STUDI OPTIMASI OFFSHORE PIPELINE

REPLACEMENT DI AREA BEKAPAI TOTAL E&P

INDONESIE, BALIKPAPAN

Jurusan Teknik Kelautan

Fakultas Teknologi Kelautan

INSTITUT TEKNOLOGI SEPULUH NOPEMBER

SURABAYA

2011

Oleh :

Ema Sapitri 4307 100 112

Dosen Pembimbing:

1. Ir. Hasan Ikhwani, M. Sc

2. Prof. Ir. Daniel M. Rosyid, Ph. D Mentor :

1. Faisal Akbar, HS ENG/CST/PWK TEPI 2. Hendri Sudjianto, PE ENG/CST/PWK TEPI

OUTLINE

LATAR BELAKANG

PERUMUSAN MASALAH

DATA OFFSHORE PIPELINE

BATASAN MASALAH

METODOLOGI PENELITIAN

ANALISIS & PEMBAHASAN

KESIMPULAN

MANFAAT

LATAR BELAKANG

• Offshore pipeline replacement

merupakan aktivitas rutin di

perusahaan migas (design life)

• Selama ini di TOTAL E&P

Indonesie, Balikpapan menggunakan

studi komparasi

utk melakukan

desain pipa

• Perlu adanya studi optimasi

• Flowrate (produksi) pipa di area

bekapai dari platform BK ke BP-1

menurun

• Perlu adanya laying analisis

LOKASI

REPLACEMENT

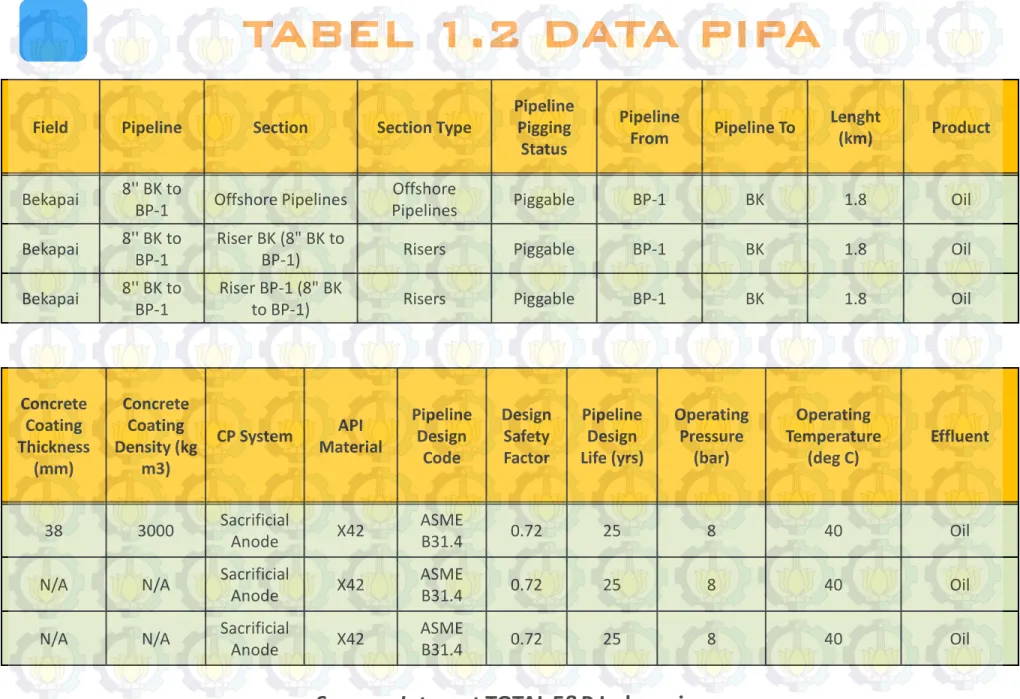

TABEL 1.2 DATA PIPA

Source : Intranet TOTAL E&P Indonesie

Field Pipeline Section Section Type

Pipeline Pigging Status Pipeline From Pipeline To Lenght (km) Product Bekapai 8'' BK to BP-1 Offshore Pipelines Offshore

Pipelines Piggable BP-1 BK 1.8 Oil

Bekapai 8'' BK to BP-1

Riser BK (8" BK to

BP-1) Risers Piggable BP-1 BK 1.8 Oil

Bekapai 8'' BK to BP-1

Riser BP-1 (8" BK

to BP-1) Risers Piggable BP-1 BK 1.8 Oil

Concrete Coating Thickness (mm) Concrete Coating Density (kg m3) CP System API Material Pipeline Design Code Design Safety Factor Pipeline Design Life (yrs) Operating Pressure (bar) Operating Temperature (deg C) Effluent 38 3000 Sacrificial Anode X42 ASME B31.4 0.72 25 8 40 Oil

N/A N/A Sacrificial

Anode X42

ASME

B31.4 0.72 25 8 40 Oil

N/A N/A Sacrificial

Anode X42

ASME

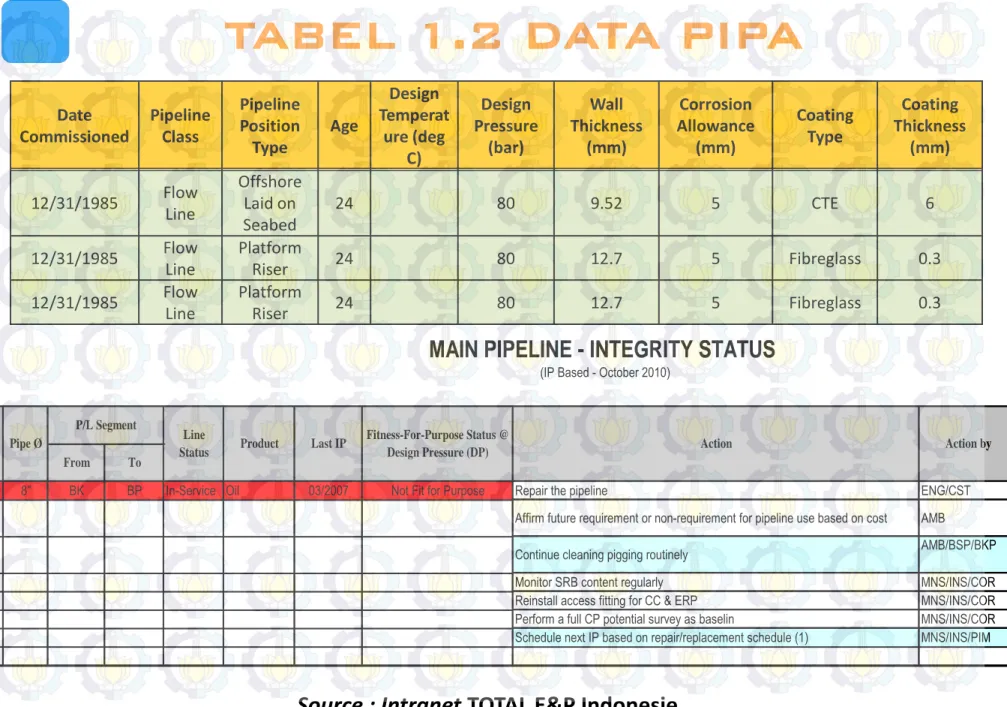

TABEL 1.2 DATA PIPA

Source : Intranet TOTAL E&P Indonesie

Date Commissioned Pipeline Class Pipeline Position Type Age Design Temperat ure (deg C) Design Pressure (bar) Wall Thickness (mm) Corrosion Allowance (mm) Coating Type Coating Thickness (mm) 12/31/1985 Flow Line Offshore Laid on Seabed 24 80 9.52 5 CTE 6 12/31/1985 Flow Line Platform Riser 24 80 12.7 5 Fibreglass 0.3 12/31/1985 Flow Line Platform Riser 24 80 12.7 5 Fibreglass 0.3

9 8" BK BP In-Service Oil 03/2007 Not Fit for Purpose Repair the pipeline ENG/CST Affirm future requirement or non-requirement for pipeline use based on cost AMB

Continue cleaning pigging routinely AMB/BSP/BKP Monitor SRB content regularly MNS/INS/COR Reinstall access fitting for CC & ERP MNS/INS/COR Perform a full CP potential survey as baselin MNS/INS/COR Schedule next IP based on repair/replacement schedule (1) MNS/INS/PIM

Line Status From Action by Fitness-For-Purpose Status @ Design Pressure (DP) To

Product Last IP Action

MAIN PIPELINE - INTEGRITY STATUS (IP Based - October 2010)

No Pipe Ø

DATA PIPA

DATA PRODUKSI/PROSES PIPA

Source : DEPT.ENG/PRO TOTAL E&P Indonesie Production/Process Data

Oil Flow Rate, Qo = 70.4 STBD = 395.30 ft3/day

Gas Flow Rate, Qg = 4.1 MMScfd = 4189.91 ft3/day

Water Flow Rate, Qw = 100 bwpd = 561.50 ft3/day

Operating Pressure, P = 8 bar = 116.03 psi

Maximum Operating Temperature, T = 40 0C = 563.67 0R

Design Pressure, Pd = 80 bar = 1160.30 psi

ENVIRONMENT DATA

PERUMUSAN MASALAH

1. Bagaimana meminimalkan berat pipa untuk mendapatkan

diamater luar pipa (Do) dan tebal pipa (t) yang optimum

dengan mempertimbangkan constraint (kendala) berikut :

1. Stress Analysis, yang menjadi constraint adalah

hoop stress.

2. Buckling Analysis, yang meliputi : system collapse

check dan propagation buckling.

2. Bagaimana stabilitas pipa di dasar laut (on bottom

stability : vertical stability dan lateral stability) ?

3. Berapa panjang bentangan pipa yang diijinkan dan

panjang bentangan kritis pipa (free span analysis) ?

4. Bagimana laying analysis dan persentase yield stress

yang dihasilkan dari pemodelan OFFPIPE ?

5. Berapa dimensi diameter luar pipa (Do) dan tebal pipa (t)

yang optimum untuk dapat dioperasikan di BK-BP 1

MANFAAT

1. Memberikan

manfaat

dan

kontribusi nyata bagi perusahaan

TOTAL E&P Indonesie, Balikpapan

khususnya dan instansi terkait

atau lembaga penelitian serta

masyarakat pada umumnya.

2. Memberikan informasi / data

sebagai referensi bagi perusahaan

migas, lembaga penelitian atau

instansi lain yang terkait maupun

pihak independent.

BATASAN MASALAH

1. Studi ini dilakukan di perusahaan TOTAL E&P Indonesie, Balikpapan, yaitu studi optimasi pada pipa lepas pantai di area Bekapai yang menghubungkan platform BK ke BP1 dengan diameter original 8 inchi.

2. Variabel optimasi Diameter luar pipa (Do) dan tebal pipa (t)

3. Constraint yang dipertimbangkan stress analysis : hoop stress, buckling analysis : system collapse dan propagation buckling.

4. Parameter desain yang diperhitungkan meliputi : perhitungan on bottom stability, stress analysis, buckling analysis dan free span analysis.

5. Metode instalasi yang digunakan metode S-lay (pipa di area interfield offshore, d = 35 m).

6. Laying analysis dengan bantuan pemodelan software OFFFPIPE. 7. Pipeline design codes yang digunakan :

• ASME B 31.4 2009 (Main Code)

• DNV RP-F109 2010 – OBS (On Bottom Stability) • DNV RP-F110 2007 – Global Buckling

• DNV RP-F105 2006 – Free Span

• DNV RP-E305 1988 – OBS (On Bottom Stability)

• DNV OS-F101 2010 – SPS (Submarine Pipeline System) • API RP-14E 1991 – Line Sizing

8. GS dari TOTAL yang digunakan :

• GS EP COR 220 2010 -- Corrosion

METODOLOGI PENELITIAN

ANALISIS & PEMBAHASAN

Kalkulasi Dimensi Awal Pipa

Erosional velocity

Dengan :

V

e=

kecapatan aliran tererosi, feet/second

c

=

konstanta empiris

ρm

=

mixture density dari gas/liquid pada tekanan dan suhu tertenti, lbs/ft

3P

=

Tekanan pada saat beroperasi, psia

S

l=

Spesific gravity cairan (Air = 1, gunakan garvitasi rata-rata untuk

campuran air hidrokarbon) pada kondisi standart

R

=

Ratio gas/liquid, ft

3/barrel pada kondisi standart

T

=

Suhu pada saat beroperasi,

0R

S

g=

Spesific gravity gas (udara=1) pada kondisi standart

Z

=

Faktor kompresibilitas gas

A

=

Minimum pipe cross-sectional area yang dibutuhkan, in

2/1000

ANALISIS & PEMBAHASAN

Kalkulasi Dimensi Awal Pipa

Pressure Drop

Dengan :

Q

g=

Laju aliran gas, million cubic feet/day (14,7 psia dan 60

0F)

S

g=

Spesific gravity gas (udara = 1)

Q

l=

Laju aliran cairan, barrels/day

S

l=

Spesific gravity cairan (air = 1)

=

Penurunan tekanan, psi/100 feet

d

i=

Diameter dalam pipa, inchi

=

Density gas/cairan pada aliran tekanan dan suhu tertentu, lbs/ft

3ANALISIS & PEMBAHASAN

Kalkulasi Dimensi Awal Pipa

Reference : API RP-14 E-1991 (Line Sizing)

Dari erosional velocity criteria dihasilkan minimum pipe inside diameter

sebesar 2.525 in

Penurunan tekanan (pressure drop) sebesar 1.18 psi/100 ft.

Karena diameter terlalu kecil, sehingga dipilih 4.5 in & 6.625 in dalam

mechanical design

Diameter original 8 in tetap dipakai sebagai batasan maksimum dalam

optimasi

ANALISIS & PEMBAHASAN

Kalkulasi Tebal Pipa (Pipe Wall Thickness)

Reference : ASME B31.4 2009

Dengan :

Do

=

Diamater luar pipa, in (mm)

F

1=

Faktor desain hoop stress (Tabel 3.9)

P

e=

Tekanan eksternal pipa, psi

S

h=

Hoop stress, psi

S

y=

Specified Minimum Yield Strength, psi

T

=

Tebal pipa nominal, in (mm)

Pe

=

Tekanan Eksternal pipa, psi

w

=

Massa jenis air, kg/m

3h

=

Kedalaman air laut, m

ANALISIS & PEMBAHASAN

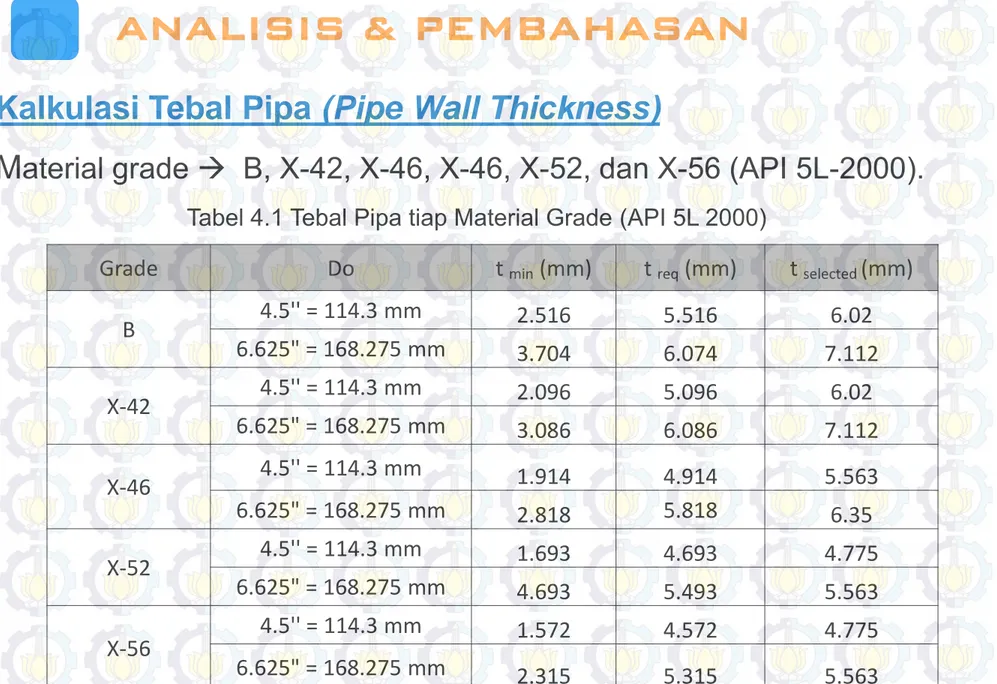

Kalkulasi Tebal Pipa (Pipe Wall Thickness)

M

aterial grade B, X-42, X-46, X-46, X-52, dan X-56 (API 5L-2000).

Tabel 4.1 Tebal Pipa tiap Material Grade (API 5L 2000)

Grade Do t min(mm) t req(mm) t selected (mm)

B 4.5'' = 114.3 mm 2.516 5.516 6.02 6.625" = 168.275 mm 3.704 6.074 7.112 X-42 4.5'' = 114.3 mm 2.096 5.096 6.02 6.625" = 168.275 mm 3.086 6.086 7.112 X-46 4.5'' = 114.3 mm 1.914 4.914 5.563 6.625" = 168.275 mm 2.818 5.818 6.35 X-52 4.5'' = 114.3 mm 1.693 4.693 4.775 6.625" = 168.275 mm 4.693 5.493 5.563 X-56 4.5'' = 114.3 mm 1.572 4.572 4.775 6.625" = 168.275 mm 2.315 5.315 5.563

ANALISIS & PEMBAHASAN

Analisis Tegangan (Stress Analysis)

Hoop Stress

Dengan :

Do

=

Diamater luar pipa, in (mm)

F

1=

Faktor desain hoop stress (Tabel 3.9)

P

e=

Tekanan eksternal pipa, psi

S

h=

Hoop stress, psi

S

y=

Specified Minimum Yield Strength, psi

T

=

Tebal pipa nominal, in (mm)

Longitudinal Stress & Combined Stress

Dengan :

F2 & F

3=

Faktor desain combined stress (Tabel 2.9)

Sl

=

Longitudinal Stress

ANALISIS & PEMBAHASAN

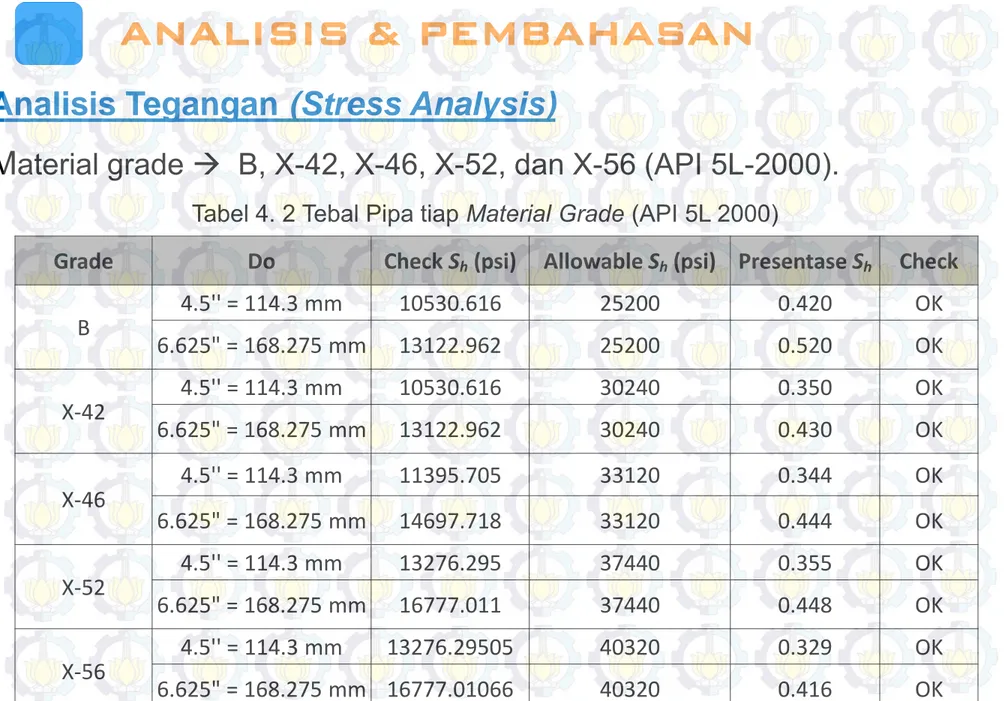

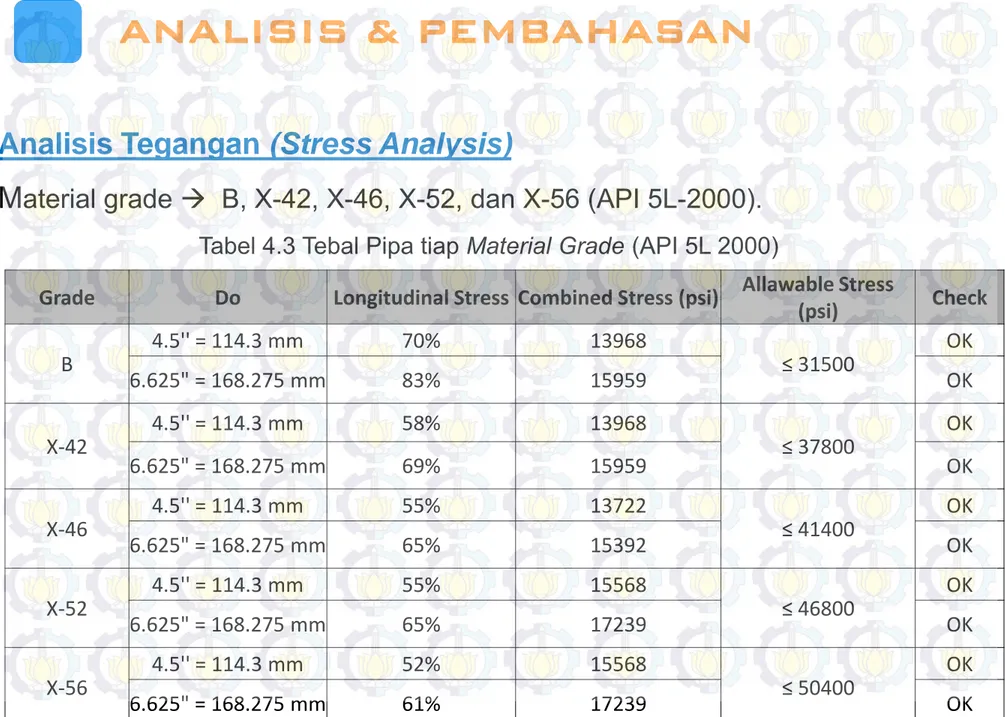

Analisis Tegangan (Stress Analysis)

M

aterial grade B, X-42, X-46, X-52, dan X-56 (API 5L-2000).

Tabel 4. 2 Tebal Pipa tiap Material Grade (API 5L 2000)

Grade Do Check Sh (psi) Allowable Sh (psi) Presentase Sh Check

B 4.5'' = 114.3 mm 10530.616 25200 0.420 OK 6.625" = 168.275 mm 13122.962 25200 0.520 OK X-42 4.5'' = 114.3 mm 10530.616 30240 0.350 OK 6.625" = 168.275 mm 13122.962 30240 0.430 OK X-46 4.5'' = 114.3 mm 11395.705 33120 0.344 OK 6.625" = 168.275 mm 14697.718 33120 0.444 OK X-52 4.5'' = 114.3 mm 13276.295 37440 0.355 OK 6.625" = 168.275 mm 16777.011 37440 0.448 OK X-56 4.5'' = 114.3 mm 13276.29505 40320 0.329 OK 6.625" = 168.275 mm 16777.01066 40320 0.416 OK

ANALISIS & PEMBAHASAN

Analisis Tegangan (Stress Analysis)

M

aterial grade B, X-42, X-46, X-52, dan X-56 (API 5L-2000).

Tabel 4.3 Tebal Pipa tiap Material Grade (API 5L 2000)

Grade Do Longitudinal Stress Combined Stress (psi) Allawable Stress

(psi) Check B 4.5'' = 114.3 mm 70% 13968 ≤ 31500 OK 6.625" = 168.275 mm 83% 15959 OK X-42 4.5'' = 114.3 mm 58% 13968 ≤ 37800 OK 6.625" = 168.275 mm 69% 15959 OK X-46 4.5'' = 114.3 mm 55% 13722 ≤ 41400 OK 6.625" = 168.275 mm 65% 15392 OK X-52 4.5'' = 114.3 mm 55% 15568 ≤ 46800 OK 6.625" = 168.275 mm 65% 17239 OK X-56 4.5'' = 114.3 mm 52% 15568 ≤ 50400 OK 6.625" = 168.275 mm 61% 17239 OK

ANALISIS & PEMBAHASAN

Analisis Buckling (Buckling Analysis)

Karakteristik Collapse

Dengan :

P

c=

Tekanan collapse, psi

P

el=

Tekanan collapse elastic, psi

P

p=

Tekanan collapse plastis, psi

f

o=

Ovality

D

=

Diameter luar, in

t

2=

Tebal minimum dinding pipa

E

=

Modulus young (30022811,71 psi)

α

fab=

Faktor toleransi fabrikasi

ANALISIS & PEMBAHASAN

Analisis Buckling (Buckling Analysis)

System Collapse Check

Dengan :

p min = Tekanan internal minimum, psi

= Material resitance factor, (Tabel 2.14) = Safety class resistance factor

Pc = Tekanan collapse, psi

Propagation Buckling

Kondisi terjadinya propagation buckling jika :

Ppr < Pin < Pe Dengan :

Pe = tekanan eksternal, psi

Ppr = Tekanan perambatan buckling, psi

fy = Tegangan yield, psi

D = Diameter luar pipa, in

t2 = Tebal minimum dinding pipa, in

αfab = Faktor fabrikasi

Ppr

Pe

m sc

ANALISIS & PEMBAHASAN

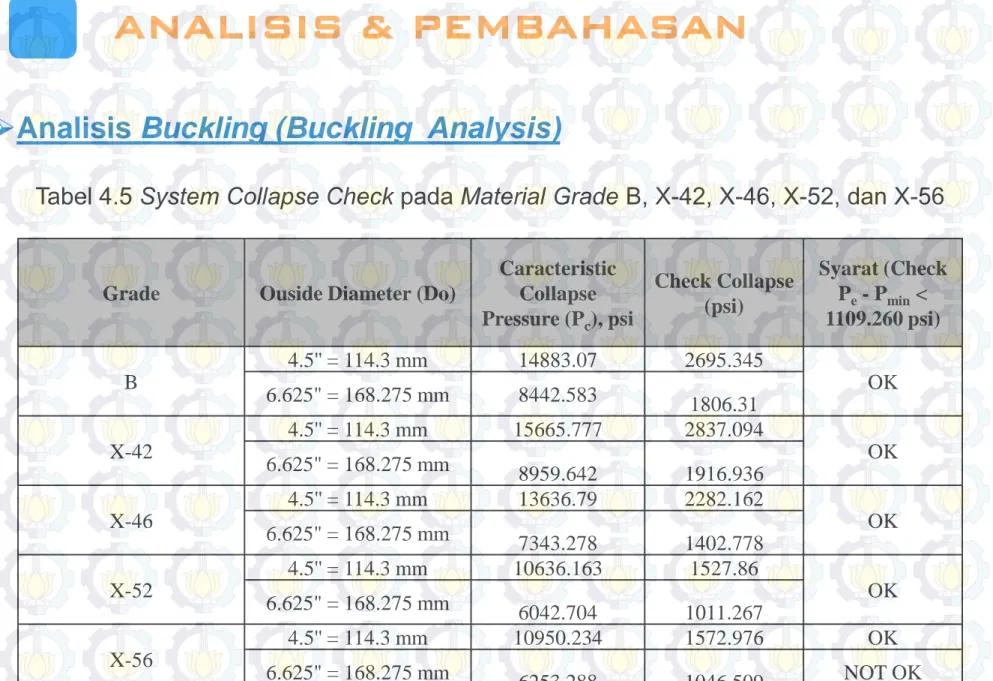

Analisis Buckling (Buckling Analysis)

Tabel 4.5 System Collapse Check pada Material Grade B, X-42, X-46, X-52, dan X-56

Grade Ouside Diameter (Do)

Caracteristic Collapse Pressure (Pc), psi Check Collapse (psi) Syarat (Check Pe- Pmin< 1109.260 psi) B 4.5'' = 114.3 mm 14883.07 2695.345 OK 6.625" = 168.275 mm 8442.583 1806.31 X-42 4.5'' = 114.3 mm 15665.777 2837.094 OK 6.625" = 168.275 mm 8959.642 1916.936 X-46 4.5'' = 114.3 mm 13636.79 2282.162 OK 6.625" = 168.275 mm 7343.278 1402.778 X-52 4.5'' = 114.3 mm 10636.163 1527.86 OK 6.625" = 168.275 mm 6042.704 1011.267 X-56 4.5'' = 114.3 mm 10950.234 1572.976 OK 6.625" = 168.275 mm 6253.288 1046.509 NOT OK

ANALISIS & PEMBAHASAN

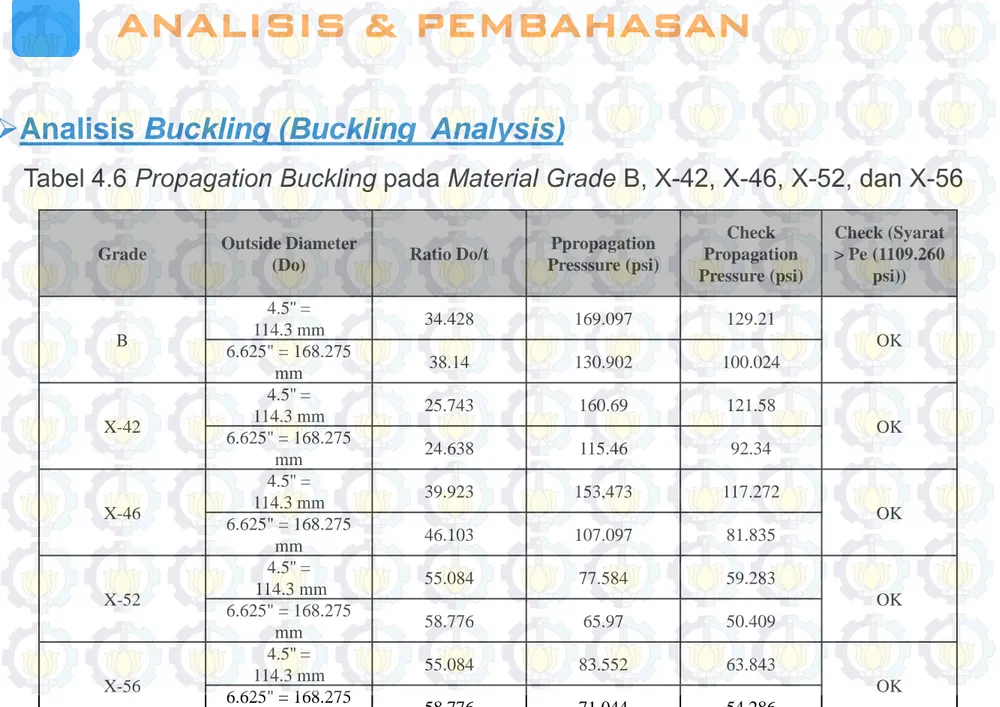

Analisis Buckling (Buckling Analysis)

Tabel 4.6 Propagation Buckling pada Material Grade B, X-42, X-46, X-52, dan X-56

Grade Outside Diameter

(Do) Ratio Do/t

Ppropagation Presssure (psi) Check Propagation Pressure (psi) Check (Syarat > Pe (1109.260 psi)) B 4.5'' = 114.3 mm 34.428 169.097 129.21 OK 6.625" = 168.275 mm 38.14 130.902 100.024 X-42 4.5'' = 114.3 mm 25.743 160.69 121.58 OK 6.625" = 168.275 mm 24.638 115.46 92.34 X-46 4.5'' = 114.3 mm 39.923 153,473 117.272 OK 6.625" = 168.275 mm 46.103 107.097 81.835 X-52 4.5'' = 114.3 mm 55.084 77.584 59.283 OK 6.625" = 168.275 mm 58.776 65.97 50.409 X-56 4.5'' = 114.3 mm 55.084 83.552 63.843 OK 6.625" = 168.275 mm 58.776 71.044 54.286

ANALISIS & PEMBAHASAN

Stabilitas Pipa (On Bottom Stability)

Stabilitas Vertikal (DNV-RP-F109 2010)

Dengan :

=

Safety factor

b

=

Gaya apung pipa tiap satuan panjang, N/m

w

s=

Berat pipa yang terpendam tiap satuan panjang, N/m

s

g=

Pipe spesific density

Gaya apung pipa tiap satuan panjang (b) dan

berat pipa yang tenggelam tiap satuan panjang (ws)dapat dihitung dengan formula berikut :

Dengan :

=

Masa jenis air laut (1025 kg/m

3)

g

=

Percepatan gravitasi (9,81 m/s

2)

ANALISIS & PEMBAHASAN

On Bottom Stability

Stabilitas Lateral (DNV-RP-F109 2010)

Dengan :

=

Faktor keselamatan (safety factor)

=

Beban hidrodinamis pada arah horisontal, N/m

=

Beban hidrodinamis pada arah vertikal, N/m

=

Tahanan tanah pasif, N/m

=

Koefisien gesek

=

berat pipa yang tenggelam tiap satuan panjang, N/m

Dari kalkulasi tidak pipa diameter 4.5 in dan 6.625 in masih stabil secara

vertikal maupun lateral

ANALISIS & PEMBAHASAN

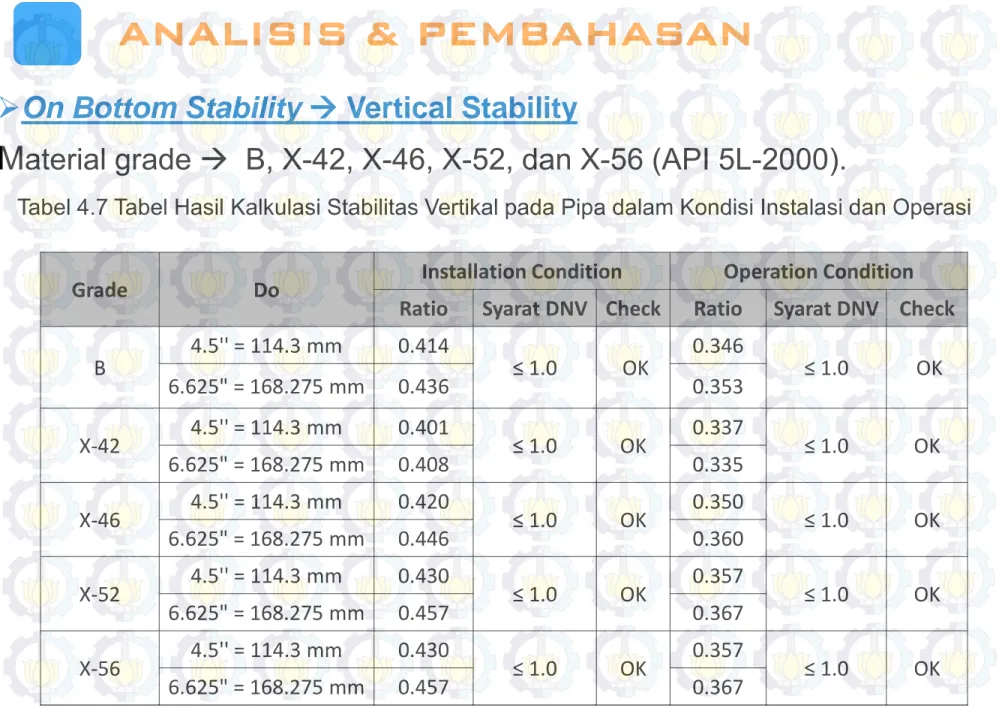

On Bottom Stability Vertical Stability

M

aterial grade B, X-42, X-46, X-52, dan X-56 (API 5L-2000).

Tabel 4.7 Tabel Hasil Kalkulasi Stabilitas Vertikal pada Pipa dalam Kondisi Instalasi dan Operasi

Grade Do Installation Condition Operation Condition Ratio Syarat DNV Check Ratio Syarat DNV Check

B 4.5'' = 114.3 mm 0.414 ≤ 1.0 OK 0.346 ≤ 1.0 OK 6.625" = 168.275 mm 0.436 0.353 X-42 4.5'' = 114.3 mm 0.401 ≤ 1.0 OK 0.337 ≤ 1.0 OK 6.625" = 168.275 mm 0.408 0.335 X-46 4.5'' = 114.3 mm 0.420 ≤ 1.0 OK 0.350 ≤ 1.0 OK 6.625" = 168.275 mm 0.446 0.360 X-52 4.5'' = 114.3 mm 0.430 ≤ 1.0 OK 0.357 ≤ 1.0 OK 6.625" = 168.275 mm 0.457 0.367 X-56 4.5'' = 114.3 mm 0.430 ≤ 1.0 OK 0.357 ≤ 1.0 OK 6.625" = 168.275 mm 0.457 0.367

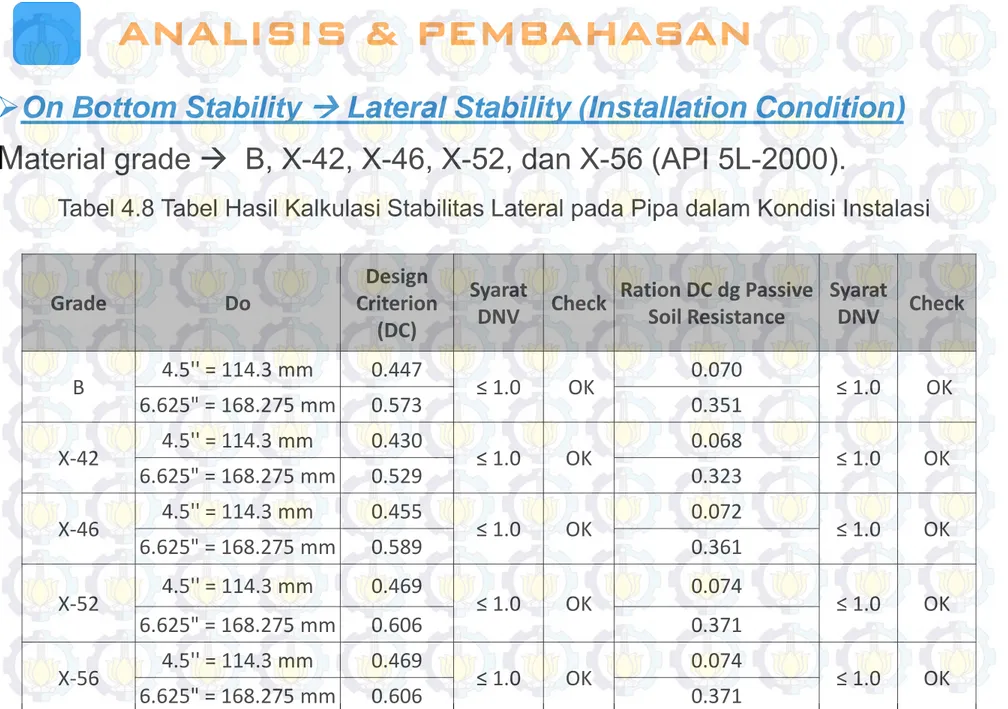

ANALISIS & PEMBAHASAN

On Bottom Stability

Lateral Stability (Installation Condition)

M

aterial grade B, X-42, X-46, X-52, dan X-56 (API 5L-2000).

Tabel 4.8 Tabel Hasil Kalkulasi Stabilitas Lateral pada Pipa dalam Kondisi Instalasi

Grade Do Design Criterion (DC) Syarat DNV Check Ration DC dg Passive Soil Resistance Syarat DNV Check B 4.5'' = 114.3 mm 0.447 ≤ 1.0 OK 0.070 ≤ 1.0 OK 6.625" = 168.275 mm 0.573 0.351 X-42 4.5'' = 114.3 mm 0.430 ≤ 1.0 OK 0.068 ≤ 1.0 OK 6.625" = 168.275 mm 0.529 0.323 X-46 4.5'' = 114.3 mm 0.455 ≤ 1.0 OK 0.072 ≤ 1.0 OK 6.625" = 168.275 mm 0.589 0.361 X-52 4.5'' = 114.3 mm 0.469 ≤ 1.0 OK 0.074 ≤ 1.0 OK 6.625" = 168.275 mm 0.606 0.371 X-56 4.5'' = 114.3 mm 0.469 ≤ 1.0 OK 0.074 ≤ 1.0 OK 6.625" = 168.275 mm 0.606 0.371

ANALISIS & PEMBAHASAN

On Bottom Stability

Lateral Stability (Oparation Condition)

M

aterial grade B, X-42, X-46, X-46, X-52, dan X-56 (API 5L-2000).

Tabel 4.9 Tabel Hasil Kalkulasi Stabilitas Lateral pada Pipa dalam Kondisi Operasi

Grade Do Design Criterion (DC) Syarat DNV Check Ration DC dg Passive Soil Resistance Syarat DNV Check B 4.5'' = 114.3 mm 0.700 ≤ 1.0 OK 0.112 ≤ 1.0 OK 6.625" = 168.275 mm 0.860 0.465 X-42 4.5'' = 114.3 mm 0.700 ≤ 1.0 OK 0.112 ≤ 1.0 OK 6.625" = 168.275 mm 0.860 0.465 X-46 4.5'' = 114.3 mm 0.712 ≤ 1.0 OK 0.113 ≤ 1.0 OK 6.625" = 168.275 mm 0.884 0.478 X-52 4.5'' = 114.3 mm 0.773 ≤ 1.0 OK 0.117 ≤ 1.0 OK 6.625" = 168.275 mm 0.911 0.493 X-56 4.5'' = 114.3 mm 0.773 ≤ 1.0 OK 0.117 ≤ 1.0 OK 6.625" = 168.275 mm 0.911 0.493

ANALISIS & PEMBAHASAN

Free Span Analysis

M

aterial grade B, X-42, X-46, X-52, dan X-56 (API 5L-2000).

Tabel 4. 10 Tabel Hasil Kalkulasi Free Span Analysis pada Material Grade B, X42, X46, X52, dan X56

Grade Outside Diameter (Do)

Span Lenght,

Ls (m)

The Critical Span Lenght for

In-Line Motion,

LC-IL (m)

The Critical Span Lenght for

Cross Flow Motion 1, LC-CF (m) Check Ls < LC-IL & LC-CF B 6.625" = 168.275 4.5'' = 114.3 mm 8,819 12,617 17,889 OK mm 12,430 14,000 27,832 X42 6.625" = 168.275 4.5'' = 114.3 mm 8,775 12,554 17,800 OK mm 12,305 13,859 27,552 X46 6.625" = 168.275 4.5'' = 114.3 mm 8,692 12,436 17,632 OK mm 11,855 13,703 27,241 X52 6.625" = 168.275 4.5'' = 114.3 mm 8,443 12,080 17,128 OK mm 11,855 13,352 26,544 X56 6.625" = 168.275 4.5'' = 114.3 mm 8,443 12,080 17,128 OK mm 11,855 13,352 26,544

ANALISIS & PEMBAHASAN

Laying Analysis

Analisis laying pipa pada saat instalasi dilakukan dengan bantuan software

OFFPIPE untuk pengecekan terhadap besarnya yield stress maksimum yang

terjadi baik pada daerah over bend maupun sag bend.

Berikut tabel bending stress maksimum yang dijinkan pada daerah over bend

maupun sag bend.

Tabel 8. Maximum Allowable Bending Stress (Referensi : Laying Analysis PT. Dwi Satu Mustika Bumi)

LAYING ANALISYS

Gambaran Proses Laying Analysis

LAYING ANALISYS

Laying Analysis Hasil Pemodelan Software OFFPIPE

Material grade B, X-42, X-46, X-52, dan X-56 (API 5L-2000).

Tabel 4.10 Persentase Yield Stress sebagai Output dari (Hasil Pemodelan) software OFFPIPE

Grade Do Percent Yield Stress (Overbend) Max. Allowable Yield Stress (Overbend) Check Percent Yield Stress (Sagbend) Max. Allawable Yield Stress (Sagbend) Check B 4.5'' = 114.3 mm 103.08% ≥ 85% NOT OK 49.28% ≤ 70% OK 6.625" = 168.275 mm 311.01% 70.06% NOT OK X-42 4.5'' = 114.3 mm 81.64% ≤ 85% OK 44.88% ≤ 70% OK 6.625" = 168.275 mm 82.10% 65.54% X-46 4.5'' = 114.3 mm 74.66% ≤ 85% OK 40.97% ≤ 70% OK 6.625" = 168.275 mm 78.64% 65.11% X-52 4.5'' = 114.3 mm 66.04% ≤ 85% OK 36.24% ≤ 70% OK 6.625" = 168.275 mm 67.82% 59.77% X-56 4.5'' = 114.3 mm 72.60% ≤ 85% OK 33.34% ≤ 70% OK 6.625" = 168.275 mm 66.75% 49.41%

PEMODELAN OPTIMASI

Pemodelan optimasi hanya dilakukan pada material grade B, 42, dan

X-52 , karena :

Mengacu ke desain lama (diameter in, material grade X-42)

Material grade B tidak lolos laying analysis pada pemodelan OFFPIPE

Material grade X-56 terlalu tinggi grade-nya

Material Grade X-52

Tabel 4.11 Data Diameter dan Tebal Pipa Material Grade X-52

Hoop Stress (Psi) System Collapse (Psi) Propagation Buckling (Psi)

D (in) t (in) D (in) t (in) D (in) t (in)

4,5 0,0755 4,5 0,139 4,5 0,183

6,625 0,11 6,625 0,25 6,625 0,22

PEMODELAN OPTIMASI

Kemudian akan diplot dalam grafik untuk mencari titik optimum.

.

Gambar 4. 3 Grafik Optimasi tiap Constraint pada Material Grade X52

y = 0,0001x2+ 0,0147x + 0,0066 y = -0,0409x2+ 0,5072x - 1,3153 y = -0,0002x2+ 0,0196x + 0,0988 0 0,05 0,1 0,15 0,2 0,25 0,3 0 1 2 3 4 5 6 7 8 9 T eb al Pi p a (i n )

Diameter Luar Pipa (in)

Grafik Optimasi tiap Constraint (Psi)

Hoop Stress X-52 System Collapse X-52 Propagation Buckling X-52 Poly. (Hoop Stress X-52) Poly. (System Collapse X-52) Poly. (System Collapse X-52) Poly. (Propagation Buckling X-52)

PEMODELAN OPTIMASI

Sehingga titik optimumnya adalah : (7.2 , 0.1132).

Hal ini berarti pada material grade X-42 diameter luar pipa yang

optimum adalah 7.2 in dan tebal pipanya optimum adalah 0.1132 in.

Dengan berat pipa = 36.029 lb/in.

Karena diameter luar ini tidak disediakan dalam schedule pipa

(API 5L 2000), maka dipilih yang mendekati diameter luar dan tebal

pipa dalam schedule pipa, yaitu diameter luar pipa 8.625 in dan

tebal pipa 0.125 in.

KESIMPULAN

1. Meminimalkan berat pipa dilakukan dengan bantuan Microsoft Excel dengan

membuat persamaan objektif tiap constraint dengan memplotkan 2 variabel

diameter luar dan tebal pipa pada grafik.

2. Pipa dengan Ø 4.5” dan Ø 6.625” pada masing-masing material grade (B,

X-42, X-46, X-52, dan X-56 masih stabil baik kondisi instalasi maupun operasi.

3. Panjang bentangan pipa masih memenuhi (kurang dari) panjang bentangan

kritis pipa.

4. Laying analysis (pemodelan OFFPIPE) menunjukkan bahwa pada material

grade B dengan Ø 4.5” dan Ø 6.625” persen yield stress-nya melebihi

maximum yield stress yang diijinkan, sementara pada material grade pada

X-42, X-46, X-52, dan X-56 masih memenuhi.

5. Diameter pipa (Do) dan tebal pipa (t) yang optimum untuk dapat dioperasikan di

BK-BP 1 platform area Bekapai adalah Ø 8.625’’, dan tebal 0.125 in dengan

berat minimal pipa 36.029 lb/in dan material grade X-52.

DAFTAR PUSTAKA

API RP-14E. 1991. Recommended Practice for Design and Installation of Offshore Production Platform

Piping System. Northwest Washington, DC. American.

API Spec-5L. 2000. Spesification for Line Pipe. American Petroleum Institute, American.

ASME B31-4. 2009. Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids. The American Society of Mechanical Engineers, American.

Bai,Y. 2001. Pipeline and Risers. Oxford. Elsevier Science Ltd.

DNV OS-F101. 2010. Submarine Pipeline Systems. Det Norske Veritas, American.

DNV RP-F109. 2010. On-Bottom Stability Design of Submarine Pipelines. Det Norske Veritas, American. DNV RP-F110. 2007. Global Buckling of Submarine Pipelines Structural Design Due to High

Temperature/High Pressure. Det Norske Veritas, American

DNV RP-F105. 2006. Free Spanning Pipelines. Det Norske Veritas, American

DNV RP-E305. 1988. On-Bottom Stability Design of Submarine Pipelines Det Norske Veritas, American. GS EP COR 220. 2011. Corrosion, Three Layer Polyethylene External Coating for Pipelines. TOTAL E&P

Indonesie.

Guo, B., Song, S., Chacko, J., dan Ghalambor, A. 2005. Offshore Pipeline. Elsiver, United State. Halliwell, R. (1986). An Introduction to Offshore Pipeline. University College, Cork.

Intranet TOTAL E&P Indonesie.

Mouselli, A. 1981. Offshore Pipeline Design, Analysis and Methods. PenWell Books, Oklahoma.

Rosyid, D.M. 2009. Optimasi, Teknik Pengambilan Keputusan secara Kuantitatif. ITS Press, Surabaya.

Tahrizi, A. 2010. Report of On the Job Training Bekapai Pipeline Analysis BKP-SNP 12” Pipeline

Depressurisation Study and BK-BP1 New Pipeline Design, Balikpapan.