UNIVERSITI TEKNIKAL MALAYSIA MELAKA

A STUDY OF SAFETY AND HEALTH AWARENESS AND

NOISE ASSESSMENT AT STAMPING DIE COMPANY

This report submitted in accordance with requirement of the Universiti Teknikal

Malaysia Melaka (UTeM) for the Bachelor Degree of Manufacturing Engineering

(Manufacturing Management) (Hons.)

by

SITI NUR ADIBAH BINTI ITHNIN

B051010249

890515-09-5190

UNIVERSITI TEKNIKAL MALAYSIA MELAKA

BORANG PENGESAHAN STATUS LAPORAN PROJEK SARJANA MUDA

TAJUK: A St udy of Safet y and Healt h Awareness and Noise Assessment at St amping Die Company

SESI PENGAJIAN: 2012/ 2013 Semest er 2

Saya

SITI NUR ADIBAH BINTI ITHNIN

mengaku membenarkan Laporan PSM ini disimpan di Perpust akaan Universit i Teknikal Malaysia Melaka (UTeM) dengan syarat -syarat kegunaan sepert i berikut :

1. Laporan PSM adalah hak milik Universit i Teknikal Malaysia Melaka dan penulis. 2. Perpust akaan Universit i Teknikal Malaysia Melaka dibenarkan membuat salinan

unt uk t uj uan pengaj ian sahaj a dengan izin penulis.

3. Perpust akaan dibenarkan membuat salinan laporan PSM ini sebagai bahan pert ukaran ant ara inst it usi pengaj ian t inggi.

4. **Sila t andakan (

√

)SULIT

TERHAD

TIDAK TERHAD

(Mengandungi maklumat yang berdarj ah keselamat an at au kepent ingan Malaysiasebagaimana yang t ermakt ub dalam AKTA RAHSIA RASMI 1972)

(Mengandungi maklumat TERHAD yang t elah dit ent ukan oleh organisasi/ badan di mana penyelidikan dij alankan)

Alamat Tet ap:

1692, Lorong Kempas 7/ 1,

Taman Kempas,

Sungai Pet ani, Kedah

Tarikh: _________________________

Disahkan oleh:

Cop Rasmi:

Tarikh: _______________________

APPROVAL

This report is submitted to the Faculty of Manufacturing Engineering of

UTeM as a partial fulfillment of the requirements for the degree of Bachelor

of Manufacturing Engineering (Manufacturing Management) (Hons.).The

members of the supervisory committee are as follow:

………

(Principal Supervisor)

DECLARATION

I hereby, declared this report entitled “A Study of Safety and Health Awareness

and Noise Assessment at Stamping Die Company” is the results of my own

research except as cited in references.

Signature

:

……….

Author’s Name

:

Siti Nur Adibah Binti Ithnin

Date

:

………

ABSTRAK

Laporan ini disediakan untuk menerangkan kajian kesedaran keselamatan dan

kesihatan di kalangan pekerja dan penilaian bunyi di syarikat acuan dan alat tekan.

Kajian ini meliputi Akta Keselamatan & Kesihatan Pekerjaan (OSHA), OSHA 1994,

bahaya, pendedahan bunyi bising dan pencegahan bunyi di Miyazu Malaysia Sdn

Bhd (MMSB). Kaji selidik dijalankan mengenai tahap kesedaran pekerja kepada

Kesihatan dan Keselamatan di persekitaran tempat kerja.Kajian ini juga akan

mengkaji tentang tahap bunyi yang dihasilkan mesin merujuk kepada piawai OSHA.

Data yang telah diperolehi daripada beberapa kaedah termasuk pemerhatian,

temuramah orang yang berkenaan, kaji selidik kepada pekerja di kawasan yang

dinyatakan dan pengukuran teknikal. Data akan dikumpul menggunakan peralatan

berkaitan seperti Digital Sound Level Meter. Tahap standard piawai pendedahan

bunyi di kawasan yang dinyatakan dikaji dan dibandingkan dengan data yang

diperolehi dalam keputusan kajian ini.Keputusan yang ditunjukkan akan

dipertingkatkan dengan beberapa cadangan untuk mengurangkan atau memperbaiki

masalah.

ABSTRACT

This report is provided to explain a study of safety and health awareness among

worker and noise assessment at stamping die company. This study covers the

Occupational Safety and Health Administration (OSHA), OSHA 1994, hazard, noise

exposure and noise improvement at Miyazu Malaysia Sdn Bhd (MMSB). This study

carried out survey regarding to level of awareness among worker to Safety and

Health in the workplace.This study also about noise level produces by machine

compare to OSHA standard. The data was obtained from several methodologies

includes observation, interview the authorized person, questionaire among worker in

specified area and technical measurement. The data were collected by the related

equipment such as Digital Sound Level Meter. The standard level of exposure on the

focused area studied and compared with current value that obtained in this study.The

result show will be improved by some recommedation to minimized or eliminated

the problem.

DEDICATION

To my beloved family thanks for continuous support to me in performing this

difficult task, and the journey does not end here.

To my supervisor, Mr. Al Amin bin Mohamed Sultan and Co- Supervisor, Mr. Mohd

Shahrizan bin Othman for being receptive and critical, and challenging me to be a

better student.

To all course mate, for always support me, and also to my entire friend, for their

sacrifice, encouragement, and support towards project accomplishment.

Thank You

ACKNOWLEDGEMENT

Utmost gratefulness to The Almighty ALLAH SWT for the abundant blessing and

favours for me to accomplished the research Projek Sarjana Muda.

I would like to extend my warmest gratitude to my supervisor and my co- supervisor,

Mr. Al Amin bin Mohamed Sultan and Mr. Mohd Shahrizan bin Othman for their

excellent supervision, invaluable guidance, advice trust, constant help, support,

encouragement and assistance towards me throughout this project.

I would also like to thank Miyazu Malaysia Sdn Bhd, and their staff as they provided

me to make data collection, and always shows their sincere kindness in helping and

gave me useful information.

Ina addition, I would like to thank my family whose endless encouragement gave me

the added strength and inspiration to carry out this project to the best of my ability.

At the same time, I would like to thank my friends and course mate for their

constructive comments throughout the accomplishment of this project.

TABLE OF CONTENT

Abstrak

i

Abstract

ii

Dedication

iii

Acknowledgment

iv

Table of Content

v

List of Tables

ix

List of Figures

x

List Abbreviations, Symbols and Nomenclatures

xii

CHAPTER 1: INTRODUCTION

1

1.1

Background of study

1

1.2

Problem Statement

2

1.3

Objective

3

1.4

Scope of project

4

1.5

Importance of Study

4

1.6

Report Outline

5

1.7

Summary

5

CHAPTER 2: LITERATURE REVIEW

6

2.1

Occupational Safety and Health Administration (OSHA)

6

2.1.1 Objective of OSHA

8

2.1.2 Occupational Safety and Health Act 1994

8

2.1.3 Scope of OSHA 1994

10

2.1.4 Objective of OSHA 1994

10

2.1.5 Principles of OSHA 1994

10

2.2

OSHA Issues in Manufacturing Company

11

2.3

Hazards in Workplace

12

2.3.1 Safety and Health Hazard

13

2.4

Noise Hazard

13

2.4.1 Definition of Noise

14

2.4.2 Noise Exposure

15

2.4.3 Noise Level Equipment

18

2.5

Noise Prevention

19

2.6

Previous Case Study Noise Exposure

24

2.7

Summary

28

CHAPTER 3: METHODOLOGY

29

3.1

Project Overview

29

3.1.1 Process Flow Chart

30

3.2

Methodology

31

3.3

Primary Data

31

3.3.1 Interview

32

3.3.2 Observation

32

3.3.3 Questionnaire

32

3.4

Secondary Data

33

3.5

Data Collection

33

3.5.1 Design of Questionnaire

34

3.5.2 Design of Interview

36

3.5.3 Noise Level Measurement

37

3.6

Data analysis

39

3.6.1 Statistical Method

39

3.7

Suggestion and Recommendation

40

3.8

Company Background

41

3.8.1 General Information

42

3.9

Gantt Chart

43

3.10

Summary

44

CHAPTER 4: RESULT & DISCUSSION

45

4.1

Introduction to Data Collection

45

4.2

Results and Data Analysis of Questionnaire

46

4.2.1 Personal Information

46

4.2.1.1 Gender

46

4.2.1.2 Working Experience

47

4.2.1.3 Working Hours

47

4.2.1.4 Types of Risks

48

4.2.2 Work Environment Issues

49

4.2.2.1 Work Environment and Noise Exposure

49

4.2.2.2 Dust and Lighting

50

4.2.2.3 Personal Protective Equipment

51

4.2.2.4 Health Quality and Accident

52

4.2.2.5 Health Screening

53

4.2.3 Safety and Health Awareness

54

4.2.3.1 Safety and Health Quality

54

4.2.3.2 Level of Safety and Health Policy

54

4.2.3.3 Safety Exposure and Safety Awareness

55

4.2.3.4 Occupational Safety and Health Act (OSHA)

56

4.2.3.5 Safety Instruction and Safety Campaign

56

4.2.3.6 Health Care by Employer

57

4.2.3.7 Social Security Organization (SOCSO)

58

4.2.3.8 OSHA Information

58

4.3

Result of Interview Session

59

4.4

Result of Observation

62

4.5

Result and Data Analysis of Noise Assessment

64

4.6

Discussion

72

4.6.1 Level of Awareness OSHA

72

4.6.2 Work Environment and Health Issues

74

4.6.3 Noise Assessment

75

4.7

Suggestion of Safety and Health Issues

78

4.8

Suggestion of Noise Improvement

79

4.8.1 Hearing Protection

79

4.8.2 Enforcement by the Administration

79

4.8.3 Machine Improvement

82

CHAPTER 5: CONCLUSION & RECOMMENDATION

83

5.1

Conclusion

83

5.2

Recommendation

84

REFERENCES

85

APPENDICES

86

LIST OF TABLES

2.1

Difference between FMA 1967 with OSHA 1994

9

2.2

OSHA’s Permissible Noise Exposure

16

2.3

Some commonly used engineering controls

20

3.1

Step in Designing Questionnaire

34

3.2

Types of Information

35

3.3

Gantt Chart

43

4.1

Types of Risks Percentages

48

4.2

Interview Session Result

60

4.3

Findings of Observation

62

4.4(a)

Average Noise Level for Day 1

65

4.4(b)

Average and Variance for Each Machine

65

4.4(c)

Summary of ANOVA Result

65

4.5(a)

Average Noise Level for Day 2

66

4.5(b)

Average and Variance for Each Machine

66

4.5(c)

Summary of ANOVA Result

67

4.6

T-test Result

67

4.7

F-test Result

68

4.8

Part 1 (Noise Comfortable)

69

4.9

Part 2 ( Noise Level Awareness and PPE)

70

4.10(a) Part 3 (PPE)

70

4.10(b) Part 3 (PPE)

71

4.10(c) Part 3 (PPE)

71

4.11

Percentage every needs aspects of Safety and Health

72

LIST OF FIGURES

2.1

Elements: Occupational Health

7

2.2

Typical Noise Levels in Manufacturing Sector

17

2.3

A modern sound level meter

18

2.4

A noise dosimeter

19

2.5

Sound Curtain or Sound Blankets

21

2.6

Composite Foam

21

2.7

Hearing Protection Devices

23

3.1

Process Flow Chart

30

3.2

Specifications Digital Sound Level Meter Model 407730

37

3.3

Noise Measurement Mapping Diagram

38

4.1

The Types of Data Collection

45

4.2

The Distribution by Gender

46

4.3

The Distribution by Working Experience

47

4.4

The Distribution by Working Hours

47

4.5

The Distribution by Types of Risks

48

4.6

Comfort with Work Environment Percentages

49

4.7

Comfort with Noise Exposure Percentages

50

4.8

Comfort with Dust Percentages

50

4.9

Comfort with Lighting Percentages

51

4.10

Wearing PPE during work Percentages

51

4.11

Health Quality Percentages

52

4.12

Accident during work Percentages

52

4.13

Health Screening Percentages

53

4.14

Safety and Health Policy Percentages

54

4.15

Level of Safety and Health Policy Percentages

54

4.16

Level of Safety and Health Policy Percentages

55

4.17

OSHA Percentages

56

4.18

Safety Instruction Percentages

56

4.19

Health Care by Employer Percentages

57

4.20

SOCSO Percentages

58

4.21

OSHA Information Percentages

58

4.22

Plant Machinery Layout

64

4.23

Graphical Comparison of Noise Level between Day 1 and Day 2

69

4.24

Level of Awareness Diagram

73

4.25

Noise Mapping Layout

79

4.26

Noise Mapping Layout with Hearing Protection

81

4.27

Sample of Silencers

82

LIST OF ABBREVIATIONS, SYMBOLS AND

NOMENCLATURE

OSHA

-

Occupational Safety and Health Administration

PPE

-

Personal Protection Equipment

DOSH

-

Department Occupational Safety and Health

FMA

-

Factory and Machinery Act

WHO

-

World Health Organization

ISO

-

International Organization for Standardization

TWA

-

Time weighted average

ANSI

-

American National Standard Institute

PSM

-

Projek Sarjana Muda

MMSB

-

Miyazu Malaysia Sdn Bhd

ANOVA

-

Analysis of Variance

6 This chapter describes the introduction section of the report. It contains the problem

statement, objectives, importance of study and scope. This chapter also describes

background of study that related to the problem statement.

1.1

Background of study

Working workplace must be safe and comfort for all workers to work. A good

working environment will increases productivity and efficiency the company.

Sanjeev (2005) defines a safety working environment is the workplace has been

assessed for hazards and the hazards are eliminated or controls have been

implemented so that the company is able to operate safely.

A hazard is a source or potential source of human injury, ill health or disease

(Comcare, 2005). Hazard also can be defined such as anything will cause to injury or

ill health at workplace. Some hazards are easy to identify and obvious but others are

not for example, exposure to noise, poor lightning, chemicals and etc. All worker

need to be aware of the issues that will be effect on their health and safety at the

workplace. In other hand, the worker have to work in good environment where risk

to their safety and health are properly controlled.

INTRODUCTION

7 However, worker and employee have a legal responsible to look after safety and

health at workplace. Safety and health management system and programs are

designed with the purpose of ensuring the safety, health and welfare of person at

work and protection to other people from hazards to safety and health arising from

the activities of person at work.

The sound is also play an important part in our environmental especially in the

workplace area. The unwanted sound will become a noise to human hearing and

effect the human peacefulness. The high noise can cause human to lose their hearing

ability that is very important in human life. In the short term, the noise did not bring

any side effect to us but in the long term it can possibly hurt our hearing (Ahmad,

2008).

Because of that, this study was conducted to identify the level of awareness worker

about Occupational Safety and Health Administration (OSHA) regarding to hazard at

workplace. Besides, noise level exposures were access in order to reduce unwanted

sound in the industry. This study is done in the working area at Miyazu Malaysia Sdn

Bhd (MMSB), which is one of the parts of stamping die industry.

1.2

Problem Statement

Safety and Health issues are important in industries sector. Employer has responsible

to ensure their worker comfort and safe during work. Industries selected for this

study involved manufacturing sector which include stamping die, plastic mould,

module assembly, engineering services and production services. This company is

required to adhere to the requirements of the OSHA 1994 but it will be interesting to

know how the level of awareness worker about Occupational Safety and Health

Administration (OSHA) and hazards in stamping die workplace. In order to measure

the safety and health awareness among worker, it is importance to know condition of

8 Besides, worker of this company also exposed to noise but the stamping die areas

which exceed the OSHA standard is not identified. From that, it concern to know the

noise level in the specified area. In addition, worker of these company not wear any

Personal Protection Equipment (PPE) such as ear plug or ear muff were they are

exposed to noise during work. But, the PPE are provided.

1.3

Objectives

Three specific objectives have been simplified of this study. There are:

i) To assess the safety and health awareness among stamping die company

worker

ii) To analyze the noise level of machine refers to OSHA standard.

iii)To suggest the proper solution according to excessive noise level at stamping

die company

1.4

Scope of Project

This study was focused on the level of safety and health awareness worker at

workplace. Interview and questionnaire conducted to evaluate the level of awareness

regarding to OSHA and hazard during visit the company. A questionnaire consists 22

question have been prepared for 30 workers. Noise level at this company was

measured using Digital Sound Level Meter and collected for each machine at

Tooling Plant workplace. Based on the measurement, the most critical noise level is

identified and the proper solution suggested. Besides, noise mapping are used to

identify which area are most critical exposed to noise. A questionnaire also used in

noise assessment to find relationship between noise measurement and comfortable of

worker to noise at workplace. Then, some suggestions are proposed to reduce the

entire problem. In addition, this study focused on the work environment in Miyazu

9

1.5

Importance of Study

Regarding to this study, some benefits are give to the several parties such as

company employer, company worker and student. From employer view, this project

can help company to change their work environment based on safety and health

issues. Besides, the company can increase productivity, reduces injury and

comfortable of working environment. This study also may help the worker of

company to protect their health. The worker may change the workstation or

workplace while they do the job and it will give the comfortable for them. In

addition, this study also gives benefits to student to increase the ergonomic

knowledge based on real situation in manufacturing working area. The student also

exposed and applied the technical measurement based on hands on practice such as

noise level assessment.

1.6

Report Outline

Chapter 1 introduces the project which is including objectives, problem statement

and scope of project. In this chapter, it describes the study on working environment

which is related to Occupational Safety and Health Administration and hazard in the

company.

Chapter 2 describes the literature review on definition of OSHA and hazard and the

theoretical of health hazard, noise exposure, and definition of noise, method to

measure noise level and noise prevention method.

Chapter 3 represents the flow chart that carried out for the whole process of the

methodology such as in gathering information, collecting data and result evaluation

10 Chapter 4 represents development the data collection by using methods of

questionnaires, interview and observation. The results are analyzed and discussed by

constructed the measurement by using Microsoft Office Excel software. Besides, this

chapter discuss about suggestion for the improvement regarding to problem

statement.

Chapter 5 describes the conclusion and recommendation for future work.

1.7

Summary

This chapter is introducing the project background and the objective of the project. In

addition, the problem statement and scope of study also being clarify in order to limit

the range of this project conduct. The following chapters consist of the literature

11 This literature review explores the dominant themes includes study and research of

published materials like journals, thesis, case study, technical document, and online

library. Generally, the purpose of a review is to analyze critical segment of a

published body of knowledge through summary, classification and comparison of

prior research studies, reviews of literature, and theoretical articles. This chapter will

describe topics that related topic such as Occupational Safety and Health (OSHA),

definition of hazards and theory of health hazards. It also describes about noise

exposure and theory of noise such as definition of noise, noise equipment and

suggestion from previous study to prevent noise exposure.

2.1

Occupational Safety and Health Administration (OSHA)

Occupational safety and health is a major concern to many countries. A simple

definition of “ occupational safety and health (OSH)” in respect of a “ place of work”

or “ person at work” is , the “ state of being safe “ or “ the absence of factors that

could lead to accidents, injuries or interruptions to work” Occupational Safety and

Health Act (OSHA) is an act to make further provisions for securing the safety,

health and welfare of persons at work, for protecting others against risks to safety or

health in connection with the activities of persons at work, to establish the National

Council for Occupational Safety and Health, and for matters connected therewith

(Alwi, 2011,pp4).

LITERATURE REVIEW

12 Goetsch (2008,p13) describes the Occupational Safety and Health Administration

(OSHA) is the government’s administrative arm for the Occupational Safety and

Health (OSH Act).Formed in 1970, OSHA sets and revokes safety and health

standards, conduct inspections, investigates problem, issues citations, assesses

penalties, petitions the courts to take appropriate action against unsafe employers,

provides safety training, provides injury prevention consultation and maintains a

database of health and safety statistics.

According to Tatiya (2011) Occupational Safety and Health is traditional way to deal

with legislation, regulation, standards, safety guidelines, accident investigations and

safety inspections which provide information on causes of accidents amongst

particular groups of employees. There are four elements in Occupational Health.

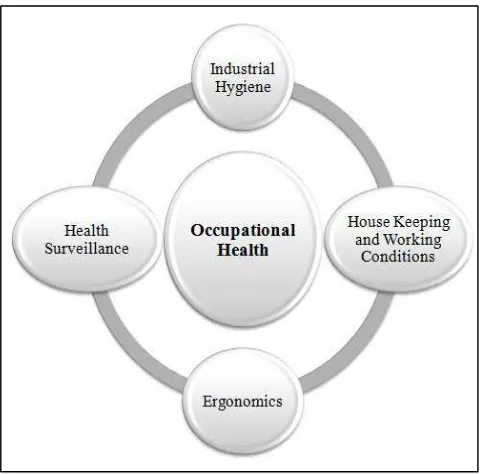

Figure 2.1 shows the relationship between four elements of Occupational Health.

Cray and Mendeloff (2002) state OSHA does tens of thousands of inspections, and

imposes millions of dollars in penalties each year, but most workplaces are only

rarely visited, penalties are low relative to the cost of abating many workplace

hazards, and many injuries are unrelated to OSHA standards.

[image:23.612.206.448.412.649.2]13 Nowadays, environmental in industries can be a great danger to human if not

controlled properly. All the danger can be called hazards. According to the OSHA

rules and regulation, the environmental hazards can be minimized in order to protect

the worker and the general public. OSHA standards have required conditions or

adoption or use of one or more practices, methods or process to protect workers on

the job and to endure that worker have and use personal protective equipment (PPE)

when required for safety. The general duty of the OSH Act requires that employee

provide a workplace that free from hazards. (Geotsch, 2008, pp91)

2.1.1 Objective of OSHA

In order to prevent worker from injuries and illness, OSHA have their own objective

to achieve. The main objectives of OSHA are implemented in the company so that

employees can enjoy a better work place, safe and healthy by making and enforcing

laws and standards for safety and health at work. Cray and Mendeloff (2002) state

the mission of the Occupational Safety and Health Administration (OSHA) is to

“promote the safety and health of America’s working men and women” and part of

this mission is a goal to reduce workplace injuries. OSHA may impact workplace

injuries through one or more mechanisms. OSHA also allows the enforcement of

certain standards needed to protect workers. In addition, it seeks to prevent

employees from making works that may cause injury, illness and death.

2.1.2 Occupational Safety and Health Act 1994 (Malaysia)

According to DOSH (2006), Occupational Safety and Health Act (OSHA) were

enforced in Malaysia on 25th February 1994 with the intent to ensure safety, health

and welfare of all persons at all places of work. The Act also provides for a

consultative process at the policy level with the establishment of Nation Council for

Occupational Safety and Health. This consultative process extends to where safety

and health programs are implemented with both employers and employees