Eur. J. Mech. A/Solids 18 (1999) 465–479

Elsevier, Paris

Analysis of interfacial cracks emanating from a hole in a bi-material plate

J.S. Kuanga, Y.H. Wangb

aDepartment of Civil Engineering, Hong Kong University of Science & Technology, Kowloon, Hong Kong bDepartment of Civil Engineering, Huazhong University of Science & Technology, Wuhan, China

(Received 12 July 1997; revised and accepted 10 August 1998)

Abstract– In this paper the boundary collocation method has been used successfully to analyse the interfacial cracks emanating from a hole in a bi-material plate. The stress functions are assumed such that they can satisfy a series of governing conditions, such as the equilibrium equations in the domain, the boundary conditions on the crack surfaces, and the stress and displacement conditions on the crack surfaces and across the interface. Moreover, they can also represent the stress singularity at the crack tips. Thus, only the boundary conditions on the hole and the external boundary of the plate are necessarily to be considered, and they can be approximately satisfied by the collocation method and least square technique. Numerical investigations for two cases, two-equal-crack and one crack, are carried out. It is shown that the proposed method is effective and gives satisfactory results. In addition, the proposed approach shows many advantages compared to other methods and can be used for investigating more general cases of cracks emanating from a hole in a bi-material plate.Elsevier, Paris

1. Introduction

It is well recognised that cracks originate most frequently from stress concentration areas developed around holes. In engineering practice of “stress relief”, holes may be drilled at the end of a thin slot to reduce the stress concentration. When holes are drilled at the interface of two different metals which are bound or welded together, cracks could grow from these holes. Similar phenomena occur in composite interfaces. For example, concrete is made as a two-phase composite consisting of mortar and aggregate inclusions. At the interface, air froth or voids could exist, and cracks may emanate from these regions. In the analysis of rock fracture, it is important to investigate the interaction and coalescence of pressurised fracture proceeding from the boreholes. Therefore, the study of interfacial cracks emanating from holes in a bi-material structural element has its practical significance.

The boundary collocation method (BCM) (Sawyer and Anderson, 1972) has been shown as an effective method for a variety of crack problems for plates of finite geometry with isotropic and homogeneous materials. For the bi-material interfacial crack problem, the analysis is different from that in isotropic and homogeneous bodies, since a special stress singularity at the crack tips exists (Erdogan, 1963, 1965; Rice and Sih, 1965). A series of assumed complex stress functions for the central or edge interfacial crack in a bi-material plate have been proposed, and the BCM is used to calculate the stress intensity factors (Woo et al., 1992).

satisfied by the BCM and least square technique. Numerical investigations for two cracking cases, two-equal-cracks and one crack, under biaxial or uniaxial loading are given and the results are presented in the related figures and discussed.

2. Basic formulation

As shown by Muskhelishvili (1953), the representations of the in-plane stresses in an isotropic and homogeneous plate by two complex functions, 8(x) and ω(x), lead to a general method of solving two-dimensional plane problems. The stresses and displacements which are related to those functions can be expressed as

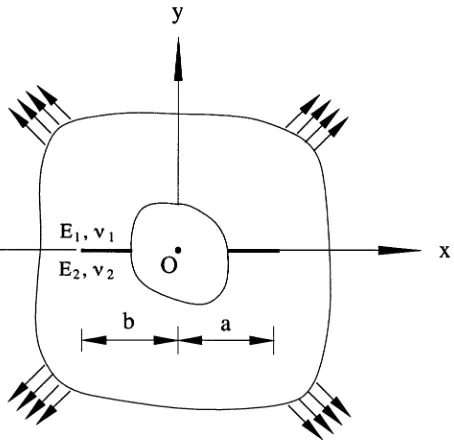

As shownfigure 1, two cracks emanating from a hole are situated along the interface of a bi-material plate. Both materials in the upper and lower regions of the plate are assumed to be isotropic and homogeneous.

Analysis of interfacial cracks emanating from a hole in a bi-material plate 467

Figure 1.Crack emanating from a hole in a bi-material plate.

whereEk andFkare the complex coefficients to be determined;εis defined as the bi-elastic constant, given by

ε= 1

82(z)=e2π ε

The displacement can then be determined by Eq. (3). It is obvious that the displacements are single-value in both the upper and lower regions. In addition, there are equal displacements of the upper and lower regions along the interface. Although the plate infigure 1is an internal multi-connection one, the single-value displacement condition is still satisfied automatically with the assumed stress functions.

Therefore, it is a only need for the boundary conditions on the hole and external boundaries of the plate to be considered, and they can be approximately satisfied by the BCM. For a boundary point in the upper or lower region, two stress equations with the complex coefficientsEk andFk can be developed. If the total number of points taken on the hole and the external boundary isL, 2Lequations are developed. Thus, if the term number of the summation of the stress functions isM+N, 4(M+N )real unknowns need to be determined. When the number of equations is equal to that of the unknowns,Ek andFk can be determined. Usually, in order to obtain better results more boundary points are taken, and the least square technique is employed to solve the equations.

Once the complex coefficients Ek and Fk are determined, the stress intensity factors will be calculated conveniently (Rice and Sih, 1965). For the right crack tip(z=a),

KI−iKII=2

By substituting81(z)into Eqs (13) and (14), the stress intensity factors for the right and left crack tips can

Analysis of interfacial cracks emanating from a hole in a bi-material plate 469

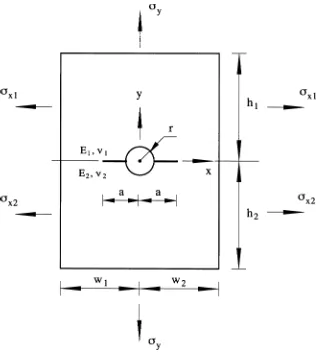

Figure 2.Two equal cracks emanating from a circular hole in a bi-material rectangular plate. 3. Numerical investigations

Two cracking cases, namely two-equal-crack and single-crack, for a circular hole in a rectangular plate are investigated. The non-dimensional SIF valuesKI/KoandKII/Koare calculated and presented in the following

examples, in which

Ko=σ

√

π ar−1/2∓iε, (17)

whereσ is the applied stress.

3.1. Two equal cracks

A case of two equal cracks emanating form a circular hole in a rectangular plate shown in figure 2 is investigated. In order to ensure the strain componentεx is continuous along the interface, the applied loading and material constants should satisfy the following relations (Rice and Sih, 1965),

σx2=

E2

E1

σx1+

ν2−

E2

E1

ν1

Figure 3.KI/Kofor differentRandr/aratios (a/w=0.1, two equal cracks, biaxial loading).

for plane stress, and

σx2=

E2

E1 1

−ν12

1−ν22

σx1+ ν

2

1−ν2−

E2

E1

ν1(1+ν1)

1−ν22

σy (19)

for plane strain.

Two loading cases in the analysis will be considered. One is the biaxial loading, in which σx1, σx2and σy satisfy Eq. (18) or (19). The other is the uniaxial loading, whereσx1=σx2=0, but the elastic material constants

should satisfy a certain relation described in Eq. (18) or (19).

3.1.1. Biaxial loading

The dimensions of the plate, hole and cracks shown infigure 2are as follows:

h1=h2=1, andw1=w2=1,

relative crack length:a/w=0.1 to 0.8,

ratio of hole radius to crack length:r/a=0.1,0.25 and 0.5.

The material properties are:

ν1=ν2=0.3,

E1=1, andE2=1,3,4,10,25,100 and 1000.

The applied loads σx1 and σy are taken as unit, and σx2 is determined by Eq. (18) for plane stress case.

Analysis of interfacial cracks emanating from a hole in a bi-material plate 471

Figure 4.KII/Kofor differentRandr/aratios (a/w=0.1, two equal cracks, biaxial loading).

number of summation terms: M=N=15, number of points on the hole boundary: Nh=90, number of points on each plate side: N1=N2=40.

Numerical results are obtained and presented for various bi-material constantRratios(R=E2/E1).

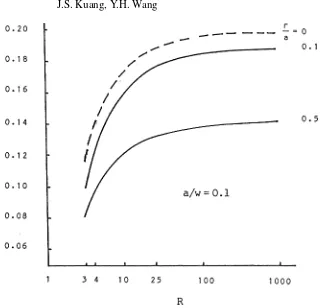

The computed values of KI and KIIfor different R ratios are shown infigures 3and 4, where the relative

crack length a/w=0.1. Figure 3shows that the values of KI/Ko decreases asR increases, but R seems to

have negligible effect on theKI/Kovalues whenR >25. It is also shown infigure 3that with the sameRratio

the smaller the ratior/a, the larger theKI/Kovalue. Moreover, when the hole is very small, sayr/a=0.1, the

present results trend to agree with those of the central crack problem(r/a=0)(Erdogan, 1965). Fromfigure 4

it can be seen that the value ofKII/Ko increases rapidly with the increase inR ratios when R <25. This

indicates that the shear effect is highly sensitive to the difference between the elastic moduli of two materials.

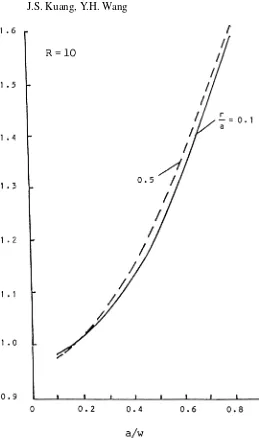

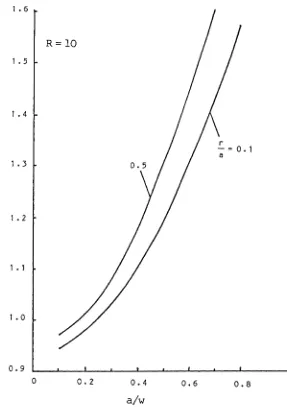

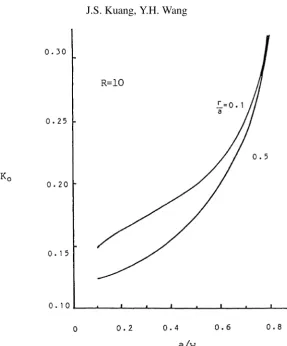

Variations ofKIand KIIfor different crack lengtha/ware given infigures 5and6. Fromfigure 5it is seen

that KI/Ko increases as the value of a/w increases. Figure 6 shows that when a/w increases there is little

change inKII/Ko. Until the value ofa/wbecomes larger than 0.6,KII/Koincreases fast.Figures 5and6also

Figure 5.KI/Kofor differenta/wandr/aratios (R=10, two equal cracks, biaxial loading). 3.1.2. Uniaxial loading

The same plate in Subsection 3.1.1 is considered for this loading case. The loading conditions are: σx1=

σx2=0, andσy=1. In the analysis it is assumed thatE1=1 andν2=0.3.E2andν1can be determined using

Eq. (6) and the continuous condition of strainεx along the interface of two materials gives:

ν1/E1=ν2/E2.

Assuminga/w=0.1, the computed results ofKIandKIIvarious ratios ofRare presented infigures 7 and 8. It is seen that the curves infigure 7 are similar to those infigure 3. With the same value ofR, the larger the ratior/a, the smaller the value ofKI/Ko in biaxial loading case (figure 3); while the larger the ratior/a, the

Analysis of interfacial cracks emanating from a hole in a bi-material plate 473

Figure 6.KII/Kofor differenta/wandr/aratios (R=10, two equal cracks, biaxial loading).

Figure 8.KII/Kofor differentRandr/aratios (a/w=0.1, two equal cracks, uniaxial loading).

the plate under uniaxial loading.Figure 8shows the values ofKII/Kowith different ratior/afor variousR. It

can be seen that the variation ofKII/Kois similar to that in biaxial loading case (figure 4).

Figures 9and10show the computed results ofKIandKIIfor different ratios ofa/w. Fromfigure 9it is seen

that theKI/Ko curves are similar to those in the biaxial loading case (figure 5), but the ratior/a has a more

significant effect on theKI/Kovalues.Figure 10shows thatKII/Koincreases as the ratioa/wincreases; while

for the biaxial loading case (figure 6) there is little change in theKII/Kovalue whena/w <0.6. 3.2. Single crack

The proposed method and the procedure for analysing the problem of two equal cracks emanating from a circular hole in a rectangular plate can be used for solving the single crack problem. In this case, the left or right crack can be considered as a fictional crack. Let the crack tip be in the hole. For convenience, it coincides with the origin of the coordinates. Thus, takingb=0 (the left crack is considered as a fictional crack) in the formulae, the calculation procedure is the same as that in the two-equal-crack case.

Consider the problem of a crack which is emanated from a circular hole in a rectangular plate under uniaxial loading. The crack length isa. The dimensions and material properties are the same as those in the example of Subsection 3.1.1.

Assuming that the crack lengtha/w=0.1, and the hole radiusr/a=0.1,0.25, and 0.5. The stress intensity factors are calculated for various values ofR. The results ofKI/KoandKII/Koare presented infigures 11and 12. Similar to those in the two-equal-crack case,figure 11shows that the value ofKI/Kodecreases with the

Analysis of interfacial cracks emanating from a hole in a bi-material plate 475

Figure 9.KI/Kofor differenta/wandr/aratios (R=10, two equal cracks, uniaxial loading).

has a significant effect on the value ofKI/Ko; while there is little effect in the two-equal-crack case (figure 7). Figure 12shows the results ofKI/Kofor differentRratios. It can be seen that the variation ofKII/Kois similar

to that in the two-crack shown infigure 8.

The variations of SIFs for different crack length a/w are plotted in figures 13 and 14. From figure 13, it is seen that theKI/Ko curves have similar shapes to those in the problem of two cracks (figure 9), but their

increasing rates are lower than those infigure 9. Figure 14 shows that the value of KII/Ko increases as the

crack lengtha/wincreases, and the variation profile is very similar to that in the two crack case presented in

Figure 10.KII/Kofor differenta/wandr/aratios (R=10, two equal cracks, uniaxial loading). 4. Conclusions

Based on the plane elasticity of complex variable theory, a set of stress functions is proposed in this paper for calculating the SIFs of cracks emanating from a circular hole in a finite bi-material plate. The governing equations in the domain, the stress-free conditions on the crack surfaces, and the stress and displacement continuous conditions on the interface have been satisfied. On the other hand,r−1/2∓iεstress singularity exists at the crack tips. The boundary conditions of the hole and the plate can be satisfied approximately by the boundary collocation method.

Two common cracking cases, two-equal-crack and one-crack, are studied, and numerical investigations for different loading conditions, material constants, crack lengths and hole radius have been carried out. For a special case where the hole is very small, the present results show good agreement with those of a central crack in a finite bi-material plate. Moreover, different computing parameters, such as different numbers of summation terms or numbers of collocation points on the hole and /or the external boundaries, are investigated. It can be seen that the results are stable, provided that the numbers of the terms and the points are not too small.

Analysis of interfacial cracks emanating from a hole in a bi-material plate 477

Figure 11.KI/Kofor differentRandr/aratios (a/w=0.1, one crack, uniaxial loading).

Figure 13.KI/Kofor differenta/wandr/aratios (R=10, one crack, uniaxial loading).

Analysis of interfacial cracks emanating from a hole in a bi-material plate 479

References

Erdogan F., 1963. Stress distribution in a nonhomogeneous elastic plane with cracks. J. Appl. Mech., ASME 30, 232–236. Erdogan F., 1965. Stress distribution in bonded dissimilar material with cracks. J. Appl. Mech., ASME 32, 403–410. Muskhelishvili N.I., 1953. Some Basic Problems of Mathematical Theory of Elasticity. English ed. Noordroff, Groningen. Rice J.R., Sih G.C., 1965. Plane problems of cracks in dissimilar media. J. Appl. Mech., ASME 32, 418–423.

Sawyer S.G., Anderson R.B., 1972. Engrg. Fracture Mech. 4, 605–616.