UNIVERSITI TEKNIKAL MALAYSIA MELAKA

ONLINE MONITORING AND CONTROL FROM A DATABASE

SERVER FOR MANUFACTURING SYSTEM

This report submitted in accordance with requirement of the Universiti Teknikal Malaysia Melaka (UTeM) for the Bachelor Degree of Manufacturing Engineering

(Robotic and Automation) with Honours.

by

MOHD SHAFADILAH BIN MASHOR

DECLARATION

I hereby, declared this report entitled “Online Monitoring and Control from a Database Server for Manufacturing System” is the results of own my research except

as cited in references.

Signature:………

APPROVAL

This report is submitted to the Faculty of Manufacturing Engineering of UTeM as a partial fulfillment of the requirements for the degree of Bachelor of Manufacturing Engineering (Robotic and Automation) with Honours. The member of supervisor committee is as follow:

(Signature of Supervisor)

ABSTRACT

ABSTRAK

DEDICATION

Special Dedicated to My Beloved Family

Mashor Dasuki Rohayati Poying Nur Shafika Mashor Mohd Azmir Mashor

My Supervisor En. Shariman Abdullah

ACKNOWLEDGEMENTS

Assalammualaikum. First of all, I want to say that I am very grateful to God, because of

God’s grace; I finally succeeded in finishing my Projek Sarjana Muda (PSM). I would like to thanks to my project supervisor, Encik Shariman Bin Abdulllah because of his guidance and advice on my project in many ways kept me going. I appreciate all his suggestions and encouragement through out the process of completing this PSM. I also want to say thanks to my parents who have helped me a lot throughout of the process do my project. Always support me and give me encouragement until the end of this project.

To my brother and also to my sister that always stay besides me, support me when I’m

down and never give up with me. To my friends, because always help me and give an advice to improve my project. To all lecture because has given cooperation and teachings to me. Thanks to all who has to be involved in this project “Online Monitoring

And Control From Database Server For Manufacturing System”, for all the help,

support, encouragement, cooperation and advice that they all has give to me throughout this project.

TABLE OF CONTENT

2.2.2 Remote Data Objects (RDO) 14 2.2.3 ActiveX Data Objects (ADO) 152.3 Database Software 16

2.3.1 Microsoft Access 16

2.3.2.1 Microsoft SQL Server 2000 17 2.3.2.1.1 Database Architecture 19

2.3.3 MySQL 20

2.3.4 mSql 21

2.4 Pc to Plc Communications 22

2.4.1 Serial Port 27 2.6.3 Serial Communication for PLC 44

2.7 Sensor 49

2.7.1 Temperature Sensor 50 2.7.1.1 Temperature Control System using LM35 50

2.8 Summary 52

3. Methodology 53

3.1 Introduction to Project Methodology 53 3.2 Methodology Flow Chart 54 3.2.1 Identified Problem Statements 55 3.2.2 Project Planning Using Gantt chart 55 3.2.3 Information Searching 58

3.2.3.1 Books 58

3.2.3.4 Discussion with lecturer 59 3.2.4 Literature Review 59 3.2.5 Software Design 60

3.2.6 Testing 60

3.2.6.1 SQL Server 2000 Testing 61 3.2.6.2 Visual Basic 6.0 Testing 61 3.2.6.3 PC to PLC communication Testing 61

3.2.7 Analysis 61

3.2.8 Improvement 62

3.3 Summary 62

4. Conclusion of PSM 1 63

LIST OF TABLES

2.1: Microsoft SQL Server 2000 Architecture 18 2.2: Show cmd operation 25 2.3: 9-pin serial port pin outs, male (Corey, 2000) 32 2.4: 25-pin serial port pin outs, male (Corey, 2000) 33 2.5: signal on a 25-pin parallel port connector (Corey, 2000) 35

3.1: Gantt chart for PSM 1 56 3.2: Gantt chart for PSM 2 57

LIST OF FIGURES

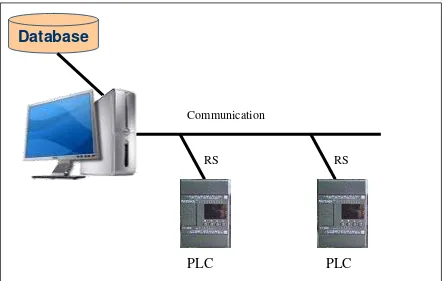

1.1: Overview Online Monitoring System 3

2.1: Relationship of four major components in Database (Date 2000) 8 2.2: Database Engine in database system 9 2.3: Example of table and field using SQL 10 2.4: Relationship between recordset and table (Fowler.com 2008).

2.5: The client side of the ODBC architecture (Freeze 2000) 12 2.6: The class diagram representing the relationships 13 for the DAO pattern (Sun Microsystems 2002)

2.7: general characteristics of RDO (McManus 1999) 14 2.8: How to gain access to information in a database 15 using ADO and OLE DB (McManus 1999)

2.9: The relationship of process in Microsoft Access 17 (Bay City 2006)

2.25: Several components in connecting a VB to database (McManus 1999) 38 2.26: The connection has been made in VB 38 2.27: Step to create database using SQL 2000. 39 2.28: Step to create database using Microsoft Access 39 2.29: Example of Ladder Diagrams Programming (Groover 2008) 42 2.30: Example programming use Functional Block 42 Diagram programming (Lewis1998)

2.31: Example of Instruction List Programming (Hugh 2001) 43 2.32: Example of Instruction List Programming (Lewis1998) 44 2.33: Coding send to serial port 46 2.34: Coding to receive data in serial communication 46 2.35: Serial output using ladder diagram 47 2.36: Massage function for serial communication 47

CHAPTER 1

INTRODUCTION

1.0 Introduction

Online Monitoring and Control from Database for Manufacturing System is an industrial control system that uses a computer system monitoring and controlling a process and use database to record the data of the process. This system consist a few subsystems to make a complete the system. The sub systems are a Human-Machine Interface (HMI), database system, programmable logic controllers (PLC) and communication infrastructure. Human-Machine Interface or HMI is the apparatus which presents process data to a human operator, and through which the human operator monitors and controls the process. The HMI of this system is where data is processed and presented to be viewed and monitored by a human operator. This interface usually includes controls function where the individual can interface with the system. HMI are an easy way to standardize the facilitation of monitoring multiple PLC. Usually PLC will run a pre programmed process, but monitoring each of them individually can be difficult, usually because they are spread out over the system. Because PLC historically had no standardized method to display or present data to an operator, the system communicates with PLC throughout the system network and processes information that is easily disseminated by the HMI. HMI also can be linked to a database, which can use data gathered from PLC to give option to the operator to retrieve or key in the data.

smaller systems, the master station may be composed of a single Personal Computer (PC). In larger systems, the master station may include multiple servers, distributed software applications, and disaster recovery sites. To increase the integrity of the system the multiple servers will often be configured in a dual-redundant or hot-standby formation providing continuous control and monitoring in the event of a server failure.

Third subsystem is PLC. This subsystem connecting to sensors in the process, converting sensor signals to digital data and sending digital data to the database system. The PLC, located at a remote site, gathers data from field devices such as sensor, pumps and valves into memory until the HMI initiates a send command. The central processing unit within the PLC receives a data stream hardware equipment protocol. When the PLC sees its specific address embedded in the protocol, data is interpreted and the CPU directs the specified action to take.

Last subsystem is communication infrastructure. This subsystem function is to connect the PC to the PLC. Online Monitoring System used direct serial or modem connections to meet communication requirements, although Ethernet and IP are also frequently used at large sites. Integration of serial devices into this system network infrastructure offers distinct advantages for seeking to centralize their operations, overcome the distance limitations of standard serial communications or lower costs associated with hands-on administration of these devices. However, integrating serial communications into a network is difficult as Ethernet topology is not capable of directly transmitting serial data from one device to another. Most devices used in data acquisition or control applications, such as time clocks, traffic control signals, data collectors and alarm panels are usually serial based because it is a reliable and low-cost technology.

1.1 Project Overview

Online Monitoring and Control from Database for Manufacturing System will work by relationship between database, PLC and Human Machine Interface. This system refers to centralized systems which monitor and control entire sites or complexes of systems spread out over large areas. Most control actions are performed automatically by PLC. Data collection begins at the PLC level and includes meter readings and equipment status reports that are communicated. Data is then compiled and formatted in such a way that a control room operator using the HMI can make decisions to adjust or override PLC controls. Data may also be fed to a database, often built on a commodity database system, to allow trending and other analytical auditing.

.

Figure 1.1: Overview Online Monitoring System

Database

PLC

PLC

Communication

1.2 Advantages of System

When one system is developing, the important thing is to convince people that the system is good and useable. One practical way to convince the people is by show the advantage of the system. For Online Monitoring System, there are several advantage that the people will get when use this system. First advantage is grown and the demands for reliable and accurate performance and trend data have increased. Second advantage is the worker need to be able to remotely and instantaneously, identify problem that are

Nowadays, the readout of the majority of data collection in environmental or industrial is not true. It is because occur some adjustment to correct the data especially in down time problem. So, this project is developing to avoid incorrect data collection and to automate the solution when a problem occurs.

1.4 Objective

There are several objectives need to achieve in this project: (a) To make database using SQL Server 2000.

(b) To retrieving data from SQL Server 2000 using Visual Basic 6.0. (c) To design Human Machine Interface Visual Basic 6.0.

1.5 Scope

CHAPTER 2

LITERATURE REVIEW

2.0 Introduction

2.1 Database

A database is a logically coherent collection of data with some inherent meaning, representing some aspect of real world and which is designed, built and populated with data for a specific purpose. A phone book, for instance, could be considered a database as it stores related pieces of information such as name and phone number. However, in the world of computers, a database usually refers to a collection of related pieces of information stored electronically. Aside from the ability to store data, a database also provides a way for other computer programs to quickly retrieve and update desired pieces of data. Beside that, database also is a collection of information that is organized so that it can easily be accessed, managed and updated. In one view, databases can be classified according to types of content: bibliographic, full-text, numeric, and images.

McManus J. P. (1999), claim database is a repository of information. Relational databases are storage data in table which are in turn composed of rows, also known as records and columns, also known field, enable to retrieve subjects of data from table and enable to connect table together for the purpose of retrieving related record stored in different table. Freeze W.S. (2000), claim a database is simply a genera-purpose tool that allows people to store any information that can be read and updated by one or more concurrent application programs in secure and reliable fashion.