P1 - 1

Making Blondo Flour as Protein Source Food with Physical,

Mechanical and Chemical Treatments on Virgin Coconut Oil (VCO)

Processing Waste

Anak Agung Istri Sri Wiadnyani and I Wayan Rai Widarta

Faculty of Agricultural Technology, Udayana University, E-mail:

asriwiadnyani@yahoo.com

Abstract

VCO processing resulted in waste of blondo, but till now the waste has not been used maximally. In fact, blondo still contain high protein, high oil residue and some water. The objective of this research was to use VCO waste in form of blondo to be blondo flour that has potential to develop as alternative protein source food.This research was started with physical treatment (centrifugation) in 4000 rpm for 30 minutes on fresh blondo, mechanical treatment (hydraulic compression) at 200 kg/cm2 and chemical treatment (extraction with hexane solvent) on wet blondo. Then, the blondo yield was observed. The blondo was dried in oven dryer at 600C and followed with analysis of water content, oil content, protein content, peroxide value, and free fatty acid. The result indicated that the best output was obtained in chemical treatment with extraction with hexane solvent on wet blondo with 29% yield, 3.38% water content, 22.04% oil content, 57.82% protein content, 2.90% free fatty acid and 3.18 meq/kg peroxide value.

Key words: Blondo, VCO, Sentrifugation, Hydraulic Pressed, Hexane

Introduction

One of the processed products of coconut which is very promising and has big opportunity to develop is pure coconut oil or frequently called as Virgin Coconut Oil (VCO). The processing technology of coconut into VCO can be chosen from simple to complicated technologies. Several methods used in the making of VCO are: enzymatic making, fermentation making, acid making, centrifugation, and fishing (Setiaji and Prayuga, 2006). In the making go VCO, besides it is obtained its oil, we can get dregs in the form of white

compound, whose composing component is protein and generally called as “blondo” (Kwon et al., 1996). Protein will break, thus lipoprotein binding in coconut milk will also break. Then, the oil bound by that binding will come out and gather into one (Anon, 2010).

Up to now, “blondo” is still assumed as waste by the society, so that it is less used, because it is only used to feed livestock or to make pepes(a kind of food). “Blondo” obtained contains high protein and the oil residue and has high water content, so that physically,

“blondo” is still in the form of slurry. Recently, the processing of “blondo” as a result of

VCO making traditionally is carried out by heating. It produces coconut oil and black-brown

“blondo”, which cannot stand for long time. To reserve “blondo”, it can be carried out by

reducing oil residue and water, so that it is obtained “blondo” flour. The reduction or oil residue and water can be carried out physically, such as by centrifugation and mechanical way by using hydraulic kemp or chemical way with solvent extraction.

The study of food technological research related to the usage of VCO production waste recently is very relevant. This is supported by the reduction of protein source food, so

P1 - 2 The general objective of this research is to use VCO waste in the form of “blondo”

into “blondo” flour as one of food alternatives as protein source and to find out the characteristic of “blondo” which has been treated physically, mechanically, and chemically.

Materials and methods

Material and Tools

The main materials used in this research were coconut, Pancing Oil, and n-Hexane. Chemical substances used in analysis were NaOH, acetate-chloroform acid, calium iodide, natrium thiosulfat, alcohol, Na2S2O3, Phenolpthalin indicator, amilum, KOH, NaBorat, I2, and Br2. Those were obtained from Food Analysis Laboratory, Biochemical and Nutrition, Science and Food Technology Department, Agricultural Technology Faculty, Udayana University.

Research tools used were coconut grater, filter, knife, plastic washbasin, plastic tube (big, medium, and small), casa cloth, plastic funnel, plastic pipe, filter paper, measuring glass, stove, centrifuge, hydraulic kempa, extraction tools, and chemical analysis tools.

Research Process

This research comprised of 2 stages, the making of VCO and the making of blondo flour.

Stage 1. VCO Making Process

The researcher decided to use blondo as a result of VCO waste in the industry of coconut processing into VCO, which certainly there is a guarantee in the similarity of blondo result or the oil obtained, so that it did not cause to high bias in the result of blondo flour or in the analysis. The industry chosen by the researcher was local producer, PT. Setya Putra Perkasa, located in Nitikan N0.8 Yogyakarta with its trade mark Healthy Co. The selection of this industry was because the procedure used was stated in the Journal American Oil Chemistry Society (Rukmini and Rahardjo, 2010).

Stage 2. The Making of Blondo Flour

Blondo is the side product of coconut oil making in wet way without heating. Blondo which still contains oil and water was squeezed. Subsequently, it was divided into 4 parts. The first part was without treatment, the second part was used physical treatment (centrifugation) in 4000 rpm in speed with duration of 30 minutes. The third part was mechanical treatment (hydraulic kempa) with pressure of 200 kg/cm2. The fourth part was using chemical treatment (extraction using n-hexane solvent) for wet blondo.

Blondo as a result of the treatment was subsequently dried in dryer cabinet in temperature of 600C for 24 hours. Blondo as a result of drying was then grinded and filter in 40 mesh filter. Subsequently blondo flour was ready to analyze.

Analysis

Analysis of Peroxide Value

The determination of peroxide value was based on titration method (Sudarmadji et al., 1997) Analysis of Free Fatty Acid

P1 - 3 Water Content Analysis

The determination of water content using oven method (AOAC, 1995) Protein Content Analysis

The determination of protein content using Kjeldahl method (AOAC, 1995) Oil Content Analysis

Fat and oil content was determined using soxhlet method (AOAC, 1995).

Results and discussion

Blondo Yield

Blondo which was not treated, which still contained oil and water was directly dried using oven in temperature of 600C for 48 hours. But, it could not be dried completely and formed flour because water and oil content was still high. The result obtained in control was in the form of paste. Blondo which was not treated was used as control for other treatments at the time of parameter analysis, such as water content, fat content, FFA, protein content or peroxide valu. Blondo rendemen can be seen in Table 1.

From the three method carried out, it can be seen that chemically extraction using hexane solvent produced the lowest rendemen of 29.00% compared to other treatments, in which the resulted blondo was drier with physic or mechanical method, because hexane solvent can free more water and oil. The result of blondo separation and oil and water residue using hexane extraction was continued with drying to obtain blondo flour to analyze dried in dryer oven without any additional treatment to remove oil and water, so that its water content was still very high. High water content will react with oil, so that it fastened the hydrolysis process part of the fat into free fat acid, fastened by alkali and enzymes (Buckle et al., 1987).

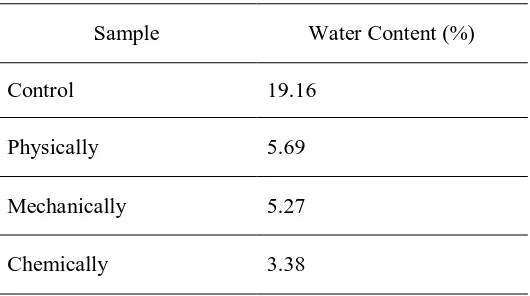

P1 - 4 Table 2. Water content blondo flour

Sample Water Content (%)

Control 19.16

Physically 5.69

Mechanically 5.27

Chemically 3.38

Oil Content

Table 3 shows that the highest oil content was in control of 58.25%, and the lowest oil content was in chemical treatment using extraction with hexane of 22.04%. It was smaller compared to physic or mechanical treatment. This maybe because blondo oil content removed and the drying temperature triggered the removal of oil trapped in blondo aggregate. Extraction depended on several factors, such as the size of particle, type of solvent, temperature, and mixing (Maryadi, 2004). The extraction method used was maceration by soaking the material in the solvent in the temperature of 550C and protected from light. The extraction method using solvent was good enough and the usage of non polar solvent of hexane, which has low boiled temperature, was good because it did not make the blondo damaged.

Data on oil content obtained from all treatments was too high. Oil content of milk concentrate was <10% (Anon, 2003), powder milk was 15-26% (Anon, 1999), and coconut protein concentrate was 5% (Mashita, 2004). This was certainly supported the oil damage through the process of hydrolysis or oxidation, which will promote the formation of free fatty acid and hydroperoxide.

Table 3. Oil content blondo flour

Sample Oil Content (%)

Control 58.25

Physically 36.11

Mechanically 24.80

Chemically 22.04

Protein Content

P1 - 5 was compared between water and oil content, protein content was very relevant. The lower the water and oil content, the higher was the protein content.

Table 4. Protein content blondo flour

Sample Protein Content (%)

Control 24.41

Physically 45.80

Mechanically 43.36

Chemically 57.82

Free Fat Acid Content

The highest free fatty acid content was obtained in control treatment of 4.92% and the lowest was in chemical treatment of 2.90%, having lower oil content compared to physical and mechanical treatments. Extraction treatment with solvent or other treatments having very high free fat acid, above the allowed maximum standard for cooking oil was of 0.5% (Anon, 1995). Free fat acid of blondo can be seen in Table 5.

The high content of free fat acid which was obtained in all treatment was might be caused by high oil content, so that it was needed better method to minimize the existing oil in blondo. Hydrolysis can be caused by the existing of water in oil, so that it will fasten oil destruction, and oil will change into free fat acid and glycerol which can cause rancid (Ketaren, 2005).

Table 5. Free Fatty Acid content blondo flour

Sample Free Fatty Acid Content (%)

Control 4.92

Physically 3.80

Mechanically 4.38

Chemically 2.90

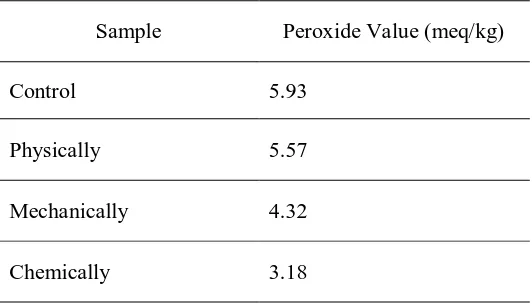

Peroxide Value

Peroxide value is the most important value to determine the degree of damage of oil or fat in food, which has big effect on the taste and smell. The biggest peroxide number was obtained in control treatment of 5.93% meq/kg and the lowest was in chemical treatment of 3.18%. This was proven with extraction treatment, which was able to remove oil and water more compared to either physic or mechanical treatments. Peroxide number of blondo flour can be seen in Table 6.

P1 - 6 stable, easy to break into fat acid. Aldehid and keton is volatile and cause rancid smell and have potential to have toxic character. obtained from chemical treatment, extraction with hexane solvent in blondo of 29%. 2) The best treatment was extraction in blondo chemically with analysis result of water content of 3.38%, oil content of 22.04%, protein content of 57.82%, free fatty acid of 2.90% and peroxide value of 3.18%. 3) Extraction treatment with hexane solvent in blondo into blondo flour was deserved to be called as protein concentrate, because it resulted almost 60% protein. 4) Free fat acid and peroxide number obtained from the best treatment was still high, over the allowed standard.

References

1. Anonymus. (1995). Proposed APCC standart for Virgin Coconut Oil, Codex stand 1-1985(rev1-1991).

2. Anonymus. (1999). Syarat Mutu Susu Bubuk. http://www.bsn.or.id. Diakses 14 Oktober 2010.

3. Anonymus. (2003). Spesificationsfor dry whey protein concentrate. United States Departement Agriculture

4. Anonymus. (2010). Coconut Oil and Its Wonderful Health Benefits.

http://www.coconut connections.com/virgin_coconut-oil.htm. Diakses 12 November 2010.

5. AOAC. (1995). Official Methods of Analysis of AOAC International. Sixteenth Edition, 5th Revision, 1999. Vol. 2. USA : AOAC Inc.

6. Buckle, K.A. (1985). Kimia pangan. Diterjemahkan oleh Purnomo, H. dan Adiono. UI-Press. Jakarta

7. Ketaren, S . (2005). Minyak dan Lemak Pangan. Universitas Indonesia (UI-Press) 8. Kwon, K.S., D., Bae, K.H., Park and K.C., Rhee. 1996. Aquaeous extraction and

P1 - 7 9. Maryadi, D. (2004). Penghilangan minyak Kelapa pada Blondo melalui metoda ekstraksi dengan pelarut. Skripsi Fakultas Matematika dan Ilmu Pengetahuan Alam, Universitas Gadjah Mada.

10.Mashita. (2004). Kajian interaksi fosfat dalam protein kelapa (blondo) hasil samping pembuatan minyak kelapa melalui metode pancingan. Skripsi Fakultas MIPA universitas Gadjah Mada, Yogyakarta.

11.Rukmini, A. and Rahardjo, S. (2010). Pattern of Peroxide Value Changes in Virgin coconut Oil (VCO) Due to Photo-Oxidation Sensitized by Chlorophyll. Journal American Oil Chemistry Society . 87:1407–1412

12.Setiaji, B and S. Prayugo. (2006). Membuat VCO Berkualitas Tinggi. Penebar Swadaya, Jakarta.