I hereby, declare I had read through this thesis entitled “Effect of Air Velocity on Solid

Waste Combustion” and I agree that this thesis had fulfilled the quality and scopes that

worth it to award Degree of Mechanical Engineering (Structure-Material).

Signature

: ………

Supervisor’s Name

: ………

i

EFFECT OF

AIR VELOCITY AND EQUIVALENCE RATIO ON

SOLID WASTE COMBUSTION

ADAM WONG YUNG SENG

This report is submitted to

Faculty of Mechanical Engineering

University Teknikal Malaysia Melaka

In Partial Fulfillment for Bachelor of Mechanical Engineering

(Structure & Material)

Faculty of Mechanical Engineering

University Teknikal Malaysia Melaka

ii

"I hereby declared that this thesis titled

'Effect of Air Velocity and Equivalence Ratio on Solid Waste Combustion ' is the result

of my own effort except as clearly stated in references the source of reference".

Signature : ____________________

iii

Special dedication to my late and loving father, Andrew Wong Kiong Ming who

passed away last year. He will always be remembered. Dedication as well to my mother

whom, also had taken good care of me. Not forgetting as well both my brothers, who

had been with me all this while.

iv

ACKNOWLEDGEMENTS

I would like to give my first credit to all my faculty staffs at Universiti

Teknikal Malaysia Melaka (UTeM) that involved in my PSM research. Among them is

Puan Ernie as my PSM supervisor. She had provided a lot of assistance and guidance

from the beginning, after I had chosen her topic as my PSM research. She always ready

to help despite of her busy work schedule. She frequently keeps track with my work

progress and provide useful advices and guidance.

v

ABSTRACT

vi

ABSTRAK

vii

TABLE OF CONTENTS

PAGE NO

.

DECLARATION

ii

DEDICATION

iii

ACKNOWLEDGEMENT

iv

ABSTRACT

v

TABLE OF CONTENTS

vii

LIST OF TABLES

x

LIST OF FIGURES

xii

LIST OF SYMBOLS

xv

LIST OF APPENDICES

xvi

CHAPTER I

INTRODUCTION

1

1.1

Introduction

3

1.2

Objective

3

1.3

Work Scopes

3

1.4

Problem Statements

4

viii

CHAPTER II LITERATURE REVIEW

5

2.1 Introduction

5

2.1.1 History of Gasification

7

2.2 Stoichimetric Combustion

10

2.3 Fixed Bed Gasifier System

11

2.4 Updraft Gasifier 14

2.4.1 Operating Systems

15

2.4.2 Process Zones 15

2.5 Application of Updraft Gasifier

17

2.6 Air Velocity 19

2.7 Equivalence Ratio 22

CHAPTER III

METHODOLOGY

26

3.1

Gasifier Of UTeM

26

3.2

Preparation of Variation of

28

Air Velocity

3.2.1 Producing Different Values of

Air Velocity

28

3.2.2 Measuring of the Air Velocity

31

3.3

Temperature Measurement

32

3.3.1 Thermocouple

32

3.3.2 Data Logger

33

3.4

Solid Waste Properties

34

3.5

Input Properties

35

3.5.1 Determination of Equivalence Ratio 36

3.6

Flame Temperature

39

ix

CHAPTER IV

EXPERIMENTAL RESULT AND DISCUSSION

41

4.1

Introduction

41

4.2

Temperature Distribution in Variation of

42

Air Velocity

4.2.1 Temperature Distribution of Zero

Air Velocity

43

4.2.2 Temperature Distribution of 3 m/s

46

4.2.3 Temperature Distribution of 4 m/s

49

4.2.4 Temperature Distribution of 5 m/s

52

4.2.5 Temperature Distribution of 6 m/s

55

4.3

Maximum Adiabatic Flame temperature

58

4.3.1 Maximum Adiabtic Flame Temperature

for all thermocouples

58

4.3.2 Adiabatic Flame temperature of all

thermocouple one

60

4.3.2 Adiabatic Flame temperature of all

thermocouple six

62

4.4

Performance Analysis of UTEM’s gasifier

64

4.5

Evaluation of Understanding/ Finding

66

CHAPTER II CONCLUSION

68

5.1 Introduction

68

5.2 Conclusion

68

5.3 Recommendation

70

REFERENCES

71

APPENDICES

74

x

LIST OF TABLES

NO. TITLE.

PAGE NO.

2.1 Types of Fixed Bed-Gasifier

13

2.2 Generic Formulas

25

3.1 Specifications of Air Blower

29

3.2 Air Velocities Obtained

30

3.3 Specifications of Data Logger

33

3.4 Feedstock Input Properties

34

3.5 Input parameters used in experimental work

35

3.6 Parameters used in determination of actual air over fuel ratio

37

3.7 Diameter of blower outlet for air velocity conducted

38

4.1 Equivalence ratio and maximum adiabatic temperature for zero

air velocity

43

xi

4.3 Equivalence ratio and maximum adiabatic temperature for 4 m/s

49

4.4 Equivalence ratio and maximum adiabatic temperature for 5 m/s

52

4.5 Equivalence ratio and maximum adiabatic temperature for 6 m/s

55

xii

LIST OF FIGURES

NO. TITLE.

PAGE NO.

2.1 Pyrolysis of Carboneous fuels char

6

2.2 Gasification of Char

6

2.3 Integrated gasification Combined Cycle, or IGCC

7

2.4 Wood Waste

8

2.5 Burning Log in Campfire

9

2.6 Fixed Bed Gasifier

11

2.7 Updraft Gasifier

14

2.8 Updraft Gasifier For Corn Drying

17

2.9 An Updraft Gasifier Plant

18

2.10 The Effect of Air Addition on Condensable Hydrocarbon

20

xiii

2.12 The Effect of Air Addition on Gasification Efficiency

21

2.13 Diagram of Equivalence Ratio and Air Fuel

25

3.1 Schematic Diagram of UteM’s Gasifier

26

3.2 Actual View of UTeM’s Gasifier

27

3.3 Working Combination of Air Blower and Pipe

28

3.4 Opened Opening

29

3.5 Closed Opening

29

3.6 Connection of Pipes

30

3.7 Anemometer

31

3.8 Thermometer Type K

32

3.9 Data Logger

33

3.10 Construction Wood

34

3.11 Whole Setting of Equipment

40

3.12 Screen View of the Data Logger Software

40

4.1 Location and listing numbers of the thermocouples in gasifier

42

xiv

4.3 Temperature distribution of 3 m/s

47

4.4 Temperature distribution of 4 m/s

50

4.5 Temperature distribution of 5 m/s

53

4.6 Temperature distribution of 6 m/s

56

4.7 Maximum Adiabatic Temperature for all Thermocouples

59

4.8 Graph for all T1 combined

61

xv

LIST OF SYMBOLS

d

=

Diameter

A

=

Area

v

=

Velocity

Q

=

Volumetric flow rate

ρ

=

Density

xvi

LIST OF APPENDICES

NO. TITLE.

PAGE NO.

A Carry Out PSM Flow Chart

75

B Grant Chart for PSM 1

76

C Grant Chart for PSM 2

77

D Technical Drawing of the Gasifier

78

E Draft Drawing of the Gasifier

79

F Calculation of Equivalence Ratio

80

1

CHAPTER 1

INTRODUCTION

1.1

Solid Waste

Despite of the progression of our humankind civilization, we have

produced many wastes. This waste may in the form of solid, liquid and gas as well

as either biodegradable or non biodegradable. Solid waste can be divided to

several types namely garbage, rubbish, ashes, industrial wastes, mining wastes,

agricultural wastes and may more others. Due to different types of solid waste,

different methods are invented and used. Among the methods are automotive

shredder residue (ASR), gasification, in-vessel composting, pyrolysis and so on.

2

According to Lefcort, M.D, (1995), gasification is a special case of

pyrolysis. It involves the process of converting carbonaceous materials into

carbon dioxide and hydrogen by reacting the raw material at high temperature

with controlled oxygen and steam. Gasification is a very efficient method for

extracting energy from many different types of organic materials. In this research,

the work will emphasize on the gasification of wood waste. The resources of

wood waste include construction fields, furniture industries, paper industries, old

furniture and so on. These solid wood wastes are usually left to decompose

naturally in the dumpsites. However, in case the solid waste is burnt with the right

method, it has the potential to generate electricity. This is a beneficial situation as

it not only reduce the solid waste but also as an alternative for energy source.

The equipment that used to convert the solid fuel is solid waste gasifier.

The solid fuels such as wood waste, saw dust briquettes and agro-residues are

converted into a gaseous fuel through a thermo-chemical process. This resultant

gas is very useful to produce heat which in turn applied in power generation

applications. There are three type of gasifiers namely downdraft, updraft and

crossdraft, which is classified according to the way air or oxygen is introduced

into it.

3

1.2

Objective

1.

To determine the optimum operating parameter of a gasifier for

different air velocity.

2.

To determine the gasifier mode operation which is either in

pyrolysis, gasification or combustion.

1.3

Work Scopes

1.

To run experimental work under various air velocity.

2.

To determine the gasifier mode operation from equivalence ratio

value.

3.

To determine the axial and outlet flame temperature distribution in

the gasifier.

4

1.4

Problems Statement

No extensive work on the gasifier through experimental or simulation work.

Hence, this study is done to analyze the performance of the gasifier with various

air velocities to get the suitable axial flame temperature.

1.5

Significant of Study

A laboratory scale of the updraft gasifier is used in this research. The updraft

5

CHAPTER 2

LITERATURE REVIEW

2.1

Introduction

Christine and Gable, S. (2008) in http://alternativefuels.about.com

described that the gasification is an exothermic reaction between a high carbon

fuel and a carefully controlled and limited supply of oxidizer, together with heat,

pressure, and steam to convert materials directly into a gas composed primarily of

carbon monoxide and hydrogen. Gasification is also identified as a type of

pyrolysis. However, the pyrolysis involved the destructive decomposition of wood

waste into charcoal, oils, tars and gas when the pyrolysis occurred at below 593

°C or 1,100°F. However in gasification, there are no formation of oil, tar and

charcoal byproducts as all the solid wood waste is converted to the burnable gas

of mainly carbon monoxide, hydrogen and methane.

Both the process of the pyrolysis and gasification is shown in the Figure

2.1 and Figure 2.2 below. In Figure 2.1, the pyrolysis occurred without sufficient

air and yields products of hydrogen (H

2

), tars and methane (CH

4). As for the

6

introduced and able to convert all char into products of

hydrogen (H₂),

carbon oxide (CO) and carbon dioxide (CO

2

).

(Source: http://en.wikipedia.org/wiki/Gasification)

Mainly the raw materials used in gasification are coal, petroleum-based

materials, and organic materials. The raw material or feedstock can be prepared

and fed, either in dry or slurried form, into a sealed reactor chamber called a

gasifier. In the gasifier, the feedstock is subjected to high heat, pressure, and

controlled amount of oxygen. The environment in the gasifier is either

oxygen-rich or oxygen-starved environment. However, oxygen is not required in mostly

commercial gasification technologies.

Gasification produces three primary products, namely hydrocarbon gases

(syngas), hydrocarbon liquids (oils) and char (carbon black and ash). The syngas

is primarily carbon monoxide and hydrogen (

≥

85 percent) and smaller quantities

of carbon dioxide and methane. Both syngas and oil has the potential in

generation of electricity and other wide usages.

Figure 2.1: Pyrolysis of

carbonaceous fuels char

7

2.1.1

History of gasification

The history of gasification dated back to mid-1800’s and had undergo a

long history of development. It is initially used to produce ‘town gas’ from coal

for heating, cooking and lightning purpose. This ‘town gas’ is later substituted by

natural gas after the founding of the gas fields. The break-out of World War II had

caused fuel shortages in Europe. This leads the Europeans to return to

gasification-powered energy to power their motor vehicles. Thus, wood gas

generators named Gasogene or Gazogene is introduced. After the war, demand for

liquid fuels remained and the German engineers made a successful production of

synthetic liquid fuel from gasified coal.

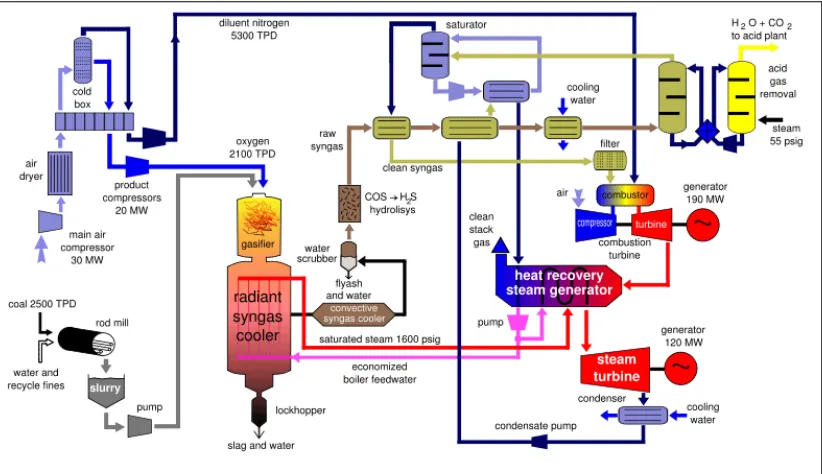

[image:24.595.114.525.484.721.2]In the 1970’s the U.S. government launched a large industrial scale

gasification projects due to the Arab Oil Embargo and the “energy crisis”. From

this development came the first Integrated Gasification Combined Cycle (IGCC)

electric generating plant. Presently, several IGCC power plants are operating

throughout the world. And crude oil price spikes and geopolitical instabilities in

major oil-producing countries have generated serious interest in using gasification

for GTL (Gas To Liquid) synthetic fuel processes.

Figure 2.3: Integrated Gasification Combined Cycle, or

IGCC