Aspek usabilitas dalam desain produk

Written by Azi Ginanjar Nugraha Category: Artikel

Published on 23 March 2011 Hits: 172

Menurut I SO, usabilit y berart i efekt ifit as, efisiensi, dan k epuasan y ang

dit et apk an pengguna sehingga t ercapai t uj uan t ert ent u dalam lingk ungan

t ert ent u. Dalam hal ini efek t ifit as berart i seberapa j auh t uj uan, at au t ugas,

t ercapai. Sedangk an efisiensi m em iliki art i j um lah usaha y ang dibut uhk an

unt uk m eny elesaik an t uj uan. Dan k epuasan m erupak an t ingk at k eny am anan

y ang pengguna rasak an saat m enggunak an produk dan seberapa dit erim a

sebuah produk bagi pengguna unt uk m encapai t uj uan m erek a.

Sebuah produk y ang dapat digunak an bagi sebagian orang, belum t ent u

dapat digunak an bagi sebagian y ang lainny a. Unt uk it u haruslah dipikirk an

k arak t erist ik apa saj a y ang ada pada pengguna y ang m em pengaruhi t ingk at

k em udahan produk . Berik ut adalah k arak t erist ik t ersebut .

1. Pengalam an

2. Dom ain Knowledge

3. Lat ar belak ang buday a

4. Disabilit y

5. Usia dan j enis k elam in

TU JU AN USABI LI TY

M in im a si Ga n ggu a n

M e m pe n ga r u h i Pr odu ct sa le s

Dalam w ak t u belak angan ini, isu produk ergonom i m erupak an hal pent ing

dalam penent uan produk y ang ak an dibeli oleh m asy arak at . Perusahaan

m enj adik an isu ini sebagai k eunt ungan t erhadap k om pet it or. Dengan

dem ikian, m ak a usabilit y ak an berdam pak bagi t ingk at penj ualan dari

sebuah produk .

Pr odu k t iv it a s

Produk y ang t idak usable di t em pat k erj a ak an m em buang w ak t u dan

ongk os. Usabilit as pada produk y ang digunak an dalam t em pat kerj a j uga

berdam pak pada t ingk at k epuasan diant ar pek erj a. Dengan dem ikian m ak a,

usabilit as ak an m em pengaruhi t ingk at produk t ivit as dari pek erj a.

Sa fe t y

Dalam beberapa k asus usabilit as dari produk dapat m em pengaruhi

k eselam at an dari pengguna. Kondisi ini dapat t erj adi apabila t erj adi

k esalahan

operasi

y ang

dilakuk an

pengguna.

Hal

ini

dapat

saj a

m enyebabk an hal y ang lebih besar, t erut am a pada penggunaan alat - alat

y ang m em iliki t ingk at resik o y ang t inggi. Unt uk it u usabilit y dari produk

perlu diperhat ik an agar pengguna

PRI N SI P U SABI LI TY D ALAM PROD UK

Perancangan produk y ang k onsist en dalam produk m em iliki pengert ian

bahw a pek erj aan y ang serupa seharusny a dapat dik erj ak an dengan cara

y ang serupa pula. Dengan dem ikian, pengguna ak an lebih m udah dalam

belaj ar unt uk m enggunak an produk , berdasark an pengalam anny a t erdahulu

dalam berint erak si dengan produk .

Ke se su a ia n

Desain unt uk k esesuaian ( Com pat ibilit y ) m erupak an m erancang produk

produk agar m et ode pengoperasian produk sesuai dengan ek spekt asi

penggunaberdasark an pada penget ahuan m erek a t erhadap t ipe lainny a dan

w aw asan m erek a. t ingk at k esesuaian dalam sebuah produk sangat

dipengaruhi oleh st ereot ip m asy arak at y ang k em udian ak an m em pengaruhi

persepsi m erek a pada sebuah obj ek .

Pe r t im ba n ga n su be r da y a pe n ggu n a

Dalam hal ini perancang haruslah m endesain sebuah produk y ang

pengoperasianny a m am perhit ungk an perm int aan y ang dit em pat k an pada

sum berday a pengguna selam a int erak si berlangsung.

Fe e dba ck

Merancang sebuah produk agar t indakan y ang dilakuk an pengguna diak ui

dan m engindik asik an hasil dari t indak an t ersebut .

Pe n ce ga h a n k e sa la h a n

Merancang sebuah produk sehingga kesalahan y ang dilakuk an user dapat

dim inim alan dan aar apabila t erj adi erroro pengguna dapat k em bali dengan

cepat dan m udah.

Merancang sebuah produk sehingga m enget ahu sej auh m ana user

m engaw asi t indak an y ang dilakuk an oleh produk .

Ke j e la sa n V isu a l

Mendesain produk dim ana inform asi y ang dit am pilk an dapat dibaca dengan

cepat dan m udah t anpa adany a k eraguan.

Pr ior it a s fu n gsion a l da n in for m a si

Merancang produk sehingga fingsi dan inform asi y ang paling pent ing dari

produk dapat dengan m udah dim asuki oleh user.

Tr a n sfe r t e k n ologi y a n g se su a i

Mem buat k esesuaian k egunaan dari t ek nologi y ang berk em bang dalam

k ont ek s lain unt uk m eningk at k an usabilit u dai produk .

Ke t e ga sa n

Merancang produk sehingga isy arat y ang diberik an sebagai fungsi dan

m et ode operasi. Prinsip k et egasan ini j uga berk ait an k epada t ingk at

am biguit as dari suat u feat ure y ang ada pada produk . dengan dem ikian,

k et egasan dari isy arat y ang diberik an oleh produk ak an m em pengaruhi

t ingk at usabilit as dari produk .

Gambaran Tentang Pr oses Desain Pr oduk ( 1) Design

Design is t he process by w hich t he needs of t he cust om er or t he m arket place are t ransform ed int o a

product sat isfying t hese needs. It is usually carried out a designer or engineer but requires help from

ot her people in t he com pany.

Design essent ially is an exercise in problem solving. Typically, t he design of a new product consist s of t he

The developm ent of a new product m ay also require t he developm ent of a prot ot ype t o pr ove t hat new

t echnologies w ork before com m it t ing resources t o full-scale m anufact ure.

The t radit ional view of t he design t o m anufact ure pr ocess is t hat it is a sequent ial process, t he out com e

of one st age is passed on t o t he next st age. This t ends t o lead t o it erat ion in t he design. I.e. having t o go

back t o an earlier st age t o correct m ist akes. This can m ake product s m ore expensive and delivered t o

t he m arket place lat e. A bet t er approach is for t he designer t o consider t he st ages follow ing design t o t ry

and eliminat e any pot ent ial problem s. This m eans t hat t he designer requires help from t he ot her

expert s in t he com pany for exam ple t he m anufact uring expert t o help ensure t hat any designs t he

designer com es up w it h can be m ade.

So w hat fact ors m ight a designer have t o consider in order t o elim inat e it erat ion?

* M anufacture - Can t he product be m ade w it h our facilities?

* Sales - Are w e producing a product t hat t he cust om er w ant s?

* Purchasing - Are t he part s specified in st ock, or do w hy have t o order t hem ?

* Cost - Is t he design going t o cost t oo m uch t o m ake?

* Transport - Is t he product t he right size for t he m et hod of t ransport ing?

* Disposal - How w ill t he product be disposed at t he end of it s life?

Design Brief

The design brief is t ypically a st at em ent of int ent . I.e. " We w ill design and m ake a Form ula One racing

car" . Alt hough it st at es t he problem , it isn't enough inf orm at ion w it h w hich t o st art designing.

Product Design Specification (PDS)

This is possibly t he m ost im port ant st age of t he design process and yet one of t he least underst ood

problem . The PDS is a docum ent list ing t he problem in det ail. It is im port ant t o w ork w it h t he cust om er

and analyse t he m arket place t o produce a list of requir em ent s necessary t o produce a successful

product . The designer should const ant ly refer back t o t his docum ent t o ensure designs are appropriat e.

To produce t he PDS it is likely t hat you w ill have t o research t he problem and analyse com pet ing

product s and all im port ant point s and discoveries should be included in your PDS.

Concept Design

Using t he PDS as t he basis, t he designer at t em pt s t o pr oduce an out line of a solut ion. A concept ual

design is a usually an out line of key com ponent s and t heir arrangement w it h t he det ails of t he design

left for a lat er st age. For exam ple, a concept design for a car m ight consist of a sket ch show ing a car w it h

four w heels and t he engine m ount ed at t he front of t he car. The exact det ails of t he com ponent s such as

t he diam et er of t he w heels or t he size of t he engine are det erm ined at t he det ail design st age. How ever,

t he degree of det ail generat ed at t he concept ual design st age w ill vary depending on t he product being

designed.

It is im port ant w hen designing a product t hat you not only consider t he product design specificat ion but

you also consider t he act ivit ies dow nst ream of t he design st age. Dow nst ream act ivities t ypically are

m anufact ure, sales, t ranspor t at ion et c. By considering t hese st ages early, you can elim inat e problem s

t hat m ay occur at t hese st ages.

This st age of t he design involves draw ing up a num ber of different viable concept designs w hich sat isfy

t he requirem ent s of t he product out lined in t he PDS and t hen evaluat ing t hem t o decide on t he m ost

suit able t o develop furt her. Hence, concept design can be seen as a t w o-st age process of concept

generat ion and concept evaluat ion

ht t p:/ / draw sket ch.about .com / .../ / w w w.ider.hert s.ac.uk/ school/ coursew are/ graphics/ engineering_draw

ing/

Gambaran Tentang Pr oses Desain Pr oduk ( 2) lanjutan Concept generation

Typically, designers capt ure t heir ideas by sket ching t hem on paper. Annot at ion helps ident ify key point s

so t hat t heir ideas can be com m unicat ed w it h ot her m em bers of t he com pany.

There are a num ber of t echniques available t o t he designer t o aid t he developm ent of new concept s.

One of t he m ost popular is brainst orm ing.

This t echnique involves generat ing ideas, t ypically in sm all groups, by saying any idea t hat com es int o

your head no m at t er how silly it m ay seem. This usually sparks ideas from ot her t eam m em bers. By t he

end of a brainst orm ing session t here w ill be a list of ideas, m ost useless, but som e m ay have t he

pot ent ial t o be developed int o a concept . Brainst orm ing w orks bet t er if t he m em bers of t he t eam have

Concept evaluation

Once a suit able num ber of concept s have been generat ed, it is necessary t o choose t he design m ost

suit able for t o fulfil t he requirem ent s set out in t he PDS. The product design specificat ion should be used

as t he basis of any decision being m ade. Ideally a m ult ifunct ion design t eam should perform t his t ask so

t hat each concept can be evaluat ed from a num ber of angles or perspect ives. The chosen concept w ill

be developed in det ail.

One useful t echnique for evaluat ing concept s t o decide on w hich one is t he best is t o use a t echnique

called 'm at rix evaluat ion'

Wit h m at rix evaluat ion a t able is produced list ing im port ant t he feat ures required from a product -

usually t his list is draw n up from t he im port ant feat ures described in t he product design specificat ion.

The product s are list ed across t he t able. The first concept is t he benchm ark concept . The qualit y of t he

ot her concept s are com pared against t he benchm ark concept for t he required feat ures, t o help ident ify

if t he concept is bet t er , w orse t han, or is t he sam e as t he benchm ark concept . The design w it h t he m ost

'bet t er t han' is likely t o be t he best concept t o develop furt her.

M ost people w ho use t he m at rix t echnique w ill assign point s, rat her t han sim ple, bet t er, w orse, sam e,

so t hat it is easier t o ident ify w hich concept s are t he best . It is also likely t hat som e feat ures of t he

design w ill be m ore im port ant t han ot hers so a w eight ing is used.

Detail design

In t his st age of t he design process, t he chosen concept design is designed in det ailed wit h all t he

dim ensions and specificat ions necessary t o m ake t he design specified on a det ailed draw ing of t he

design.

It m ay be necessary t o produce prot ot ypes t o t est ideas at t his st age. The designer should also w ork

closely w it h m anufact ure t o ensure t hat t he product can be m ade.

ht t p:/ / draw sket ch.about .com / .../ / w w w.ider.hert s.ac.uk/ school/ coursew are/ graphics/ engineering_draw

ing/

Apa itu Manufaktur dan Sejarahnya

M anufakt ur adalah suat u cabang indust ri yang mengaplikasikan peralat an dan suat u medium proses

unt uk t ransformasi bahan ment ah menjadi barang jadi unt uk dijual. Upaya ini melibat kan semua proses

ant ara yang dibut uhkan unt uk produksi dan int egrasi komponen-komponen suat u produk. Beberapa

indust ri, sepert i produsen semikondukt or dan baja, juga menggunakan ist ilah fabrikasi at au pabrikasi.

Sekt or manufakt ur sangat erat t erkait dengan rekayasa at au t eknik. - Wikipedia bahasa Indonesia

Kat a m anufakt ur berasal dari bahasa Lat in m anus fact us yang berart i dibuat dengan t angan. Kat a

m anufact ure m uncul pert am a kali t ahun 1576, dan kat a m anufact uring m uncul t ahun 1683. M anufakt ur,

dalam art i yang paling luas, adalah proses m erubah bahan baku m enjadi produk. Proses ini m eliput i (1)

perancangan produk, (2) pem ilihan m at erial, dan (3) t ahap-t ahap proses dim ana produk t ersebut dibuat .

Pada kont eks yang lebih m odern, m anufakt ur m elibat kan pem buat an produk dari bahan baku m elalui

berm acam -m acam proses, m esin dan operasi, m engikut i perencanaan yang t erorganisasi dengan baik

unt uk set iap akt ifit as yang diperlukan. M engikut i definisi ini, m anufakt ur pada um um nya adalah suat u

akt ifit as yang kom pleks yang m elibat kan berbagai variasi sum berdaya dan akt ifit as sebagai berikut :

- Perancangan Produk

- M anufact uring

- Perancangan proses

- M at erial / Bahan Baku

- M esin dan perkakas

- Product ion cont rol

- Support services

- Cust om er service

- Pem asaran

- Pem belian

- Penjualan

- Pengirim an

Hal-hal di at as t elah m elahirkan disiplin ilm u t ent ang t eknik m anufakt ur. Sesuai dengan definisi

m anufakt ur, keilm uan t eknik m anufakt ur m em pelajari perancangan produk m anufakt ur dan

perancangan proses pem buat annya sert a pengelolaan sist em produksinya (sist em m anufakt ur).

M eskipun t eknik m anufakt ur pada berbagai perguruan t inggi m em iliki ke-khas-an sendiri-sendiri nam un

selalu ada bagian yang sam a pada jurusan-jurusan t ersebut . Keilm uan t eknik m anufakt ur selalu berbasis

kepada akt ifit as pem buat an produk m anufakt ur yang m elibat kan berbagai akt ifit as dan sum berdaya

sepert i yang t elah diuraikan di at as.

Jika dicerm ati, bidang ilm u t eknik m anufakt ur sesungguhnya m erupakan sinergi (gabungan yang saling

m enguat kan) dari jurusan t eknik m esin dan t eknik indust ri. Dari t eknik m esin diadopsi ilm u-ilm u yang

t erkait dengan perancangan produk dan perancangan proses pem buat an, sedangkan dari t eknik indust ri

diadopsi ilm u-ilm u yang t erkait dengan pengelolaan sist em di indust ri m anufakt ur (indust ri yang

m enghasilkan produk m anufakt ur). Dengan dem ikian akan ada beberapa m at akuliah yang bisa dijum pai

t erdapat pada ket iga jurusan t ersebut (overlapping).

Karena sinergi t ersebut , di beberapa perguruan t inggi yang belum m em iliki t eknik m anufakt ur sebagai

jurusan t ersendiri, keilm uan t eknik m anufakt ur biasanya m enjadi bagian dari jurusan t eknik m esin at au

t eknik indust ri. Dengan demikian banyak bidang ilm u di kedua jurusan t ersebut yang juga dipelajari di

jurusan t eknik m anufakt ur.

m anufakt ur. Yang dim aksud produk m anufakt ur di sini adalah produk-produk yang pem buat annya

m elalui berbagai proses m anufakt ur. Sebagai ilust rasi, m ari kit a perhat ikan dan kit a periksa beberapa

obyek di sekit ar kit a: arloji, kursi, st apler, pensil, kalkulat or, t elpon, panci dan pem egang lam pu. Kit a

segera akan m enyadari bahw a sem ua obyek t ersebut m em punyai bent uk yang berbeda. Benda-benda

t ersebut t idak akan bisa kit a jum pai ada di alam ini sebagaim ana seolah-olah t ersedia begit u saja di

ruangan kit a. Benda-benda t ersebut t elah dit ransform asikan (dicipt akan/ dibuat ) dari berbagai m at erial

dan dirakit hingga m enjadi benda-benda yang kit a pergunakan sehari-hari.

Beberapa obyek t erdiri dari sat u kom ponen, sepert i paku, baut , kaw at , gant ungan baju. Nam un

dem ikian, kebanyakan obyek – m esin pesaw at t erbang (dit em ukan t ahun 1939), ballpoint (1938),

panggangan rot i (1926), m esin cuci (1910), AC (1928), lem ari es (1931), m esin fot ocopy (1949), dan

sem ua jenis m esin, sert a ribuan produk lainnya - dibangun dari perakit an sejum lah kom ponen yang

t erbuat dari berbagai jenis m at erial. Sem ua kom ponen t ersebut dibuat m elalui berbagai proses yang

disebut m anufakt ur (m anufact uring). Disam ping produk-produk akhir t ersebut , m anufakt ur juga

m elibat kan akt ifit as dim ana produk yang dibuat dipergunakan unt uk m em buat produk lain. Produk

t ersebut adalah m esin-m esin yang dipakai unt uk m em buat berbagai m acam produk. M isalnya m esin

press unt uk m em buat plat lem baran m enjadi bodi m obil, m esin-m esin unt uk m em buat kom ponen, at au

m esin jahit unt uk m em produksi pakaian. Aspek yang sam a pent ingnya adalah perbaikan dan peraw at an

(service and m aint enance) m esin-m esin t ersebut selam a um ur hidupnya.

link: ht t p:/ / t m .ubaya.ac.id/ index.php?opt ion=com _cont ent & view =art icle& id=19& It emid=27

Design in Manufactur ing Engineer ing ( 4)

TERMI NOLOGY

The word "design" is often considered ambiguous depending on the application.

Design and ar tDesign is often viewed as a more rigorous form of art, or art with a clearly defined purpose. The

distinction is usually made when someone other than the artist is defining the purpose. In graphic

arts the distinction is often made between fine art and commercial art.

In the realm of the arts, design is more relevant to the "applied" arts, such as architecture and

industrial design. In fact today the term design is widely associated to modern industrial product

design as initiated by Raymond Loewy and teachings at the Bauhaus and Ulm School of Design

(HfG Ulm) in Germany during the 20th Century.

pure art. One may assume his art does not convey a message based on the obvious differences

between an advertisement poster and the mere possibility of an abstract message of a Jackson

Pollock painting. One may speculate that Pollock, when painting, worked more intuitively than

would a graphic artist, when consciously designing a poster. However, Mark Getlein suggests the

principles of design are "almost instinctive", "built-in", "natural", and part of "our sense of

[image:10.612.73.203.167.350.2]'rightness'." Pollock, as a trained artist, may have utilized design whether conscious or not.

Fig. 4. The new terminal at

Barajas airport in Madrid, Spain

Design and Engineer ing

Engineering is often viewed as a more rigorous form of design. Contrary views suggest that

design is a component of engineering aside from production and other operations which utilize

engineering. A neutral view may suggest that both design and engineering simply overlap,

depending on the discipline of design. The American Heritage Dictionary defines design as: "To

conceive or fashion in the mind; invent," and "To formulate a plan", and defines engineering as:

"The application of scientific and mathematical principles to practical ends such as the design,

manufacture, and operation of efficient and economical structures, machines, processes, and

systems.". Both are forms of problem-solving with a defined distinction being the application of

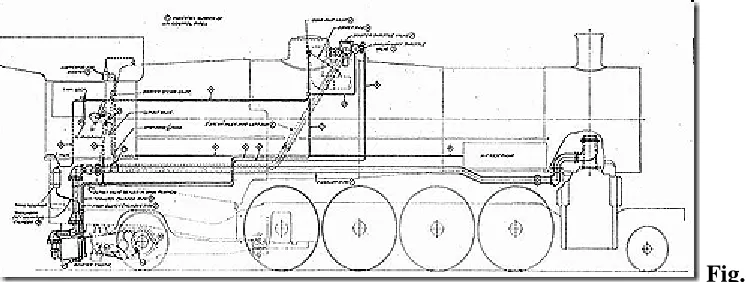

Fig. 5. A drawing for a

booster engine for steam locomotives. Engineering is applied to design, with emphasis on

function and the utilization of mathematics and science.

Design and Pr oduction

The relationship between design and production is one of planning and executing. In theory, the

plan should anticipate and compensate for potential problems in the execution process. Design

involves problem-solving and creativity. In contrast, production involves a routine or

pre-planned process. A design may also be a mere plan that does not include a production or

engineering process, although a working knowledge of such processes is usually expected of

designers. In some cases, it may be unnecessary and/or impractical to expect a designer with a

broad multidisciplinary knowledge required for such designs to also have a detailed knowledge

of how to produce the product.

Design and production are intertwined in many creative professional careers, meaning

problem-solving is part of execution and the reverse. As the cost of rearrangement increases, the need for

separating design from production increases as well. For example, a high-budget project, such as

a skyscraper, requires separating (design) architecture from (production) construction. A

Low-budget project, such as a locally printed office party invitation flyer, can be rearranged and

printed dozens of times at the low cost of a few sheets of paper, a few drops of ink, and less than

one hour's pay of a desktop publisher.

This is not to say that production never involves problem-solving or creativity, nor that design

always involves creativity. Designs are rarely perfect and are sometimes repetitive. The

imperfection of a design may task a production position (e.g. production artist, construction

worker) with utilizing creativity or problem-solving skills to compensate for what was

overlooked in the design process. Likewise, a design may be a simple repetition (copy) of a

known preexisting solution, requiring minimal, if any, creativity or problem-solving skills from

[image:11.612.75.448.72.213.2]the designer.

design fields, personal computers are also used for both design and production

Pr ocess Design

"Process design" (in contrast to "design process") refers to the planning of routine steps of a

process aside from the expected result. Processes (in general) are treated as a product of design,

not the method of design. The term originated with the industrial designing of chemical

processes. With the increasing complexities of the information age, consultants and executives

have found the term useful to describe the design of business processes as well as manufacturing

processes.

Fig. 7. An example of a

business workflow process using Business Process Modeling Notation.