Pe r iodica l:

Applie d M e ch a n ics a n d M a t e r ia ls

I SSN : 1662- 7482

Abou t :

Applied Mechanics and Mat erials publishes only com plet e volum es on given t opics, proceedings and com plet e special t opic volum es. Thus, we are not able to publish stand-alone

papers.

Applied Mechanics and Mat erials specializes in t he rapid publicat ion of proceedings of int ernat ional conferences, w orksh ops and sym posia as w ell as st at e- of- t he- art volum es on t opics of curr ent int erest in all areas of m ech anics and t opics relat ed t o m at erials science.

Aut hors ret ain t he right t o publish an ext ended, significant ly updat ed version in anot her periodical.

I n de x in g : I ndex ed by Elsevier: SCOPUS w w w .scopus.com and Ei Com pendex ( CPX)

w w w . ei.org/ . Cam bridge Scient ific Abst ract s ( CSA) w w w .csa.com , Ch em ical Abst ract s ( CA) w w w .cas. org, Google and Google Sch olar google.com , I SI ( I STP, CPCI , Web of Science) w w w .isinet .com , I n st it ut ion of Elect rical Engineer s ( I EE) w w w .iee.org, et c.

Publishing edit or: Thom as Wohlbier, TTP USA, t .w ohlbier@t t p.net

Su bscr ipt ion :

I rr egular: approx. 80 - 1 00 volum es per y ear .

The subscript ion rat e for web access is EUR 1089.00 per year.

St anding order price: 20% discount off list price

I SSN print 1660 - 9336 I SSN cd 1660 - 9336 I SSN w eb 1662 - 7482

Pe r iodica l:

APPLI ED M ECH AN I CS AN D M ATERI ALS

I SSN : 1 6 6 2 - 7 4 8 2

Edit or ia l boa r d :

Edit or s

Publishing Edit or Wohlbier , T.

Send m ail

105 Springdale Lane, Millersville, USA, PA 1755 1; Xu , X.P.

Send m ail

Edit or ia l Boa r d Cheng , Y.S.

Send m ail

Harbin I nst it ut e of Tech nology, School of Mat erials Science and Technology; P.O. Box 435, Harbin, China, 150001;

Lucas , M.

Universit y of Glasgow , Depart m ent of Mechanical Engineering; Glasgow , Unit ed Kingdom , G12 8QQ;

Pa pe r Tit le Pa ge

Experim ent al I nvest igat ion on t he Use of Secon dary Refrigerant in Freezer for Energy Savings

Aut hor s: Ar ies Pr ih Har yono, Edi Sukam t o, Sum er u, Far id Nasir Ani

Chapt er 1: Energy Conv er sion

Abst ract : This st udy pr esent s an experim ent al st udy on a fr eezer w hich has sm all cooling capacit y. Typically a fr eezer uses prim ary refrigerant .. .

2 3 3

I nv est igat ion of Nat ural Gas Com posit ion Effect s on Knock Ph enom enon in SI Gas Engines Using Det ailed Chem ist ry

Aut hor s: Ahm ad Javaher i, Vahid Esfahanian, Ali Salavat i- Zadeh, Mehdi Dar zi, Seyyed Moj t aba Mir soheil

Chapt er 1: Energy Conv er sion

Abst ract : Considering t he gr ow ing role of nat ural gas as an alt ernat ive fuel in st at ionary and aut om obile engines and t he differ ences in it s...

2 3 9

Flow Charact erist ics around Four Circular Cylinder s in Equispaced Ar ran gem ent n ear a Plane Wall

Aut hor s: A.Gr um m y Wailanduw , Tr iyogi Yuw ono, Waw an Ar ies Widodo

Chapt er 1: Energy Conv er sion

Abst ract : The flow char act erist ics around fou r circular cylinders in equispaced arr angem ent locat ed near a plane w all w ere invest igat ed...

2 4 5

Experim ent al St udy on t he Perform ance of I n - Cabin Vent ilat ion Syst em

Aut hor s: Abdul Lat iff Zulk ar nain, Cheong Weng Soon, Bam bang Supr iyo, Mohd Rozi Mohd Per ang, Henr y Nasut ion, Azhar Abdul Aziz

Chapt er 1: Energy Conv er sion

Abst ract : Parking a car under t he h ot sun w it h all window s closed could increase in - cabin t em perat ur e as high as 70°C. For such sit uat ion, hu m an...

Reduct ion of Energy Losses in t he End Wall Junct ion Area t hr ough t he Addit ion of Forw ard Facing St ep Turbulent Generat or

Aut hor s: H. Mir m ant o, Sut r isno, H. Sasongko, D.Z. Noor

Chapt er 1: Energy Conv er sion

Abst ract : The resear ch is conduct ed in order t o reduce energy losses caused by t he secondar y flow in t he endw all j unct ion. This phenom enon is caused.. .

2 5 6

Biogas Pot ent ial of Co- Subst rat es in Balinese Biogas Plant s

Aut hor s: Daniel Net t , I . Nyom an Supr apt a Winaya, I . Made Agus Put r aw an, Rolf War t m ann, Wer ner Edelm ann

Chapt er 1: Energy Conv er sion

Abst ract : This research aim s t o give an ov erview on how t o im prov e t h e biogas y eild in Balinese digest er plan t s using various co- subst r at es w hich ar e.. .

2 6 2

CFD Sim ulat ion of Heat Transfer in Fluidized Bed React or

Aut hor s: I . Nyom an Supr apt a Winaya, I . Made Agus Put r aw an, I . Nyom an Gede Suj ana, Made Sucipt a

Chapt er 1: Energy Conv er sion

Abst ract : This st udy aim s t o pr edict heat t ransfer from a heat ed bed in a gas fluidized bed using Syam lal- OBrien drag coefficient . Discret e part icles...

2 6 7

I nfluence of Bioet hanol- Gasoline Blended Fuel on Perform ance and Em issions Charact erist ics from Port I nj ect ion Sinj ai Engine 650 cc

Aut hor s: Bam bang Sudar m ant a, Sudj ud Dar sopuspit o, Dj oko Sungkono

Chapt er 1: Energy Conv er sion

Abst ract : Perform ance and em issions charact erist ics fr om port inj ect ion SI NJAI engine 650 cc operat ing on bioet hanol- gasoline blended fuels of 0 % , 5% ,.. .

2 7 3

I m proved Energy Saving for R22 Building Air Condit ioning Ret rofit t ed w it h Hydrocarbon Refriger ant , St udy Case: Civil Engineering Depart m ent of I TS

Aut hor s: Widyast ut i, Ar y Bacht iar Kr ishna Put r a, Ridho Hant or o, Ek y Novianar ent i, Ar r ad Ghani Safit r a

Chapt er 1: Energy Conv er sion

Abst ract : Sepuluh Novem ber I n st it ut e of Techn ology ( I TS) encou rages t he ECO Cam pus program . The program enables I TS t o syst em at ically ident ify,...

2 8 1

The Evaluat ion of a Rigid Sail of Ship Using Wind Tunnel Test Aut hor s: Ar ies Suliset yono

Chapt er 1: Energy Conv er sion

Abst ract : This paper described t he evaluat ion of rigid sail perform ances by using t he w ind t unnel t est . The rigid sail m odels w er e dev eloped in t he...

Biogas Potential of Co-Substrates in Balinese Biogas Plants

Daniel Nett

1,a,

I Nyoman Suprapta Winaya

2,b, I Made Agus Putrawan

3,c,

Rolf Wartmann

4,dand Werner Edelmann

5,e1Management Center Innsbruck, Environmental and Process Engineering, 6020 Innsbruck, Austria 2Mechanical Engineering Department, Udayana University, Bali-Indonesia

3Magister Program of Mechanical Engineering, Udayana University, Bali-Indonesia 4Life sciences and facility management, Einsiedlerstr. 29, 8820 Wädenswil, Switzerland 5Arbeitsgemeinschaft Bioenergie, arbi GmbH,Baar, Lättichstr. 8, 6340 Baar, Switzerland

a[email protected] , b[email protected], c[email protected], d[email protected], e[email protected]

Keywords: co-substrate, biogas, anaerobic, digestion, biogas yield, Indonesia, improvement

Abstract

This research aims to give an overview on how to improve the biogas yeild in Balinese digester plants using various co-substrates which are available in Bali. A series testing on the digestibility of substrates were set up either in the field or in the biogas laboratory. In-field analyses like testing the CO2-content and taking samples from digested manure were undertaken. Analyses such as dry matter

(DM) and organic dry matter (oDM) determination, pH measurement and FOS/TAC were handled in the biogas laboratory. The huge number of different fruits in Bali gives a good opportunity to use their wastes like Durian hulls and Banana peelings, which can not be used anymore, as co-substrates in biogas plants. The results of these investigations allow to estimate the additional biogas yield, when adding co-substrates to a cow manure biogas plant.

Introduction

The majorities of small scale biogas plants in Bali are built by the “SIMANTRI” Project and mostly follow the Chinese type. The biogas reactor is constructed from cement, pebble, brick, sand and waterproof coating material [2]. The biogas plant has an open inlet, a digester (with around 6 m3 volume) and an open outlet (Figure 1). A small pipe with 1 cm diameter leads to a gas-flow-meter and further to a U-turn pipe where the pressure is measured. A valve on the head of the reactor can be opened and closed for taking gas samples e.g. for CO2-content testing purpose. The manure is stored

next to the stall and biogas plant and in most cases not protect from sun and precipitation. The biogas plant is fed in non-continuous intervals mainly ranging between three to six days.

Figure 1: SIMANTRI 258 biogas plant

Applied Mechanics and Materials Vol. 493 (2014) pp 262-266 © (2014) Trans Tech Publications, Switzerland

doi:10.4028/www.scientific.net/AMM.493.262

This preliminary study aims to give an overview about the current development of biogas and is concentrated in the area of Southern Bali and the city of Ubud. Through the “SIMANTRI” Project, launched in 2009 by the Governor of Bali, till now more than 350 farmer groups run small cattle biogas plants. This “SIMANTRI” Project uses synergy effects from organic farming and animal husbandry, mainly cows. The cow manure is utilized for producing biogas for small cocking devices as well as light [1]. Also some small self made biogas plants, fed with cow and pig manure, are run by local farmers. For this study two “SIMANTRI” biogas plants (SIMANTRI 258 and 260) and one self made biogas plants are observed.

Methodology

To analyze and evaluate the performance of existing agricultural biogas plants a biogas laboratory has to be build up located at Technique Campus of Udayana University in Jimbaran / Bali. In-field analyses like testing the CO2-content and taking samples from digested manure are undertaken.

Analyses such as dry matter (DM) and organic dry matter (oDM) determination, pH measurement and FOS/TAC are handled in the biogas laboratory. The laboratory offers the possibility to digest available substrates from Bali. The results of these first tests allow to estimate the additional biogas yield, when adding co-substrates to a cow manure biogas plant. Two series for testing the digestibility of substrates are set up. Whereas results of biogas yield for the first series are presented in this paper. FOS/TAC- and pH-measurement are undertaken, after sampling the fresh digested inoculum, in the biogas laboratory. Each FOS/TAC- and pH-average value consists of three single measured test. The pH-value is measured during the FOS/TAC-measurement.

The term FOS/TAC refers to the proportion between organic volatile (FOS) acids and the total alkaline carbonates (TAC) [3]. This methode is used to measure the performance of the biogas plants mentioned above.

The FOS/TAC is calculated by the following formula:

/ = , , , , / , , / , , (1)

Formula explication:

- The factor of 1,66 (numerator) refers to the amount of substrate used by the Prof. Weiland (20g) and the molar mass of sulphuric acid used in the titration (0,05 molar, 0,1 N).

- The factor of 0,15 (numerator) corrects the CO2 contained in the sample

- The numbers (numerator) and 250 (denominator) are factors oft he multiplication oft he empiric formula.

- X,X is the measured start pH at each FOS/TAC testing.

An option to increase the biogas yield of biogas plants fed only with cow manure is to add co-substrates to the digestion process. Therefore ten different co-substrates are tested on dry matter (DM) using Eq. 2 and organic dry matter (oDM) using Eq. 3 [4].

% = (2)

% = 1 − ( 3)

Results and Discussion

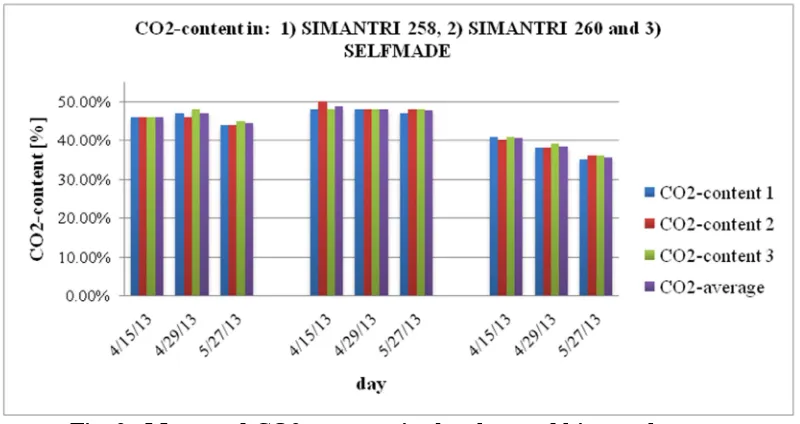

Measuring the CO2-content is done during the visits of the biogas plants. The observed

CO2-contests range between 35% of CO2 in selfmade and 50% of CO2 in SIMANTRI 260 biogas

plant as seen in Fig. 2.

Fig. 2. Measured CO2-contents in the observed biogas plants

The left three bundles of columns show SIMANTRI 258, the middle SIMANTRI 260 and the right columns show the selfmade biogas plant in Fig. 2 above. This means the composition methane gas in selfmade digester is better than the Simantri 258 and 260.

Table 1. FOS/TAC-measurement

The performance between the three biogas plants vary a lot as seen in Table 1. As SIMANTRI 258 is hungry and balanced feeded, SIMANTRI 260 is always overfeeded. In Opposite the selfmade biogas plant could use more feed to work much better.

In the first series of anaerobic digestion, Banana peeling, Durian hulls, Orange peeling and Snake fruit / Salak are chosen as the four substrates to determine.

This list below can be used to get an idea, when the biogas plant is hungry, balanced or overfeeded: > 0,6 overfeeded; reduce feeding rapidly

0,5 – 0,6 danger of overfeeding; reduce feeding 0,3 – 0,5 balanced feeding; stay at feeding level 0,2 – 0,3 hungry; increase feeding

< 0,2 very hungry; increase feeding rapidly

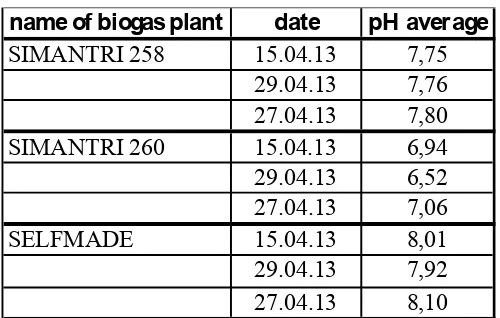

The pH-level should range between a minimum of 7,2 and 7,8 pH to have ideal digestion with microorganism. SIMANTRI 258 is within this toleranze, whereas SIMANTRI 260 is below and the selfmade biogas plant above this limit (Table 2).

name of biogas plant date FOS/TAC average

SIMANTRI 258 15.04.13 0,23 29.04.13 0,26 27.04.13 0,39 SIMANTRI 260 15.04.13 0,93 29.04.13 2,08 27.04.13 1,19 SELFMADE 15.04.13 0,24 29.04.13 0,27 27.04.13 0,17

Table 2. pH-measurement

Table 3. DM and oDM determination of co-substrates

Material DM [%] oDM [%]

Avocado hull 24,43 96,40

Banana peeling 13,42 76,02

Corn 18,90 96,29

Durian hull 14,22 91,73

Manggo hull 19,99 95,00

Nangka hull 16,60 92,77

Orange peeling 13,19 95,39

Pineapple peeling 9,99 91,07

Rice straw 37,46 74,87

Snake fruit / Salak 17,93 92,71

After calculating the dry matter using Eq. 2 and organic dry matter uding Eq. 3, a certain amount of co-substrate; 20 g +- 5% of fresh material are put into laboratory scaled digesters. The total volume of these digesters are 1090 ml. They are filled with 100 ml of fresh inoculum straight from the biogas plants, the co-substrate and with fresh water to a 300 ml mark. Afterwards filled with nitrogen gas and closed gastight with a rubber stopper. A small needle is but through the rubber stopper and connected to a gastight three-way-valve. There the pressure can be measured.

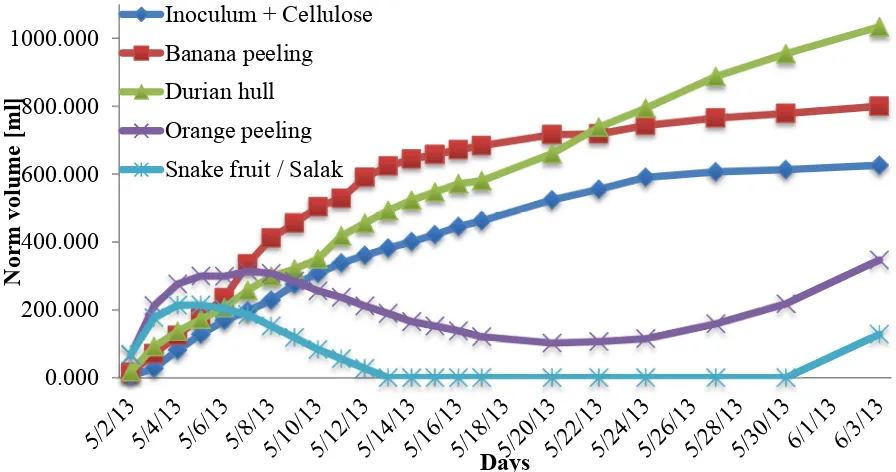

After 30 days the experiment is finished. Within these 30 days the pressure has to be measured, depending on the high of pressure, daily or every second / third day. After each measurement the gas has to be released and at the end a sum of all pressures has to be calculated. The experiment is carried out under real conditions, like they appear in the nature. So the average temperature over these days is 29,0 °C. The result can be plot as Fig. 3, showing the curve of increase in pressure when adding co-substrate to pure manure inoculum [4].

The norm volume of biogas is calculated with Equation below:

= ℎ 273,15 + 273 1,013

(Eq. 4)

name of biogas plant date pH average

SIMANTRI 258 15.04.13 7,75 29.04.13 7,76 27.04.13 7,80 SIMANTRI 260 15.04.13 6,94 29.04.13 6,52 27.04.13 7,06 SELFMADE 15.04.13 8,01 29.04.13 7,92 27.04.13 8,10

Fig. 3. Biogas yield with additional co-substrates

It is seen from Fig. 3, Banana peeling and Durian hulls show a very good performance and increase the biogas yield very much. Orange peeling and Snake fruit show at the beginning good improvement of biogas yield but it decreases afterwards. Possible reasons could be the acidity of both fruits or the essential oils within them. Those might influence the bacteria so they can not digest the substrates. Further investigations have to be carried out to give more detailed information about adequate co-substrates for improving the performance of existing biogas plants.

Summary

So far all known biogas plants in Bali are only fed with mainly cattle manure and sometimes with pig or a mixture of cattle and pig manure. The huge number of different fruits in Bali gives a good opportunity to use their wastes like hulls and peelings, which can not be used anymore, as co-substrates in biogas plants. It was found using co-substrate such as Banana peeling and Durian hulls could increase the production of biogas.

References

[1] Agung Suryawan Wiranatha, Island Economy towards a Low-Carbon Economy (A Case Study of Bali Province, Indonesia), Udayana University, Bali – Indonesia, pp. 10-11 (2009).

[2] T. W. Widodo, A. Asari, Ana N., Elita R., Design and development of biogas reactor for farmer group scale, Indonesian Journal of Agriculture 2(2), pp. 121-128 (2009).

[3] D. Moerschner, Instructions to carry out FOS/TAC analysis by titration, Fermenter – Doktor, (2012).

[4] Moisture in Peat, (967.03) Official Methods of Analysis, Association of Official Analytical Chemists, 15th Edition, 1990, http://www.foragetesting.org/lab_procedure /sectionB /2.2/part2.2.2.2. htm (2013).

[5] S. Baum, H. Zweifel, Gasbildung (GB21) Messung des Biogaspotentials, Insitut für Biotechnologie, zhaw Züricher Hochschule für angewandte Wissenschaften, Zürich, Schweiz (2007).

0.000