Chapter 6.

Free Radical Polymerization

Table 6. 1 Commercially Important Vinyl Polymers

6.1. Introduction

6. 2 Free Radical Initiators

Four typesPeroxides and hydroperoxides

6.2.1. Peroxides and Hydroperoxides ( ROOR ) ( ROOH )

Thermal homolysis

C O O C O

Ph O

Ph

∆ C O

O Ph

2

Decomposition

C O

O

Ph Ph + CO2

Radical combination ∵ Cage effect

(confining effect of solvent molecules) Wastage reaction

Ph Ph Ph

2

C O O

Ph Ph C O

O

Ph Ph

+

Induced decomposition

C O O C

O

Ph O

Ph Ph C O O C

O

Ph O

Ph

Ph +

O C

O

Ph

C O

O

Ph Ph +

Radical stability

Ph C CH3

CH3

O CH3 C

CH3

CH3

O C O

O

Ph C O

O CH3

> > >

Unstable radical More wastage reaction Stable radical

Less wastage reaction

Half-lifes

BPO (Benzoyl peroxide)

CH3 C CH3

CH3

O O C CH3

CH3 CH3

C O O C

O

Ph O

Ph

1.4 h at 85oC

1.38 h at 145oC

Ph C CH3

CH3

O O H

C O O C O

CH3 O

CH3

Promoters

C O O C

O

Ph O

Ph

CH3 Ph N

CH3 +

+ CH3

Ph N

CH3

O C

O

Ph +

O O

Ph C

-CH3

Ph N

CH3

O C

O

Ph +

+

No initiation of polymerization

∵ No N in polymers

6.2.2. Azo Compounds

C(CH3)2 N N

CN CN

(CH3)2C

CN

(CH3)2C

2 + N2

AIBN (Azobisiso(butyronitrile))

Radical combination

CN

C(CH3)2 CN

(CH3)2C CN

(CH3)2C 2

C N C(CH3)2 CN

(CH3)2C

(CH3)2C

C N

(CH3)2C

6.2.3. Redox Initiators

Production of free radicals by one–electron transfer reactions. Useful in low–temp polymerization and emulsion polymerization

C(CH3)2 OOH

Ph Fe2+

O

Ph C(CH3)2 + OH + Fe3+

+

-HOOH Fe2+ + OH Fe

3+

+ HO - +

O

3SOOSO

3-

+

S

2O

32-+

SO

42-+

-

SO

-

-4

S

2O

36.2.4. Photoinitiators

RSSR

hν

2 RS

C O

CH Ph

OH

Ph

O

C Ph

OH

Ph CH

+ hν

C O

Ph C

O

Ph C

O

Ph hν

2

The major advantages of photoinitiation:

The reaction is essentially independent of temp

Polymerization may be conducted even at very low temperatures

Better control of the polymerization reaction

6.2.5. Thermal Polymerization

Ph H

Ph +

2

∆ CH

CH2

CH CH2

CH CH3

Diels-Alder dimer

Transfer of H atom to monomer Molecule-induced homolysis

6.2.6. Electrochemical Polymerization

RCH

CH

2+

e

-RCH

CH

2_

RCH

CH

2RCH

CH

2+

e

-+

Radical ions : initiate free radical or ionic polymerization or both

6. 3 Techniques of Free Radical Polymerization Techniques

Method Advantages Disadvantages

Bulk Simple Rxn exotherm difficult to control No contaminants added High viscosity

Suspension Heat readily dispersed Washing and drying required Low viscosity Agglomeration may occur Obtained in granular form Contamination by stabilizer

Solution Heat readily dispersed Added cost of solvent

Low viscosity Solvent difficult to remove

Used directly as solution Possible chain transfer with solvent Possible environmental pollution

Emulsion Heat readily dispersed Contamination by emulsifier

Low viscosity Chain transfer agents often needed High MW obtainable Washing and drying necessary Used directly as emulsion.

6. 4 Kinetics and Mechanism of Polymerization

Formation of the initiator radicalAddition of the initiator radical to monomer Initiation

Initiator R

R CH2 CH

Y

+ R CH2 CH

Y

Propagation

CH CH2

Y

CH CH2

Y

+ CH2 CH

Y

CH CH2

Y

Termination CH CH2

Y

HC H2C

Y +

Coupling or combination

Disproportionation

CH CH2

Y

HC H2C Y

CH CH

Y

H2C H2C Y

Coupling almost exclusively at low temp Polystyrene

CH

CH2 + HC H2C CH2 CH HC H2C

C CH2

C

+ O OCH3 CH3

C H2C C

O

OCH3 CH3

C CH

C

+ O OCH3 CH3

HC H2C C

O

OCH3 CH3 Disproportionation

PMMA

∵

Steric repulsionElectrostatic repulsion

Initiator

k

dR

R

+ M

k

iM

1 InitiationPropagation

+ M

kp

M2 M1

+ M

kp

M3 M2

+ M

kp

M(x+1) Mx

Termination

+ My

ktc

M(x+y)

Mx Coupling

+ My

ktd

Initiation rate (Ri)

[ ]

[ ]

I

fk

2

dt

M

d

R

i=

•

=

dwhere

[M•] = total conc of chain radicals

[I] = molar conc of initiator

f = initiator efficiency = 0.3 ~ 0.8

Termination rate (Rt)

[ ]

[ ]

2 tt

2

k

M

dt

M

d

R

=

−

•

=

•

Steady-state assumption Ri = Rt

[ ]

[ ]

2t

d

I

2

k

M

fk

2

=

•

[ ]

[ ]

t d

k

I

fk

M

•

=

[ ]

[ ][ ]

[ ]

[ ]

t d p

p p

k

I

fk

M

k

M

M

k

dt

M

d

R

=

−

=

•

=

Propagation rate (Rp)

Average kinetic chain length ( )

ν

= Average # of monomer units polymerized per chain initiated

[ ][ ]

[ ]

[ ]

[ ]

(

[ ]

[ ]

)

21 dt p

t p 2

t p

t p

i p

I

k

fk

2

M

k

M

k

2

M

k

M

k

2

M

M

k

R

R

R

R

=

•

=

•

•

=

=

=

ν

ν

=

DP

ν

2

Coupling•

Gel effect, Trommsdorff effect, Norris-Smith effectOccurs in bulk or concentrated solution polymerizations

η↑ Chain mobility↓ R [M•] ↑

t↓

Rp↑ Release of more heat R

i↑ Rp↑

Polymerization of MMA in benzene 50°C benzoylperoxide

•

Chain transfer reactionsTransfer of reactivity from the growing polymer chain

to another species

Chain-end radical abstract a H atom from a chain

Chain branching

2) Backbiting : intramolecular chain transfer

3) C.T. to Initiator or Monomer

Important with monomers containing allylic hydrogen, such as propylene

Reactive radical

Resonance-stabilized radical

∴ High-mol-wt polypropylene cannot be prepared

CH2 C CH3

COOCH3

CH2 C CH3

COOCH3

+ allylic hydrogen

C.T. to monomer

Propagation

CH2 CH CH3

COOCH3

CH2 C CH2

COOCH3 +

CH2 C CH2

COOCH3

Resonance-stabilized radical CH2 C

CH3

COOCH3

CH2 C

CH3

C

O

OCH3

CH2 C CH3

COOCH3

CH2 C

CH3

C

O

OCH3

Resonance-stabilized radical

4) C.T. to Solvent or Chain transfer agents

CCl4

Transfer reaction rate

[ ][ ]

M

T

k

R

tr=

tr•

where T = transfer agent Kinetic chain length

[ ]

[ ]

• = ν M k 2 M k t p[ ][ ]

[ ]

• +∑

[ ][ ]

• =[ ]

• +[ ]

∑

[ ]

• = + = ν T k M k 2 M k T M k M k 2 M M k R R R tr t p tr 2 t p tr t p trw/o transfer agent

with transfer agent

[ ]

[ ]

[ ]

[ ]

[ ]

[ ]

M[ ]

T C 1 M k T k 1 M k T k M k 2 1 T p tr p tr t tr

∑

∑

∑

+ ν = + ν = + • = ν T p trC

k

k

=

Chain transfer constant[ ]

[ ]

M

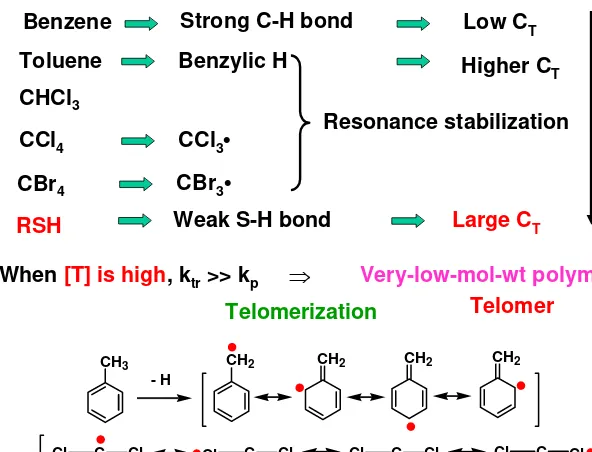

Table 6.5 CTfor St and MMA

Strong C-H bond

Benzene Low CT

Toluene Benzylic H Higher C

T

Weak S-H bond Large CT CCl3• Resonance stabilization

CHCl3

CCl4 CT↑

CBr3•

CBr4 RSH

Very-low-mol-wt polymer

Telomerization

When [T] is high, ktr >> kp ⇒

Telomer

CH3 CH2 CH2 CH2 CH2

- H

C Cl Cl

Cl C Cl

Cl

Cl C Cl

Cl

Cl C Cl

ο Inhibitors

Added to monomers to prevent polymerization

during shipment or storage

Must be removed by distillation of monomer or extraction

Alkylated Phenol

R' . +

OH R R

R

R'H + R R

R

R R

R O

R R

R

R

R R

R

. O O

.

R .

R' . OR' R R

R

R R

R

R R

R O

R

R R

R

O

+ 'R +

% Polymerization

Time 0

No inhibitor

Inhibitor

More inhibitor

Induction period

Induction periods are common even with purified monomer

o Atom Transfer Radical Polymerization (ATRP)

ο Living free radical Polymerization

No chain termination or chain transfer

CH3CHCl

Ph

+ Cu(I)(bpy) CH3CH Ph

. + Cu(II)(bpy)Cl

H2C CH Ph

CH3CHCH2CHCl

Ph Ph

+ Cu(I)(bpy) CH3CHCH2CH Ph Ph

.

+ Cu(II)(bpy)Cl

bpy = bipyridyl =

N N

Polymerization of styrene

Transfer of Halogen atom

propagation

Preventing radical termination

o Addition of a Stable Free Radical

CH2CH Ph

. +

N

H3C CH3

H3C

CH3 O

.

CH2CH Ph

N

H3C CH3

H3C

CH3 O

TEMPO (2,2,6,6-tetramethylpiperidinyl-1-oxy) Too stale to initiate polymerization

Promotes decomposition of BPO to benzoyloxy radicals

Propagation Prevent termination

[ ]

[ ]

o o I M DP =All the chains are initiated at about the same time. No chain termination or transfer reactions.

ο Emulsion Polymerization

Smith-Ewart kinetics

[ ]

⎟

⎠

⎞

⎜

⎝

⎛

=

2

N

M

k

R

p pwhere [M] = concentration of monomer in the polymer particle

Rate of radical entry into the particle

[ ]

[ ]

[ ]

[ ]

I

fk

2

N

M

k

N

R

M

k

M

k

d p i pp

=

=

ρ

=

ν

Average kinetic chain length

ν

=

DP

N Ri = ρ[ ]

(

)

0.6s 4 . 0

i a E

R k N ⎟ ⎠ ⎞ ⎜ ⎝ ⎛ µ =

k = constant (0.37~0.53)

µ = rate of increase in the volume of a polymer particle [E] = concentration of micellar emulsifier

as = interfacial area occupied by an emulsifier molecule in the micelles

where

[ ] [ ]

0.4 0.6E

,

I

6.5. Stereochemistry of Polymerization

Steric and electrostatic interactions are responsible for stereochemistry of free radical polymerization

1) Interaction between Terminal unit & Monomer

Mirror approach

CH2C CH2C Y

X Y X .

C C Y X H

H

CH2C CH2C Y X

CH2 Y X

C Y

X .

etc

Isotactic polymer

Nonmirror approach

CH2C CH2C X

Y Y X .

C C Y X H

H

CH2C CH2C Y X

CH2 X Y

C Y

X .

etc

2) Interaction between Terminal unit & Penultimate unit

C

C

P CH3

CO2CH3 H

H

C

CO2CH3 CH3 CH2 C

CH3

CO2CH3

C

C

P CH3

CO2CH3 H

H

C

CO2CH3 CH3 CH2 C

CH3

CO2CH3

P: bulkiest group

If terminal carbon has sp2 planar structure,

Interaction between terminal unit & monomer is dominant factor

If terminal carbon has sp3 hybridization,

Interaction between penultimate unit & terminal unit is dominant factor

Stereoregularity ↑ as T

↓

Free radical polymerization of MMA at T < 0 oC

Crystalline polymer

Syndiotactic

(Expect) As size of substituent groups ↑, stereoregularity ↑

(Experiment) bulkier substituent

Less syndiotactic than PMMA under the same conditions

CH2 C CH3

6.6 Polymerization of Dienes

6.6.1. Isolated DienesCrosslinked polymer

Cooperative addition of one double bond to the other of the monomer

Independent reaction

Cyclic polymer

5- or 6-membered ring

Cyclopolymerization:

Cyclopolymerization of divinylformal

.

R +

O O O O

R

O O R

O O R

. .

O O R

O O R

.

head-to-tail mode six-membered ring

head-to-tail mode five-membered ring

Head-to-tail mode

Head-to-head mode

Six-membered ring

Highly crosslinked polymers Diallyl monomer

C

C O

O O

O

Used for manufacturing

electrical or electronics items (circuit boards, insulators,

television components, etc)

preimpregnating glass cloth or fiber for

fiber-reinforced plastics

Diallyl phthalate

O O

O O

2

Used for applications requiring good optical clarity

(eyeware lenses, camera filters,

panel covers, and the like)

6.6.2. Conjugated Dienes

H2C CH HC CH2 RH2C CH2

H

C CH2 .

RH2C HC CH CH2 .

.

R

CH2CH CH CH2

CH2

C C

CH2

H H

CH2

C C H

H CH2

Pendant vinyl groups unsaturation in the chain

cis trans

1,3-butadiene

1,4-addition 1,2-addition

CH2 C CH CH3

CH2

CH2CH CH CH2

CH3

CH2CH C CH2

CH3

CH3

CH2

C C

CH2

H H

CH2

C C H

H CH2

cis trans

1,2-addition 3,4-addition cis-1,4-addition trans-1,4-addition Isoprene (2-methyl-1,3-butadiene)

Natural rubber

(Hevea) Predominant

10%

trans-1,4 s-trans

s-cis cis-1,4 As T↑ , cis-1,4 ↑

CH2 C CH CH2

Sn(n-C4H10)3

cis-1,4 s-cis

Table 6.6 Structures of Free Radical-Initiated Diene Polymers

percent

Monomer

Polymerization

Temperature(℃) cis-1,4 trans-1,4 1,2 3,4

kp:

6.7 Monomer Reactivity

-C6H5 < -CN < -COOCH3 < -Cl < -OCOCH3 o Three factors in monomer reactivity

1) Resonance stabilization of free radicals: kp↓

-C6H5 > -CN > -COOCH3 > -Cl > -OCOCH3

Reactive monomer Stable monomer

Reactive radical Stable radical

Inverse relationship between monomer reactivity and kp Radical reactivity is the major factor.

R +

R R R R

2) Polarization of double bond by substituents: kp↓

Extreme polarization prevents free radical polymerization

e.g.

CH2 C

CN

CN CH2 CH

OCH3 No radical polymerization

C C C C

C C

Homolytic fission Heterolytic fission

Anionic Cationic polymerization

3) Steric hindrance: kp↓

CH2 CH

X

CH2 C

Y

X CH CH CH CH

Y X

kp: MMA < MA

CH2 C

COOCH3

C

H H

H CH2 C

COOCH3 H

MA MMA

∵ Resonance stabilization of the radical by hyperconjugation and steric hindrance

o Free energy of polymerization

∆Gp = ∆Hp - T∆Sp

∆H < 0 : exothermic, π-bond in monomer → σ-bond in polymer ∆S < 0 : monomer → covalently bonded chain structure

∴ Degree of freedom (randomness) ↓

favorable

unfavorable

(1) The higher the resonance stabilization of monomer, l∆Hl ↓ (2) Steric strain in polymer, l∆Hl ↓

(3) Decrease in H-bonding or dipole interaction on polymerization, l∆Hl ↓

Monomer Polymer

energy

π-bond σ-bond

Resonance Stabilization

of monomer ∆H Steric strain

Decrease in

Table 6.7 ∆H and ∆S of Polymerization

Monomer

-△H (kJ/mol)

-△S

(J/mol)

Acylonitrile 77 109

1,3-Butadiene 78 89

Ethylene 109 155

Isoprene 75 101

Methyl methacrylate 65 117

Propylene 84 116

Styrene 70 104

Tetrafluoroethylene 163

-Vinyl acetate 90

-o P-olymerizati-on-dep-olymerizati-on Equilibrium

Mx + M M(x+1) kp

kdp

where

kdp = depropagation rate constant

Tc T

kdp

kp [M]

kp [M] - kdp

At Tc

[ ][ ]

M• M = k[ ]

M•kp dp

Equilibrium constant

[ ]

[ ][ ]

e[ ]

e kdpp k M1 M

M M

K = =

• • =

where [M]e = equilibrium monomer concentration

∆G = ∆Go + RT ln K

where ∆Go= ∆G in standard state

(pure monomer or 1-M solution monomer,

pure polymer or 1-M repeating units of polymer) At equilibrium

∆G = 0

∆Go = ∆Ho - T

c∆So = - RTc ln K = RTc ln [M]e

[ ]

e oo c

M ln R S

H T

+ ∆

∆

=

[ ]

R S RT

H M

ln

o

c o

e

∆ − ∆

=

R

S

o

∆

−

[

]

R

S

RT

H

M

ln

o

c

o

e

∆

−

∆

=

R

H

o

∆

[

]

eM

ln

1

c

T

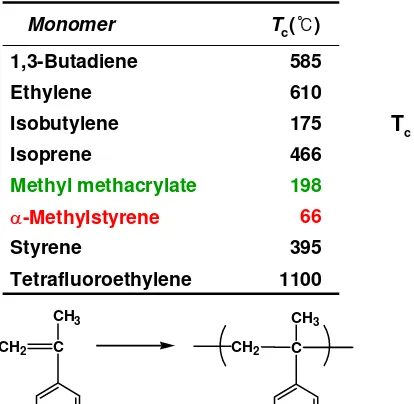

Table 6.8 Tc of Pure Liquid Monomers Monomer Tc(℃)

1,3-Butadiene 585

Ethylene 610

Isobutylene 175

Isoprene 466

Methyl methacrylate 198

α-Methylstyrene 66

Styrene 395

Tetrafluoroethylene 1100

[ ]

e oo c

M ln R S

H T

+ ∆

∆ =

CH2 C

CH3

CH2 C

CH3

-△H = 35 kJ/mol

Tc = 66 oC

6.8 Copolymerization

Reaction Rate

k11

M1

•

+ M1 M1•

k11 [M1•] [M1] k12M1

•

+ M2 M2•

k12 [M1•] [M2] k21M2

•

M1

•

+ M k

21 [M2•] [M1] 1

k22

M2

•

+ M2 M2•

k22 [M2•] [M2]o Steady-state assumption for [M1•] and [M2•] k12 [M1•] [M2] = k21 [M2•] [M1]

o Rate of consumption of M1 and M2

[ ]

[

][ ]

[

][ ]

1 2 21 1 1 11 1 M M k M M k dt M d • + • = −[ ]

[

][ ]

[

][ ]

2 2 22 2 1 12 2 M M k M M k dt Md = • + •

−

[ ]

[ ]

o Instant composition of copolymer

[ ]

[ ]

[

[

]

]

[

[

]

]

⎟⎟ ⎠ ⎞ ⎜⎜ ⎝ ⎛ • + • • + • = 2 22 1 12 2 21 1 11 2 1 2 1 M k M k M k M k M M M d M d[

]

[ ][

[ ]

]

2 12 2 1 21 1 M k M M kM • = •

o Monomer reactivity ratio

1 12 11 r k k = 2 21 22 r k k =

o Copolymer (composition) equation

o Instantaneous composition of feed and polymer

[ ]

[ ] [ ]

1 21 2 1 M M M f 1 f + = − =

f1 = mole fraction of M1 in the feed f2 = mole fraction of M2 in the feed

[ ]

[ ] [ ]

1 21 2 1 M d M d M d F 1 F + = − =

F1 = mole fraction of M1 in the copolymer F2 = mole fraction of M2 in the copolymer

[ ]

[ ]

11 2 1 F 1 F M d M d − =

[ ]

[ ]

2 1 2 1 f f M M =[ ]

[ ]

[ ]

[ ]

[ ] [ ]

[ ] [ ]

⎟⎟ ⎠ ⎞ ⎜⎜ ⎝ ⎛ + + = 2 2 1 2 1 1 2 1 2 1 M r M M M r M M M d M d ⎟⎟ ⎠ ⎞ ⎜⎜ ⎝ ⎛ + + = − = − 2 1 1 2 2 1 1 2 1 1 1 f f r f r f f f 1 F 1 F F 1 ⎟⎟ ⎠ ⎞ ⎜⎜ ⎝ ⎛ + + =− 1 2 2

2 1 1 2 1 1 1 f r f f f r f f F 1 F 2 1 2 1 1 2 2 2 2 1 2 1 1 2 1 1 2 2 1 1 2

1 r f f f

[ ]

[ ]

212 1 M d M d F F

F = =

[ ]

[ ]

2 1 2 1 M M f f f = =

[ ]

[ ]

[ ]

[ ]

[ ] [ ]

[ ] [ ]

⎟⎟ ⎠ ⎞ ⎜⎜ ⎝ ⎛ + + = 2 2 1 2 1 1 2 1 2 1 M r M M M r M M M d M d 2 2 1 2 1 r f f f r r f 1 f r f F + + = ⎟⎟ ⎠ ⎞ ⎜⎜ ⎝ ⎛ + + =f

f

r

F

r

fF

+

2=

1 2+

(

)

1 2 2 r F f r F F 1 f ⎟⎟ ⎠ ⎞ ⎜⎜ ⎝ ⎛ − = −

Finemann and Rose Equation

(

)

F

F

1

f

−

1 - r1r2

2 2 2 2

1 2

1 1

2 1 2

1 1 1

f

r

f

f

2

f

r

f

f

f

r

F

+

+

+

=

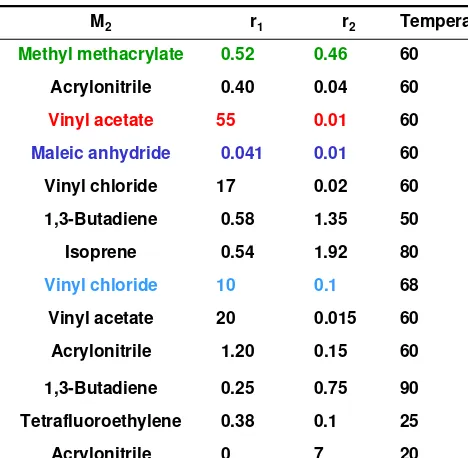

1) r1 = r2 = 1

No preference for homopolymerization or copolymerization Random copolymer

F1 = f1 e.g. M

1 = ethylene M2 = vinyl acetate r1 = 0.97 r2 = 1.02

2) r1 = r2 = 0

Alternating copolymer

F1 = 0.5 e.g. M

1 = styrene r1 = 0.041

3) 0 < r1, r2 < 1

More common e.g. M

1 = styrene r1 = 0.52

M2 = methyl methacrylate r2 = 0.46

Azeotropic copolymerization

[ ]

[ ]

[ ]

[ ]

2 1 2 1 M M M d Md =

[ ]

[ ]

[ ]

[ ]

[ ] [ ]

[ ] [ ]

⎟⎟ ⎠ ⎞ ⎜⎜ ⎝ ⎛ + + = 2 2 1 2 1 1 2 1 2 1 M r M M M r M M M d M d[ ] [ ]

[ ] [ ]

M r M 1M M r 2 2 1 2 1 1 = + +

[ ]

[ ]

14) 1 << r1 and r2 << 1

e.g. M

1 = styrene M2 = vinyl acetate r1 = 55 r2 = 0.01

M1 = styrene M2 = vinyl chloride r1 = 17 r2 = 0.02

Essentially homopolymer

5) r1

•

r2 = 1e.g. M

1 = MMA

r1 = 10 r2 = 0.1

M2 = vinyl chloride Ideal copolymerization

r1

=

r2 = 1 Real random copolymerization The more r1 and r2 diverge, the less random2 2 2 2 1 2 1 1 2 1 2 1 1 1 f r f f 2 f r f f f r F + + + =

(

)

(

)

1 1 2Table 6.9 Reactivity Ratios

M1 M2 r1 r2 Temperature(℃)

Styrene Methyl methacrylate 0.52 0.46 60

Styrene Acrylonitrile 0.40 0.04 60

Styrene Vinyl acetate 55 0.01 60

Styrene Maleic anhydride 0.041 0.01 60

Styrene Vinyl chloride 17 0.02 60

Styrene 1,3-Butadiene 0.58 1.35 50

Styrene Isoprene 0.54 1.92 80

Methyl methacylate Vinyl chloride 10 0.1 68

Methyl methacylate Vinyl acetate 20 0.015 60

Methyl methacylate Acrylonitrile 1.20 0.15 60

Methyl methacylate 1,3-Butadiene 0.25 0.75 90

Ethylene Tetrafluoroethylene 0.38 0.1 25

Ethylene Acrylonitrile 0 7 20

r1 = r2 = 1 r1 = r2 = 0

0 < r1, r2 < 1 1 << r1 and r2 << 1

r1

•

r2 = 1 r1 =10, r2 = 0.1Azeotropic composition

2 1

2 1

r r 2

r 1 f

− −

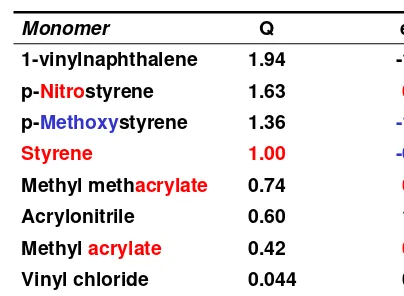

Q-e Scheme (Alfrey-Price Treatment)

k12 = P1Q2 exp (- e1e2)

P1 = reactivity of radical M1

•

Q2 = reactivity of monomer M2 e1 = polarity of monomer M1 e2 = polarity of monomer M2 where(

)

(

)

[

1(

1 2)

]

2 1 2 1 2 1 1 1 1 1 12 11

1 exp e e e

Q Q e e exp Q P e e exp Q P k k

r ⎟⎟ − −

⎠ ⎞ ⎜⎜ ⎝ ⎛ = − − = =

(

)

[

2 2 1]

1 2

2 exp e e e

Q Q

r ⎟⎟ − −

⎠ ⎞ ⎜⎜ ⎝ ⎛ =

Styrene: standard

Q = 1.00 e = - 0.80

Resonance factor ( + steric factor)

Polarity factor

+ : electron-withdrawing group

Table 6.10 Reactivity (Q) and Polarity (e) of Monomer

Monomer Q e

1-vinylnaphthalene 1.94 -1.12

p-Nitrostyrene 1.63 0.39

p-Methoxystyrene 1.36 -1.11

Styrene 1.00 -0.80

Methyl methacrylate 0.74 0.40

Acrylonitrile 0.60 1.20

Methyl acrylate 0.42 0.60

Vinyl chloride 0.044 0.20

CH2 CH + CH2 CH

O C CH3 O

CH2 CH

O C CH3 O

Little tendency

No resonance-stabilization

Resonance-stabilization

M1 = Styrene M2 = Vinyl acetate r1 = 55 r2 = 0.01

Styrene Q = 1.00 e = - 0.80 Vinyl acetate Q = 0.026 e = - 0.22

M1 = Styrene M2 = MMA

Styrene Q = 1.00 e = - 0.80

r1 = 0.52 r2 = 0.46

MMA Q = 0.74 e = 0.40

H3

CH2 C C CH3

O

OCH3 + CH2 C

CH3

C O

OC CH2 CH

Each radical has about twice as much tendency to react with its opposite monomer

Copolymerization of styrene and maleic anhydride

Strong tendency toward alternation (r1 and r2 = ~ 0) 1) Polar effects in the transition state

Electron transfer

Electron transfer

2) Formation of Charge-transfer complexes between comonomers Homopolymerization of charge-transfer complex

~ (DA)n D+..A- + D+..A- ~ (DA)

n+1 D+..A -charge-transfer complex

<Evidence>

(1) Rp maximum when monomer composition ratio = 1:1 maximum conc. of donor-acceptor complex (2) Alternation is independent of monomer feed ratios,

and other reactive monomers included with the feed fail to react while alternating copolymer is forming

(3) Rp is enhanced by addition of Lewis acids,

which increase the acceptor properties of one of the monomers (4) Chain transfer agents have little effect on the mol. wt.

Other compounds that undergo free radical-initiated copolymerization with vinyl monomers are CO and SO2

CH2 CH R CH2 CH

R

CO

SO2

CH2 CH R

C O

CH2 CH R

SO2 polyketones