M2 S2

P.Gargini

Attacking the Red Brick Walls of the

International Technology Roadmap

for Semiconductors

(ITRS)

Dr. Paolo Gargini

Chairman ITRS

2001 Edition

M2 S2

P.Gargini

What is the ITRS?

• A consensus reference document with a 15

year outlook on the requirements of the

semiconductor industry

– Provides a

reference

document for Equipment,

Materials and Software

Suppliers

on the

Needs

of the

Semiconductor Industry and on

Possible Solutions

M2 S2

P.Gargini

Technology Hierarchy

•

Technology Needs

•

Possible Solutions

•

Detailed Solutions

•

Implementation

Example:

•

Reduce Signal Propagation Delay of

Interconnections

•

Metal Potential Solution: Cu Metal

Dielectric Potential Solution: Low K

Dielectric

•

Use: Cu CVD Seed Layer + Cu

Plating+ CMP+Low K CVD

•

Establish Supplier Infrastructure

Tech

nol

ogy

Ro

adm

ap

Do

ma

in

Tech

nol

ogy

Im

ple

me

nta

tion

Do

ma

M2 S2

P.Gargini

Roadmap Editions

Japan

Korea

Europe

Taiwan

USA

2002ITRS

Update

2001ITRS

2000ITRS

Update

1999ITRS

1998ITRS

Update

1997NTRS

1994NTRS

1992NTRS

http://public.itrs.net

2001 Edition

1991

M2 S2

P.Gargini

P. Gargini

International and Domestic Timing

Domestic

Domestic

3Q

USA

Europe

2Q

1Q

Domestic

Domestic

Region A

Region B

Time

4Q

Korea

Japan

Taiwan

1999, 2002

2000

2001

M2 S2

P.Gargini

M2 S2

P.Gargini

Mission of ITRS

IRC

Technology Needs

Potential Solutions

in

near & long term

ITWG

ITWG

•

Policy

•

Goals

•

Schedule

•

Coordination

among ITWGs

•

Coordination

among

Associations

TWG

TWG

TWG

TWG

TWG

ESIA

KSIA

SIA

TSIA

JEITA

(STRJ)

Design

Test

M2 S2

P.Gargini

International Technology Working

Groups

• Assembly & Packaging

• Design

• Factory Integration

• Front End Process

• Interconnect

• Lithography

• PIDS, Emerging Devices

• Test

ITWG

• Environment, Safety,

Health

• Metrology

• Modeling and Simulation

• Yield Enhancement

Cross ITWG

M2 S2

P.Gargini

2001 Edition

ITRS Framework

Factory Integration

Yield Enhancement

QFP

BGA

PGA

Printed Wiring Board

Assembly

Test

Wells

Source / Drain

- Extension

Isolation

Channel

Contacts

FEP

Lithography

PIDS

Metrology Modeling

Starting Material

Interconnect

Design

M2 S2

P.Gargini

Chapters of ITRS 2001

Glossary

ORTC

12 ITWGs : Design to Modeling & Simulation

- Scope

- Difficult Challenges

- Technology Requirement

- Potential Solutions

System Drivers

Difficult Challenges

Grand Challenges

Introduction

M2 S2

P.Gargini

Contact Information for the ITRS

¾

For general questions or information regarding ITRS publications and

public forums visit the ITRS web site

http://public.itrs.net

[

note that

there is no “www” in our web site address

.].

To order a Roadmap through email, use the ITRS email address

or access the ITRS web site.

¾

Other questions or comments?

call

Linda Wilson

ITRS Information Manager

512.356.3605

Sarah Mangum

ITRS Webmaster

512.356.3558

2001 ITRS Book and CD sales

•

$25 for CDs, $35 for CDs shipped outside the U.S.A

•

$50 for Books, $65 for ITRS books shipped outside the U.S.A.

M2 S2

P.Gargini

Composition of the Technology

Working Group (ITWG) in 2001

TWG Members by Regions

TWG Members by Affiliations

23%

54%

22%

Consortia /

Research Inst. /

University

193

Equipment /

Materials

Suppliers 185

Chip Makers

445

1%

Other

10

Europe

68

Taiwan

161

8%

19%

8%

Korea

64

Japan

222

USA

324

M2 S2

P.Gargini

DuPont Company

Silicon Valley Group, Inc

ION Systems

M+W Zandar

Nanya Technology Co.

Compaq Computer Corp

Asyst Technologies, Inc.

Sumitomo Sitix Corp.

Varian

Air Products & Chemicals

Etec Systems, Inc.

n-Line Corporation

K&S

Applied Materials

KLA-Tencor

Tokyo Electron America

SEMI

Novellus Systems

Wacker Siltronic Corp.

Agilent Technologies

Winbond Electronics Corp.

Axcelis Technologies, Inc.

Komatsu Silicon

MEMC

Canon Inc.

CamLine

Ebara

Rohm

Sanyo

FSI International

Genus

Ibis Technology

Okmetic Ltd.

SiGen

Soitec

Tokin Corp

BOC Edwards

Nortel Networks

Cadence

Intransa

UBC

ATMI

Cabot Corporation

E4 Technologies

Praxair, Inc.

SONY

URS Corporation

Dow Chemical

Micronix

ASM Lithography

Nikon Corporation

Photronics, Inc.

Shipley Company, Inc.

Episil Technologies

Metrology Edge

Therma-Wave

Oki Electric Ind. Co., Ltd.

M2 S2

P.Gargini

DETAILED SOLUTIONS

And

M2 S2

P.Gargini

From Strategy to Implementation

From Strategy to Implementation

Technology Needs

Possible Solutions

ITRS

Implementation

Suppliers

IC Makers

OEM

Suppliers

Consortia

M2 S2

P.Gargini

Use of ITRS as a Global Planning Tool

Use of ITRS as a Global Planning Tool

Internal

Internal

R&D

R&D

Consortia

Consortia

Suppliers

Suppliers

External

External

R&D

R&D

SRC

Natl Lab

ISMT

IMEC

LETI

MEDEA

MIRAI

ASET

M2 S2

P.Gargini

PR

JR

i

Consortia Locations

IRAI

IRAI

M2 S2

P.Gargini

M2 S2

P.Gargini

R

R

®

®

'68 '70

'72 '74

'76 '78

'80 '82

'84 '86

'88 '90

'92 '94

'96 '98

'00 '02

10

17

10

16

10

15

10

14

10

13

10

12

10

11

10

10

10

9

Units

Source: WSTS/Dataquest/Intel, 8/02

Source: WSTS/Dataquest/Intel, 8/02

10

18

Transistors Shipped per

Transistors Shipped per

Year

M2 S2

P.Gargini

Worldwide Semiconductor

R

R

®

®

1

10

100

1000

'68 ’70 '72 '74 '76 '78 '80 '82 '84 '86 '88 ’90 '92 '94 '96 '98 '00 '02

1

10

100

1000

'68 ’70 '72 '74 '76 '78 '80 '82 '84 '86 '88 ’90 '92 '94 '96 '98 '00 '02

$B

$B

Source: Intel/WSTS, 8/02

Source: Intel/WSTS, 8/02

Worldwide Semiconductor

Revenues

M2 S2

P.Gargini

R

R

®

®

Average Transistor Price

Average Transistor Price

by Year

by Year

0.0000001

0.000001

0.00001

0.0001

0.001

0.01

0.1

1

10

'68 '70 '72 '74 '76 '78 '80 '82 '84 '86 '88 '90 '92 '94 '96 '98 '00 '02

$

$

Source: WSTS/Dataquest/Intel, 8/02

M2 S2

P.Gargini

ITRS GUIDING PRINCIPLE

50% TRANSISTOR AREA READUCION

GENERATION TO GENERATION

50%

M2 S2

P.Gargini

Pentium

®

Processor

Pentium

®

Pro

Processor

Pentium

®

II

Processor

Pentium

®

III

Processor

Pentium

®

4

Processor

0.8µ

0.6µ

0.35µ

0.25µ

0.18µ

0.13µ

Intel’s Process Technology

Basic Feature Size in microns

M2 S2

P.Gargini

DEFINITIONS

And

M2 S2

P.Gargini

Technology Node Definition

One half of the smallest pitch in the technology,

Typically represented by the first metal layer

M2 S2

P.Gargini

Half Pitch (=Pitch/2) Definition

(Typical

DRAM)

Metal

Pitch

(Typical

MPU/ASIC)

Poly

M2 S2

P.Gargini

MOS Transistor

Scaling

(1974 to present)

S=0.7

[0.5x per 2 nodes]

M2 S2

P.Gargini

ITRS

ITRS

P.Gargini

10

1994 NTRS Roadmap

Year: 95 96 97 98 99 00 01 02 03 04 05 06 07

1/2 pitch* 350 250 180 130

100

*

Dimensions for minimum half pitch and isolated line in nm

Source: National Technology Roadmap for Semiconductors

M2 S2

P.Gargini

100

70

50

35

25

WAS

IS

91

64

45

31

22

X

130

0.7

90

0.7

65

0.7

45

0.7

32

0.7

90

65

45

32

22

Actual

Technology Nodes (nm)

M2 S2

P.Gargini

1999 ITRS Timing

Year of Production

2001

2002

2003

2004

2005

2006

2007

DRAM ½ Pitch

130

115

100

90

80

70

65

MPU/ASIC ½ Pitch

150

130

107

90

80

70

65

MPU Pr Gate Length

90

75

53

45

40

35

MPU Ph Gate Length

53

45

37

32

28

25

65

65

MPU Pr Gate Length

1999

180

2000 2001

2002

130

2003 2004

2005

100

DRAM ½ Pitch (nm)

165 150

120 110

MPU Gate Length (nm)

140

120

85-90

80

MPU / ASIC ½ Pitch (nm)

230

210

180

160

145

130

115

ASIC Gate Length (nm)

180

165

150

130

120

110

100

180

130

100

100

70

65

65

100

Year of Production

2001 ITRS Timing

-1

-2

-4

M2 S2

P.Gargini

Production Ramp-up Model and Technology Node

Volume (Parts/Month)

1K

10K

100K

Months

0

-24

1M

10M

100M

Alpha

Tool

12

24

-12

Development

Production

Beta

Tool

Production

Tool

First

Conf.

Papers

First Two

Companies

Reaching

Production

2

Volume (Wafers/Month)

20

200

2K

20K

200K

M2 S2

P.Gargini

Innovation

1.4X

Technology

2X

Manufacturing

1.4X

3-year cycle

(1977~1995)

M2 S2

P.Gargini

1980

1990

2000

2010

2020

100

1000

10,000

10

DRAM Chip Size Trend

38mm

2

75mm

2

150mm

2

300mm

2

1.4X/3-years

1M

1G

1T

~2

~2

X die growth in 6 years

X die growth in 6 years

Ch

ip

S

iz

e

(m

m

2

)

Max Litho Field

(4X)

M2 S2

P.Gargini

Innovation

1.4X

Technology

2X

Manufacturing

1.4X

3-year -> 2-year cycle

(~1995-2010)

3-year cycle

4X/3 Years

1.4X

->

1.0X

M2 S2

P.Gargini

1980

1990

2000

2010

2020

100

1000

10,000

10

DRAM Chip Size Trend

38mm

2

75mm

2

150mm

2

300mm

2

800mm

2

1.4X/3-years

1M

1G

1T

~2

~2

X die growth in 6 years

X die growth in 6 years

Ch

ip

S

iz

e

(m

m

M2 S2

P.Gargini

TABLES

And

M2 S2

P.Gargini

Table’s Structure

• All tables are divided in two parts:

–

Near Term

• Six year outlook (e.g., 2001-2007)

• All values are reported on a yearly basis

–

Long Term

M2 S2

P.Gargini

Tables’ Color Scheme

• A new category will be introduced starting with

2002ITRS Update

Solutions Exist

White

Yellow

Solutions Being Pursued

No Known Solutions

M2 S2

P.Gargini

YEAR

TECHNOLOGY NODE

2008 70 nm 2011 50 nm 2014 35 nm DRIVER

[1] DRAM ½ Pitch (nm) 70 50 35

[2] MPU Ga t e Lengt h (nm) 45 32 22

[3] MPU / ASIC ½ Pitch (nm) 80 55 40

[4] ASIC Ga t e Lengt h (nm) 70 50 35

[5] Minimum logic Vdd (V) (desktop) 0.6–0.9 0.5–0.6 0.3–0.6 M Gate

[6] Tox equivalent (nm) 0.8–1.2 0.6–0.8 0.5–0.6 M Gate [7] Nominal I

on at 25 °C (µA/µm) [NMOS/PMOS]

high performance

750/350 750/350 750/350 M Gate [8] Maximum Ioff at 25 °C (nA/µm)

(For minimum L device) high-performance

40 80 160 M Gate [9] Gate delay metric CV/I (ps) high-performance 3.7 2.6 2.4

[10]Percent static power reduction necessary due to innovative circuit/system design

91 97 98 M Gate M & A ½ [11]Nominal I

on at 25 °C (µA/µm) [NMOS/PMOS] low power

490/230 490/230 490/230 A Gate [12]Maximum I

off at 25 °C (pA/µm) (For minimum L device) low power

40 80 160 A Gate [13]Gate delay metric CV/I (ps) low power 5.6 4.5 3.7

[14]Percent static power reduction necessary due to innovative circuit/system design

95 98 99 A Gate M & A ½ [15]VT 3s variation (±mV) (For minimum L device) 25 17 17 M Gate

[16]S/D extension junction depth, nominal (µm) 0.02–0.028 0.013–0.02 0.01–0.014 M Gate

Work in Progress -- - Not for Publication

Interconnect/7-8-99/CCase

DRAM Long Term Requirements

Y

EAR OFI

NTRO DUCTION“

TE CHNOLOGY NODE”

2 008

70 nm

2 011

50 nm

2 014

35 nm

DRAM pitch

70

50

35

Number of metal levels

4

4

4

Contact A/R – stacked capacitor

10.5

12

13.5

Lo cal wiring pitch (nm) non-contacted

140

100

70

Specific co ntact resistance (

Ω

-cm

2)

8 E-8

3 E-8

2 E-8

Specific via resistance (

Ω

-cm

2)

6E-10

3E-10

1.5E-10

Metal effective resistivity (

µΩ

-cm)

2.2

2.2

2.2

Interlevel metal insulator - effective dielectric constant (k)

2.5 - 3.0

2.0 - 2.5

2.0 - 2.3

Solutions Exist Solutions B eing Pursue d No Known Solutions

No Known Solutions to A/R

High

κ

materials may provide some relief

Table 28a Memory and Logic Technology Requirements—Near Term

Y

EART

ECHNOLOGYN

ODE1999

180 nm

2000 2001

2002

130 nm

2003 2004

2005

100 nm

D

RIVER1

DRAM ½ Pitch (nm)

180

165

150

130

120

110

100

2

MPU Gate Length (nm)

140

120

100

85

80

70

65

3

MPU / ASIC ½ (nm)

230

210

180

160

145

130

115

4

ASIC Gate Length (nm)

180

165

150

130

120

110

100

5 Minimum logic V

dd (V) (desktop)

1.5–1.8 1.5–1.8 1.2–1.5 1.2–1.5 1.2–1.5 0.9–1.2 0.9–1.2M GATE

6 Tox equivalent (nm) 1.9–2.5 1.9–2.5 1.5–1.9 1.5–1.9 1.5–1.9 1.2–1.51.0–1.5M GATE

7 Nominal Ion at 25 °C (µA/µm) [NMOS/PMOS] high-performance

750/350 750/35 0

750/350 750/350 750/35 0

750/350 750/350M GATE

8 Maximum Ioff at 25 °C (nA/µm) (For minimum L device) high performance

5 7 8 10 13 16 20 M GATE

9 Gate delay metric CV/I (ps) high-performance 11 9.4 8.6 7.3 6.9 6.1 5.7

10Percent static power reduction necessary due to innovative circuit/system design

0

33 48 55 71 77 81

M GATE

M & A ½ 11Nominal Ion at 25 °C (µA/µm)

[NMOS/PMOS] low power

490/230 490/23 0

490/230 490/230 490/23 0

490/230 490/230A GATE

12Maximum I

off at 25 °C (pA/µm)

(For minimum L device) low power

5 7 8 10 13 16 20 A GATE

13Gate delay metric CV/I (ps) low power 18 16 13 11.2 10.7 8.8 8.2

14Percent static power reduction necessary due to innovative circuit/system design

0 36 55 65 80 85 88 A GATE

M & A ½ 15VT 3σ variation (±mV)

(For minimum L device)

50 50 42 42 42 33 33 M GATE

16S/D extension junction depth, nominal (µm) 0.045– 0.07 0.04 – 0.065 0.04– 0.06 0.03–0.05 0.03– 0.048 0.028– 0.044 0.025– 0.04 M GATE

Solutions Exist Solutions Being Pursued No Known Solutions

Table 46b MPU Interconnect Technology Requirements—Long Term

Y

EART

ECHNOLOGYN

ODE2008

70 nm

2011

50 nm

2014

35 nm

MPU ½ pitch

80

55

40

MPU gate length (nm)

45

32

22

Number of metal levels 9 9–10 10

Number of optional levels – ground planes/capacitors 3 4 4

Jmax (A/cm2

)—wire (at 105°C) 2.1E6 3.7E6 4.6E6

Imax (mA)—via (at 105°C) 0.18 0.16 0.11

Local wiring pitch (nm) 185 130 95

Local A/R (for Cu) 1.9 2.1 2.3

Cu local dishing (nm), 5% × height 9 7 5

Intermediate wiring pitch (nm) 240 165 115

Intermediate wiring dual damascene A/R (Cu wire/via) 2.5/2.3 2.7/2.4 2.9/2.5

Cu intermediate wiring dishing (nm), 15 micron wide wire, 10% × height

30 22 17

Dielectric erosion (nm), intermediate wiring 0 0 0

Minimum global wiring pitch (nm) 390 275 190

Global wiring dual damascene A/R (Cu wire/via) 2.8/2.9 2.9/3.0 3.0/3.1

Cu global wiring dishing (nm), 15 micron wide wire, 10% × height

55 38 29

Conductor effective resistivity (µΩ-cm) Cu wiring 1.8 <1.8 <1.8

Barrier/cladding thickness (nm) 0 0 0

Interlevel metal insulator—effective dielectric constant (κ) 1.5 <1.5 <1.5

Solutions Exist Solutions Being Pursued No Known Solutions

DRAM interconnect technology

Table 46a MPU Interconnect Technology Requirements—Near Term

YEAR

TECHNOLOGY NODE

1999 180 nm

2000 2001 2002 130 nm

2003 2004 200 100

MPU ½ pitch 230 210 180 160 145 130 11

MPU gate length (nm) 140 120 100 85 80 70 65

Number of metal levels 6-7 6–7 7 7–8 8 8 8–

Number of optional levels— ground planes/capacitors

0 0 0 2 2 2 2

Jmax (A/cm2

)—wire (at 105°C) 5.8E5 7.1E5 8.0E5 9.6E5 1.1E6 1.3E6 1.4

Imax (mA)—via (at 105°C) 0.36 0.36 0.33 0.32 0.29 0.27 0.2

Local wiring pitch (nm) 500 450 405 365 330 295 26

Local wiring A/R (for Al) 2 2 2.1 2.1 2.2 ** **

Local wiring A/R (for Cu) 1.4 1.4 1.5 1.5 1.6 1.6 1.

Cu local dishing (nm), 5% × height 18 16 15 14 13 12 11

Intermediate wiring pitch (nm) 640 575 520 465 420 375 34

Intermediate wiring A/R (Al) 2.2 2.3 2.4 2.5 2.6 ** **

Intermediate wiring dual damascene A/R (Cu wire/via)

2.0/2.1 2.1/2.1 2.2/2.1 2.2/2.1 2.2/2.2 2.3/2.2 2.4/

Cu intermediate dishing (nm), 15 micron wide wire, 10% × height

64 60 57 51 46 43 41

Dielectric erosion (nm), intermediate wiring, 50% areal density, 10% × height

64 60 57 51 46 43 41

Minimum global wiring pitch (nm) 1050 945 850 765 690 620 56

Global wiring A/R (Al) 2 2.1 2.2 2.3 2.4 ** **

Global wiring dual damascene A/R (Cu wire/via)

2.2/2.4 2.3/2.6 2.4/2.7 2.5/2.7 2.6/2.8 2.7/2.8 2.7/

Cu global wiring dishing (nm), 15 micron wide wire, 10% × height

116 109 102 95 90 84 76

Conductor effective resistivity (µΩ-cm) Al wiring

3.3 3.3 3.3 3.3 3.3 ** **

Conductor effective resistivity (µΩ-cm) Cu wiring*

2.2 2.2 2.2 2.2 2.2 2.2 2.

Barrier/cladding thickness (for Cu wiring) (nm)***

17 16 14 13 12 11 10

Interlevel metal insulator —effective dielectric constant (κ)

3.5–4.0 3.5–4.0 2.7–3.5 2.7–3.5 2.2–2.7 2.2–2.7 1.6–

* Assumes a conformal barrier/ nucleation layer ** This technology is not expected to extend to this node

*** Calculated for a conformal layer in local wiring to meet minimum effective conductor resistivity

Solutions Exist Solutions Being Pursued No Known Solutions

Work in Progress --- Not for Publ ication

Interconnect/7-8-99/CCase

DRAM Short Term Requirements

YEA R OF INTRODUCTION “TECHNOLOGY NODE”

199 9 180 nm

200 0 2001 2002 130 nm

2003 2004 200 5 100 nm

DRAM p itch 18 0 16 5 15 0 13 0 12 0 11 0 10 0 Number of metal levels 3 3 3 3-4 4 4 4 Contact A/R – s tacked

capacitor

6.3 6.7 7.1 7.5 8.0 8.5 9.0

Local wiring pitch (nm) non-co ntacted

36 0 33 0 30 0 26 0 24 0 21 0 20 0

Specific co ntact resistance (Ω-cm2

)

6E-7 3E-7 2E-7

Specific via resistance (Ω-cm2

)

7E-9 2E-9 1E-9

Metal effective resistivity (µΩ-cm)

3.3 3.3 3.3 3.3 3.3 3.3 2.2

Interlevel metal insulator -effective dielectric cons tant (κ)

4.1 4.1 4.1 3. 0 - 4.1 3. 0 - 4.1 3. 0 - 4.1 2. 5 - 3.0

Solutions Exist Solutions Being Pursue d No Known Solutions

Table 28a Memory and Logic Technology Requirements—Near Term

Y

EART

ECHNOLOGYN

ODE1999

180 nm

2000 2001

2002

130 nm

2003 2004

2005

100 nm

D

RIVER1

DRAM ½ Pitch (nm)

180

165

150

130

120

110

100

2

MPU Gate Length (nm)

140

120

100

85

80

70

65

3

MPU / ASIC ½ (nm)

230

210

180

160

145

130

115

4

ASIC Gate Length (nm)

180

165

150

130

120

110

100

5Minimum logic V

dd (V) (desktop)

1.5–1.8 1.5–1.8 1.2–1.5 1.2–1.5 1.2–1.5 0.9–1.2 0.9–1.2M GATE

6Tox equivalent (nm) 1.9–2.5 1.9–2.5 1.5–1.9 1.5–1.9 1.5–1.9 1.2–1.5 1.0–1.5M GATE

7Nominal Ion at 25 °C (µA/µm) [NMOS/PMOS] high-performance

750/350 750/35 0

750/350 750/350 750/35 0

750/350 750/350M GATE

8Maximum Ioff at 25 °C (nA/µm) (For minimum L device) high performance

5 7 8 10 13 16 20 M GATE

9 Gate delay metric CV/I (ps) high-performance 11 9.4 8.6 7.3 6.9 6.1 5.7

10Percent static power reduction necessary due to innovative circuit/system design

0

33 48 55 71 77 81

M GATE

M & A ½ 11Nominal Ion at 25 °C (µA/µm)

[NMOS/PMOS] low power

490/230 490/23 0

490/230 490/230 490/23 0

490/230 490/230A GATE

12Maximum I

off at 25 °C (pA/µm)

(For minimum L device) low power

5 7 8 10 13 16 20 A GATE

13Gate delay metric CV/I (ps) low power 18 16 13 11.2 10.7 8.8 8.2

14Percent static power reduction necessary due to innovative circuit/system design

0 36 55 65 80 85 88 A GATE

M & A ½ 15VT 3σ variation (±mV)

(For minimum L device)

50 50 42 42 42 33 33 M GATE

16S/D extension junction depth, nominal (µm) 0.045– 0.07 0.04 – 0.065 0.04– 0.06 0.03–0.05 0.03– 0.048 0.028– 0.044 0.025– 0.04 M GATE

Solutions Exist Solutions Being Pursued No Known Solutions

YEAR

TECHNOLOGY NODE

2008 70 nm 2011 50 nm 2014 35 nm DRIVER

[1] DRAM ½ Pitch (nm) 70 50 35

[2] MPU Gat e Lengt h (nm) 45 32 22

[3] MPU / ASIC ½ Pitch (nm) 80 55 40

[4] ASIC Gat e Lengt h (nm) 70 50 35

[5] Minimum logic Vdd (V) (desktop) 0.6–0.9 0.5–0.6 0.3–0.6 M Gate

[6] Tox equivalent (nm) 0.8–1.2 0.6–0.8 0.5–0.6 M Gate [7] Nominal Ion at 25 °C (µA/µm) [NMOS/PMOS]

high performance

750/350 750/350 750/350 M Gate [8] Maximum Ioff at 25 °C (nA/µm)

(For minimum L device) high-performance

40 80 160 M Gate [9] Gate delay metric CV/I (ps) high-performance 3.7 2.6 2.4

[10]Percent static power reduction necessary due to innovative circuit/system design

91 97 98 M Gate M & A ½ [11]Nominal Ion at 25 °C (µA/µm) [NMOS/PMOS] low

power

490/230 490/230 490/230 A Gate [12]Maximum Ioff at 25 °C (pA/µm)

(For minimum L device) low power

40 80 160 A Gate [13]Gate delay metric CV/I (ps) low power 5.6 4.5 3.7

[14]Percent static power reduction necessary due to innovative circuit/system design

95 98 99 A Gate M & A ½ [15]VT 3s variation (±mV) (For minimum L device) 25 17 17 M Gate

[16]S/D extension junction depth, nominal (µm) 0.02–0.028 0.013–0.02 0.01–0.014 M Gate

Table 46a MPU Interconnect Technology Requirements—Near Term

YEAR

TECHNOLOGY NODE

1999 180 nm

2000 2001 2002 130 nm

2003 2004 200 100

MPU ½ pitch 230 210 180 160 145 130 11

MPU gate length (nm) 140 120 100 85 80 70 65

Number of metal levels 6-7 6–7 7 7–8 8 8 8–

Number of optional levels— ground planes/capacitors

0 0 0 2 2 2 2

Jmax (A/cm2

)—wire (at 105°C) 5.8E5 7.1E5 8.0E5 9.6E5 1.1E6 1.3E6 1.4

Imax (mA)—via (at 105°C) 0.36 0.36 0.33 0.32 0.29 0.27 0.2

Local wiring pitch (nm) 500 450 405 365 330 295 26

Local wiring A/R (for Al) 2 2 2.1 2.1 2.2 ** **

Local wiring A/R (for Cu) 1.4 1.4 1.5 1.5 1.6 1.6 1.

Cu local dishing (nm), 5% × height 18 16 15 14 13 12 11

Intermediate wiring pitch (nm) 640 575 520 465 420 375 34

Intermediate wiring A/R (Al) 2.2 2.3 2.4 2.5 2.6 ** **

Intermediate wiring dual damascene A/R (Cu wire/via)

2.0/2.1 2.1/2.1 2.2/2.1 2.2/2.1 2.2/2.2 2.3/2.2 2.4/

Cu intermediate dishing (nm), 15 micron wide wire, 10% × height

64 60 57 51 46 43 41

Dielectric erosion (nm), intermediate wiring, 50% areal density, 10% × height

64 60 57 51 46 43 41

Minimum global wiring pitch (nm) 1050 945 850 765 690 620 56

Global wiring A/R (Al) 2 2.1 2.2 2.3 2.4 ** **

Global wiring dual damascene A/R (Cu wire/via)

2.2/2.4 2.3/2.6 2.4/2.7 2.5/2.7 2.6/2.8 2.7/2.8 2.7/

Cu global wiring dishing (nm), 15 micron wide wire, 10% × height

116 109 102 95 90 84 76

Conductor effective resistivity (µΩ-cm) Al wiring

3.3 3.3 3.3 3.3 3.3 ** **

Conductor effective resistivity (µΩ-cm) Cu wiring*

2.2 2.2 2.2 2.2 2.2 2.2 2.

Barrier/cladding thickness (for Cu wiring) (nm)***

17 16 14 13 12 11 10

Interlevel metal insulator —effective dielectric constant (κ)

3.5–4.0 3.5–4.0 2.7–3.5 2.7–3.5 2.2–2.7 2.2–2.7 1.6–

* Assumes a conformal barrier/ nucleation layer ** This technology is not expected to extend to this node

*** Calculated for a conformal layer in local wiring to meet minimum effective conductor resistivity

Solutions Exist Solutions Being Pursued No Known Solutions

Table 46b MPU Interconnect Technology Requirements—Long Term

Y

EART

ECHNOLOGYN

ODE2008

70 nm

2011

50 nm

2014

35 nm

MPU ½ pitch

80

55

40

MPU gate length (nm)

45

32

22

Number of metal levels 9 9–10 10

Number of optional levels – ground planes/capacitors 3 4 4

Jmax (A/cm2)—wire (at 105°C) 2.1E6 3.7E6 4.6E6

Imax (mA)—via (at 105°C) 0.18 0.16 0.11

Local wiring pitch (nm) 185 130 95

Local A/R (for Cu) 1.9 2.1 2.3

Cu local dishing (nm), 5% × height 9 7 5

Intermediate wiring pitch (nm) 240 165 115

Intermediate wiring dual damascene A/R (Cu wire/via) 2.5/2.3 2.7/2.4 2.9/2.5

Cu intermediate wiring dishing (nm), 15 micron wide wire, 10% × height

30 22 17

Dielectric erosion (nm), intermediate wiring 0 0 0

Minimum global wiring pitch (nm) 390 275 190

Global wiring dual damascene A/R (Cu wire/via) 2.8/2.9 2.9/3.0 3.0/3.1

Cu global wiring dishing (nm), 15 micron wide wire, 10% × height

55 38 29

Conductor effective resistivity (µΩ-cm) Cu wiring 1.8 <1.8 <1.8

Barrier/cladding thickness (nm) 0 0 0

Interlevel metal insulator—effective dielectric constant (κ) 1.5 <1.5 <1.5

Solutions Exist Solutions Being Pursued No Known Solutions

DRAM interconnect technology

M2 S2

P.Gargini

What is a Red Brick Wall?

• The Red Brick Wall is not used in the ITRS

• The concept has been introduced in

presentations to separate and to highlight a

region in a table that is mostly “RED”

beyond a certain year

M2 S2

P.Gargini

Approaching a

“Red Brick Wall”

Challenges/Opportunities for Semiconductor R&D

1999 Results

Year of Production:

1999

2002 2005

2008

2011 2014

DRAM Half-Pitch [nm]:

180

130

100

70

50 35

Overlay Accuracy [nm]:

65

45

35

25

20

15

MPU Gate Length [nm]:

140

85-90

65

45

30-32

20-22

CD Control [nm]:

14

9

6

4

3

2

T

OX

(equivalent) [nm]:

1.9-2.5

1.5-1.9

1.0-1.5

0.8-1.2

0.6-0.8

0.5-0.6

Junction Depth [nm]:

42-70

25-43

20-33

16-26

11-19

8-13

Metal Cladding [nm]:

17

13

10

0

0

0

M2 S2

P.Gargini

25 nm

15nm

0

100

200

300

400

500

0

0.2

0.4

0.6

0.8

Drain Voltage (V)

Dr

ain Cur

re

nt (

µ

A/

µ

m)

Vg =0.8V

0.7V

0.6V

0.5V

0.4V

0.3V

Intel’s 15nm NMOS

M2 S2

P.Gargini

Year of Production:

2001

2003 2005

2007

2010 2016

DRAM Half-Pitch [nm]:

130

100

80

65

45 22

Overlay Accuracy [nm]:

46

35

28

23

18

9

MPU Gate Length [nm]:

90

65

45

35

25

13

CD Control [nm]:

8

5.5

3.9

3.1

2.2

1.1

T

OX

(equivalent) [nm]:

1.3-1.6

1.1-1.6

0.8-1.3

0.6-1.1

0.5-0.8

0.4-0.5

Junction Depth [nm]:

48-95

33-66

24-47

18-37

13-26

7-13

Metal Cladding [nm]:

16

12

9

7

5

2.5

Inter-Metal Dielectric

Κ:

3.0-3.6

3.0-3.6

2.6-3.1

2.3-2.7

2.1

1.8

“Red Brick Wall”

becoming permeable

Challenges/Opportunities for Semiconductor R&D

M2 S2

P.Gargini

Roadmap Acceleration and Deceleration

Year of Production:

1999

2002 2005

2008

2011 2014

DRAM Half-Pitch [nm]:

180

130

100 70

50

35

Overlay Accuracy [nm]:

65

45 35

25

20

15

MPU Gate Length [nm]:

140

85-90 65

45

30-32 20-22

CD Control [nm]:

14

9

6

4

3

2

T

OX

(equivalent) [nm]:

1.9-2.5

1.5-1.9

1.0-1.5 0.8-1.2 0.6-0.8 0.5-0.6

Junction Depth [nm]:

42-70

25-43

20-33

16-26

11-19

8-13

Metal Cladding [nm]:

17

13

10

000

Inter-Metal Dielectric

Κ:

3.5-4.0

2.7-3.5 1.6-2.2

1.5

M2 S2

P.Gargini

CLASSICAL CMOS

And

M2 S2

P.Gargini

MOS Transistor

Scaling

(1974 to present)

S=0.7

[0.5x per 2 nodes]

M2 S2

P.Gargini

The Incredible Shrinking

The Incredible Shrinking

Silicon Technology

Silicon Technology

0.25

0.25

µ

µ

Gate

Gate

Spacer

Spacer

Salicide

Salicide

0.35

0.35

µ

µ

Salicide

Salicide

Spacer

Spacer

Salicide

Salicide

Gate

Gate

0.18

0.18

µ

µ

Gate

M2 S2

P.Gargini

®

®

Material Evolution in MOS

Material Evolution in MOS

200

0’s

60’

s

70’

s

80’

s

90’

s

Al

SiO2

Al-Si

SiO2

Poly

Al-Cu

SiO2

WSi2

/

Poly

Ti/TiN

Al-Cu

SiO2

TiSi2

/

Poly

Ti/TiN

W

Al-Cu

SiO2

TiSi2

/

Poly

Ti/TiN

W

Low K

Al-Cu

SiO2/SiN

Silicon

Silicon

Silicon

Silicon

Silicon

Silicon

XSi?

/

Poly

Ti/TiN

W

ELK

M2 S2

P.Gargini

®

®

Material Evolution in MOS

Material Evolution in MOS

Al-Si

SiO2

Poly

Al-Cu

SiO2

TiSi2

/

Poly

Ti/TiN

W

New

New

New

New /Voids

Cu/New

SiO2

M aterial Additions

M aterial Replacements

2000-2010

90’s

M2 S2

P.Gargini

Primary barriers to MOSFET scaling are:

High I

on

/I

off

ratio (I

off

= Channel leakage current)

Low Standby leakage current (Gate + Channel leakage)

–

Low channel leakage current (Electrostatic scaling)

–

Low gate leakage current

Bulk-Si MOSFET

Substrate

Gate

Source

Drain

Gate

Leakage

Channel

Leakage

Gate Dielectric Scaling

M2 S2

P.Gargini

Is There Any Oxide Left?

20 nanometer

transistor

PolySi

Silicon

PolySi

Silicon

Gate oxide less than 3

atomic layers thick

M2 S2

P.Gargini

Bulk CMOS Scaling Challenges

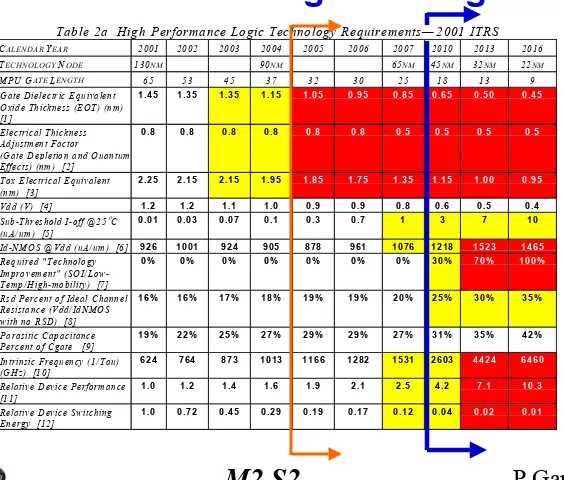

Table 2a High Performance Logic Technology Requirements— 2001 ITRS

C

ALEND AR

Y

EAR

2001

2002

2003

2004

2005

2006

2007

2010

2013

2016

T

ECH NO LO G Y

N

O D E

130

NM

90

NM

65

NM

45

NM

32

NM

22

NM

M PU G

ATE

L

ENG TH

65

53

45

37

32

30

25

18

13

9

Gate Dielectric Equivalent

Oxide Thickness (EOT) (nm)

[1]

1.45

1.35

1.35

1.15

1.05

0.95

0.85

0.65

0.50

0.45

Electrical Thickness

Adjustment Factor

(Gate Depletion and Quantum

Effects) (nm) [2]

0.8

0.8

0.8

0.8

0.8

0.8

0.5

0.5

0.5

0.5

Tox Electrical Equivalent

(nm) [3]

2.25

2.15

2.15

1.95

1.85

1.75

1.35

1.15

1.00

0.95

Vdd (V) [4]

1.2

1.2

1.1

1.0

0.9

0.9

0.8

0.6

0.5

0.4

Sub-Threshold I-off @25

°

C

(uA/ um) [5]

0.01

0.03

0.07

0.1

0.3

0.7

1

3

7

10

Id-NM OS @Vdd (uA/ um) [6]

926

1001

924

905

878

961

1076

1218

1523

1465

Required " Technology

Improvement" (SOI/

Low-Temp/ High-mobility) [7]

0%

0%

0%

0%

0%

0%

0%

30%

70%

100%

Rsd Percent of Ideal Channel

Resistance (Vdd/IdNM OS

with no RSD) [8]

16%

16%

17%

18%

19%

19%

20%

25%

30%

35%

Parasitic Capacitance

Percent of Cgate [9]

19%

22%

25%

27%

29%

29%

27%

31%

35%

42%

Intrinsic Frequency (1/Tau)

(GHz) [10]

624

764

873

1013

1166

1282

1531

2603

4424

6460

Relative Device Performance

[11]

1.0

1.2

1.4

1.6

1.9

2.1

2.5

4.2

7.1

10.3

Relative Device Switching

Energy [12]

M2 S2

P.Gargini

1.E-14

1.E-12

1.E-10

1.E-08

1.E-06

1.E-04

10

100

1000

Physical Gate Length (nm)

I

Off

(A/

µ

m)

Intel 15nm

transistor

Intel 30nm

transistor

Intel 20nm

transistor

Research data in literature ( )

Production data in literature ( )

1.E-06

1.E-05

1.E-04

1.E-03

1.E-02

1.E-01

1.E+00

1.E+01

1.E+02

1.E+03

5

10

15

20

25

Physical Tox (Å)

Jo

x

(A

/cm²) @1V In

v

e

rs

ion

SiO2 Gate Leakage

(from literature)

1.E-06

1.E-05

1.E-04

1.E-03

1.E-02

1.E-01

1.E+00

1.E+01

1.E+02

1.E+03

5

10

15

20

25

Physical Tox (Å)

Jo

x

(A

/cm²) @1V In

v

e

rs

ion

1.E-06

1.E-05

1.E-04

1.E-03

1.E-02

1.E-01

1.E+00

1.E+01

1.E+02

1.E+03

5

10

15

20

25

Physical Tox (Å)

Jo

x

(A

/cm²) @1V In

v

e

rs

ion

SiO2 Gate Leakage

(from literature)

M2 S2

P.Gargini

High

M2 S2

P.Gargini

Interconnect Grand Challenges

Near Term (2001-2007)

Enhancing Performance

■

Introduction of New Materials

:

●

High Conductivity and Low k Dielectric

■

Integration of New Processes and

Structures :

●

High Complexity

Long Term (2008-2016)

Enhancing Performance

■

Identify Solutions which address Global

Wiring Scaling:

●

Beyond Copper and Low k

●

Material Innovation to accelerate Design,

M2 S2

P.Gargini

®

®

Interconnect and

Interconnect and

Dielectric Materials

Dielectric Materials

1

2

3

R

e

si

st

iv

it

y

(

µµohm.cm)

2

3

1

Relative Dielectric Constant K

4

Cu

Air

Start

Aluminum

End

M2 S2

P.Gargini

Near Term (2001-2007)

Cost-effective Manufacturing

■

Coordinated Design Tools and

Simulators :

●

Mix Signal Co-design and Simulation

●

Transient Thermal Analysis Tool

●

Thermal Mechanical Analysis Tool

●

Electrical Analysis Tool

-

Power Disturbs

-

EMI

-

High Frequency / Current and

Lower Voltage Switching

Assembly & PKG Grand Challenges

Chip

Package

QFP

BGA

PGA

M2 S2

P.Gargini

M2 S2

P.Gargini

CMOS Future Directions

70%/2-3year

70% / 2-3year

Equivalent Scaling

2005-2014

??/2-3year

2X Performance/2-3year

Integrated Solutions

2000-2014

New Devices

2010-20XX

1970-2004

Traditional Scaling

Features

M2 S2

P.Gargini

The Ideal MOS Transistor

Fully Surrounding

Metal Electrode

High-K

Gate Insulator

Fully Enclosed,

Depleted

Semiconductor

Band Engineered

Semiconductor

Low Resistance

Source/Drain

Drain

Source

M2 S2

P.Gargini

Emerging Research Devices

Pursuing CMOS Scaling to the End

Bulk CMOS

–

Conventional bulk (SiO2, poly gate, etc..)

–

Introduction of new materials (high-K gate, metal gate

electrode,high mobility channel, etc.)

Non Classical CMOS Structures

–

Ultra thin channel (SOI)

–

Channel engineered structures

M2 S2

P.Gargini

BOXSource

Drain

Source

Gate

Drain

Si fin - Body!

FinFET

Band Engineered Transistor

Double Gate Transistor

Ultra-Thin Body SOI

2001 ITRS

New Transistor Definitions

M2 S2

P.Gargini

CNN

Nanotube

Molecular

SRT

SET

QD

RTD

M2 S2

Time

P.Gargini

Emerging Technology Sequence

SET

RSFQ

QCA

Molecular

RTD-FET

Strained

Si

Vertical

Transistor

FinFET

double gate

Planar

FD SOI

Quantum

computing

CNN

Defect

Tolerant

QCA

3D

Integration

Molecular

Architecture

Non-Classical

CMOS

Memory

Logic

Emerging

Technology

Vectors

Phase Change

Nano

SET

Molecular

Magnetic RAM

M2 S2

P.Gargini

Conclusions

•

The ITRS

has become a common

reference document

for the

Semiconductor Community

•

CMOS

will

remain

the device of choice for the foreseeable future

(>10yrs)

• Introduction of

Non-classical

CMOS in manufacturing will occur

within this decade

(~5years)

• Many

new materials

will be necessary->

Back to basics

• Design, Silicon Process, Package and System interaction will

continue to increase-> Need

integrated design

methodology

•

Innovation in:

Architecture, Logic, Memory and Devices is

marking the

Renaissance

of the Semiconductor Industry

•

Economical

challenges are

exceeding

the resources of any

individual company or consortium-> Cooperation is a must

M2 S2

P.Gargini

SUPPORT THE ITRS!!!!

SUPPORT THE ITRS!!!!

SUPPORT THE ITRS!!!!

SUPPORT THE ITRS!!!!