Optimization Of Machining Parameters In High Speed Milling Of Aluminum 6061.

Teks penuh

Gambar

Dokumen terkait

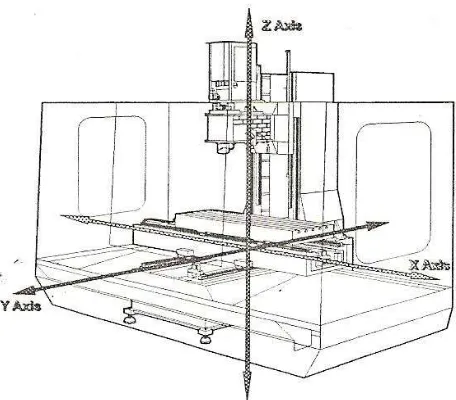

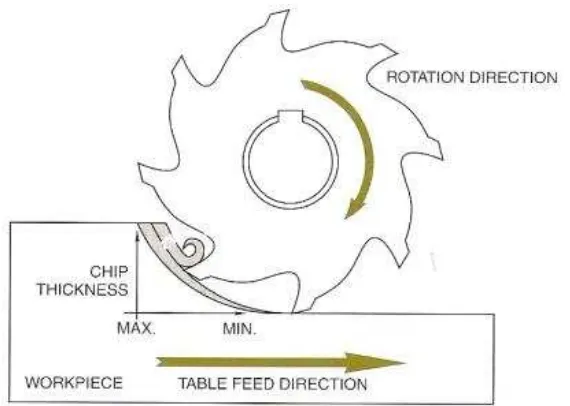

The present work, deals with the study of machining parameters (i.e. spindle speed, feed rate and depth of cut) and its effects against machining performance (i.e. surface

Consequently, a machined surface is a replica of the cutting edge which carries valuable information related to the tool condition (i.e., sharpness or bluntness)

spindle speed, feed rate and depth of cut will produce different type of

TAJUK: THE STUDY ON THE EFFECTS OF CUTTING PARAMETERS IN NEAR END CUTTING SPEED NORMAL RANGE MACHINING.. Sukacita dimaklumkan bahawa tesis yang tersebut di atas bertajuk “ THE

Determination of the tool length effect in the milling operation is important due to its controlling influence on the surface roughness, tool wear and the quality of the

This experiment studies the optimization of machining parameters for milling operati on on carbon fiber reinforced plastic (CFRP) material using the Taguchi method. Taguchi m

Keywords:- Duplex 2205 stainless steel, CBN Insert, cutting speed, Feed and Depth of Cut Turning machine, Surface roughness, Factorial design, Response surface methodology, JAYA

main effect plots for S/N ratios of speed, feed & depth of cut of Rz Above discussion shows that the surface roughness varies very quickly as feed rate varies and with cutting speed..