International Conference on IML 2011

Yugowati Praharsi

1,2*and Hui-Ming Wee

21

Department of Information Technology,

Satya Wacana Christian University, Indonesia

2

Department of Industrial and System Engineering,

Chung Yuan Christian University, Taiwan

*

[email protected]

Abstract

Closed loop supply chain (CLSC) reflects on how green supply chain management is practiced in every line. In this study, we aim to build the conceptual framework and to model the closed loop supply chain which involves 3 echelon levels, i.e.: manufacturer, distributor, and retailer. The collection of used product is done by centralized and decentralized systems. The analysis of conceptual frameworks can be used for the decision makers on how to implement it in the real world. The mathematical model and its optimal values can provide managerial insights to closed loop supply chain researchers.

Keywords: closed-loop supply chain, decentralization,

centralization.

1. Introduction

Green supply chain refers to the sustainability of environmental impacts arising from the existing supply chain processes by an institution or organization. Many business organizations are facing the shortages of natural resources and increasing waste disposal products already in use. Therefore, the improvement of environmental quality should be sought. In recent year, various means were suggested to create a green environment. Some initiatives come from: 1) manufacturers and suppliers, 2) governments and non-profit organizations, 3) retailers, and 4) consumers.

Roles that can be done by the manufacturers and suppliers are: a) reduce waste by increasing efficiency and effectiveness; b) add plants to remanufacture waste into raw materials or new product; c) build a residual waste processing facilities needed that may be joined with other business company; d) dispose waste that already meet the quality standards. Government and non-profit organization issued various policies to reduce global warming effects and to stabilize climate. Retailers respond to the packaging waste reduction. Initiatives from consumers can be manifested in: a) making their home green, i.e.: using household appliances with energy efficient and reducing carbon emissions by using public transportation ; b) reverse supply chain, i.e.: collecting things that have been used in certain places such as retailers for the remanufacture [1].

Implementation of green supply chain management gives impact to the effectively closed loop supply chain (CLSC) [2]. In the CLSC, goods are delivered from manufacturers to the customers and also from the customers back to the manufacturers for remanufacturing. Many CLSC papers have been presented in the literature. Savaskan et al. [3] studied CLSC which involved 3 options for collecting products, i.e. manufacturer, retailer, and third party logistics. In decentralization system, they found that the agent who is closer to the customers is the most effective for used product collecting process. Chung et al. [4] studied about optimal policy for a CLSC which is considered multi

echelons. They showed that there was significant increase in the joint profit among the supplier, manufacturer, third-party recycle dealer and retailer when the integrated policy is implemented. Karakayali et al. [5] analyzed the decentralized collection and processing of end-of–life products. They showed that a collector driven channel would be preferred by the OEM to increase the collection rate when the end of life products is homogenous.Shi et al. [6] studied the optimal production planning for a multi-product closed loop system with uncertain demand and return. The results show that the fluctuation of product demand gives the great impacts to the production and the used product acquisition policies.

In this study, we aim to build the conceptual framework and to model the CLSC which involves 3 echelon levels, i.e.: manufacturer, distributor, and retailer. The collection of used product is done by centralized and decentralized systems. It is expected that the profit in each level and the return rate of used product can be maximized through this proposed closed loop supply chain. It can give managerial insight for decision makers who involve 3 echelons in their business model.

The remaining parts of this paper are organized as follows. Conceptual framework of CLSC is given in section 2. Notations and assumptions are described in section 3. Proposed mathematical models are given in section 4. Finally, conclusions are summarized in section 5.

2. Conceptual Framework of CLSC

In this paper, there are 4 proposed conceptual frameworks, i.e.: a) centralize collecting process at manufacturer, and decentralize collecting process at: b) distributor, c) distributor and retailer, and d) retailer.

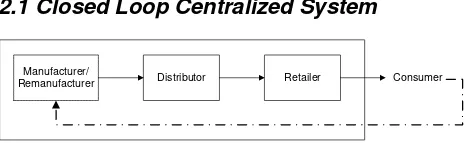

2.1 Closed Loop Centralized System

Manufacturer/

Remanufacturer Distributor Retailer Consumer

Figure 1: Closed Loop Centralized System

In Figure 1, the collecting process of used product is centralized at manufacturer. Manufacturer could process the used product to turn into new product by adding some process facilities in order for saving the material. However consumers should send the used product by their self to the manufacturer for remanufacturing.

Closed-Loop Supply Chain Model

Closed Loop Supply Chain Model for Centralized and Decentralized System

Figure 2: Closed Loop Decentralized System at Distributor

In Figure 2, the collecting process of used product is decentralized at distributors. In this framework, manufacturer recognizes her distributors. This could simplify the transportation network and trigger selling new products and collecting the used products at the distributor level.

2.3 Closed Loop Decentralized System (at

Figure 3: Closed Loop Decentralized System at Distributor & Retailer

In Figure 3, the collecting process of used product is decentralized at distributors and retailers. Retailers get involved in the collection of used products because retailers face directly with the end of user. In this framework, distributor recognizes his retailers. This still could simplify the transportation network and trigger selling new products and also collecting the used products more at the retailer level. It is proposed that there is investment cost sharing between distributor and retailer, so that they gain more benefit by this collaboration.

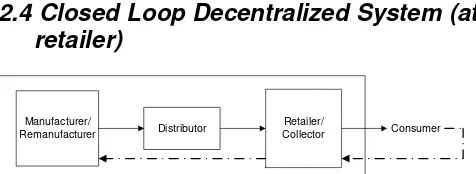

2.4 Closed Loop Decentralized System (at

retailer)

Manufacturer/

Remanufacturer Distributor

Retailer/

Collector Consumer

Figure 4: Closed Loop Decentralized System at Retailer

In Figure 4, the collecting process of used product is decentralized at retailers. There might be more efficient network for used product directly to the manufacturer. The network is chosen starting from the retailer because the retailer has closer position to the consumers. It is expected that it will give great impact to the collecting process of used product and demand of new product.

3. Assumptions & Notations

The following assumptions are used in this paper:

If The quality of used product/return product is the same

The product is just one item/homogeneous product

The unit cost of remanufacturing an used product is smaller than the unit cost for manufacturing a new product (Crf < Cmf)

The return rate of used product from consumers is in the

range [0, 1]

There is unequal costs of collection because of collecting positions and economic of scales

There is a fixed payment, A, for end consumers who return a used product by retailer, distributor, or directly manufacturer. It is hoped that all consumers will return a used product because of supported environment.

Consider 3 echelons SC and model a multilateral monopoly between manufacturer, distributor, and retailer.

In all models of supply chain, manufacturer has the power to access information at the level of retailers and distributors and lead the Stackelberg game.

The single period setting is considered in all models in which many used products have been generated from the previous period.

Company already incorporates the process of remanufacturing used products into the whole production process, so the company can process a new product derived from raw materials or part or all of these used products.

The following notations are used in this paper:

λD(p) : Total number of units used product which is returned by consumers

λ : Return rate of used product from consumers [0, 1]

D(p) : Demand for new product as function of product price

A : Fixed payment given to consumers for their returned a used product by manufacturer, distributor, or retailer

PR : The retail selling price of product in the market

PD : The distributor selling price of product

Cmf : Cost of manufacturing a new product

Crf : Cost of remanufacturing a used product

B : the unit transfer price of a returned product from retailer to the distributor (determined by manufacturer)

C : the unit transfer price of a returned product from distributor to the manufacturer (determined by manufacturer)

X : the unit transfer price of a returned product from retailer to the manufacturer (determined by manufacturer)

WM : the wholesale price from manufacturer level

I : Promotion/invest cost, � = �

4.1 Manufacturer Collecting (Model M)

Manufacturer set the wholesale price by herself because she is a Stackelberg leader. We begin by profit function at retailer and distributor level. The profit function at distributor level is in Eq. (1).

�� = �� ��− = − �� ��− (1)

International Conference on IML 2011

�� = +

(2)

The profit function at retailer level is in Eq. (3).

�� = �� ��− �� = − �� ��− �� (3)

Substituting Eq. (2) into Eq. (3) and deriving it to �� gives the optimal price at retailer level:

�� = +

(4)

The profit function at manufacturer level is in Eq. (5).

� = [ − ��+ � △] − � − �

= − [ − ��+ � △] − �

− � −

(5)

The first order derivation of Eq. (5) gives the simultaneously optimal solutions for wholesale price and return rate as:

∗ = ( ��− △ − �) + (6)

�∗ = △ − − ∗ (7)

4.2 Distributor Collecting (Model D)

The profit function at distributor level is in Eq. (8).

��� = �� ��− + � �� − � −

� ��

= − �� ��− + � − �� −

� − � − ��

(8)

The first order derivation of Eq. (8) gives the simultaneously optimal solutions for distributor price and return rate as:

�∗�= ( − � − ) + (9)

�∗�= − �∗� − (10)

Given �∗�and �∗�, the profit function at manufacturer level is in Eq. (11)

Substituting �∗� into Eq. (11) and deriving it to gives the optimal wholesale price as:

∗ =

+

− ∗ △ − − (12)

The profit function at retailer level is in Eq. (13).

��� = �� ��− �⋆� = − �� ��− �⋆� (13)

Substituting �∗� into Eq. (13) and deriving it to �� gives the optimal price at retailer level as:

�∗�={ ( − � − )} + (14)

4.3 Distributor & Retailer Collecting (Model

DR)

The profit function at retailer level is in Eq. (15).

���� = �� ��− �� + � �� − � −

� ��

= − �� ��− �� + � − �� −

� − � − ��

(15)

The first order derivation of Eq. (15) gives the simultaneously optimal solutions for retailer price and return rate as:

�∗�= +��−� − (16)

�∗�= − − �∗� (17)

Given �∗�and �∗�, the profit function at distributor level is in Eq. (18).

���� = �⋆� ��− + �⋆� �⋆� − � −

�⋆� �⋆�

= − �⋆� �

�− + �⋆� −

�⋆� − �⋆� − �⋆� − �⋆�

(18)

The profit function at manufacturer level is in Eq. (19).

��� =

�⋆� [ −

��+ �⋆�△] − �⋆� �⋆�

= − �⋆� [ −

��+ �⋆�△]

− �⋆� − �⋆�

(19)

4.4 Retailer Collecting (Model R)

The profit function at retailer level is in Eq. (20).

The first order derivation of Eq. (20) gives the simultaneously optimal solutions for retailer price and return rate as:

�� = �⋆� [ −

��+ �⋆�△] − �⋆� �⋆�

= − �⋆� [ −

��+ �⋆�△] −

�⋆� − �⋆�

(11)

���= �� ��− �� + � �� − �

− � ��

= − �� ��− �� + � − ��

Closed Loop Supply Chain Model for Centralized and Decentralized System

�∗�=��+ ⁄ + � − (21)

�∗�= − ��

−

(22)

Given �∗�, the profit function at distributor level is in Eq. (23).

���= �⋆� ��−

= − �⋆� �

�−

(23)

Substituting �∗� into Eq. (23) and deriving it to �� gives the optimal distributor price as:

�∗�= + − � − (24)

Given �∗�and �∗�, the profit function at manufacturer level is in Eq. (25)

Substituting ∗ into Eq. (25) and deriving it to gives the optimal wholesale price as:

∗ = + ��− △ − { − �

�

− }

+� −

(26)

5. Conclusion and Future Work

Conceptual frameworks and mathematics models which are involved manufacturer, distributor, and retailer for centralized and decentralized used product collecting system have been built in this paper. The analysis of conceptual frameworks can be used for the decision makers on how to implement it in the real world. The mathematics model and its optimal values can provide managerial insights to closed loop supply chain researchers. Future works can be followed by applying case study.

References

[1] R. Basu and J. N. Wright, "Green Supply Chain," Total Supply Chain Management, pp. 245-257, 2008.

[2] Q. Zhu, J. Sarkis, and K.-h. Lai, "Green Supply Chain Management Implications for "Closing the Loop"," Transportation Research Part E, vol. 44, pp. 1-18, 2008.

[3] R. C. Savaskan, S. Bhattacharya, and L. N. V. Wassenhove, "Closed-Loop Supply Chain Models with Product Remanufacturing," Management Science, vol. 50, pp. 239-252, 2004.

[4] S.-L. Chung, H.-M. Wee, and P.-C. Yang, "Optimal Policy for a Closed-Loop Supply Chain Inventory System with

Remanufacturing," Mathematical and Computer Modelling, vol. 48, pp. 867-881, 2008.

[5] I. Karakayali, H. Emir-Farinas, and E. Ackali, "An Analysis of Decentralized Collection and Processing of End-of-Life Products," Journal of Operations Management, vol. 25, pp. 1161-1183, 2007.

[6] J. Shi, G. Zhang, and J. Sha, "Optimal Production Planning for a Multi-Product Closed Loop System with Uncertain Demand and Return," Computers and Operations Research, vol. 38, pp. 641-650, 2011.

��= �⋆� [ −

��+ �⋆�△]

− �⋆� �⋆�

= − �⋆� [ −

��+ �⋆�△]