Rheological properties of lesquerella gum fractions

recovered by aqueous extraction

Ronald A. Holser

a,*, Craig J. Carriere

b, Thomas P. Abbott

aaNew Crops Research,National Center for Agricultural Utilization Research,Agriculture Research Ser6ice, USDA11815North Uni6ersity St.,Peoria,IL61604,USA

bBiomaterials Processing Research,National Center for Agricultural Utilization Research,Agriculture Research Ser6ice, USDA1815North Uni6ersity St.,Peoria,IL61604,USA

Received 6 May 1999; accepted 22 December 1999

Abstract

Lesquerella fendleriseeds contain a cross-linked carbohydrate gum with viscoelastic properties that may be used for industrial and edible applications. Laboratory studies compared the rheological behavior of gum isolates obtained from whole seed, defatted hull, and defatted meal fractions. Gum yields and rheological properties were determined for gum isolates from each of these fractions. All gum isolates exhibited positive hysteresis, which provided evidence of structure formation in 1% solutions. Values of storage and loss modulus were reported from oscillatory experiments over an angular frequency range of 0.1 to 100 rad/s using a controlled-stress rheometer. Whole seed meal appears to be the most cost-effective fraction from which to recover gums. Published by Elsevier Science B.V.

Keywords:Lesquerella; Gums; Rheology; Process analysis

www.elsevier.com/locate/indcrop

1. Introduction

The seeds ofLesquerella fendlericontain a

nat-ural gum with potential application as a

thicken-ing or gellthicken-ing agent in edible and non-edible formulations. Lesquerella gum was previously iso-lated and determined to be composed

predomi-nately of arabinogalactan with 15%

galactouronosyl residues and cross linked by diva-lent calcium and magnesium ions (Abbott et al., 1994; Wu and Abbott, 1996). The oil from les-querella seed is a source of long-chain hydroxy fatty acids that can be used as a feedstock for the manufacture of industrially important specialty chemicals (Mikolajcak et al., 1962; Thompson, 1985; Roetheli et al., 1991). Seeds typically con-tain 25% oil, although selective breeding has

pro-* Corresponding author. Tel.: +1-309-6816213; fax: + 1-309-6816524.

E-mail address: [email protected] (R.A. Holser)

1Names are necessary to report factually on available data;

however, the USDA neither guarantees nor warrants the stan-dard of the product, and the use of the name by USDA implies no approval of the product to the exclusion of others that may also be suitable.

duced seeds with 29% oil and a lesquerolic acid content of 56% (Barclay et al., 1962; Thompson and Dierig, 1994; Dierig et al., 1996). The seed coat gum of lesquerella represents an additional natural product with potential commercial value. An efficient process for the recovery of the gum as a co-product of seed oil production could improve the market position of lesquerella and lead to increased utilization of this new crop. Industrial interest in the oil and meal continues and the commercial status of lesquerella as a crop has been recently reviewed (Abbott et al., 1997).

The object of this study was to investigate the yields and rheological performance of crude gum isolates obtained from lesquerella seeds, defatted hulls, and defatted wholeseed meal. These frac-tions represent sources for the isolation of gums from the oil recovery process. Gums isolated from

each source were characterized initially by

Brookfield viscosity measurements and subse-quently by thixotropic-loop and oscillatory

exper-iments using a controlled-stress rheometer.

Quality and yield were compared for gums iso-lated from each fraction and discussed in relation to a process where the recovery of lesquerella seed oil was a primary objective.

2. Materials and methods

2.1. Sample preparation

L. fendleri seed (NU64621) was obtained from

the NCAUR seed collection. Defatted whole seed meal and defatted hull fractions were obtained

from International Flora Technologies, Ltd.

(Gilbert, AZ). Samples of guar, tragacanth, and xanthan gums were obtained from ICN Pharma-ceuticals, Inc. (Costa Mesa, CA).

Seed coat gums were isolated from each frac-tion by washing 30 g samples with 1-l of de-ion-ized water. The seed and water mixture was stirred on a magnetic stirring plate at 25°C for 30 min. Half of the initial volume of water was decanted and replaced with an equivalent volume of de-ionized water. This was repeated once and the mixture was subjected to high-speed shear for 45 s, in a laboratory blender to facilitate release of

the gums from the seed coat. This sheared

mate-rial was centrifuged at 5520×g to separate gums

from insoluble residue. The supernatant was

col-lected and centrifuged a second time at 25 900×

g.

Water was removed from the isolated gum frac-tions by freeze-drying (Lyph-Lock Model 18, Labconco, Kansas City, MO). The freeze-dried material was analyzed for gum content by the Dubois method (Abbott et al., 1995). Apparent viscosities were determined on 1% solutions of the gum isolates prepared in de-ionized water using a Brookfield viscometer. A Model 4537 viscometer (Lab-line Instruments, Inc., Melrose, Park, IL) was used with an L3 spindle operated at 30 RPM and 25°C. All isolation experiments were repli-cated three or more times and reported values exhibited a relative standard deviation of less than 7%.

2.2. Rheological methods

Rheological measurements were performed

with a controlled-stress rheometer (Model

CSL2

500, CarriMed, Dorking, England). All the rheological measurements were performed using a 6-cm plate with a 2° cone fixture. The rheometer was equipped with a Peltier plate to control

cham-ber temperature to A, 0.2°C. Hysteresis loop

ex-periments were conducted over the shear rate

range of 0 – 250 s−1. The upward and downward

cycles of the loop were kept equal, with a total cycle time of 4 min. Oscillatory frequency sweep experiments were conducted by applying a con-stant strain of 30% over an angular frequency range of 0.1 to 100 rad/s. Torque sweeps were conducted on each of the materials to ensure that the applied strain used in the oscillatory experi-ments were within the linear viscoelastic range.

3. Results

Table 1

Average values of viscosity, yield, and purity for freeze-dried gums

Yield (%)

Source Viscositya(cP) Purity (%)

1826

Seedb 21.2 46.4

14.8

800 44.6

Mealc

30.4

Hullsd 915 39.1

aBrookfield viscosities measured for 1% aqueous solutions

of freeze-dried gum isolates at 25°C.

bN=3, RSDB7%. cN=3, RSDB7%. dN=6, RSDB7%.

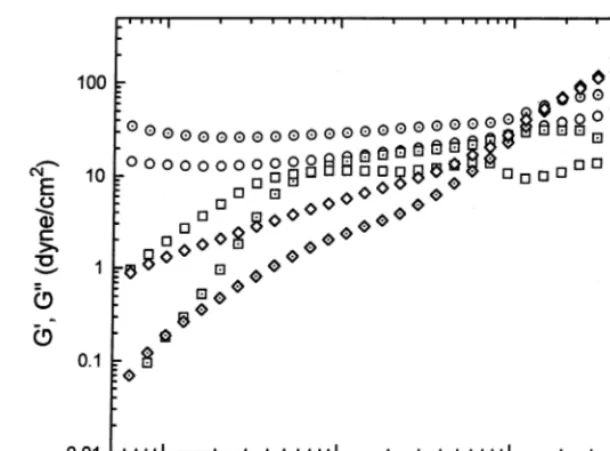

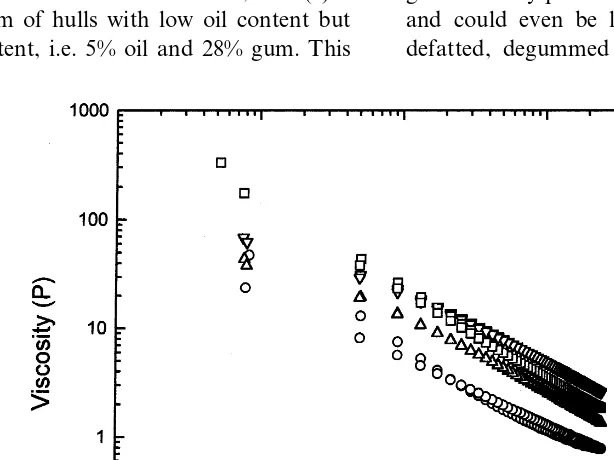

change in viscosity with shear rate during hys-teresis loop experiments. The first cycle of increas-ing and decreasincreas-ing shear rate is presented in Fig. 1 for 1% solutions of gums isolated from each fraction. Clockwise hysteresis behavior is ob-served in each of the gum isolates with the defat-ted meal isolate showing the greatest hysteresis. The defatted hull isolate and whole seed isolate showed progressively diminishing hysteresis ef-fects. In addition, each of the materials displayed shear-thinning behavior over the entire shear rate range studied. None of the samples displayed

evidence of shear-thickening behavior. Time

sweep data (not presented) on each of the

solu-tions was conducted at a shear rate of 10 s−1for

20 min. Each of the materials displayed a slight stress overshoot with a rapid decay to a steady plateau. Thixotropic or rheopectic behavior was not observed for any of these materials.

Oscillatory experiments were performed to in-vestigate the response of each gum isolate to sinusoidally varying shear in terms of the storage

modulus, G%, and loss modulus, G¦. The

predomi-nate response of the defatted meal gum isolate at low frequency oscillations was viscous or dissipa-defatted hull gum isolates, and 1826 cp for whole

seed gum isolates. The purities of gum isolates, as glucose, from defatted meal and defatted hull fractions were 44.6 and 39.1%, respectively. The purity of gum isolates from the whole seed frac-tion was 46.4%. Gum yields were reported on the basis of the mass of the source material and were 21.2% from whole seed, 14.8% from defatted whole seed meal, and 31.4% from defatted hulls. The rheological properties of each gum isolate were further characterized by measuring the

Fig. 2. Response of defatted meal ( G%,G¦), defatted hull ( G%,G¦), and seed gum ( G%,2G¦) isolates to oscillatory shear in 1% solutions at 25°C in terms of storage modulus, G%, and loss modulus, G¦.

tive as indicated by the magnitude of the loss modulus (Fig. 2). As the angular frequency was increased beyond 1 rad/s, the storage modulus became dominant indicating an elastic response. The response of the whole seed gum isolate was qualitatively similar; however, the change in pre-dominance occurred at a higher frequency, i.e. greater than 10 rad/s. The defatted hull gum isolate responded differently from the other two gum isolates and was dominated by the storage modulus over the frequency interval, 0.1 – 100 rad/ s. This behavior is indicative of the development of a gel or network structure being formed in the solution (Ferry, 1980).

4. Discussion

The isolation and recovery of lesquerella gum from the seed coat may be considered in terms of yield, purity, and rheological properties. Gum isolates obtained from whole seed, defatted whole seed meal, and defatted hulls exhibited moderate variation in each of these attributes. Gum yield was greatest in the isolate obtained from the hull

fraction, whereas the purity of this material was the lowest as measured by the Dubois method.

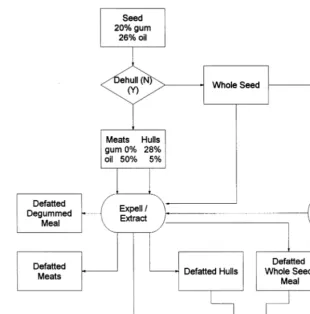

Commercial development of lesquerella gum requires the identification of potential applica-tions for the gum and an efficient process for its recovery. A conceptual flowplan for an integrated oil and gum recovery process is presented in Fig. 4 showing the source of each gum isolate fraction investigated. We have assumed for this analysis that the seed oil is the more valuable product so that each material stream that contains oil is subjected to either a mechanical press or solvent extraction. Further, we have assumed that the gum recovery process is the same regardless of the feedstock. While it is reasonable to consider the unit operations equivalent, we recognize that the capital equipment costs and the operating costs would differ depending on capacity. The design capacity of the equipment is dependent on the particular feedstock. Starting from whole seed, the decision to remove the hulls would produce: (1) a material stream of seed meats with a negligi-ble gum content and increased oil content, i.e. 50% versus 26% oil in the whole seed; and (2) a material stream of hulls with low oil content but high gum content, i.e. 5% oil and 28% gum. This

would require an additional unit operation, decor-tication, which is not necessary to generate the other fractions considered for gum recovery. Wu and Abbott (1996) studied various milling, siev-ing, and air classification schemes to improve the gum yields within this hull fraction. They were able to achieve an increase in gum content for a hull sub-fraction exceeding 50% gum by pin-milling three times at 18 000 RPM. This sub-frac-tion represented approximately 20% of the total hull fraction. The value of the gum combined with the value of the dehulled meats must justify the extra capital equipment and manufacturing costs associated with the isolation of gums from any de-hulled seed fraction.

Alternatively, whole seed could be defatted di-rectly and the defatted meal subjected to the gum recovery process. In this case, the gum isolate could be recovered downstream of the typical oil recovery process. This flow-plan has the advan-tage of not requiring complete integration of the gum recovery process with the oil recovery system and could even be located at another site. The defatted, degummed whole seed meal would be

Fig. 4. Flowsheet for the recovery of lesquerella oil and seed coat gums from whole seed, defatted whole seed meal, and defatted hull fractions.

suitable as a high protein source for animal feed or similar purposes. The moisture level of this wet residual meal could be reduced by a less energy-intensive drying method, e.g. sun drying, because the degradation of oil is no longer a concern.

Finally, isolation of seed coat gums from whole seed upstream of the oil recovery process is possi-ble. Water content needs to be reduced from the wet condition coming out of the gum recovery process to less than 10% prior to entering the oil recovery section. This is not a technical difficulty, but an additional operating expense is required to remove the excess moisture.

5. Conclusion

Lesquerella gum was isolated from whole seed, defatted hulls, and defatted meal fractions. Solu-tions of these materials exhibited positive hys-teresis and moderate variations in loss and storage modulus depending on isolate source.

process. A gums recovery process operating on the defatted meal in this way could be idled or brought on-line in response to market demand.

Acknowledgements

The assistance of Mark Klokkenga was greatly appreciated in performing gum isolation studies.

References

Abbott, T.P., Wu, Y.V., Carlson, K.D., Slodki, M.E., Klei-man, R., 1994. Isolation and preliminary characterization of Lesquerella fendleri gums from seed, presscake and defatted meal. J. Agric. Food Chem. 42, 1678 – 1685. Abbott, T.P., Nelsen, T.C., Kleiman, R., 1995. Seed surface

gums content using the Dubois carbohydrate analysis. Ind. Crops Prod. 4, 185 – 192.

Abbott, P.P., Dierig, D.A., Foster, M.A., Nelson, J., Coates, W., Felker, F.C., Frykman, H.B., Carlson, K.D., Arquette, J., 1997. Current status of lesquerella as an industrial crop. Inform 8, 1169 – 1175.

Barclay, A.S., Howard, S.G., Jones, Q., 1962. The search for new industrial crops II: Lesquerella (Cruciferae) as a source of new oilseeds. Econ. Bot. 16, 95 – 100.

Dierig, D.A., Thompson, A.E., Rebman, J.P., Kleiman, R., Phillips, B.S., 1996. Collection and evaluation of new lesquerella andPhysariagermplasm. Ind. Crops and Prod. 5, 53 – 63.

Ferry, J.D., 1980. Viscoelastic Properties of Polymers, 3rd edition. Wiley, New York, pp. 501 – 508.

Fox, J.E., 1997. Seed gums. In: Imeson, A. (Ed.), Thickening and Gelling Agents for Food. Chapman and Hall, New York, pp. 262 – 283.

Mikolajcak, K.L., Earle, F.R., Wolff, I.A., 1962. A search for new industrial oils. VI. Seed oils of the genusLesquerella. J. Am. Oil Chem. Soc., 39, 78-80.

Rinaudo, M., 1992. The relation between the chemical struc-ture of polysaccharides and their physical properties. In: Phillips, G.O., Williams, P.A., Wedlock, D.J. (Eds.), Gums and Stabilisers for the Food Industry 6. Oxford University Press, New York, pp. 51 – 61.

Roetheli, J.C., Carlson, K.D., Kleiman, R., Thompson, A.E., Dierig, D.A., Glaser, L.K., Blase´, M.G., Goodell, J., 1991. Lesquerella as a Source of Hydroxy Fatty Acids for Indus-trial Products. Government Publication Series, USDA, CSRS, Washington, DC.

Thompson, A.E., 1985. New native crops for the arid South-west. Econ. Bot. 39 (4), 436 – 453.

Thompson, A.E., Dierig, D.A., 1994. Initial selection and breeding of Lesquerella fendleri, a new industrial oilseed. Ind. Crops Prod. 2, 97 – 106.

Wu, Y.V., Abbott, T.P., 1996. Enrichment of gum content from Lesquerella fendleri seed coat by air classification. Ind. Crops Prod. 5, 47 – 51.