Full Terms & Conditions of access and use can be found at

http://www.tandfonline.com/action/journalInformation?journalCode=lpte20

Download by: [National Cheng Kung University] Date: 29 August 2016, At: 01:10

Polymer-Plastics Technology and Engineering

ISSN: 0360-2559 (Print) 1525-6111 (Online) Journal homepage: http://www.tandfonline.com/loi/lpte20

The Effect of Dynamic Vulcanization on the

Properties of Polypropylene/Ethylene-Propylene

Diene Terpolymer/Natural Rubber (PP/EPDM/NR)

Ternary Blend

Halimatuddahliana & H. Ismail

To cite this article: Halimatuddahliana & H. Ismail (2008) The Effect of Dynamic Vulcanization on the Properties of Polypropylene/Ethylene-Propylene Diene Terpolymer/Natural Rubber (PP/EPDM/NR) Ternary Blend, Polymer-Plastics Technology and Engineering, 48:1, 34-41, DOI: 10.1080/03602550802539270

To link to this article: http://dx.doi.org/10.1080/03602550802539270

Published online: 17 Dec 2008.

Submit your article to this journal

Article views: 88

View related articles

The Effect of Dynamic Vulcanization on the Properties

of Polypropylene/Ethylene-Propylene Diene Terpolymer/

Natural Rubber (PP/EPDM/NR) Ternary Blend

Halimatuddahliana

1and H. Ismail

21

Department of Chemical Engineering, Universitas Sumatera Utara, Indonesia

2

School of Materials and Mineral Resources Engineering, Universiti Sains Malaysia, Penang, Malaysia

The effects of dynamic vulcanization on the process development and some properties, such as tensile properties, swelling index, gel content, crystallinity, and morphology, of the polypropylene (PP)/ethylene-propylene diene terpolymer (EPDM)/natural rubber (NR) blends were investigated. Dynamically vulcanized blends show higher stabilization torque than unvulcanized blends. In terms of tensile properties, the tensile strength and tensile modulus (stress at 100%elongation, M100) of the vulcanized blends have been found to increase as compared with the unvulcanized blends, whereas the elongation at break is higher in the blend with richer EPDM con-tent. These results can be attributed to the formation of cross-linking in the rubber phase. The formation of cross-links in the rubber phase has also been proved by swelling index and gel content. The percentage of crystallinity of the blends is decreased by dynamic vulcanization. Scanning electron microscopy (SEM) micrographs from the surface extraction of the blends support that the cross-links occurred during dynamic vulcanization.

Keywords Crystallinity; Dynamic vulcanization; Gel content; Swelling index

INTRODUCTION

Several works have reported the dynamic vulcanization of TPE, especially the PP=EPDM blends, and most of the investigations focused on the processing and the improve-ments of mechanical and physical properties of the blends[1–6]. However, replacement of EPDM with NR in

PP=EPDM blends has been considered due to the

reduction of the cost. It has also been observed that the partial replacement of EPDM by NR decreased the proper-ties of PP=EPDM blends[7]. Therefore, dynamic vulcaniza-tion has been introduced in the PP=EPDM=NR blend to improve the properties of such blends.

Dynamic vulcanization has been extensively applied to the vulcanization of the soft elastomer phase of a blend with rigid thermoplastics. The process is carried out under high shear and above the melting point of the thermoplas-tic at sufficiently high temperature to activate and complete the vulcanization. During dynamic vulcanization of rub-bers, the polymeric chains of the base elastomer become interconnected, converting the viscous gum into an elastic network. In dynamic vulcanization of the thermoplastics elastomer, the structure is generated in small rubber parti-cles dispersed in the thermoplastic polymer matrix. Various types of curatives can generally be used in dynamic vulca-nized blends, such as sulfur, phenolic resin, and peroxide. This paper examines the effect of dynamic vulcanization with sulfur on the process development and some proper-ties, such as tensile properproper-ties, chemical and oil resistances, and gel content of the PP=EPDM=NR blends, along with the accompanying characteristics in the crystallinity and morphology.

EXPERIMENTAL

Materials

Polypropylene (PP) homopolymer used in this study was an injection-molding grade, supplied by Titan PP Polymers (M) Sdn Bhd, Johor, Malaysia (TITANPRO 6331 grade), with a melt flow index (MFI) value of 14 gr=10 min at 230

C and 2.16 kg. Ethylene-propylene diene terpolymer (EPDM-EPT 3072E), with Mooney viscosity, ML (1þ4)

74 at 100

C was purchased from Luxchem Trading Sdn. Bhd. Natural rubber (SMR L), with Mooney viscosity, ML(1þ4), 73 at 100

C was obtained from Hokson Rubber Trading Sdn. Bhd, Seremban. Curatives, i.e., 5 phr of zinc oxide (ZnO), 1.5 phr of stearic acid, 1 phr of N-cyclohexyl-2-benzothiazol sulfenamide (CBS), 0.4 phr of antioxidant, and curing agent, i.e., 2 phr of sulfur, were industrial grade chemicals from Bayer (M) Sdn. Bhd.

Address correspondence to H. Ismail, School of Materials and Mineral Resources Engineering, Universiti Sains Malaysia, 14300 Nibong Tebal, Penang, Malaysia. E-mail: [email protected]

ISSN: 0360-2559 print/1525-6111 online DOI: 10.1080/03602550802539270

Preparation and Processing

Studies were conducted on PP=EPDM=NR blends consisting of two systems viz. unvulcanized blend and vulcanized blend, where each blend covered different blend compositions viz. 50=50=0, 50=40=10, 50=30=20, 50=20=30, 50=10=40, and 50=0=50. Thermoplastic elastomer blends were prepared by melt mixing in an internal mixer, Haake Polydrive with Rheomix R600=610, at temperature and rotor speed of 180C and 50 rpm, respectively.

During blending, thermoplastic PP were first loaded into the internal mixer and pre-mixed for 2 min, followed by the rubbers (EPDM and NR). For unvulcanized, the blends were taken out after 6 min of mixing. The corre-sponding dynamic vulcanization blends were prepared in the same manner except that the curatives were added after 5 min of mixing and followed by sulfur at 7 min, and the mixing time was prolonged until 10 min. The samples were then sheeted by passing through a 2 roll-mill and allowed to cool at room temperature.

Specimens for testing were compression molded using an electrically heated hydraulic press machine. The machine was pre-heated at 180C for 6 min, followed by another 4 min of compression under the same temperature. The specimen was allowed to cool under pressure for a further 4 min. A similar procedure was adopted for all blend systems.

Tensile Properties

Tensile tests were carried out according to ASTM D412 on an Instron Machine, and 2-mm thick dumbbell speci-mens were cut from the molded sheets with a Wallace die cutter. The specimen was tested using a constant rate (50 mm=min) at room temperature of 25C. The results were quoted based on the average value of five specimens tested for each blend system.

Swelling Test

Determination of the index of swelling was carried out according to ASTM D471. The specimens with dimensions

30 mm5 mm2 mm were cut and weighed using an

electrical balance. The test pieces were then immersed in toluene for 12 h and in oil (IRM 903) for 48 h at room tem-perature. The samples were then removed from toluene and oil, wiped with tissue paper to remove excess liquid from the surface, and weighed. The swelling index of the blends was then calculated as follows:

Swelling index¼W2

W1100% ð1Þ

Where W1¼weight of specimen before immersion, and

W2¼weight of specimen after immersion.

Gel Content

The degree of cross-linking in the rubber was measured after extraction in boiling cyclohexane for 8 h. The samples were dried at 80C for 30 min and subsequently weighed. The percentage of gel content of the blends was then calcu-lated as follows:

% gel content¼Wg

Wo

100% ð2Þ

Where Wg and W0 are sample weights after and before extraction, respectively.

Differential Scanning Calorimetry (DSC) Study

Thermal analysis measurements of selected blend sys-tems were performed using a DSC-7 Perkin Elmer differen-tial scanning calorimeter. The samples were programmed and heated at 20C=min to about 200C and maintained at this temperature for 10 min to ensure a complete melting of the crystals. The melting temperature (Tm) and the heat of fusion (DHf) were measured during the heating cycle.

Morphology Studies

Morphological evaluations of PP=EPDM=NR surfaces were done using a scanning electron microscope (SEM), model Leica Cambridge S-360. The unvulcanized blend samples were solvent-extracted using n-hexane for 2 days at room temperature to extract the rubber phase from the blend. The samples were then dried to remove excessive solvent. The vulcanized samples were etched with nitric acid for 2 days, washed with water, and then dried. All the samples were mounted on aluminum stubs and sputter-coated with a thin layer of gold to avoid electrostatic charging during examination. The examinations were done within 24 h of preparation.

RESULTS AND DISCUSSION

Process Development

The plastograms of sulfur vulcanized blends as com-pared to unvulcanized blends of PP=EPDM=NR blends with 50=50=0, 50=30=20, and 50=0=50 blend compositions are shown in Fig. 1. In sulfur vulcanization, curing ingredi-ents minus sulfur were added at the 5th min, whereas sulfur was added at the 7th min of mixing. The torque started to rise after the 7th min, at which sulfur was added, and stabi-lized at higher values than corresponding unvulcanized blends.

The raised torque values of sulfur vulcanized blends over that of unvulcanized blends indirectly indicate the increasing melt viscosity at the processing temperature. This implies that curing occurred. As cross-links are formed in the rubber phase, intermolecular slippage is restricted and the deformability of the rubber particles is decreased[8]. Consequently, melt viscosity of the blends

increases, requiring a higher energy requirement for the melt processing of sulfur vulcanized blends than the control counterparts.

Further, they show an increasing torque value as the NR content increases. As can be seen from Fig. 1, the increase in the torque with increasing NR content is evidence that the high cross-link formation occurred more on the NR phase than on the EPDM phase. This behavior may be explained as follows: incorporation of NR involves simul-taneous replacement of a portion of cross-linkable EPDM in the blend. Consequently, the unsaturated bonds for for-mation of cross-link were increased, which are prepared by NR. As well, EPDM, being a copolymer of two olefin monomers (ethylene and propylene), is a partially saturated elastomer, thus it is less cross-linked by the accelerated-sulfur cure systems that are commonly employed in the vulcanization of NR. However, as mentioned previously, interaction between NR and PP is weaker than PP and EPDM. Therefore, the increasing viscosity with increasing NR content and hence cross-link density may not be fol-lowed considerably with the tensile properties, which will be discussed next.

It is also worth noting that on the vulcanized blend with-out NR content (50=50=0 PP=EPDM=NR) the torque did not increase significantly. This could be due to the type of the EPDM (EPT 3072E) used, which contained oil. This allows the preparation of softer compositions with signifi-cant improvement in processability. In the melt, the oil par-titions between the phases and greatly lowers the viscosity, resulting in improved processing. In addition, the oil expands the volume fraction of the solid cross-link rubber phase, resulting in improvement of processability[3].

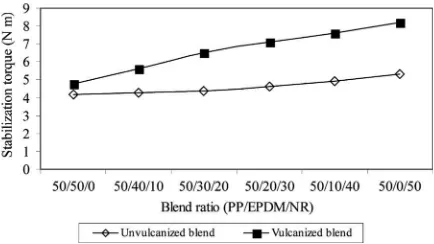

The comparison of stabilization torque values between sulfur vulcanized blends with unvulcanized blends is pre-sented as a function of blend compositions in Fig. 2. It can be seen that the stabilization torque increased as NR content increased for both vulcanized and unvulcanized

blends. When the NR is present as an additional dispersed phase in the PP phase, an unstable melt of blends could be expected because the PP becomes insufficient to provide a melt flow. As more NR particles are present in the PP continuous phase, the amount of rubber particles that can exist as dispersed phase become more, and conse-quently, the raised stabilization torque becomes higher.

Further, it shows that the stabilization torque of the dynamically vulcanized blend lies above the unvulcanized blend for every blend composition. During mixing, the vul-canized molecule chains could not be easily deformed by shearing action of the rotor, which is related to increasing the power requirement and enhances the frictional resist-ance of the blend against deformation[1].

Tensile Properties

The effects of dynamic vulcanization on tensile strength, tensile modulus (M100), and elongation at break of PP=EPDM=NR blend as compared with the unvulcanized blends are presented in Figs. 3, 4, and 5, respectively. It is clear from the results that the dynamic vulcanization process significantly enhances the tensile strength over unvulcanized blends as can be seen in Fig. 3.

The improvement in tensile strength by dynamic vulca-nization is well explained in the literature of elastomer=

plastic blends[9,10]. Formation of cross-links in the elastomer phase facilitating stress transfer contributes to such enhancement. This enhancement is a result of many factors. First, cross-linking increases the molecular entan-glements and forms a network structure resulting in an enhancement in stress transfer between phases. Second, under shear, the particle size of vulcanized rubber decreases, so the smaller the rubber particle size, the higher the tensile properties. Third, the particles distribute more uniformly in the matrix and, therefore, stress can be trans-ferred to the material more effectively. Finally, the dynamic vulcanization of the rubber component restricts the rubber particles coalescence and subsequently improves the properties.

FIG. 2. Comparison of stabilization torque between unvulcanized and vulcanized PP=EPDM=NR blends.

In tensile strength, the sulfur vulcanized blend has a more pronounced effect in the EPDM richer blends over the NR richer blends. This implies that the formation of cross-links is not the only factor that governs this improve-ment. The dynamic vulcanization, which resulted in cross-links in the rubber phase and is more pronounced in the NR rich blend is not indicated in this possibility. The good interactions between PP-EPDM over PP-NR contribute to enhanced tensile properties. As the NR content increased, the number of good interface regions available in the blends was decreased. This indicates that the interfacial adhesion between components plays an important role in achieving enhanced properties. The deterioration of tensile strength of the blend richer in NR content indicates the lower capability of vulcanized NR particles to support transfer of stress from the polymer matrix to the particles. The effect of dynamic vulcanization on the tensile modulus (M100) of PP=EPDM=NR blend as compared to the unvulcanized blends is shown in Fig. 4. The tensile modulus (M100) registers a marked improvement with the dynamic vulcanization, which proves the progressive devel-opment in cross-linking. This behavior is easily attributed to the increased strength in the rubber regions and the entanglements in the rubber phase owing to cross-linking, and the implication is increasing stiffness of the blend.

Here, vulcanized blends could not resist the deformability of the macromolecules, hence increasing the M100. How-ever, M100 of the 50=0=50 PP=EPDM=NR vulcanized blend is not reported because it ruptured before 100% elongation at break was achieved.

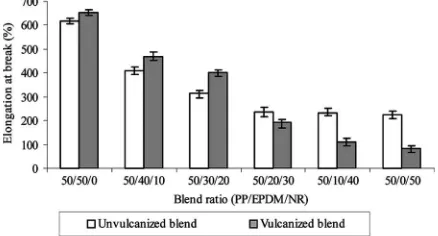

Figure 5 shows the comparison of elongation at break

between unvulcanized and sulfur vulcanized PP=

EPDM=NR blends. It can be seen that vulcanized blends show higher elongation at break in the EPDM richer blend. The elongation at break of the sulfur vulcanized blend con-taining richer NR shows an inverse relation with the EPDM rich blend. It shows that the elongation at break of the dynamically vulcanized blend is lower than the unvulcanized one and decreases gradually as the NR takes the dominant content over EPDM until minimum value is attained (at 50=0=50 blend). This indicates that the vulca-nized rubber phase does not significantly increase the initial resistance to the deformation of the macromolecules in the NR richer blend. The reason is as follows: although NR content increases, the chemical cross-linking of rubber restricts mobility of the polymer chain. In addition, when the NR content is high, vulcanized NR particles may exist mostly in the continuous phase, resulting in significant resistance to the deformation of macromolecules. This will narrow down the effect of rubber on the elongation at break. In addition, the number of poor interface regions available in the blends and lack of interfacial adhesion may affect the elongation at break.

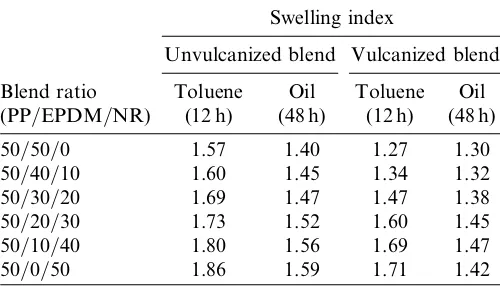

Swelling Index

Results presented in Table 1 show the comparison of swelling index between sulfur PP=EPDM=NR vulcanized blends with unvulcanized blends as a function of blend composition. The swelling index values of blends in toluene and oil are shown in the same table and indicate the chemi-cal and oil resistance of the blends, respectively.

It can be seen that swelling index of PP=EPDM=NR blends after immersion in toluene for 12 h increased with increasing NR content. Here, EPDM has a low level of FIG. 3. Comparison of tensile strength between unvulcanized and

vulcanized PP=EPDM=NR blends.

FIG. 4. Comparison of tensile modulus (M100) between unvulcanized and vulcanized PP=EPDM=NR blends.

FIG. 5. Comparison of elongation at break between unvulcanized and vulcanized PP=EPDM=NR blends.

polarity, consisting of only carbon and hydrogen atoms with little unsaturation (the main chain has no double bonds). As compared with NR, which has double bonds in the main chain, EPDM is considerably less polar than NR[11]. Therefore, EPDM exhibits less swell in toluene (polar liquid) compared with NR, and its blend conse-quently leads to high chemical resistance.

On the other hand, Table 1 also shows that the swelling index of PP=EPDM=NR blends after immersion in oil IRM 903 for 48 h increased with increasing NR content. Even though EPDM has lower polarity than NR, which swells easier in oil (nonpolar liquid), due to the good

inter-action between PP and EPDM, the 50=50=0 PP=

EPDM=NR blend possesses higher resistance to oil than those of 50=30=20 and 50=0=50 PP=EPDM=NR blends. Here, the good interaction between PP and EPDM inhibits the penetration of oil into the rubber.

Table 1 depicts that the swelling index values of dynamically vulcanized blends exhibit lower values than their unvulcanized counterparts for toluene and oil as well. The introduction of cross-links into the rubber phase inter-rupts this diffusion process and results in a reduction in the swelling index. Table 1 shows that dynamically vulcanized rubber is effective as evidenced by a similar decrease in the swelling index. The reductions of swelling index signify the different tensile properties of the vulcanizates as shown in tensile strength.

However, the increase in NR content in the blends has also increased the swelling index. Here, even though high cross-link formations have occurred, the decreased compatibility between PP and NR decreased the chemical and oil resistance of the blends.

Gel Content

The effect of dynamic vulcanization on the percent gel content of PP=EPDM=NR blend with respect to the

unvulcanized blends is presented in Table 2. The results show that the introduction of NR into the PP=EPDM blend decreased gel content of the blends. This effect is more pronounced for NR richer blends and indicates that NR is easier to extract by cyclohexane compared with EPDM. This can be attributed to the good interaction between PP and EPDM, hence during extraction the rub-ber particles (EPDM) were not easily extracted from the continuous phase (PP). This observation also confirms the tensile properties as mentioned before, where the good interaction between PP and EPDM is disturbed by NR addition.

Table 2 also depicts that the dynamic vulcanization pro-cess gives rise to a sensible increase in gel content as well as a considerable reduction of the percent of extractable elas-tomer by cyclohexane with respect to the corresponding unvulcanized blends. A higher gel content means that fewer main chains have been extracted, which can be attributed to the cross-links formation. During the cross-linking reac-tion, the average molecular weight of the chain increases, thus causing the sample to become gradually insoluble in solvent.

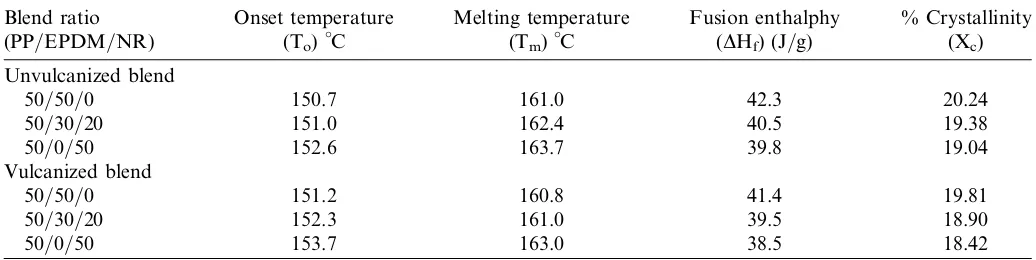

Differential Scanning Calorimetry (DSC)

Figure 6 shows the effect of sulfur on DSC scans of PP=EPDM=NR blends with different blend compositions as compared with the unvulcanized blends. The area of the melting endothermic was measured as the heat of fusion (DHf). The parameter Xcdetermines the percentage of crystallinity blends. The Xcin this study was calculated by dividing the measuredDHfby theDHfof 100% crystal-line material. TheDHffor polypropylene as a fully crystal-line material is 209 J=g[12]. It can be seen that all blend compositions have almost the same pattern of heating thermogram, which showed no change in the curves on inclusion of NR. The thermal properties of the blends are governed by the crystalline PP=EPDM blend alone because NR is an amorphous polymer. Therefore, a marginal change in melting temperature (Tm) and onset temperature TABLE 1

Swelling index of dynamically vulcanized PP=EPDM=NR blends as compared with unvulcanized blends after

immersion in toluene and oil IRM903

Swelling index

Gel content of selected dynamically vulcanized PP=EPDM=NR blends as compared with unvulcanized

(To) of PP=EPDM blend was observed with the addition of NR, as can be seen in Table 3.

However, a slightly increased To in the 50=30=20 and 50=0=50 PP=EPDM=NR blends clearly indicates that the introduction of NR in the blend results in delayed nucleation and thus implies an increasing heterogeneity in spherulite size. The reduction rate of crystallization in the presence of NR due to the restricted mobility of the PP=EPDM segments by NR addition thereby leads to lacking alignment in the crystal lattice[13].

It is clear from the heating curves that the melting temperature of PP does not change significantly by the dynamic vulcanization with respect to the control blends. It is also interesting to note that incorporation of NR does not show any influence on melting temperature (Tm) of dynamic vulcanized blends. However, careful investigation of heating scans of the dynamic vulcanized blend, which are shown in Table 3, show a shift of onset temperature (To) toward a slightly higher value. It seems to be due to the cross-link formation, which makes the chain unfolding of PP plausible at a bit higher temperature.

Vulcanized blends exhibit low fusion enthalpy over control blends at each blend composition. This obser-vation supports that the percentage of crystallinity is less in the vulcanized blends. This result attests to the increased chain entanglements due to vulcanization, which may in turn interrupt the ability of PP macromolecules to align. The cross-link acts as a local defect and this would lead to the reduction in percentage of crystallinity. In addition, the reduction due to the formation of cross-links in the rubber phase caused an increase in its viscosity. This restricted the process of crystallization and crystal growth in PP. Hence the overall crystallinity of the blend is decreased.

The result further shows that in control and vulca-nized systems, fusion enthalpy (DHf) decreased slightly as NR was introduced and hence the percentage of crystallinity (Xc) of the blends also decreased. Here, as NR content increases in the blends, such reduction in fusion enthalpy of the blends can occur because the content of nucleating agent component (EPDM) is reduced. However, it shows that the degree of orien-tation does not much affect the strength property in these blends. Though the PP orientation is one factor that will impart tensile properties of these blends, the continuous nature of the matrix (PP) allows the load to be shared. And there is some evidence that percent-age of crystallinity of the blends is less disturbed by the dynamic vulcanization. Hence, blends still exhibit higher tensile strength compared to the control blends as explained before.

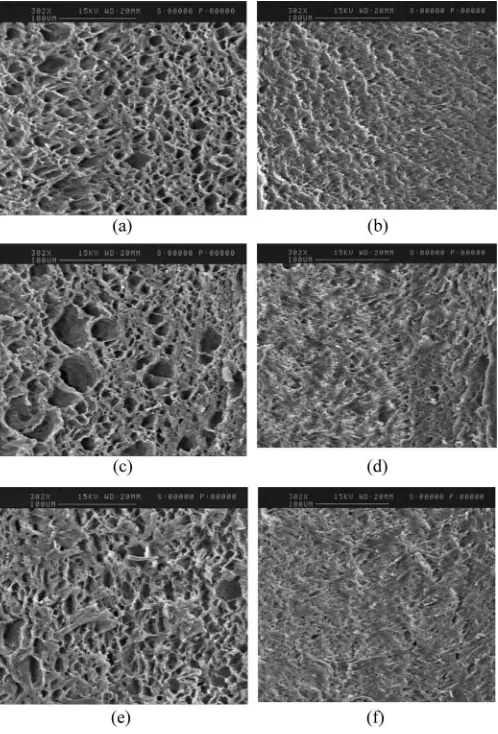

Morphology Studies

Figures 7a–f presents the SEM micrographs of extracted selected PP=EPDM=NR blends for both dynamic vulca-nized and unvulcavulca-nized blends. The honeycomb structure of the micrographs on the unvulcanized blends (Figs. 7a, c, and e) shows a large number of voids, which consist of dark and light spots. The dark spots correspond to the FIG. 6. The effect of dynamic vulcanization on DSC scans of

PP=EPDM=NR blends as compared with unvulcanized blends with differ-ent blend compositions.

TABLE 3

Thermal properties of dynamic vulcanization of PP=EPDM=NR blends as compared with unvulcanized blends derived from DSC scan thermogram

empty holes left behind by the rubber after dissolving in n-hexane. The light spots represent the insoluble PP phase. There was an indication of the heterogeneous phase structure of PP=EPDM=NR blends for every blend compo-sition. Here, one component is expected to form a discrete phase (rubber) dispersed in the other component forming the continuous phase (plastic) and thus giving rise to a two-phase system. In these systems, during processing the low viscosity component tends to become the continuous phase, whereas the high viscosity is a discrete phase. How-ever, Fig. 7a shows that the rubber particles (EPDM) are well dispersed in the continuous phase of PP indicating good adhesion between PP and EPDM.

It can be seen that upon extraction, the rubber particles of vulcanized blends (Figs. 7b, d, and f) were not easily extracted from the continuous phase. These nature micrographs reveal that the blends achieved vulcanized rubber properties due to the formation of cross-links.

Simultaneously, the holes in the vulcanized blends are smaller and less obvious than those of unvulcanized blends, and the dispersibility of rubbers in PP matrix are markedly improved. Here, during the dynamic vulcaniza-tion process, stable domain morphology of vulcanized particles is obtained and consequently produces better blend properties.

The micrographs also show that the vulcanized rubber particles are dispersed more uniformly in the continuous phase of PP. This could be attributed to the immobilization of the rubber particles by cross-linking and therefore breaking down to small size under the applied shear field[14]. According to Sabet et al.[3], during dynamic vulca-nization of TPE, the rubbers and the thermoplastic undergo a phase inversion to maintain the thermoplasticity of the blend. In the initial stage of dynamic vulcanization, two co-continuous phases are generated and as the degree of cross-linking advances while mixing, the continuous rubber phase becomes elongated further and further and then breaks up into polymer droplets. As these rubber par-ticles are forming as droplets, the PP becomes a continuous phase.

CONCLUSION

Dynamically vulcanized PP=EPDM=NR blends exhibit higher stabilization torque, tensile strength, and tensile modulus (M100) but lower elongation at break with EPDM rich content than unvulcanized blends. The enhancement of gel content and the reduction of swelling index have also proved the formation of cross-links. Dynamically vulca-nized blends show slightly lower percentage of crystallinity than unvulcanized blends. The development of finer vulca-nized rubber particles due to the cross-links formation improves stability of the morphology, which improves the properties of the blends.

ACKNOWLEDGEMENT

The authors would like to thank Yayasan Felda for the research grant that made this research work possible.

REFERENCES

1. Coran, A.Y.; Patel, R. Rubber–thermoplastic compositions Part I. EPDM-polypropylene thermoplastic vulcanizates. Rubb. Chem. Technol.1980,53, 141–153.

2. Lopez-Manchado, M.A.; Arroyo, M. New developments in dynamically cured PP-EPDM blends. Rubb. Chem. Technol.2001, 74, 211–220.

3. Sabet, S.A.; Puydak, R.C.; Rader, C.P. Dynamically vulcanized thermoplastic elastomers. Rubb. Chem. Technol.1996,69, 476–493. 4. Ellul, M.D. Novel dynamically vulcanized elastomer-polypropylene

blends with improved elasticity. Rubb. Chem. Technol. 2003, 76, 202–211.

5. Xiao, H.; Huang, S.; Jiang, T.; Cheng, S. Miscibility of blends of ethylene-propylene diene terpolymer and polypropylene. J. Appl. Polym. Sci.2002,83, 315–322.

6. Sariatpanahi, H.; Nazokdast, H.; Dabir, B.; Sadaghiani, K.; Hemmati, M. Relationship between interfacial tension and dispersed-phased particle size in polymer blends. I. PP=EPDM. J. Appl. Polym. Sci.2002,86, 3148–3159.

7. Halimatuddahliana; Ismail, H. Thermoplastic elastomer based on PP=EPDM=ENR25 and PP=EPDM=NR blends. Polym. Plast. Tech. Eng.2004,43, 357–368.

8. George, J.; Varughese, K.T.; Thomas, S. Dynamically vulcanized thermoplastic elastomer blends of polyethylene and nitrile rubber. Polymer2000,41, 1507–1517.

9. Jain, A.K.; Nagpal, A.K.; Singhal, R.; Gupta, K. Effect of dynamic crosslinking on impact and other mechanical properties of polypropylene=ethylene-propylene diene rubber blends. J. Appl. Polym. Sci.2000,78, 2089–2103.

10. Saroop, M.; Mathur, G.N. Studies on the dynamically vulcanized polypropylene (PP)=butadiene styrene block copolymer (SBS) blends: Rheological properties. J. Appl. Polym. Sci.1997,65, 2703–2713. 11. Ciesielski, A. An Introduction to Rubber Technology, Rapra

Technology, Ltd.: Shawbury, UK, 1999.

12. Greco, R.; Manacarella, C.; Martuscelli, E.; Ragosta, G. Polyolefin blends: 2. Effect of EPR composition on structure, morphology and mechanical properties of iPP=EPR alloys. Polymer1987,28, 1929–1936. 13. Choudhury, N.R.; Chaki, T.K.; Dutta, A.; Bhowmick, A.K. Thermal, X-ray and dynamic mechanical properties of thermoplastic elastomeric natural rubber-polyethylene blends. Polymer1989,30, 2047–2053. 14. Crevecoeur, J.J.; Nelissen, L.; Van Der Sanden, M.C.M.; Mencer, H.J.;

Hogt, A.H. Impact strength of reactively extruded polystyrene=

ethylene-propylene diene rubber blends. Polymer1995,36, 753–757.