5-

229.5 "C), SPTT (242.7 _ 243.6"C),

FT

(236.9_

242.7.C), BT

(265.5 _ 268.2"C), RR (1.03-

l.I5

mt/hou0,Bp

(

'50_

52 mbar) and feed rate 850-

900 kg/hour. It is found baseon the predicted operating conditions

at

W

(23.36 mbar ), T TQfi -

218 "C), SPTT (244 -245 .C),FI

(246

-

247"C),BT

(263 -264C), RR(

l.0l

_

1.09 mVhour),BP

(50

mbar) and feed rare g50_

900 kg/hour.Feed temperature

is

actually found lower than the predicted one becauseof

the limitationof

the oil thermal heater system (OTHS) capacity.It's

suggested stronglyto

improve vacuum system capacity soit

can be achieved 3 -5 mbar Tp in of the single column to improve the total performance of the single columnfor

this

special product. The highest vacuum pressure 2 mbar is also stated by [9] to get the better resultsof

fractionation/distillation products.110i104-37-]7 III:1,IJINS @i Augusr 20lt IfjNS

@

International Journal of Engineering & Technology IJET-IJENS Vo1: I

I

No: 04 15-

!";I.rences

:::-:--:.::.

E.,

1985.,"Oii

Seeds Oils and Fats",-

l'd

Edition"B.E

Oil

Publishing House,-. ::-.:r

R and McPherson, W", 1979., "Fractional- -

.:-on", JAOCS,Vol.

56:743A-

745A :-:,::--.nn,

R."

Demmering,

G.,

Kreutzer,-

.-:3man,M.,

Plachinka,J.,

Steihrner, U., -:-

FattyAcid",

Henkel KGaA, Dusseldorf,;:=:-.

Republic of German.*

l

- .-. F.,

2006.,

"Official

Method

And;.-,rmended

Practicesof

the

American Oi1I-::--srs

Society",5thEdition,

2nd

Printing,-

-,-S Press, USA.::-

..-

8.L,, 1989., "Applied Process Design for-

-.

::;a1 and Petrochemical Plants", Volume -2,-'-

::riion,

Gulf Publishing Company, Houston.:. :

-nd

Hahn. GmbH,

1998.,"Fatty

Acid:-.:-onation",

Flora Sawita Chemindo, Medan, : -:-:sia-

-

-r"

Sawita

Chemindo,2005.,

"Production:

-:::rg

Control", Medan, Indonesia;-:.

E.. 1979., "Interrelationshipsin

Fatty Acid -*-,::ssing", JAOCS, Vo1.56; 7 45A-746A":r:irnann, A.

E.

S.,

1990.,::=:-:onation/Distillation

:

Improvement in-.- .:).

Efficiency, Energy and Environment-.::;ts",

Proceeding

World

Conference on.

..

Chemicalinto

21" Century, Kala Lumpur f.:.::3:'i. S., 1985., "Oils and Fatsof

Food", UI:::...

Jakarta.I

",::aphies

Muhammad Yuuf. Ritonga was bom in

Sipirok, Tapsel, North Sumatera province, lndonesia, on August 19,1962. He studied and graduate in North Sumatem University since 51 degree till obtaining his doctor.

He had being a lecture since 1989 in Chemical

Engineering Deptrtment, North Sumatera

University. He has 20 years of special field

;,ri::-.r: oleo chemical industry since l989in troubleshmting, u: : ;- : :i::i. start up, commissioning; oils and fats pretrcatment

;iL- :-:-:. glycerin purification, fatty acid dry fractionation,

' :-;::;:::. distillation md fractionation. His experiences related

"" : :l {ibhawana Utama (now called PT. Eco Green as a Fatty

[11] Muhammad.

Y. R.,

1996., "Practical Distillationtr',

Study

Progam

of

Chemical Engineer, Facultyof

Engineering, Universityof

Sumatera Utara, Medan, Indonesia.ll2l

Muhammad.Y.

R., 2009., 'Fatty Acidsof

OleoChemical Industry",

Proceeding

National Conference of Chemical Engineer, University of Sumatera Utara, Medan, Indonesia.t13l

Peter,W. Faesler.,

Karl

Kolmezt.,

Wang SengKek., 2004., "Revamp Strategiesfor

FattyAcid

Distillation

SectionIn

Oleo-Chemical Plants", Sulzer Chemtech, Singapore.[14]

SulzerChemtec. 2006., "Separation Technology for the Chemical Process Industry- Oleo chemicalStep

Into

a

Growing

Market

with

Sulzer Chemtech : 12".ll5l

Thomas, H.W. 1985., "Bailey's Industrial Oil andFat Product", Volume

3.

JhonWiley

&

Sons,New Yorlc

[16]

Unichema lntemational. 1998., "Fatty Acid DataBook"

2ndEdition,

Unichema, Republic of German.[17] Van Winkle. M., 1967., "Distillation", Mc. Graw -Hill Book Company, New

York

[8]

Yusuf Ritonga. M.,2010.,

"Optimization of the Providingof

StearicAcid

Basedon

Refined Bleached DeodorizedPalm

Stearin (RBDPS)Which

is

Stable Accordingto

the

Quality Standard",Doctor

Program,FMIPA,

USU, Medan, Indonesia.Alcohol and Glycerin Plant) md PT. Flora Sawita Chemido (as Fatty

Acid and Glycerin Plant), He had been done many resetrches relate

to oleo chemical industry ; fatty acid and glycerin products

diversification and modification and design and modification of

operating condition of the specific process in oleo chemical industry, on the plant scale. He also released many mmuscripts on the various science and technical journals relate to fatty acid and glycerin in the terrns splitting of various natural oils md fats, hydrogenation, distillation, fractionation and dry ftactionation of various fatty acid base on various natuml oils and fats. He is the author of book

Distillri Praktis. He planned to release two books (had being edited

till now on) ;"Practical Distillation Prirciples" and "Hydrolysis

Oik and Fats in Oleo Chemical Industy".

/

LEMBAR

HASIL PENILAIAN SEJAWAT

SEBIDANG

ATAU

PEER

REWEW

KARYA

ILMIAH

:

JURNAL

ILMIAH

Judul Jurnal

Ilmiah

(Artikel)

:

Providing

Vegetable Stearic

Acid

SuperV

1895 SFrom Hydrogenated

Of

Crude Vegetable Stearic

Acid

HCV

1895 SWith

A

Single

Fractional Distillation Column

:

Dr.Ir.

Muhammad Yusuf. Ritonga,

MT

:

a.Nama

Jurnal

:International

Journal

of

Engineering

&

Science

IJET/IJENS

Penulis Jurnal

Ilmiah

Identitas Jurnal

Ilmiah

(beri

/pada

kategori yang tepat)

Hasil

Penilaian Peer Review

:b.

Nomor/Volume

c.

Edisi (bulanltahun)

d. Penerbit

e.

Jumlah halaman

04111

Agustus

201I

1JENS

Publisher

-Pakistan

167KategariPublikasi

Jumal

Ilmiah

, d

Jurnal

llmiah

Internasional

f]

Jurnal

Ilmiah Nasional Terakreditasi

I

Jurnal

Ilmiah Nasional Tidak

Terakreditasi

Komponen

Yang

Dinilai

Nilai

Maksimal

Jurnal llmiah

Nilai

Akhir

Yang

Diperoleh

Internasig/al

TE

Nasional

Terakreditasi

n

Nasional

Tidak

Terakreditasi

tl

a.

Kelenskapafl

unsur

isi buku (10%)

sF

ge

b.

Ruang

lingkup

dan kedalaman

pembahasan{30%)

70

Jr,

/

c. Kecukupan

dankemutahiran

data/informasi

danmetodolosi (30%)

s&

2t,

?

d.Kelengkapan unsur

dankualitas

penerbit

(30%)

te

Je,?

Total

=

(100o/o)g/,9

Medan,

...(A.

:....!.*.:...*.Qf.*...

Nama

: Prof.

Dr. Harry

Agusnar.

M.

Sc.Phil

NIP

:

19530817

i98303

1002

tJnit

kerja

:

FMIPA

-

USU

i..i i1

Reviewer, _-

./

-A

g

Judul

Jumal Ilmiah

(Artikel)

Penulis Jurnal

Ilmiah

Identitas Jurnal

Ilmiah

Kategori Publikasi

Jurnal

Ilmiah

(beri

/pada

kategori yang

tepat)

Hasil

Penilaian Peer Review

:LEMBAR

IIASIL

PEMLATAN SEJAWAT SEBIDANG

ATAU PEER

REYIEW

KARYA

ILMIAH

:

JURNALILMIAH

:

Providing

Vegetable Stearic

Acid

SuperV

1895 SFrom Hydrogenated

of

Crude Vegetable Stearic

Acid

HCV

1895 SV/ith

A

Single

Fractional Distillation

Colurnn

.:

Dr.

h.

Muhammad

Yusuf. Ritonga,

MT

:

a.Nama

Jurnal

b.

Nomor/Volume

c.

Edisi (bulariitahun)

d.Penerbit

e.

Jumlah halaman

:

International

Journal

of Engineering

&.zc ScienceIJET/IIENS

04/11

Agustus

20i

i

IJENS

Publisher

-Pakistan

16'7

, lV

Jumal Ilmiah

Internasional

I--l

Jumal

Ilmiah Nasional Terakreditasi

t]

Jurnal

IlmiahNasional Tidak Terakreditasi

Medan,..4

Reviewer

2Nama

NIP

,r,,%,s,auan.u.

si

:

19600618198703 1002Unit

kerja

:FMIPA

-

Guru Besar

Biokirnia

-Universitas

Negeri Medan

Nilai

Maksimal

Jurnal Ilmiah

Internasioual

d

Nasional

Tidak

Terakreditasi

E

unsur

isi buku (10%

b.

Ruang

lingkup

dankedalaman

pembahasanc. Kecukupan

dankemutahiran

data/informasi

dand.Kelengkapan unsur

dankualitas penerbit

(30%)

:

l