Cutting Tool Parameter Optimization For Surface Roughness Of Mild Steel Material Using Taguchi Methodt.

Teks penuh

Gambar

Dokumen terkait

The scope of this project is to study the cutting parameters which spindle speed and feed rate and to study the surface roughness of AISI 1045 carbon steel by using wet

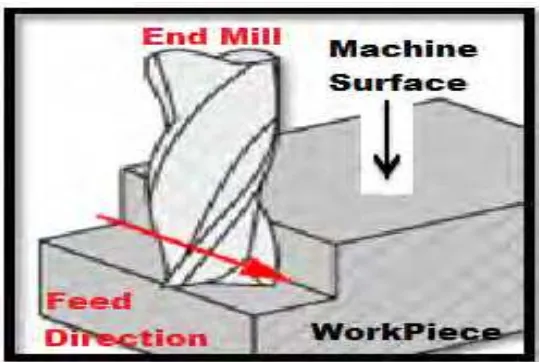

This study is mainly focusing on investigating the effect of spindle speed, feed rate and depth of cut to surface finish of the machined workpiece and also to

• To analyze the effect of CNC milling parameters such as cutting speed, depth of cut, and feed rate to the surface roughness and microhardness of 6061 T6..

spindle speed, feed rate and depth of cut will produce different type of

What are the influence of machining parameters (feed rate and depth of cut) of the surface grinding machine to the surface roughness for mild steel and carbon

The response surface methodology RSM was employed for modeling and analyzing the influence of cutting parameters on the surface roughness and uses of cutting tool, three principal

It can be concluded that pocket working on CNC milling machines with variations in spindle speed and cutting direction results in normalization of the roughness level of N6 as a result

Machining parameter level Machining parameters Parameter level 1 2 3 Spindle speed rpm Feed rate mm/min Depth of cut mm 600 55 0.25 900 70 0.50 1100 85 0.75 Various approaches