UNIVERSITAS ISLAM INDONESIA FM-UII-AA-FKU-01/R0

Faculty : Industrial Technology Meeting : 8

Department : Industrial Engineering Chapter : 2

Subject Couse Code : 52213702 Total Page : 18

Subject Course Name : Computer Simulation Year : 2018

TABEL OF CONTENT 1. General Purpose ... 2

2. Concept and Terminology in Flexsim ... 2

2.1. Flexsim ... 2

2.2. Object ... 2

2.2.1. Fixed Resource ... 3

2.2.2. Task Executor... 4

2.3. Object Port Connection ... 5

2.4. Flexsim Models ... 7

2.4.1. Basics Objects on Flexsim ... 7

2.4.2. Other Objects on Flexsim Model ... 10

2.4.3. Flowitem ... 13

2.4.4. Trigger ... 14

2.4.5. Modelling with Flexsim ... 15

UNIVERSITAS ISLAM INDONESIA FM-UII-AA-FKU-01/R0

Faculty : Industrial Technology Meeting : 8

Department : Industrial Engineering Chapter : 2

Subject Couse Code : 52213702 Total Page : 18

Subject Course Name : Computer Simulation Year : 2018

INTRODUCE FLEXSIM

1. General Purpose

1. Students understand the basic concept of Flexsim tools. 2. Students able to build models using Flexsim.

3. Students can analyze the model based on the report

2. Concept and Terminology in Flexsim

2.1.Flexsim

FlexSim is powerful yet easy-to-use software for simulation. A comprehensive and innovative simulation engine is hidden behind drag and drop controls, drop-down lists and many other intuitive features that make it accessible for anyone to experiment with a model. All simulation models are created to scale and are presented using 3D visuals, so it becomes easy to view and recognize bottlenecks in the production line or other deficiencies within the system. FlexSim also gives decision makers the tools to confirm their observations, with impressive statistical reporting and analysis built right into the software. Flexsim can solve the problem such as manufacturing, health care, material handling, mining, logistic, packaging, and aerospace , warehouse, etc.

2.2.Object

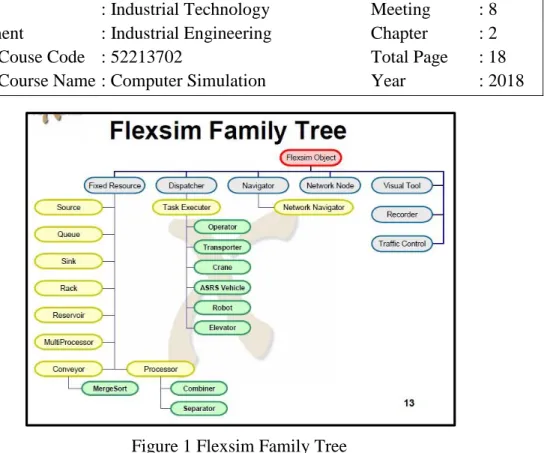

The main objects in Flexsim can be classified into two types, fixed resources and task executers. Fixed Resources are objects which send and/or receive flowitems such as Source, Conveyor, Processor, Queue, and Exit. Task Executers are mobile resources that perform assigned tasks, for example are Transporter and Operator.

UNIVERSITAS ISLAM INDONESIA FM-UII-AA-FKU-01/R0

Faculty : Industrial Technology Meeting : 8

Department : Industrial Engineering Chapter : 2

Subject Couse Code : 52213702 Total Page : 18

Subject Course Name : Computer Simulation Year : 2018

2.2.1.Fixed Resource

Fixed Resource object are the backbone of a simulation model. They‟re used to define the product flow. Fixed Resource can do:

Push or pull flowitems. Process of product.

Queue of product (accumulate up to a max content) Call an operator to utilized (for process/ set up)

Call to transport and carry the product to the next process.

There is no transfer time (transfer time = zero) between fixed resource object. Almost every modeling behaviour defined on fixed resource, that is:

How long to process the product. The next product delivery location. Call an operator to process the product.

Call an object that assigned to transport the product to the next fixed resource, then the product will be processed

UNIVERSITAS ISLAM INDONESIA FM-UII-AA-FKU-01/R0

Faculty : Industrial Technology Meeting : 8

Department : Industrial Engineering Chapter : 2

Subject Couse Code : 52213702 Total Page : 18

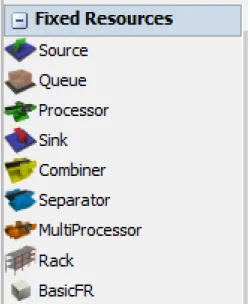

Subject Course Name : Computer Simulation Year : 2018 There is the fixed resources objects:

Figure 2 Task Executor Objects In Flexsim

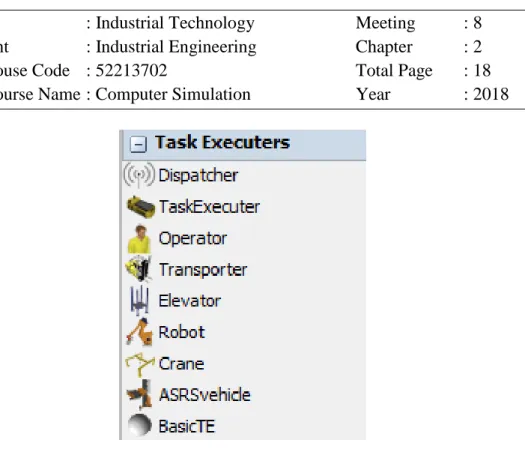

2.2.2.Task Executor

Task Executers is used to execute task sequence. A task sequence is a list of tasks which are to be completed based on the assigned. For example: TRAVEL to Queue LOAD flowitem TRAVEL to Processor UNLOAD flowitem. Task sequences are created and dispatched automatically when the “USE Transport” or “USE Operator” boxes are checked on a Fixed Resource. Custom task sequences can also be created and dispatched using commands A task is an activity or instruction to be performed by a Task Executer object such as loading, unloading, traveling, delaying or simply being utilized. When a Task Executer receives a task sequence, it will start executing the tasks one by one until the task sequence is either finished or preempted by a preempting task sequence of higher priority. There is task executor objects:

UNIVERSITAS ISLAM INDONESIA FM-UII-AA-FKU-01/R0

Faculty : Industrial Technology Meeting : 8

Department : Industrial Engineering Chapter : 2

Subject Couse Code : 52213702 Total Page : 18

Subject Course Name : Computer Simulation Year : 2018

Figure 3 Task Executor Objects In Flexsim

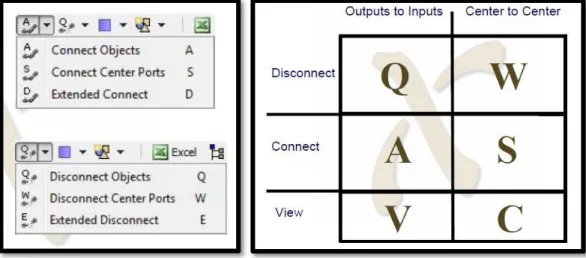

2.3.Object Port Connection

There are two types of port connections, that is output/input port dan center port. On output/input port there is output-to-input port connections that define possible flowitem route to fixed resource or from fixed resource.

UNIVERSITAS ISLAM INDONESIA FM-UII-AA-FKU-01/R0

Faculty : Industrial Technology Meeting : 8

Department : Industrial Engineering Chapter : 2

Subject Couse Code : 52213702 Total Page : 18

Subject Course Name : Computer Simulation Year : 2018 Center port are be used for referencing purposes, especially used to point a task executor to be called for the processing or transportation of a flowitem.

Figure 5 Center Ports

Objects can have an unlimited number of ports. A port connection is needed for each possible routing choice in the model. The actual port that a flowitem passes through depends on the selected rule for the object that is either doing the pushing or the pulling.

UNIVERSITAS ISLAM INDONESIA FM-UII-AA-FKU-01/R0

Faculty : Industrial Technology Meeting : 8

Department : Industrial Engineering Chapter : 2

Subject Couse Code : 52213702 Total Page : 18

Subject Course Name : Computer Simulation Year : 2018 2.4.Flexsim Models

2.4.1.Basics Objects on Flexsim

There are four basic objects (fixed resource) to build a model, that is source, queue, processor, and sink.

Figure 7. Basic Object to Build A Model a. Source

Source is used to introduce flowitems into the model. The arrival rate of flowitems will be based on an Inter-Arrival Time, Arrival Schedule or Sequence. Most models will start with a source.

UNIVERSITAS ISLAM INDONESIA FM-UII-AA-FKU-01/R0

Faculty : Industrial Technology Meeting : 8

Department : Industrial Engineering Chapter : 2

Subject Couse Code : 52213702 Total Page : 18

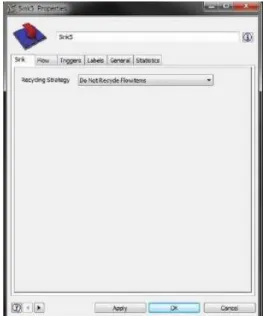

Subject Course Name : Computer Simulation Year : 2018 b. Sink

Sink is used as an exit point for flowitems. Flowitems can only “exit‟ the model via the Sink. Your last chance to record information about the flowitems is in the On Entry trigger of the Sink.

Figure 9 Window Properties of Sink

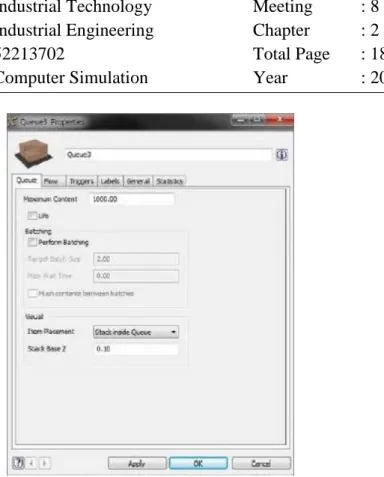

c. Queue

The Queue is used to stage Flowitems for downstream operations. Queues are used in the model wherever work-in-process (WIP) exists between the process. A Queue may be a table, basket, line or waiting room.

UNIVERSITAS ISLAM INDONESIA FM-UII-AA-FKU-01/R0

Faculty : Industrial Technology Meeting : 8

Department : Industrial Engineering Chapter : 2

Subject Couse Code : 52213702 Total Page : 18

Subject Course Name : Computer Simulation Year : 2018

Figure 10. Window Properties Of Queue

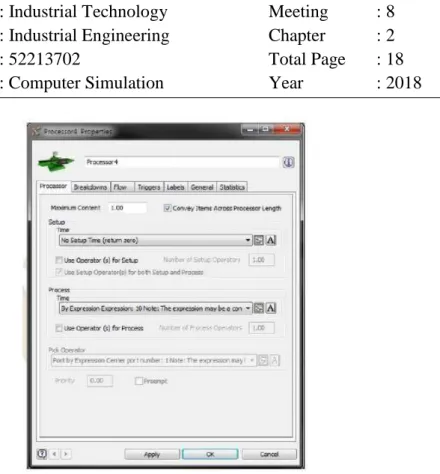

d. Processor

A Processor is used anytime an operation is performed on a Flowitem. A Processor can be any kind of machine or station; anything that would take time to manipulate a flowitem. The Flowitems must stay in the Processor for the sum of the Setup Time and the Process Time plus any Blocked Time. The idle time may also include time waiting for an operator, time waiting for a transporter and time waiting for the Processor to be repaired if broken down.

UNIVERSITAS ISLAM INDONESIA FM-UII-AA-FKU-01/R0

Faculty : Industrial Technology Meeting : 8

Department : Industrial Engineering Chapter : 2

Subject Couse Code : 52213702 Total Page : 18

Subject Course Name : Computer Simulation Year : 2018

Figure 11. Window Properties Processor

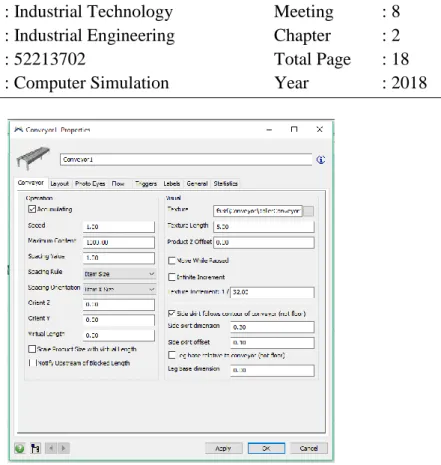

2.4.2.Other Objects on Flexsim Model a. Conveyor

Conveyor is a tool to convey flow items from one location in the model to another location. Time to convey depends on the conveyor‟s length divided by its speed. Can be accumulating or not. If not, all parts on the conveyor stop when a part at reaches the end of the conveyor and is blocked (like a Belt conveyor). Conveyors can take the actual length of the flow items and the Conveyor sections into account when calculating accumulation and available space. You can define a combination of many straight and curved sections all on one conveyor object.

UNIVERSITAS ISLAM INDONESIA FM-UII-AA-FKU-01/R0

Faculty : Industrial Technology Meeting : 8

Department : Industrial Engineering Chapter : 2

Subject Couse Code : 52213702 Total Page : 18

Subject Course Name : Computer Simulation Year : 2018

Figure 12. Window Properties Conveyor

b. Operator

An Operator will model the human tasks such as machine setup or manual assembly. The Operator can also be used to transport flowitems from one Fixed Resource to another. Operator really has no additional functionality beyond the Task Executer itself. Operator can move in x, y, and z directions.

UNIVERSITAS ISLAM INDONESIA FM-UII-AA-FKU-01/R0

Faculty : Industrial Technology Meeting : 8

Department : Industrial Engineering Chapter : 2

Subject Couse Code : 52213702 Total Page : 18

Subject Course Name : Computer Simulation Year : 2018

UNIVERSITAS ISLAM INDONESIA FM-UII-AA-FKU-01/R0

Faculty : Industrial Technology Meeting : 8

Department : Industrial Engineering Chapter : 2

Subject Couse Code : 52213702 Total Page : 18

Subject Course Name : Computer Simulation Year : 2018 c. Transporter

A Transporter is used in a model where a forktruck, AGV or some other transport vehicle might be used. It is used to transport flowitems from one fixed resource to another. The Transporter can travel in x, y and z directions. During the offset travel forkslift or lower in the z direction as needed to pick or place flow items. Transporters can load many Flow Items from multiple locations and then unload the Flow Items separately to multiple locations

Figure 14. Window Properties Transporter

2.4.3.Flowitem

Flowitems are the entities that are passed from one fixed resource to the other within a model. Flowitems are actually flexsim objects which hold information that can be set and queried in the model. This information can do anything from describing process times to making routing decissions and anything in between..

UNIVERSITAS ISLAM INDONESIA FM-UII-AA-FKU-01/R0

Faculty : Industrial Technology Meeting : 8

Department : Industrial Engineering Chapter : 2

Subject Couse Code : 52213702 Total Page : 18

Subject Course Name : Computer Simulation Year : 2018 All flowitem have an attribute called itemtype. Itemtype is a numeric identifier yang used to distinguish the “type” of flowitem in process and routing decisions in a model. For example, getitemtype ( flowitem ), setitemtype ( flowitem, value ), getname (object), setname ( object, “name” ), setcolor ( object, red, green, blue ), or colorred ( object )

a. Flowitem flow

Flowitem are passed from one object to the other one in zero time by ignoring of where the object location in the model layout. To creat delay time in flowitem flow, add conveyors or task executors for transport.

Convey time depends on the conveyor’s length and speed.

Transport time between objects depends on the distance between the objects, plus the task executer’s speed, acceleration, & deceleration b. Flowitem bin

Resource contains copies of object in flowitem bin. Any changes made to objects in the bin affect the flowitems that are created by resource. It used to create labels, set size, color, shape, etc.

2.4.4.Trigger

Triggers define and customize system behaviour at a spesific event occurence such as:

- Write/ read information to/from flowitem

- Change visual properties of flowitem atau objects - Send a massage to other objects

- Change behavior of objects, etc

UNIVERSITAS ISLAM INDONESIA FM-UII-AA-FKU-01/R0

Faculty : Industrial Technology Meeting : 8

Department : Industrial Engineering Chapter : 2

Subject Couse Code : 52213702 Total Page : 18

Subject Course Name : Computer Simulation Year : 2018

Figure 15. Triggers on Processor

The concept of trigger, such as:

- When a particular event occurs on an object, the triggers function.

- Users can make a variety of things to happen when the triggers function (trigger logic).

- There are triggers when a flowitem enters or exits an object. And there are triggers when a process time finishes or a repair time is complete.

- Each type or object has a unique unit of triggers

2.4.5.Modelling with Flexsim

Felxsim is a “unitless” platform. Time and length units are “user-definable” – consistency is the key. Basic steps of modeling in flexsim:

1. Create a layout using objects which are contained on flexsim. 2. Make port connections

3. Edit the look and behavior of objects. 4. Compile and run the simulation 5. View the output

UNIVERSITAS ISLAM INDONESIA FM-UII-AA-FKU-01/R0

Faculty : Industrial Technology Meeting : 8

Department : Industrial Engineering Chapter : 2

Subject Couse Code : 52213702 Total Page : 18

Subject Course Name : Computer Simulation Year : 2018 2.4.6.Flexsim Report

a. Summary Report

Table 1. Explanation Summary Report

Report Description

stats_content The remaining of entities in the object or system when the simulation is complete.

stats_contentmin The number of minimum content that can enter into object or system

stats_contentmax The number of maximum content that can enter into object or system

stats_contentavg The number of average content that can enter into object or system

stats_input The number of entities that enters object or system

stats_output The number of entities that coming out of object or system stats_staytimemin Minimum stay time of an object or system

stats_staytimemax Maximum stay time of an object or system stats_staytimeavg Average stay time of an object or system

state_current Conditions that occur on objects in a certain time state_since Time that indicates the last condition of the entities Idle Time when the object was not processing flowitem/idle processing Object time to processing all flowitem

UNIVERSITAS ISLAM INDONESIA FM-UII-AA-FKU-01/R0

Faculty : Industrial Technology Meeting : 8

Department : Industrial Engineering Chapter : 2

Subject Couse Code : 52213702 Total Page : 18

Subject Course Name : Computer Simulation Year : 2018 b. State Report

Table 2 Explanation of State Report

Report Description

Idle Time/percentage of time when the object was not processing flowitem/idle

Processing Time/percentage of object time to processing all flowitem

Busy Time/percentage of system busy time

Blocked Time/percentage of blocked flowitem times to the next process

Generating Time/percentage of source time to generate flowitem Empty Time/percentage of object time to not accept

flowitem

Collecting Time/percentage of time to combine the entities Releasing Time/percentage of time to realeasing flowitem Waiting for

operator

Time/percentage of object time to waiting for operator to do the operation.

Waiting for transporter

Time/percentage of object time to waiting for transporter to carry the items to be distributed Breakdown Time/percentage of process time that stopped yet

scheduled (machine downtime)

Scheduled down Time/percentage of process time that stopped yet scheduled (break time)

Conveying Time/percentage of entities time in conveyor Travel empty Time/percentage of transporter’s time to travel

without carrying the load.

Travel loaded Time/percentage of transporter’s time to travel with carrying the load

Offset travel empty

Time/percentage of operator’s time to direct to move without carrying the load.

Offset travel loaded

Time/percentage of operator’s time to direct to move with carrying the load.

UNIVERSITAS ISLAM INDONESIA FM-UII-AA-FKU-01/R0

Faculty : Industrial Technology Meeting : 8

Department : Industrial Engineering Chapter : 2

Subject Couse Code : 52213702 Total Page : 18

Subject Course Name : Computer Simulation Year : 2018

Report Description

Loading Time/percentage of time to load flowitem Unloading Time/percentage of time to unload flowitem Down Time/percentage of process time that stopped yet

unscheduled

Setup Time/percentage of time to setup the objects Utilize Time/percentage of object time to process all

DELSIM Lab 2017-2018(Genap)

©STUDI KASUS 1

PT Delsim Star adalah perusahaan yang bergerak di bidang pembuatan gelas plastik. Perusahaan tersebut kini telah memproduksi 3 jenis gelas yaitu gelas A, B dan C. Perusahaan tersebut memproduksi gelas dengan menerapkan proses produksi make to stock. Pimpinan perusahaan tetap menginginkan adanya peningkatan performansi perusahaan sehingga akan dilakukan eksperimen dengan menggunakan metode simulasi. Simulasi dilakukan dengan menggunakan tool flexsim 6.

Proses pembuatan gelas dimulai dari kedatangan plastik sebagai bahan baku pembuatan gelas tersebut. Kedatangan plastik berdistribusi exponential(0,0.5,0). Plastik yang datang akan dicetak di tiga mesin berbeda dan akan menghasilkan tiga bentuk gelas yang berbeda. Setiap mesin akan memiliki 1 orang operator yang melakukan proses pencetakan pada mesin tersebut. Setelah selesai dicetak maka plastik tersebut akan dibawa ke bagaian pengecatan dengan menggunakan conveyor dengan kecepatan 1 m/s, panjang conveyor 10 meter dimana 5 meter bagian lurus dan lainnya melengkung. Plastik yang sudah dicat akan dibawa ke tempat penampungan sementara. Seperti yang disebutkan sebelumnya bahwa tempat pencetakan plastik terbagi menjadi tiga mesin yang berbeda. Presentase kedatangan plastik yang masuk ke masing-masing mesin adalah tipe A sebanyak 25%, tipe B 15%, dan tipe C sebanyak 60%.

No Lokasi Waktu proses (minute) Kapasitas lokasi (unit) 1 Pencetakan A 0.5 1 2 Pencetakan B 0.75 1 4 Pencetakan C 0.5 1 5 Pengecatan uniform(4, 8, 0) 4 6 Penampungan 10000

Sebagai seorang analis, Anda diminta untuk memodelkan kasus diatas dengan menggunakan software Flexsim 6 dengan waktu simulasi selama 8 jam.

General Information : Time Units : Minute Distance Units : Meter

Tugas anda :

1. Analisalah model yang anda buat gunakan reports and statistics! (ceritakan tentang proses pembuatan model dan komponen komponen yang ada di dalamnya )

STUDI KASUS 2

Permen adalah sejenis gula-gula (confectionary) adalah makanan berkalori tinggi yang pada umumnya berbahan dasar gula, air, dan sirup fruktosa. Produk ini sudah ada sejak peradaban di mesir. Permen menjadi makanan yang digemari oleh anak-anak karena rasa yang manis dan mempunyai manfaat tertentu. Sehingga tak heran kalau permen sering disebut fun food. Karena produk-produk permen menyenangkan untuk dikonsumsi, tidak jarang orang mengkonsumsi dalam jumlah yang banyak. Hal ini dapat mengakibatkan kegemukan, kerusakan gigi (dental caries) dan lain-lain, yang jika diperiksa secara medis sebenarnya disebabkan oleh konsumsi gula yang berlebihan. Kegemukan terjadi jika lebih banyak nutrisi atau zat gizi yang diserap dibandingkan dengan yang diperlukan tubuh. Nutrisi tersebut berasal dari bahan makanan pada umumnya, dan tidak hanya berasal dari permen.

Parameter mutu yang penting dalam permen adalah tekstur yang merupakan jumlah beberapa sifat fisik termasuk densitas, kekerasan, plastisitas atau elestisitas dan konsistensi. Sifat-sifat tersebut bervariasi dalam jenis permen yang berbeda, antara lain lunak (soft), tekstur empuk pada marshmallow atau “chocolate cream centers” sampai keras seperti gelas pada permen keras (hard candy). Sifat atau sifat sifat tertentu yang diinginkan bervariasi tergantung dari tekstur yang diinginkan pada suatu jenis pemen. Pengukuran kuantitatif sifat-sifat fisik tidak banyak dilakukan dan sebagian besar masih menggunakan istilah-istilah pembuatan permen (candy maker), yaitu “short”, “tender”, “firm”, “chewy” dan lain-lain. Tetapi apapun sifat tekstur tersebut, keseragaman dan kehalusan pada umumnya diinginkan, sehingga permen yang “grainy” atau “gritty” pada umumnya kurang popular

PT DelMint merupakan salah satu perusahaan yang bergerak dalam pembuatan permen yang mempunyai kualitas baik. system produksi sudah disusun sedemikian rupa agar mampu memenuhi standard dan kualitas yang diinginkan oleh pasar. Namun akhir-akhir ini perusahaan mempunyai permasalahan yaitu permintaan yang banyak namun tidak mampu dipenuhi oleh pabrik. Salah satu penyebabkan diperkirakan adalah mekanisme kerja dalam shopfloor. Untuk memastikan hal itu perusahaan memintan bantuan anda untuk menganalisa dan memperbaiki system produksi yang ada menggunakan pendekatan simulasi. Software yang digunakan adalah Flexim 6.0.

Proses produksi diawali dengan kedatangan gula sebagai bahan utama. Gula datang dengan distribusi exponential(0, 3, 0). Setelah gula datang, maka akan masuk ke proses pelarutan. Ini dilakukan untuk melarutkan gula dan pelarutan haruslah sempurna supaya tidak terbentuk Kristal premature. Untuk proses pelarutan dibutuhkan suhu yang sangat tinggi sekitar 112 sampai 116 C. tahap selanjutnya adalah blending, dimana ada penambahan mentega agar larutan tidak mudah lengket. Setelah beberapa saat, adonan yang telah jadi akan dilakukan proses blending Flavour. Proses ini merupakan proses penambahan rasa. Ada 3 rasa yaitu Strawberry, Grape dan Orange. Karena ada tiga rasa maka jumlah mesin juga ada tiga di proses blending Flavour. Perusahaan telah menetapkan bahwa persentase untuk permen rasa strawberry sebesar 30 %, untuk permen rasa grape sebesar 35 % dan permen rasa orange sebesar 35 %. Setiap proses mempunyai waktu yang berbeda-beda.

Setelah proses penambahan rasa sudah selesai, proses selanjutnya adalah proses pemekatan. Pada proses ini untuk menguji apakah larutan gula sudah pekat untuk dibuat permen. Mekanisme pengujiannya dengan uji air dingin. Pada proses ini perlu pengawasan yang ketat karena kualitas dari permen ditentukan diproses ini. Tingkat keasaman perlu menjadi salah satu prioritas, maka dari itu setelah proses pemekatan, dilakukan proses PH Controlling. Untuk memindahkan adonan dari proses pemekatan ke PH Controlling membutuhkan conveyor dengan panjang 8 meter dan kecepatan standard. Hal ini dilakukan untuk mempercepat proses

Untuk membantu kelancaran proses produksi, perusahaan mempunyai transporter yang bertugas membawa adonan dari proses blending ke proses blending Flavour, setiap sekali angkut transporter mampu membawa 25 adonan. Berikut adalah data kapasitas dan waktu proses setiap mesin.

No Lokasi Waktu proses

(second)

Kapasitas lokasi (unit)

1 Pelarutan 360 92

2 Blending 300 45

4 Blending Flavour Strawberry normal(600, 50, 1) 10

5 Blending Flavour Grape 400 40

6 Blending Flavour Orange uniform(300, 500, 0) 25

7 Pemekatan 80 100

8 PH Controlling 40 30

Sebagai seorang analis, Anda diminta untuk memodelkan kasus diatas dengan menggunakan software Flexsim 6 dengan waktu simulasi selama 8 jam.

General Information:

Time Units : Second Distance Units : Meter