Flavour Industry Wastewater Management Case Study

FAYZA A. NASR*, NAGWA M. BADR and HALA S. DOMA

Water Pollution Research Department, National Research Center, Tahrir street,Dokki,Cairo, Egypt

Summary. This study is carried out to propose an appropriate treatment technology for wastewater discharged from a flavor production factory. Industrial wastewater discharged from this factory ranges between 50–70 m3/d with an average value of 60 m3/d. The major source of pollution in this factory is due to cleaning of the vessels therefore the treatment has been carried out on the end-of pipe wastewater. The wastewater is characterized by high values of COD, BOD, TSS and Oil and grease 4646, 2298, 1790 and 626 mg/l respectively. Primary sedimentation of the wastewater for four hours reduced the COD, BOD, TSS and Oil and grease by 43, 47, 80 and 74%, respectively. For the treatment of the produced wastewater, the biological treatment process such as activated sludge, rotating biological contactor (RBC), up-flow anaerobic sludge bed reactor (UASB) have been selected. The results from each treatment process proved to be efficient for the treatment of such wastewater. The treated wastewater characteristics are in compliance with the Egyptian law which regulates the discharge of industrial wastewater to the sewerage system. The RBC was selected and installed by the factory as it has the advantage of low operating and maintenance costs. The factory RBC performance was monitored; characteristics of the treated effluent in terms of oil and grease, COD, BOD and TSS were 27, 362, 139 and 95 mg/l, respectively.

Keywords:flavour, wastewater, treatment, rbc; uasb; activated sludge

Introduction

Food sufficiency is a major concern for the developing countries. This explains the importance of food indus-try in Egypt in relation to other industrial sectors. The food industry is of high production value and is impor-tant user of water. So food industry wastewater that is discharged into water resources form a main source of pollution. The characteristics of food-processing wastewater exhibit extreme variation. The BOD may be as low as 100 mg/l or as high as 100,000 mg/l. The wastewater may be highly alkaline (pH 11.0) or highly acidic (pH 3.5). Similarly, the volume of wastes may be almost negligible in some industries, but reaches one or more million m3per day in other. Food-processing wastewaters usually contain organic matter (in the dissolved or colloidal state) in

vary-*Corresponding author. E-mail: Fayzanasr@hotmail.com

32 Nasr, Badr and Doma

1998). Recently, the use of anaerobic technology for treating organic wastewater has gained acceptance in many countries. Among several anaerobic processes, the up-flow anaerobic sludge blanket (UASB) is the most widely applied for treatment of food industry wastewater (Lettinga et al., 1991, El-Gohary et al., 2000). It is an attractive alternative for the treatment of industrial wastewater discharged from alcoholic and soft drink bottling industries, fruit and vegetable can-neries, dairy industry and brewing process (Lettinga and Hulshoff Pol.,1986).This study deals with the wastewater discharged from a flavor-production fac-tory at 6th of October City. The facfac-tory employs 50 workers and is operated for one shift/day, six-days/ week. The factory produces natural and artificial fla-vors in liquid and powder forms. The major processes at the factory are performed in batch modes. The fac-tory discharges around 60 m3/day mix of industrial and domestic wastewater into the municipal sewer system.

The main objective of the present study was to eval-uate the use of an alternative biological treatment sys-tem for the treatment of flavor-production factory ef-fluent, in order to permit its safe discharge into the sewer system.

Materials and methods

Sampling

Due to the considerable variation in the wastewater quality over time, composite samples were collected from the end of pipe effluent and the treatment systems.

Laboratory analyses

The Physico-chemical characteristics were investi-gated to cover the following parameters: pH-value, total suspended solids (TSS), total phosphate, COD, total Kjeldahl nitrogen and oil & grease. The analyses were carried out according to the APHA (1998).

Treatability options

Field survey and analysis of the wastewater discharged from the factory indicated the presence of relatively high concentrations of COD and BOD. The conven-tional and most commonly method for treating such food industry wastewater is biological treatment.

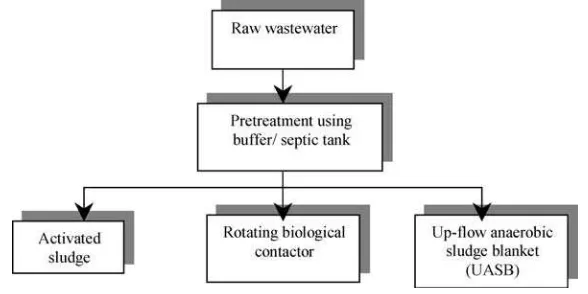

The end of pipe wastewater was subjected to the following treatment techniques as shown in Fig. 1:

Primary treatment

The wastewater is fed into a multifunction buffer/septic tank (5×2×1.5 m) installed in the factory (Fig. 2).

The tank is divided into four equal chambers that allow the flow of wastewater from one chamber to the next by gravity. The first three chambers allow the separation of solids and oil and grease, also the pH is adjusted by using 70% sodium hydroxide in the fourth chamber. The detention time in this tank is four hrs.

Activated sludge treatment system

Batch laboratory experiments were carried out using activated sludge process. Two liters Plexiglas labo-ratory columns were used. The wastewater was in-oculated with activated sludge from plant treating

Figure 2. Buffer/Septic tank (15 m3valume).

domestic sewage. The aeration was stopped daily to let the sludge settle then the supernatant was drained and the column was refilled again with the wastewater until considerable amount of acclimatized sludge was produced. To study the effect of aeration period on the activated sludge, several experiments were conducted. A fixed amount of sludge (3–4 g/l) was transferred to a column to which the pretreated wastewater was added. The phosphorus and nitrogen salts have been added prior to the process to compensate the deficiency of these nutrients. A detention time ranging from one hour to twenty-four hours was examined. Dissolved oxygen concentration was adjusted to maintain a min-imum concentration of 2 mgO2/l. Characterization of the treated wastewater was carried out after 60 minutes of settling.

Rotating biological contactor treatment system (Lab Unit)

The rotating disc experimental unit (RBC), which is shown in Fig. 3, consists of 5.19 L basin, divided into four compartments of equal volume, 32 PVC

Figure 3. Schematic diagram of the experimental RBC system.

discs were mounted on horizontally shaft rotated by a variable speed electric motor. Each compart-ment accommodated 8 discs of 14 cm diameter. The (PVC) discs provide 0.95 m2 of total surface area for microbial growth and were submerged in the tank to about 50% of the disc diameter. The discs were rotated at 4 rpm. The RBC is followed by a five liters sedimentation unit. The RBC system was fed continuously by pretreated wastewater. The bi-ological unit was operated at hydraulic load around 0.03 m3/m2d. The average organic load was 0.63g BOD/m3/d.

Anaerobic treatment system

The experiment was performed in 1.7-liter volume prespyx laboratory-scale UASB reactor with effec-tive volume 1.5 liter (Fig. 4). The reactor was in-oculated with 11.5 g VSS/l flocculent sludge from a nearby anaerobic sludge treatment plant. The reactor was equipped with solid-gas separators. The reactor was fed continuously with the pretreated wastewater at two different hydraulic retention times of 8 and 6 hrs.

Results and discussion

Production process

34 Nasr, Badr and Doma

Figure 4. UASB reactor for anaerobic treatment.

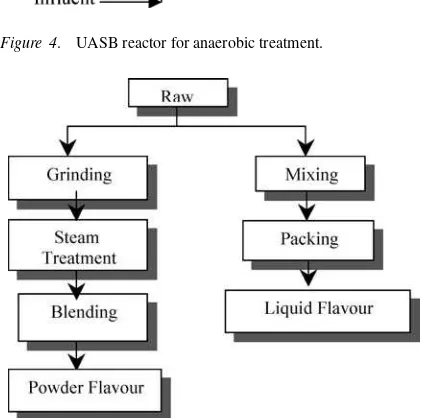

Figure 5. Flavour manufacturing flowchart.

liquid forms are included in the flavors manufacturing, for example tomato, onion, pepper, garlic lemon oil, orange oil, sugar and salt etc. The powder flavors are produced after being passed through four processes. Grinding of crystal size raw materials is carried out then steam treatment is performed to melt fatty in-gredients, followed by blending the different compo-nents according to a set proportion and the product is then packed before it is ready for distribution. The liquid flavours production comprises only two steps, the mixing process whereby ingredients are mixed ac-cording to specification then the product is packed and distributed. The production processes clearly require cleaning of the vessels used in each process. Water is used for such cleaning and it carries pollutants be-fore being discharged into the sewerage system. Gen-eral cleaning of the processing area constitutes another

source of wastewater. Therefore, the treatment has to be carried out on the end of pipe.

Wastewater characteristics

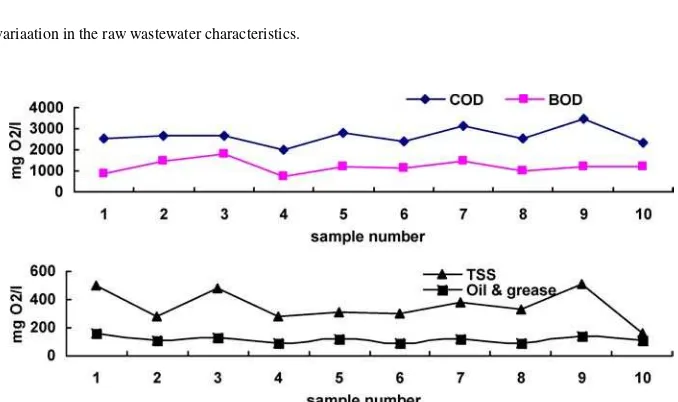

Physico-chemical characteristics of the wastewater discharged from the end of pipe effluent are presented in Table 1 and illustrated in Fig. 6. The results showed that the final effluent of the factory contains high con-centration of COD and BOD; which reached 6920 and 3825 mg O2/l, with average values of 4646 and 2298 mgO2/l respectively. The final effluent was nearly acidic in nature, the pH varied between 4.1 and 5.6; the total suspended solids (TSS) ranged from 589 to 3268 mg SS/l with an average of 1790 mg/l. Also the results showed a deficiency in the phosphorus and ni-trogen concentration, the average concentrations were 4.6 mgP/l and 14.6 mgN/l. The wastewater contains considerable amount of the oil & grease that reached 2186 mg/l with an average of 626 mg/l.

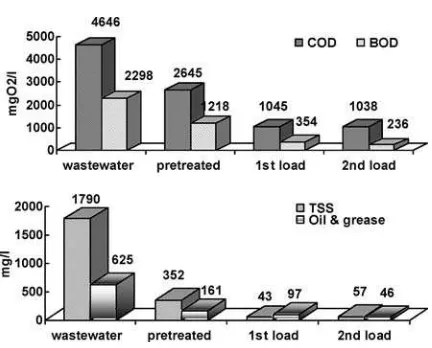

Primary treatment

The wastewater is acidic and contains considerable amounts of total suspended solids (1790 mg/l) and oil & grease (626 mg/l) which may adversely affect the microbial activity. Therefore, sedimentation and pH adjustment were necessary prior to the biological treatment step. This was carried out in a multifunction buffer/septic tank with a detention time of 4 hrs. The characteristic of the wastewater after the pretreatment unit is recorded in Table 2 and illustrated in Fig. 7. The oil & grease concentration was reduced by 74% and reached 161 mg/l on the average. Also, a considerable removal of COD and BOD occurred which reached 43% and 47% respectively and 80% of the TSS was removed.

Total nitrogen and phosphorus concentrations are 14.8 and 4.3 mg/l respectively. The analysis of the pre-treated wastewater showed that the ratio of BOD: N: P is 100: 1.2: 0.4. This indicates that the concentration of nitrogen and phosphorus is not sufficient for the bi-ological treatment process, therefore, their concentra-tion was adjusted by adding nitrogen and phosphorus salts to reach the exact ratio (BOD: N: P, 100:5:1).

Activated sludge treatment system

Fla

v

our

Industry

W

aste

w

ater

Management

Case

Study

35

UASB

1ry treated wastewater Activated sludge effluent RBC(Lab unit) 1st. load 2nd. load

Parameters∗ Unit Raw wastewater % R % R % R 6.8 kgCOD/m3·d %R 9 kgCOD/m3·d % R Egyptian law

PH 5.1 5.2 7.5 7.0 7.4 7.1 6–9

Chemical oxygen mgO2/l 4646 2645 43 109 96 144 95 1045 60 1038 61 1100

demand

Biological oxygen mgO2/l 2299 1218 47 30 98 73.1 94 354 71 326 73 600

demand

Total organic mgN2/l 14.6 14.8 – 8.9 41 3.4 78 9 43 7.8 48 100

Nitrogen

Total phosphorous mgP/l 4.6 4.3 – 0.6 86 1.6 62 1 72 0.9 79 25

Total suspended mgSS/l 1790 352 80 22 94 24 94 43 87 57 84 800

solids

Oil & grease mg/l 626 161 74 42 74 21 87 97 39 46 71 100

36 Nasr, Badr and Doma

Table 2. Characteristics of the treated wastewater using the RBC installed in the factory

Raw wastewater 1ry. treated % removal RBC % removal

Parameters Unit Min. Max Avg Min. Max. Avg. Min. Max. Avg. Min. Max. Avg. Min. Max. Avg.

Egyptian law

PH 4.13 5.6 5.1 4.8 5.5 5.2 5.1 7.2 6.4 6–9

Chemical oxygen mgO2/l 3166 6920 4646 1978 3462 2645 38 50 43 127 543 362 94 84 86 1100 demand

Biological oxygen mgO2/l 1572 3825 2298 752 1800 1218 52 53 47 25 385 139 97 79 88 600 demand

Total organic mgN2/l 13.4 23.5 14.6 11.5 20 14.8 14 15 - 2.3 8.4 4 80 58 71 100 Nitrogen

Total phosphorous mgP/l 2 9.5 4.6 1.4 9.2 4.3 30 — - 0.6 2.2 1.4 57 76 67 25 Total suspended mgSS/l 589 3268 1790 160 510 353 73 84 80 33 205 95 79 59 73 800

solids

Oil & grease mg/l 149 2186 626 89 161 116 40 93 81 5.2 64 27 94 60 77 100

∗Average results of 10 time.

Figure 6. The variaation in the raw wastewater characteristics.

Figure 8. Effect of detention time on COD removal using activited sludge system.

hour to twenty-four hours using a MLSS of 3 g/l Fig. 8. Analysis of the treated effluent indicated that the high-est BOD removal was achieved at a retention time of 3 hours. Average residual values of COD, BOD, TSS and oil & grease were 109 mgO2/l, 30 mgO2/l, 22 mg/l and 42 mg/l, respectively (Table 1). These values are in agreement with the standards set by the Egyptian law for discharging treated wastewater into the sewerage system.

Rotating biological contactor system (lab unit)

The RBC was fed with the primary treated wastewater at an organic loading rate of 0.03 kg COD/m3/day. The results of the analysis of the treated effluents are pre-sented in (Table 1 & Fig. 9). COD and BOD residual

values ranged from 80 to 303 mgO2/l and from 30 to 146 mgO2/l with an average of 144 and 73 mgO2/l, respectively. Oil and grease varied from 5 to 66 mg/l with an average of 20.9 mg/l. The average of total sus-pended solids was 23.6 mg/l. From the available data, it can be concluded that the treated wastewater is in com-pliance with the standards given by the Egyptian law, which regulates the discharge of industrial wastewater into the sewerage system.

Anaerobic treatment system

The UASB reactor was fed during the investigation period with the pretreated wastewater. Two organic loading rate were investigated namely 6.8 and 9 kg

38 Nasr, Badr and Doma

Figure 10. Performance of the anaerobic treatment during differ-ent organic laods.

COD/m3.d, at hydraulic retention time of 8 and 6 hours respectively.

The results obtained during these chores are illus-trated graphically in Fig. 10. Available data showed that increasing the applied organic loading rate from 6.8 to 9 kg COD/m3.d did not affect the COD removal rate. During the two loads the average COD removal ranged between 60% and 61%.The corresponding val-ues were 1045 and 1038 mgO2/l (Table 1). Also, the BOD removal was not affected with changing the or-ganic loading rates. The BOD average removal values were 71% and 73%. The residual values of the total suspended solids were 43 and 57 mg SS/l. From the previous results, the 6 hours detention time was the rec-ommended duration for the anaerobic treatment. These values are in agreement with the standards set by the Egyptian law for discharging treated wastewater into the sewerage system.

Rotating biological contactor treatment system in the factory

The RBC was selected and installed by the factory as it has the advantage of low operating and maintenance costs. The RBC was fed continuously with the effluent from the pretreatment unit. It consists of a four stages RBC. Each stage was filled with plastic packed mate-rials in the form of rings which provide a total surface area of 4000 m2(Fig. 11). The discs were rotated at 3–5 rpm with approximately 45% of the surface area sub-merged in the wastewater. The total liquid volume of

Figure 11. The rotating biological contactor and the settling tank in the factory.

the system was 6 m3.The hydraulic load applied to the RBC was 0.02 m3/m2.d. The water is dosed to the RBC by rotating cups mounted on a large disc attached to the main shaft. The factory RBC performance was moni-tored. Table 2 shows the characteristics of the treated effluent. Residual values of COD and BOD ranged from 127 to 543 and 25 to 385 mgO2/l with average values of 362 and 139 mgO2/l, respectively. Corre-sponding average removal values were 86% and 88%. The average percentage removal of total suspended solids was 73%. The corresponding residual concen-tration was 95 mg/l. The average residual value of oil and grease was 27 mg/l with 77% corresponding re-moval value. The characteristics of the treated effluent are comparable with the results obtained by using the lab unit RBC.

Conclusion

The obtained results using the activated sludge, rotat-ing biological contactor and UASB technology proved to be efficient for the treatment of wastewater dis-charged from a flavor production factory. The wastew-ater characteristics of each treatment process are in compliance with the Egyptian law which regulates the discharge of industrial wastewater to the sewerage sys-tem. The factory installed RBC proved to be efficient and reliable on account of the characteristics of the treated effluent as compared to the results obtained from the lab unit.

References

Industry,’ Accepted in IAWQ 19th Biological International Con-ference, Vancouver, Canada, pp. 21–26.

APHA.: 1998, ‘Standard Methods for the Examination of Water and Wastewater,’ 20th Edition (American Public Health Association, AWWA, WEF Washington, D.C.)

Busten, B., Eikebrokn C. and Thorvaldsem, G.: 1990, ‘Coagulation as Pretreatment of Food Industry Wastewater,’Wat. Sci Tech. 22(9), 18.

Deborah, M., Lary, B., Edwin, B., Daniel, L. and Roger, H.: 1981, ‘Coupled Trickling Filter-Rotating Biological Contactor Nitrifi-cation Process,’J. WPCF53, 1499–1480.

El-Gohary F., Abou-Elela, S. and Ali, H.I.: 1987, ‘Manage-ment of Wastewater from Soap and Food Industries: A Case Study,’The Science of the Total Environment 66, 203– 212.

El-Gohary, F., Nasr, F.A., Riffat, A.W. and Hamdy, I.A.: 2000, ‘Cost Effective Pre-Treatment of Agro-Industrial Wastewater,’ Envi-ronmental Management and Health11(4), 297.

El-Gohary, F. and Nasr, F.A.: 1999, ‘Cost Effective Pre-Treatment of Food Processing Industrial Wastewater,’The Third Middle East

Conference on Marine Pollution and Effluent Management, 23– 25 Nov., Kuwiat.

Lettinga, G. and Hulshoff, Pol, L.: 1986, ‘Advanced Reactor Design, Operation and Economy,’Wat. Sci. Tech.18, 99–108. Lettinga, G.,van Knippenberg, K., Veenstra, S. and Wiegant, W.:

1991, ‘Upflow Anaerobic Sludge Blanket (UASB), Low Cost Sanitation Research Project in Bandung/Indonisia,’ Final Re-port, Wageningen University, February.

Metcalf, L. and Eddy, H.P.: 1991, ‘Wastewater Engineering Treat-ment Disposal and Reuse,’ McGraw. Hill Book Company, Inc., New York.

Nemerow, N.L. and Dasgupts, A.: 1991, ‘Industrial and hazardous waste treatment,’ Van Nostrand Reinhold, New York. Ni, J.Q. and Nyns, E.J.: 1993, ‘Biomethanation; A Developing

Technology in Latin America,’ Catholic University of Louvain and Bermen Overseas Research and Development Association, Druckerei Verwoht, Bermen, Germany.