I.D.G. Ary Subagia and Yonjig Kim*

Tensile behavior of hybrid epoxy composite

laminate containing carbon and basalt fibers

Abstract: This paper investigated the effect of the incor-poration of basalt fibers on the tensile properties of car-bon fiber-reinforced epoxy laminates manufactured by vacuum-assisted resin transfer molding. The purpose of this research was to design a carbon-basalt/epoxy hybrid composite material that is of low cost in production, is lightweight, and has good strength and stiffness. The ten-sile strength and stiffness of the hybrid laminates demon-strated a steady, linear decrease with an increase in basalt fiber content, but the fracture strain gradually increased together with the increase in the basalt layer content. In this study, the incorporation of basalt fibers into the car-bon fiber-reinforced polymer (CFRP) showed lower tensile strength than CFRP but has higher tensile strain. Further-more, we found that the arrangement and enhancement of basalt fiber into the CFRP significantly influence the mechanical properties of interply hybrid composites.

Keywords: bonding; carbon fiber-reinforced plastic; composites; tensile test; vacuum-assisted resin transfer molding (VARTM).

*Corresponding author: Yonjig Kim, Division of Mechanical Design Engineering, College of Engineering, Chonbuk National University, 567 Baekje-daero, Deokjin-gu, Jeonju, 561-756 South Korea, e-mail: [email protected]; and Advanced Wind Power System Research Center, Chonbuk National University, Korea

I.D.G. Ary Subagia: Division of Mechanical Design Engineering, College of Engineering, Chonbuk National University, 567 Baekje-daero, Deokjin-gu, Jeonju, Korea; and Mechanical Engineering, Faculty of Udayana University, Denpasar, Bali, Indonesia

1 Introduction

In recent years, hybrid composites have been increasingly developed to improve the drawbacks of single-fiber com-posites. Hybrid composites are materials consisting of two or more different fiber types, which act as reinforcement, and a polymer resin as matrix, which holds the fibers [1]. Recently, composite material has been applied to many technological products like automotive and aerospace products [2], marine parts, sports equipment [3], windmill blades [4, 5], and lightweight construction materials [6].

This is largely because of the good mechanical properties and light structure of composite materials [7, 8]. Carbon fiber as reinforcement of polymeric matrix composite presents several advantages such as high modulus, high strength and stiffness, good creep resistance, low density, heat and flame resistance, and good compatibility with the epoxy matrix [9]. However, carbon fibers are relatively brittle and very expensive [10]. Recently, glass fibers have been recommended as one of the most popular reinforce-ments that can hybridize carbon fiber-reinforced polymer (CFRP). The principal advantages of glass fibers are low cost, high tensile strength, high chemical resistance, and excellent insulating properties [11]. However, glass fibers also have several disadvantages, which include a rela-tively low tensile modulus and high density, relarela-tively low fatigue resistance, and high hardness, which causes exces-sive wear on molding dies and cutting tools, although it has a low price. In addition, glass fiber is toxic [12].

effect of nanoparticle addition to the mechanical proper-ties of composites from carbon and basalt fiber [21] and different filler fibers [22–25]. However, very few studies have been carried out on the combination of carbon and basalt fiber laminates.

In this work, we investigated the tensile properties of carbon- and basalt fiber-laminated composites, specifi-cally focusing on the effect of the number of basalt fiber layers and arrangement position on the carbon fiber com-posite laminates. The aim of this work was to assess the suitability of basalt fiber as an effective competitor of glass fiber for the reinforcement of composites. Tensile tests were carried out. The failure surfaces of the composites were analyzed by scanning electron microscopy (SEM).

2 Experimental

2.1 Materials

In the present study, we used plain woven carbon fiber (C120-3K; fabric weight = 200 ± 10 g/m2; fabric

thickness = 0.25 ± 0.02 mm) purchased from Hyun Dai Fiber Co. Ltd. (Korea), and plain woven basalt fiber (EcoB4 F210; fabric weight = 210 ± 10 g/m2; fabric

thick-ness = 0.19 ± 0.20 mm) provided by Secotech (Korea). The resin matrix used was a modified bisphenol A epoxy resin (HTC-667C; specific gravity = 1.16 ± 0.02; viscosity = 1.2 ± 0.5 kg/m.s) with a modified aliphatic amine hardener and was supplied by Jet Korea Co. (Korea).

2.2 Composite fabrication

The panels of laminates were manufactured by a vacuum-assisted resin transfer molding (VARTM) process. VARTM is an adaptation of the resin transfer molding (RTM) process that exploits vacuum pressure of < 101.32500 kPa to draw off resin to the impregnate preforms. VARTM presents many benefits in composite fabrication such as low cost, low void contents, and stable product thickness [22, 26, 27]. The schematic of the present VARTM process is shown in Figure 1. In this work, a bronze plate with dimensions of 300 mm × 300 mm was prepared and oiled with a liquid wax (for safe release) on the top of plate. Sealant tape was then placed around the plate. The carbon and basalt fibers were both cut with a dimension of 250 mm × 250 mm and arranged on the mold according to the laminate design. Next, epoxy resin with a hardener mixture ratio of 5:1 after degassing in vacuum desiccators (at -70 cmHg for 40 min), was directly

Figure 1 Schematic layout of VARTM: (1) bronze plate, (2) laminate fiber, (3) release films, (4) breather net, (5) vacuum tube, (6) plastic bag, and (7) sealant tape.

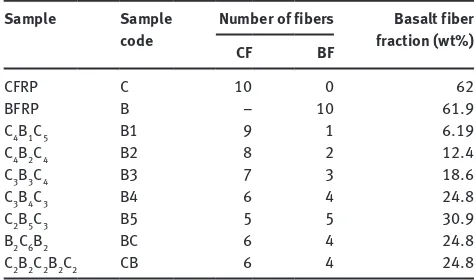

Table 1 Properties of CFRP, BFRP, and hybrid composite with different numbers and arrangement positions of basalt fiber into the carbon fiber/epoxy.

Sample Sample code

Number of fibers Basalt fiber fraction (wt%)

injected into the impregnated preform at a pressure of -80 kPa using a vacuum pump (Airtech Ulvac G-100D, ULVAC Kiko Incorporated, Japan). The panel was then dried inside an oven at 65oC for at least 2 h. In this work, we laminated

10 layers of fibers in every panel, constituting about 62 wt% of the hybrid composite. The thickness of panels manufac-tured through VARTM was approximately 2 mm. The details of the combination of the fibers are shown in Table 1.

2.3 Tensile test and characterization

performed aiming to recognize the failure mode of each hybrid composite.

3 Results and discussion

3.1 Tensile properties

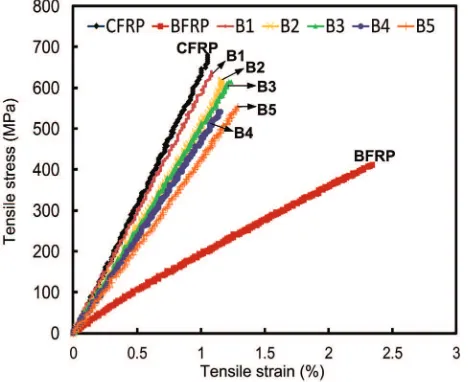

Figure 3 illustrates the typical stress-strain curves obtained from the tensile test for each laminate, and Table 2 gives the summary of the mechanical properties. Here, the basalt fabric layers were placed between carbon fabric layers (i.e., B1–B5). It can be directly noticed that the behaviors of each laminate all showed a linear trend. The slope of the stress-strain curves demonstrated a proportional decrease with the increase in the number of basalt fibers in the composite laminates. However, the tensile strain showed an increasing trend with the increase in the number of basalt fabric layers. This signi-fies that at the highest number of basalt layers, i.e., B5, the composite laminate showed the highest tensile strain. In

Figure 2 Schematic of dog-bone-type specimen for tensile test.

Figure 3 Stress-strain curves of CFRP, BFRP, and hybrid composites with different numbers of basalt fiber layers.

Table 2 Mechanical properties of CFRP, BFRP, and hybrid composites with different contents of basalt fiber into the carbon fiber/epoxy laminate.

contrast, the tensile strength of the composites with the basalt fiber has values slightly lower than that of CFRP but much higher than BFRP (see Figure 3). In other words, the enhancement depending on the content of basalt fiber has a significant impact on the ultimate strength, elastic modulus, and strain of the composite laminate. As a result of basalt reinforcement in CFRP, the interply hybrid com-posites could take more strain before incurring failure [1, 29].

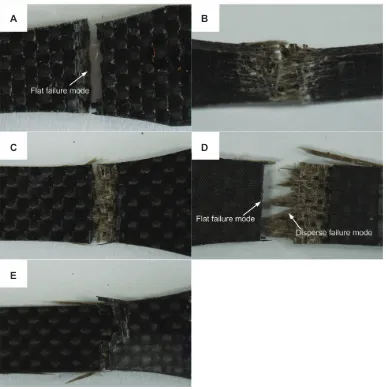

Figure 4 shows photographic images of the failed samples after the tensile test. The laminate with only one layer of basalt fiber in CFRP (Figure 4A) showed a brittle mode of failure. However, the damage modes of compos-ite laminates B2, B3, B4, and B5 (Figure 4B–D) demon-strated many dispersed failure fibers. B4, with four plies of basalt fiber, incurred flat damage on carbon layers after the tensile test and disperse fiber failure on the basalt layer (Figure 4D), which means that the interply hybrid composites can take more strain before failure under tensile loading. Similar results were also reported by other research groups [30, 31] when they investigated the behav-ior of FRP and hybrid FRP.

From Table 2, the results of the mechanical proper-ties depending on the basalt content show a linearly decreasing tensile strength and Young’s modulus values of the hybrid composites with the increase in the number of basalt layers. This signifies that the incorporation of basalt fiber significantly affected the tensile behavior of hybrid composites. However, an increase of basalt fibers also raises the strain behavior of hybrid composite.

Here, we can make the approximate relations for the tensile strength and the Young’s modulus of the interply hybrid composites as a function of the number of basalt fiber layers, x. It has been derived as follows:

σ

H = -37x+687 (MPa) (1)

E

3.2 Hybridization effect

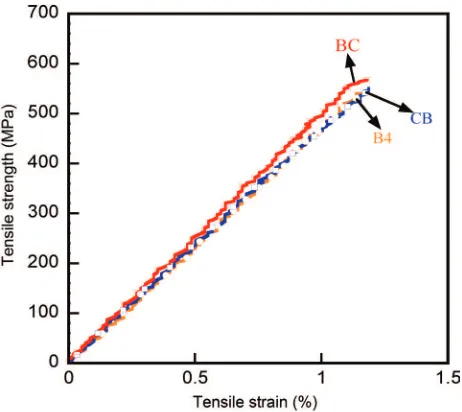

To investigate whether the arrangement of basalt fibers in the hybrid composite laminate has some effect on its tensile properties, we tested several types of specimens that have different arrangements, i.e., BC, CB, and B4 (see Table 3). In all cases, the specimens were made by using four and six plies of basalt and carbon fibers, respec-tively. In the present study, placing the basalt fibers in

A B

C

E

D

Figure 4 Optical images of failed hybrid composite under tensile loading: (A) B1, (B) B2, (C) B3, (D) B4, and (E) B5.

Table 3 Effect of the positioning of basalt or carbon fiber in the hybrid epoxy laminate.

Hybrid code

Tensile strength

σ (MPa)

Young’s modulus

E (GPa)

Tensile strain ε

B4 536 45 1.14

BC 571 49.5 1.15

CB 556 47.5 1.17

that the variation of the basalt-reinforcing position has a major effect on the tensile strength and Young’s modulus of this type of hybrid composite. Tensile strength and Young’s modulus of BC are higher than that of B4 by 6.5% and 5.3%, respectively.

3.3 Fracture characterization

Figures 6 and 7 show the SEM images of the fractured sur-faces of the present samples after the tensile test. Figure 6A shows cross-sectional damage of the BFRP, which shows rumpled failure features, whereas in Figure 6B, we can observe that the CFRP failed via a tensile mode failing by

Figure 5 Stress-strain curves of the hybrid composites with differ-ent stacking varieties: B4, BC, and CB under tensile loading.

A B

Figure 6 Low- and high-magnification SEM images for the cross section of the fracture surface of the hybrid composites: (A) BFRP and (B) CFRP.

flat features. Figure 7 shows the SEM images of cross sec-tions of the failed tensile specimens. B4 (Figure 7A) shows few carbon fiber-matrix debonding and basalt fiber shows damage in dispersed failures. In the hybrid composite BC (Figure 7B), there are some carbon fiber pullouts, debond-ing, and fiber-matrix delamination. Some longitudi-nal delaminations also occurred in basalt layers. In this case, the interfaces between carbon fiber and basalt fiber were delaminated caused by the effect of residual stress between the layers during tensile loading. At present, the carbon layers failed in a flat manner and basalt layers failed in a rumpled manner. This is due to the fact that carbon fiber is brittle and basalt fiber is relatively ductile. In the hybrid composite, with an alternatively sequenced manner (Figure 7C), some rumpled failures occurring on the basalt layer, causing delamination between the carbon layer and basalt layers, were observed, as similarly attempted by Wei et al. [19]. This made its tensile strength lower than that of other hybrid composite arrangements, even though the strain on this arrangement was a little higher (see Table 3). This phenomenon is attributed to the brittle failure of carbon fibers, where the specimen broke through all layers with an abundant rupture [32].

4 Conclusions

composites. The results suggest the possible control and balance of the tensile properties of the interply hybrid composite laminates by controlling the number of basalt fiber layers. The tensile properties of carbon-basalt/epoxy hybrid composite depended on the basalt fiber position. Here, the BC composite, wherein carbon fiber layers were inserted between basalt layers, had the highest tensile strength and Young’s modulus. The change in the type of arrangement of the basalt fiber in

the hybrid composite leads to the variation of the frac-ture mechanism of the composite under tensile loading. For B4 and CB, the delamination between carbon and basalt occurred before the fracture of reinforcing fibers, whereas for BC, the delamination occurred after the carbon layer had broken.

Acknowledgments: This research was supported by the Basic Science Research Program through the National A

B

C

A’

B’

C’

Research Foundation of Korea (NRF) funded by the Minis-try of Education, Science and Technology (2010-0022359). I.D.G. Ary Subagia acknowledges the support from the Degree General High Education (DGHE) postgraduate abroad scholarship of the Republic of Indonesia for his

Ph.D. program at Chonbuk National University in South Korea.

Received January 3, 2013; accepted June 23, 2013; previously pub-lished online August 8, 2013

References

[1] Pandya KS, Veerraju Ch, Naik NK. Mater. Des. 2011, 32, 4094–4099.

[2] Yang WB, Zhang LT, Liu YS, Cheng LF, Zhang WH. Appl. Compos. Mater. 2007, 14, 277–286.

[3] Taketa I, Ustarroz J, Gorbatikh L, Lomov SV, Verpoest I. Composites, Part A: Appl. Sci. Manuf. 2010, 41(8), 927–932. [4] Hu W, Han I, Park SC, Choi DH. J. Mech. Sci. Technol. 2012, 26,

129–135.

[5] Ryou H, Chung K, Lim JH. Met. Mater. Int. 2008, 14, 679–687. [6] Arumugam V, Shankar RN, Sridhar BTN, Stanley AJ. J. Mater. Sci.

Technol. 2010, 26, 725–729.

[7] Zhou YX, Wang Y, Jeelani S, Xia YM. Appl. Compos. Mater. 2007, 14, 17–31.

[8] Hopmann C, Michaeli W, Puch F. Sci. Eng. Compos. Mater. 2012, 19, 331–338.

[9] Goto K, Kawahara I, Hatta H, Kogo Y, Shiota I. Compos. Interfaces 2005, 12, 603–616.

[10] Wei B, Cao HL, Song SH. Mater. Des. 2010, 31, 4244–4250. [11] Artemenko SE. Fibre Chem. 2003, 35, 226–229.

[12] Feih S, Thraner A, Lilholt H. J. Mater. Sci. 2005, 40, 1615–1623. [13] Jayabal S, Natarajan U, Sathiyamurthy S. Bull. Mater. Sci. 2011,

34, 293–298.

[14] Czigany T, Poloskei K, Karger-Kocsis J. J. Mater. Sci. 2005, 40, 5609–5618.

[15] Chen ZF, Lee S, Ng M, Tang JM, Wan LL, Liu M, Lee L. Sci. Eng. Compos. Mater. 2008, 15, 165–174.

[16] Wei B, Cao HL, Song SH. Mater. Sci. Eng., A 2010, 527, 4708–4715.

[17] Bashtannik PI, Kabak AI, Yakovchuk YY. Mech. Compos. Mater. 2003, 39, 85–88.

[18] Czigany T. Compos. Sci. Technol. 2006, 66, 3210–3220. [19] Wei B, Song SH, Cao HL. Mater. Des. 2011, 32, 4180–4186. [20] Manikandan V, Jappes JTW, Kumar SMS, Amuthakkannan P.

Composites, Part B: Eng. 2012, 43, 812–818. [21] Lee JH, Rhee KY, Park SJ. Mater. Sci. Eng., A 2010, 527,

6838–6843.

[22] Rachmadini Y, Tan VBC, Tay TE. J. Reinf. Plast. Compos. 2010, 29, 2782–2807.

[23] Zeng Y, Liu HY, Mai YW, Du XS. Compos. Part B: Eng. 2012, 43, 90–94.

[24] An Q, Rider AN, Thostenson ET. Carbon 2012, 50, 4130–4143. [25] Kim HS. Met. Mater. Int. 2011, 17, 697–704.

[26] Bender D, Schuster J, Heider D. Compos. Sci. Technol. 2006, 66, 2265–2271.

[27] Simacek P, Advani SG. Compos. Sci. Technol. 2007, 67, 2757–2769.

[28] ASTMD638-10. ASTM International, West Conshohocken, PA, 2008.

[29] Liu Q, Hughes M. Composites, Part A: Appl. Sci. Manuf. 2008, 39, 1644–1652.

[30] Zweben C. J. Mater. Sci. 1977, 12, 1325–1337.

[31] Wu ZS, Wang X, Iwashita K, Sasaki T, Hamaguchi Y. Composites, Part B: Eng. 2010, 41, 396–402.