Mechanical strength testing of stalk materials and

compacting energy evaluation

E. Kronbergs *

Institute of Mechanics,Lat6ia Uni6ersity of Agriculture,J.Cakstes bul6.5., Jelga6a,LV3001,Lat6ia Accepted 8 October 1999

Abstract

The great potential of cereal lignocelluloses for use as energy or as an industrial raw material source determines the necessity to investigate the mechanical properties of stalks, as the main parts of any herbaceous material. Annual world production of cereal straw is approximately of the same amount (around 2 billion tons) as wood material production. Latvia as a country with more than 2000 lakes has wide areas, covered with reeds, which are also an important stalk material resource. Stalk cross section and structural studies show that it is a complicated structure. Special test piece preparation and clamping methods, measuring devices, testing procedure for stalk material strength testing have been worked out. Ultimate tensile (118.798.63 N/mm2) and shear (8.4790.56 N/mm2) strength,

modulus of elasticity (13.191.34 GPa) and shear modulus (0.64390.043 GPa) had been experimentally determined for wheat stalks in order to find methods for mechanical conversion with minimum energy consumption. Stalk biomass compacting methods and energy requirement for that are analysed on the basis of the results from the experiments. It has been stated, that energy for wheat straw pressing (:40 kJ/kg up to pressure 160 MPa) is one order of magnitude less than that for heating of the same mass up to 200°C in the briquetting process (:360 kJ/kg), if solid material has to be obtained. Depending on the target goals for usage, different energy saving compacting technologies can be developed. Thus the analysis of mechanical and physical properties of the stalk materials determines the profit of biomass usage. © 2000 Elsevier Science B.V. All rights reserved.

Keywords:Stalk materials; Mechanical strength testing; Compacting energy

www.elsevier.com/locate/indcrop

1. Introduction

Annual world production of cereal straw was 1900 million tons in 1987 (Munck, 1992), but in Latvia the total straw production amount in 1997 was 850 907 tons. If 20% from the total amount

could be used for energy production (171 000 t straw), it is equal to heat capacity of 57 000 t of oil. Straw biomass can be used not only for agricultural purposes and energy production but also as an industrial raw material for paper and particleboard production. Latvia as a country with more than 2000 lakes, has wide areas cov-ered with emergent vegetation-reeds — also an important stalk material resource. The aforemen-* Tel.: +371-30-80674; fax:+371-30-27238.

E-mail address:[email protected] (E. Kronbergs)

tioned stalk materials have to be used for energy and industrial purposes with a good understand-ing of the agricultural ecosystem function. As it brings about soil impoverishment and erosion, the organic residue removal from the fields must be limited. The biomass amount whose removal has no significant impact on the carbon cycle varies from 20 to 50%. In the rural area, open water systems (rivers and lakes) and wetlands also play an important role in the functioning of the agri-cultural ecosystem. For ages lake ecosystems have been acting as sinks for collecting organic and minerogenic matter (Bjork, 1988).

At the same time, soil cultivation in the catch-ment area of natural open water systems interacts with water flows. It has been stated that the intense land cultivation over the last 100 years has led to irreversible charge flows (matter loss, mainly alkaline metal cations) from agricultural soils by surface water flows. Matter losses from agricultural areas may amount to more than one

ton per hectare a year (Ripl et al., 1994). The application of fertilizers will hardly compensate for this loss, nitrogen and phosphorus fertilizers together make for only 1 – 2% of this matter loss. So, the intense soil cultivation and surface water flows lead to the acidification and desertification of the catchment area. Overloading by nutrients (N, P, K and Ca) from external sources favours the growth of plants in the lakes and this, in turn, causes intensive accumulation of sediments (sapropel) and peat.

Limnologists (Ripl et al., 1994) recommend that for the redevelopment of catchment areas of open water systems solid matter (sludge, sediments, and compost) should be transported in a direction opposite to the water flow. It is also an important biomass application, because the energy require-ment for production, packaging, transportation and application of nitrogen, phosphorus and potassium (NPK) fertilizers is 33.64 BTUs/lb., for N, 7.53 BTUs/lb., for P2O5and 5.94 BTUs/lb. for

K2O. It corresponds to the consumption of diesel

fuel 2.41 l/kg (N), 0.54 l/kg (P2O5) and 0.42 l/kg

(K2O) (Helsel, 1992). Biomass usage, directly for

energy production, or as fertilizer, is an activity with equal importance in agriculture. Dry vegeta-tion materials and their stalks as the main part of any plant material can be used for all previously mentioned purposes, but their mechanical prop-erty data and compacting energy requirement have to be investigated. Mechanical properties are important measures for the design of processing and handling equipment. Investigations of com-paction properties of such stalk materials are carried out for the development of the most eco-nomical transport and storage.

2. Materials and methods

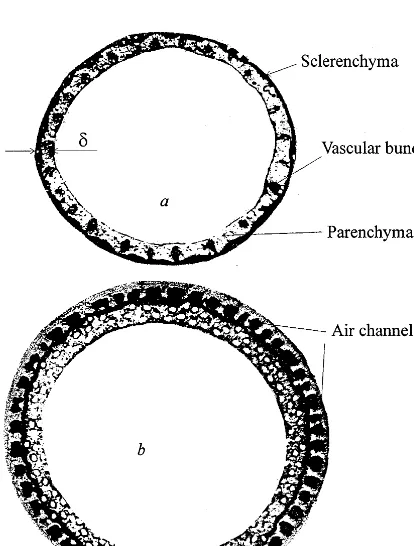

All stalk material consists of nodes and tubular internodes. The cross-section of wheat stalk with such parts as sclerenhyma, parenchyma and vas-cular bundles show us the complexity of its struc-ture. Reed stalks have some differences, such as air channels for oxygen supply to roots, because they are aquatic plants (Fig. 1). Stalk cross sec-tion can be assumed as an elliptic ring and mea-Fig. 1. Cross-section of stalks: (a) a wheat stalk, (b) a reed

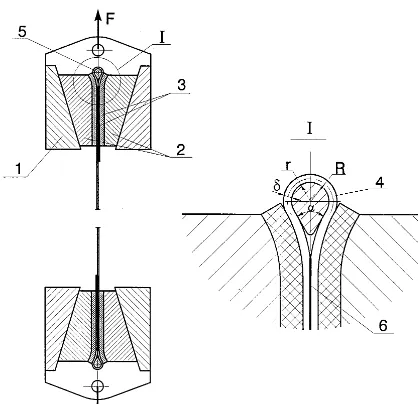

Fig. 2. Clamping of the stalk test piece for tensile testing.Fis the tensile force.

safeguarding rubber tapes 3, glued to the jaws 2. For tensile strength determination, it is recom-mended that a test piece from a stalk slice should be prepared with the width equal to triple thick-ness of the stalk material. The slice is bent around the droplet like section member and the end is connected to the main slice part with glue 6. The radiusrof the droplet like section member can be determined with inequality:

r\1 2d

E s

b

−1

(1)where d is the stalk slice thickness; E is the stalk material modulus of elasticity; sb is the stalk material tensile strength at break.

The modulus of elasticity has been calculated from Vereschagins equation on the basis of wheat stalk bending elastic deformation measurements under a determinate force. The accuracy of a stalk cross section measurement is important and a measuring microscope has to be used.

Fig. 3a shows the stalk ultimate shear stress measuring equipment. Flattened wheat stalk test piece 1, has been clamped between the equipment frame 2, and elastic lever 3, supplemented with strain gauges 4, measurement system and data collecting on the PC. Turning clockwise elastic lever 3, stalk test piece 1 has been sheared. Shear force has been recorded during all test procedure. For material cross section measurement a micro-scope also has to be used.

Shear modulus has been determined for the whole stalk material internodes part in torsion experiments.

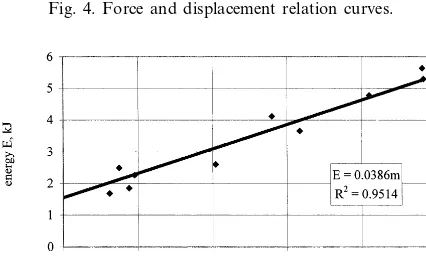

Compacting experiments have been carried out in a closed die (Fig. 3b) by means of tensile testing machine supplemented with press equipment. Wheat straw stalk material biomass with moisture content of 10% and chopped to different lengths, have been used for compacting. Chopped stalk material 1, in closed die 2, has been compacted by means of piston 3 (Fig. 3b). Force and displace-ment have been recorded in the compacting pro-cess. Maximum compacting pressure 160 Mpa has been achieved. The calculation of area under force and displacement relation curves (Fig. 4) from records, obtained in experiments, led to finding the energy requirement for wheat stalk compact-Fig. 3. Schemes of shear stress measurement and compacting

experiments: (a) shear stress measurement device, (b) closed die compacting.

sured by means of a measuring microscope for calculations of the cross-section area and mo-ments of inertia.

ing. Temperature influence on press density was also investigated. These experiments have been carried out on a laboratory hydraulic press. Prelim-inary stalk biomass was heated until the planned temperature had been achieved, then compacting started. Straw stalk biomass unit (kg) heating to temperature 200°C energy requirement calcula-tions, using Specific Heat value 1.8 kJ/kg·g rad (as for wood with a temperature 100°C), have been done. The biomass cutting (chopping) energy Ec

also for stalk biomass unit (kg) can be calculated using the known (Srivastava et al., 1993) equation:

Ec=

Esc

Lc

(2)

whereEscis the specific cutting energy per unit mass

(J·m/kg);Lc is the length of stalk cut (m).

It has been stated (Persson, 1987), that specific cutterhead energy was not affected by the moisture content, if the energy was calculated on a dry

matter basis. The value ofEc=38 J·m/kg (Persson,

1987) can be found for dry stalk material cutting energy requirement calculations.

The wheat stalk material cold compacting exper-iments with two additives have also been carried out. Dried molasses is a well-known binding agent and it was used for the biomass compacting. Admixing of the lake sediment (sapropel) additive as an antislagging agent for fuel briquettes produc-tion took place in compacting experiments. Bri-quettes obtained in the compacting experiments were measured and weighed for calculating the density.

3. Results

Ultimate tensile (118.798.63 N/mm2) and shear

(8.4790.56 N/mm2) strength, modulus of elasticity

(13.191.34 kN/mm2) and shear modulus (0.6439

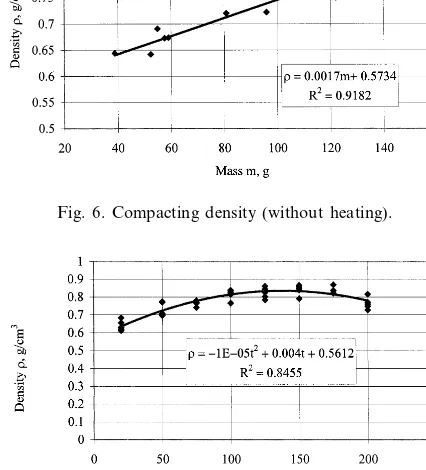

0.043 GPa) were experimentally determined for wheat stalks in order to find methods for mechan-ical conversion with minimum energy consump-tion. The energy requirement for wheat stalk compacting, calculated by integration of the area under force and displacement relation curves (Fig. 4) are reproduced in Fig. 5. Pressing energy con-sumption in high extent, depends on the stalk material biomass amount, which is in a closed die. On this basis it can be found out, that no more energy is necessary for wheat stalk material (chopped to length :2 cm) compacting up to pressure 160 Mpa than 40 kJ/kg, if every briquette obtained is :0.1 kg mass. The density of such compacted coarse chopped stalk material biomass also depends on the amount of mass, which is in a closed die (Fig. 6). The average density 0.7 g/cm3

has been obtained.

The experiments of the next series with heating the same coarse chopped wheat stalk material and pressing it up to the pressure 80 MPa show, that the average density 0.8 g/cm3 has been obtained

(Fig. 7). So with twice reduced pressure and heating stalk material up to temperature 200°C compacting density increased, but not considerably. The energy requirement for heating of the same mass up to temperature 200°C in the compacting process is :360 kJ/kg.

Fig. 4. Force and displacement relation curves.

Fig. 6. Compacting density (without heating).

comparison with coarse chopped material. Only fine chopping provide a density for compacted (t=20°C) material −0.85 g/cm3. The obtained

density is higher than the density of oak wood (0.803 g/cm3).

Cold compacting of fine chopped wheat stalk material with addition of molasses more than 9% and sapropel more than 15% provide density 1g/ cm3 without any heating (Fig. 9).

4. Discussion

Experimentally determined mechanical proper-ties are important measures for the design of processing and handling equipment. The ultimate shear strength of wheat stalks is 14 times less than ultimate tensile strength value. This fact is of main importance for cutting tool design. Stalk material tensile deformations in the cutting pro-cess have to be prevented. The ultimate tensile strength of 118.798.63 N/mm2 is higher than

tensile strength of pine wood material and this is an argument for stalk material use as a construc-tion material. The described test piece clamping method for tensile strength measurement, provide a reliability of the testing procedure with sample breaking between clamping devices. Ultimate shear stress measurement by means of elastic lever equipped with a strain gauge system can also be recommended as a reliable means for stalk mate-rial testing.

Fig. 7. Compacting density (coarse chopped, with heating).

Fig. 8. Compacting density (fine chopped, with heating).

Fig. 9. Cold compacting density. Fine chopped (ground) stalk material, selected

through a sieve with 1.5 mm eye, heated and pressed up to pressure 80 MPa enabled us to obtain the higher density :1 g/cm3 with

Wheat stalk material compacting experiment results let us evaluate the energy requirement for different density increasing methods. If there is no more energy necessary for wheat stalk material (chopped to length :2 cm) compacting up to the pressure of 160 MPa than 40 kJ/kg, in ordinary briquetting up to the pressure of 100 MPa then also the energy requirement is less. The average density 0.7 g/cm3, obtained in such coarse chopped

mate-rial compacting, is higher than pine wood density (0.498 g/cm3

). Without binding agents or heating material in the compacting process, the obtained briquette is not shock resistant. Density increasing up to 1 g/cm3

allows an increase also in shock resistance of the briquette. Compacting experi-ments have shown that fine chopping of stalk materials increases the density in the same extent as heating of the mass. Energy requirement calcu-lation results for stalk material fine chopping−25 kJ/kg is one order of magnitude less than that for heating of the mass up to 200°C temperature — 360 kJ/kg. Therefore the stalk material chopping is more preferable than heating. If solid fuel (bri-quettes or pellets) have to be obtained from stalk material — molasses can be used as a binding agent for cold compacting. Sugar production provides annually more than 22 000 tons of molasses in Latvia. As antislagging agents also are recom-mended for plant material fuels, lake sediment (sapropel) usage for this purpose is reasonable in Latvia’s conditions. Both molasses and sapropel are low cost organic materials and their influence on compacting density is positive. Further research for such fuel combustion properties should be performed to determine the optimum amount of additives for the best combustion.

5. Conclusion

Ultimate tensile (118.798.63 N/mm2

) and shear (8.4790.56 N/mm2) strength, modulus of elasticity

(13.191.34 GPa) and shear modulus (0.6439 0.043 GPa) were experimentally determined for wheat stalks in order to find methods for mechan-ical conversion with minimum energy consump-tion. These mechanical properties are important measures for the design of processing and handling

equipment, but suggested methods for tensile test piece clamping and ultimate shear stress measure-ment can be recommended for stalk material test-ing. Fine chopping of stalk materials significantly influence compacting density and is more prefer-able to heating, because energy requirement for chopping−25 kJ/kg is one order of magnitude less than that for mass heating up to 200°C temperature −360 kJ/kg. Molasses and sapropel are low cost organic materials in Latvia conditions and those can be used as binding agent and antislagging additive for stalk material solid fuel production.

Acknowledgements

The author wishes to express his gratitude to Dr ing. Aivars Strupausis for performing the tensile strength and Modulus of elasticity determination tests, MSc. ing. Aivars Kakitis for performing the shear stress measurement equipment design, col-leagues Raimonds Zarins and Ritvars Klapars for carrying out the compacting experiments.

References

Bjork, S., 1988. Redevelopment of Lake Ecosystems-A Case-Study Approach, AMBIO Vol. 17 NO.2: 90 – 98. Ripl, W., Pokorny J., Eiseltova M. and Ridgil S., 1994. An

holistic approach to the structure and function of wetlands, and their degradation. In: M. Eiseltova (Ed.), Restoration of Lake Ecosystems, an Holistic Approach. A Training handbook, pp. 16 – 35.

Helsel, Z.R., 1992. Energy and alternatives for fertilizer and pesticide use. In: Fluck, R.C. (Ed.), World Agriculture. Energy in Farm Production, vol. 6. Elsevier, New York, pp. 177 – 201.

Munck, L., 1992. The contribution of barley to agriculture today and in the future. Barley Genetics VI, volume II, Barley Research reviews 1986 – 91 Session and Workshop Summaries. Proceedings of the Sixth International Barley Genetics Symposium, July 22 – 27 1991, Helsingborg, Swe-den. Helsingborg, The Organizing Committee of the Nordic Countries, Sixth International Genetics Symposium pp. 1099 – 1109.

Srivastava, A.K., Goering, C.E., Rohrbach, R.P., 1993. Engi-neering principles of agricultural machines. In: P. De Vore-Hansen (Ed.), ASAE Textbook Number 6. Books and Journals, American Society of Agricultural Engineers, St. Josephs, Michigan,p. 601.