1*

I sm ail Sulaim an,

2Murna Muzaifa,

3Dian Hasni and

4Julius Munandar

1,2,3,

Depart m ent of Agricult ural Product Technology, Facult y of Agricult ure, Syiah Kuala

Universit y, Darussalam , Banda Aceh 23111, I ndonesia;

4

St udent of Depart m ent of Agricult ural Product Technology, Facult y of Agricult ure, Syiah

Kuala Universit y, Darussalam , Banda Aceh 23111, I ndonesia;

I n t r od u ct ion

Fresh coffee cherries are described as sm all round and reddish green berries. Coffee processing t ransform s coffee cherries int o green bean by rat io 6: 1 ( 6 kg fresh cherries to have 1 kg green bean ( I TC, 2015a). Global coffee product ion counted as green bean in 2014 reach out up t o 141.800 t housand bags, where I ndonesia supported 90.000 thousand bags ( I CO, 2015b). On t he ot her hand, t ot al world consum pt ion was 149. 265 t housand bags in 2014 where m ost ly com ing from im port ing count ries such as EU, USA, Japan and Russia ( I CO, 2015) . The num bers shows im pressive dem ands in coffee which t riggers farm ers to produce intensively as well as produces abundant by products t o handle. By assum ing t his, t here are need t o opt im alise t he robust num bers of waste, especially pulp t hat has highest percentage.

Pect in defines as water soluble carbohydrate which norm ally known as plant fiber, com m only used in food indust ry as food addit ive t o enhance text ure, viscosit y and stabilit y such as jelly, j am , m arm alade etc ( Chaubey and Kapoor, 2001; Whillet et al., 2006). By refers t o t rials in cacao pulp, t his research at t em pt s to produce pect in from coffee as well as said by Avellone et al ( 1999) pulp and m ucilage from coffee contains high num bers of pect in, sugars and prot ein.

M a t e r ia ls a nd M e t h ods

Coffee pulp t aken from Desa Geleulungi Kecam at an Pegasing Aceh Tengah dist rict s t hree t im es ( 20t h May; 2nd May and 25t h April 2015). Fresh coffee pulp t hen is cleaned, weighed, and packaged in fold-clipped vacuum t ransparent plast ic t hen st ored for 16 days, 24 days and 30 days in dark - room t em perature.

Pr oce d ur e

Coffee pulp t hen analyzed the m oist ure contents oven m et hod (Sudam adj i et al., 1997) , ash contents ( AOAC, 1997) and crude fiber content s ( Apriyant ono, 1989) . Another explorat ion m et hods carried out

* Corresponding Aut hor

: ism ail.sulaim [email protected]

Ex plor a t ion of Pu lp a n d H u sk of Ga y o Ar a bica Coffe e a s

Ra w M a t e r ia l of Pe ct in – SW OT, Risk a n d Ch e m ica l

Com pon e n t An a ly sis

Abst r a ct

Adv ances in w ast e m anagem ent offer huge possibilit ies for econom ic and social ut ilizat ion of residues from coffee product ion such as t he pulp and husk . Coffee pulp are obt ained during coffee product ion around 20- 45% of raw m at erial eit her it processed w et or dry . I n Gay o Highland areas, as a cent re of Arabica product ion in I ndonesia, coffee product ion k now n as sem i- dry ing process w here num bers of coffee residues arise up t o 40% of t ot al coffee berries. For local farm ers pulp and husk s oft en be decom pose by burning, w het her sev eral alt ernat iv es hav e been at t em pt ed indiv idually , eit her used as fert ilizer, liv est ock feed and com post . How ev er t he applicat ions abov e cov er only sm all num ber of robust coffee residues. Therefore st udies hav e been conduct ed t o ex plore possibilit y t o ex t ract pect in from coffee pulp. I m plem ent at ion of SWOT analy sis and Risk Analy sis by FMEA gain t o enhance t he inform at ion of st ren gt h, w eak ness, opport unit y and t hreat s of ex t ract ion pect in from coffee pulp/ husk s dem onst rat ed t hat t his at t em pt hav e higher possibilit y t o be m ore efficient t han ot hers t rial for bot h econ om ically and ecologically . Furt her m ore, m oist u re cont ent s, ash and crude fiber are ex am ined from fresh pulp/ husk w hich are st ored in room t em perat ures for 16 day s, 24 day s and 30 day s. The dat a dem onst rat ed t hat lengt h of st orage up t o 30 day s has im pact on increasing ash ( up t o 12.66% from 1.38% ) and solid fiber cont ent s ( up t o 28.24% from 2.70% ) w hilst m oist ure are decreased (dow n t o 15.51% from 86.08% ) w hich em phasizes t hat delay ing product ion or prolonging t he st or age of coffee residues m ight not hav e any im pact on product qualit y .

searched, collected, m apped based on SWOT and t hen counted the risk based Risk Priorit y Num ber ( RPN) as well as recom m endat ion act ions should be list ed. All of dat a was searching based on research quest ions “ t he possibilit y of using coffee pulp as raw m aterial of pect in” .

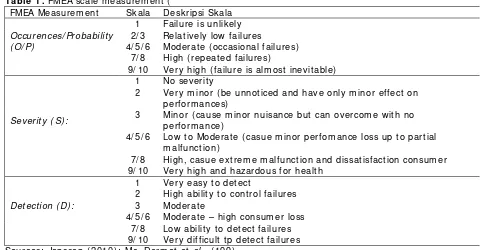

Failure Mode Evaluat ion Analysis ( FMEA) as support ive t ools t o analyze occurrences fact ors, ( possibilit y errors to be occurs) , severit y ( t he im pacts) and detect ion ( inabilit y t o det ect t he error) for all t he failures, t hen counted t he RPN, as t he sum up of m ult iplicat ion of t hese t hree aspects of FMEA. Measurem ent scale of FMA could be seen in Table 1.

Ta b le 1 . FMEA scale m easurem ent (

FMEA Measurem ent Skala Deskripsi Skala

Occurences/ Probabilit y ( O/ P)

1 Failure is unlikely 2/ 3 Relat ively low failures

4/ 5/ 6 Moderat e ( occasional failures) 7/ 8 High ( repeated failures)

9/ 10 Very high ( failure is alm ost inevit able)

Severit y ( S) :

1 No severit y

2 Very m inor (be unnot iced and have only m inor effect on perform ances)

3 Minor ( cause m inor nuisance but can overcom e with no perform ance)

4/ 5/ 6 Low t o Moderate ( casue m inor perfom ance loss up t o part ial m alfunct ion)

7/ 8 High, casue ext rem e m alfunct ion and dissat isfact ion consum er 9/ 10 Very high and hazardous for healt h

Detect ion ( D) :

1 Very easy t o det ect

2 High abilit y t o cont rol failures

3 Moderat e

4/ 5/ 6 Moderat e – high consum er loss 7/ 8 Low abilit y t o detect failures 9/ 10 Very difficult tp detect failures Sources: Janssen ( 2010) ; Mc. Derm ot et al., ( 199)

Resu lts a nd D iscussion

SWOT analysis carried out t he st rength, opportunit y as well as pointed out t he weakness and t hreat s of of using coffee pulp as raw m aterial of pect in. As shows in Figure 1 Aceh Tengah dist rict as cent re product ion of Arabica coffee in I ndonesia has pot ential resources of coffee pulp in low prices, which considers as wast e by t he farm ers at t he m om ent . According t o Bressani et al., ( 1972) each 1000 kg coffee berries produces 43% pulp, 38% coffee beans, 11.8% m ucilage, and 6.1% hulls. Therefore when reported in 2012 Aceh Tengah produced 26.163 t ons of coffee ( BPS, 2013) 43% ( 11.250 t ons) of it are coffee pulp. On t he ot her hand, research showed high int erest of Aceh Tengah farm ers t o ut ilize t he coffee wast e as fert ilizers ( PSI , 2015), cat t le feeding ( Daud et al., 2013; Usm an et al., 2013) or m edia plantat ion ( PSI , 2015) . Moreover innovat ive research developed part icleboard from t his by products ( Odih, 2009; Safriana, 2012).However t hese att em pt s could not accom m odate high num bers of coffee wast e available.

Com m ercial pect in usually produced from cit rus peel and apple pom ade ( Food Navigat or, 2014) . Report s m ent ioned t hat pect in from m aterial above com m only used in food product ion and becom ing t ight in prices on raw m aterial short age and supply chain problem s. On t he ot her hand dem ands on pect in supply in I ndonesia and Asia globally st eadily increased. BPS ( 2010) and Chahyadit ha ( 2011) assum ed t hat I ndonesia im port s 289.12 tons pect in a year where Asia requires 24.315 t ons a year. Since I ndonesia st ill lack of pect in m anufacturer pect in consum es high cost.

Threat s and weakness m ent ioned challenges and lack of resources t o obt ain t he goal of product ion pect in from coffee pulp. Recent research showed ext ract ion of water soluble carbohydrate from coffee pulp wit h wat er produced yield 10,98% wit h pect in fiber 57,24% ( Diniyah et al., 2013) by t em perature variat ion and coffee variet ies. The result s also showed that pect in have darker color and unat t ract ive ( Ningsih, 2013). Furt her researches found out using chloric acid, acet ic acid ( Sat ria & Auda, 2008) , am m onium sulfic ( Syukra, 2007) and oxalate acid ( Ut am i, 2014) . Furt herm ore Nazaruddin and Asm awat i ( 2014) pointed out t hat cacao pulp t hat ext racted wit h am m onium oxalat

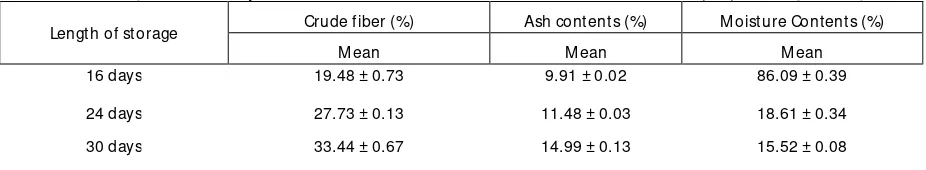

15.52% from 86.09% ) which em phasizes t hat delaying product ion or prolonging t he st orage of coffee residues m ight not have any im pact on product qualit y. Moreover the drying process of coffee pulp could be recom m ended as prevent ive act ion t o avoid m icrobial growt h.

Ta b le 2 . Changes of diet ary fiber, ash and m oisture cont ent s of fresh coffee pulp during st orage

Lengt h of st orage Crude fiber (%) Ash cont ent s (%) M oisture Content s (%)

M ean M ean M ean

16 days 19.48 ± 0.73 9.91 ± 0.02 86.09 ± 0.39

24 days 27.73 ± 0.13 11.48 ± 0.03 18.61 ± 0.34 30 days 33.44 ± 0.67 14.99 ± 0.13 15.52 ± 0.08

Con clusions

Taking everyt hing into considerat ion pect in product ion considers as effect ive t rial t o ut ilise t he availabilit y of coffee pulp in Aceh Tengah. However int ensive research t owards t he ext ract ion m et hods required t o be done, especially by adopt ion of Nazaruddin and Asm awat i 2014) m et hods.

Ack n ow led g em e n ts

The authors are t hankful t o Universit y of Syiah Kuala and Direkt orat Penelit ian dan Pengabdian Kepada Masyarakat for t he financial support in proj ect “ Unggulan Perguruan Tinggi (UPT) with cont ract num ber 035/ SP2H/ PL/ Dit .Lit abm as/ I I 2015 on Date 05t h February 2015.

Re fe r e n ce s

AOAC. ( 1997) . Official Met hod of Analy sis 15t h. Washingt on: Ed Associat on of Official Analy t ical Chem ist .

Apriy ant ono, A. ( 1989) , Pet unj uk Laborat oriu m Analisis Pan gan. Bogor : I PB Press

Av ellone,S., Guy ot , B., Michaux - Ferriere, J.P., Guiraud, E., Olguin, P, J, M., and Brillouet . ( 1999) . Cell Wall Poly saccharides of Coffee Bean Mucilage: Hist ological Charact erisat ion during Fer m ent at ion. I n Proceeding of 18t h I nt ernat ional Scient ific Colloquium on Coffee Science ( ASI C) ,463-46 7. Helsink i

Badan Pusat St at ist ik ( 2013) , Pr oduk si Kopi Aceh Tengah. Aceh Tengah.

Belfrid. 1995. Pengaruh pH dan Lam a Ek st rak si t erhadap Rendem en dan Mut u Pek t in dari Kulit Buah Kak ao. Medan: HKBP Univ ersit y .

Bressani. 1 972. I m prov em ent of prot ein qualit y by am ino acid and prot ein supplem ent at ion in Big Wood E. J ( eds) I nt ernat ional Ency clopedia of Food Nut rit ion. Vol. I I . Pergam m on Press, Ox ford.

Chahy adit ha, M.E., ( 20 11) . Pra Ran cangan Pabrik Pem bu at an Pekt in Dari Kulit Buah Kakao Dengan Kapasit as Produksi 1 2.000 Ton/ Tahun. Sk ripsi. Nort h Sum at era Univ er sit y , Medan.

Chaubey , M and Kapoor, V.P. ( 2001) . St ruct ure of galact om annan from t he seedsof cassia angust ifolia v ahl. I n Carbohy drat e Research, 332: 4 39 - 444.

Daud, M., Fuadi, Z., and Sult ana, S. ( 2 013) . Effect of Coffee Wast e as Com ponent of Com piler Rat ion Pek ing Du ck in t he Form of Wat er Com plet e Rat ion. I n Agripet 13 ( 1) : 36- 42.

Diniy ah, N., Mary ant o., Nafi, A., Sulist ia, D. and Subagio., A. ( 2013) . Ekst raksi dan Karak t erisasi Polisak arida Laru t Air dari Kulit Kopi Variet as Arabik a (Coffee Arabica) dan Robust a (Coffee Robust a). I n Jurnal Teknologi Pert anian 14( 2) : 73 - 78.

Food Nav igat or ( 2013) . Yant ai Andre Pect in increases pect in prices on raw m at erial short age. URL: ht t ps: / / foodnav igat or. com / Bu siness/ Yant ai- Andre- Pect in- increases- pect in- prices- on - raw- m at erial- short age ( 09 August 2015) .

I nt ernat ional Coffee Organisat ion – I CO ( 2015a) : Ex port ing count ries- t ot al product ion. URL: ht t ps: / / ico.org/ t rade_ st at ist ic.asp. ( 5 August 2015) .

I nt ernat ional Coffee Organisat ion – I CO ( 2 015b) : Tr ade st at ist ic - World coffee consum pt ion. URL: ht t ps: / / ico.org/ t rade_ st at ist ic.asp. ( 5 August 2015) .

I nt ernat ional Trade Cent re ( 2012) . The Coffe Ex port ers Guide. 3rd eds. Genev a, Sw it zerland. Janssen, J. ( 201 0) : Food Qualit y Managem ent Manual. Fu lda

Mc. Derm ot t , R.E.; Mik ulak , R.J. ; Beauregard, M.R. ( 1996) . The Basics of FMEA. Port land: Product iv it y I nc.

Nazaruddin, R dan Asm aw at i. 2 011. Effect of Am m oniu m Ox alat e and Acet ic Acid at Sev eral Ex t ract ion Tim e and pH on Som e Phy sicochem ical Propert ies of Pect in from Cocoa Husk s ( Theobrom a cacao) . I n African Journal of Food Science. 5 ( 15) : 79 0- 798.

Ningsih, D.S. ( 201 2) . Karakt erist ik Pekt in Lim bah Kulit Kopi Olahan Kering Variet as Arabika ( Coffeea arabica) dan Robust a ( Coffeea robust a) . Sk ripsi. Univ er sit as Jem ber, Jem ber.

Odih., I . ( 20 13) . Uj i Pot ensi Pem anfaat an Kulit Kopi di Kabupat en Aceh Tengah Menj adi Papan Part ikel dengan Menggunakan Perekat Urea Form aldehida Penol For m ald ehida dan Therm oplast ik. Theses. Univ ersit y of Gadj ah Mada, Yogy ak art a.

Pert anian Sehat I ndonesia ( 2015) . Sarasehan Program Pet ani Kopi Gay o Berday a. URL: ht t ps/ / pert aniansehat .com / read/ 201 5/ 05/ 1 3/sarasehan- program - pet ani- kopi- gay o- berday a.ht m l ( 10 Agust us 2015) .

Safriana. E., ( 2013) . Kaj ian Ek sperim ent al Pem anfaat an Ku lit Kopi sebagai Bahan Papan Part ikel unt uk Peny erap Buny i ( St udi Kasus di Kabupat en Bener Meriah dan Aceh Tebgah) . Theses. Univ ersit y of Gadj ah Mada, Yogy ak art a.

Sat ria, B dan Auda. Y., ( 2008) . Pengolahan Lim bah Kulit Pisang Menj adi Pekt in dengan Meoide Ekst rak si.Univ er sit y of Diponegoro, Sem arang.

Sudarm adj i, B., Hary ono and Suhardi. ( 1 997) , Pr osedur Analisa unt u k Bahan Makanan dan Kesehat an, Yogy ark at a: Libert y Press.

Soerensen, L.B ( 2004) . A br ief not e on lit erat u re st udies part I I. URL: ht t p: / / openarchiv e.cbs.dk / bit st ream / handle/ 10398 / 6295/ a% 20brief% 20not e% 20on% 20lit erat ure% 20 st udies % 20- % 20part % 20ii.pdf?sequence= 1 ( 10 March 20 15) .

Sy uk ra, A. ( 2007) . Ekst raksi Pek t in dari Kulit ( POD) Kakao ( Theobrom a cacao L) dengan Variasi Ting kat Keasam an ( pH) dan Wakt u Ekst raksi. Sk ripsi. Univ ersit y of Sy iah Kuala. Banda Aceh.

Ut am i., R. ( 200 8) . Ekst raksi Pekt in dari Kulit Kakao deng an Pelarut Am m onium Ok salat . Sk ripsi. Univ ersit y of Sy iah Kuala. Banda Aceh.

Usm an. , Y. Hu sin. M.N. and Rat ni, R. ( 201 3) . The supplem ent at ion peel coffee beans in t he rat ion Aceh Cat t le on in v it ro digest ibilit y . I n Agripet 13( 1) : 49 - 52.

Willat , W.G.T., Paul, K.J. and Mikk elsen, J.D. ( 2006) . Pect in: new insight s int o on old poly m er are st art ing t o gel. I n Trends in Food Science and Technology 17: 97- 104.