1

Separation of Oxalic Acid from Star Fruit Juice

by Membrane Technology

Lilis Sukeksi, Nik Meriam Nik Sulaiman, Che Rosmani Che Hassan, Ho H. Y., and Tan P. K.

Chemical Engineering Department performance liquid chromatography (HPLC). The concentration of oxalic acid in star fruit juice decreased 42.7% from green to yellow colour (ripe) star fruit. In this work, the performance of ultrafiltration for separating oxalic acid from star fruit juice was studied by performing lab scale experiments using hollow fiber membrane (polysulfone) with an area of 26cm2 and 10,000Da MWCO. The effects of various operating conditions of transmembrane pressure (1.0, 1.5, 2.0, 2.5 bar) and feed flow rate (200, 300, 350, 400 ml/min) on the performance were determined. The optimum operating conditions were found to be transmembrane pressure 2 bar and feed flow rate 350 ml/min. After performing ultrafiltration under this condition, the concentration of oxalic acid in permeate was up to 60%. In conclusion, ultrafiltration has been demonstrated as a potential technology to separate the oxalic acid from star fruit juice and it is recommended to prepare the star fruit juice with ripe fruit which has lower oxalic content.

Keywords : oxalic acid, star fruit, ultrafiltration, fruit juice

1. Introduction

Star fruit also known as Carambola, is a fruit produced from the carambola tree (Averrhoa Carambola) which is a member of the oxalis family (Oxalidaceae). Star fruits are an excellent source of vitamin C, antioxidants, is low fat, and naturally sodium and cholesterol free. There is now an increasing demand for nutraceuticals and functional foods. Therefore, there is a wide market available for star fruit products. Star fruit contained significant concentrations of oxalic acid which is greater than 100mg/serving (Online Library,n.d.). Clarified juice made from star fruit has higher concentration of the oxalic acid although it has high content of vitamin C and polyphenolics. Consumption by those with kidney failure can produce hiccups, vomiting, nausea, and mental confusion, and fatal outcomes have been documented in some patients. Oxalic acid combines with metals such as calcium, iron, sodium, magnesium, and potassium in the body to form oxalate crystals which precipitate and irritate the gut and kidneys and can lead to nutrient deficiencies (Online Library,n.d.).The calcium oxalate precipitate (better known as kidney stones) obstructs the kidney tubules.

2

2. Objective

The aims of this study are

1. To determine the amount of oxalic acid in star fruit juice at three stages of maturity. 2. Separate the oxalic acid from star fruit juice by using ultrafiltration membrane technology.

3. To study the effect of transmembrane pressure and feed flow rate during ultrafiltration of star fruit juice.

3. Theory

The membrane performance is measured by permeate flux (J) and recovery (Ci(R,P)) of oxalic acid in permeate.

2 mass in feed solution (Diqiao et al., 2008):

( , ) ( , ) KGaA, Germany), Oxalic Acid (99% GPR grade VWR International Ltd, England), and Sodium Hydroxide (99% pellets GR grade, Merck KGaA, Germany).

4.2 Apparatus

(i) Laboratory Scale Unit

The ultrafiltration apparatus includes a 6-600rpm pump (Masterflex), 10,000Da MWCO Polysulfone hollow fiber cartridge (GE Healthcare, USA), pressure gauge, weighing scale, 2L media bottles and 150ml beakers. The experimental set up diagram was shown in Figure 1.

Figure1. Experimental Set Up of Ultrafiltration System

(ii)Analyses

The HPLC analyses were carried out using Phenomenex Column Type Rezex ROA and Shimadzu HPLC system (SPD-10A UV-VIS Detector, SIL-10A Auto Injector, CTO-10AS Column Oven, LC-10AD Liquid Chromatograph, and SCL-10A System Controller).

4.3 Methodology of Experiments

4.3.1Selection of Sample

Star fruits were purchased from convenient stores and local supermarkets. Three stages of maturity for star fruits were purchased based on visual colour which was green, between green to yellow, and yellow colour.

4.3.2 Sample Preparation

3 controlled at 1 bar and the inlet flow rate was pumped at 350 ml/min. The effect of TMP was examined at 1 – 2.5 bar to obtain the optimum pressure at constant feed flow rate of 350ml/min. The ultrafiltration was stopped when the volume concentration factor, VCR (initial volume divided by the retentate volume) reached 4. The initial feed solution, permeate and retentate were collected and diluted to analyze the oxalic acid content by HPLC. Finally, the membrane was cleaned by recycling 0.1M NaOH solution at 25oC, cross flow rate of 350 ml/min and TMP of 1 bar for 30-60 min and followed by a circulation of distilled water for 30 min. The water flux was calculated to observe the recovery of the membrane performance. The experiment was repeated at different feed flow rate (200 - 400ml/min) of ultrafiltration at optimum pressure. By using the optimum conditions obtained from the experiments above, the experiment was repeated for 3 different stages of maturity for star fruit (green, green to yellow and yellow).

5. Results and Discussion

5.1 Analysis of Amount of Oxalic Acid in Star Fruit Juice at 3 Stages of Maturity

Table 1 below shows the concentration of oxalic acid for permeate and retentate at three stages of maturity (green, between green to yellow, and yellow) at 2 bar pressure and 350 ml/min flow rate.

The concentration of oxalic acid decreased 42.7% (from 4.59mg/g to 2.63mg/g) when the maturity of star fruit from green to yellow (ripe) as shown in Table 1. This result is supported from previous report which concentration of oxalic acid had variation of 0.8mg/g to 7.3mg/g for ripe star fruit (Wilson et al., 1982). This showed that the different maturity stage of star fruit influenced the oxalic acid content in star fruit. Therefore, it is recommended that star fruit should be consumed when it is completely ripe.

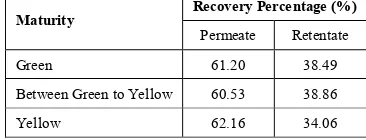

Table 2 shows almost same value of recovery percentage of oxalic acid in permeate and retentate for different stages of maturity. The recovery percentage is around 60% in permeate at 2 bar and 350 ml/min which most of the oxalic acid was found in permeate. Thus, different maturity stage does not affect the ultrafiltration performance. Any molecule smaller than molecular weight cut–off (MWCO) of membrane (10,000Da MWCO) would pass through the membrane and go into permeate. Therefore, most of the oxalic acid in star fruit juice is recovered in permeate up to 60% of recovery percentage.

Table 1. Concentration of Oxalic Acid for Permeate and Retentate at Different Maturity Stage

Mass Concentration(mg/g) Mass(g) Maturity

Sample Permeate Retentate Sample Permeate Retentate

Green 4.59 3.78 7.25 0.74 0.45 0.28

Between Green to Yellow 3.13 2.59 4.64 0.50 0.30 0.20

Yellow 2.63 2.28 3.19 0.42 0.26 0.14

Table 2. Recovery Percentage of Oxalic Acid for Permeate and Retentate at Different Stages of Maturity.

Recovery Percentage (%) Maturity

Permeate Retentate

Green 61.20 38.49

Between Green to Yellow 60.53 38.86

Yellow 62.16 34.06

5.2 Effect of Transmembrane Pressure (Tmp)

4 Figure 2. Permeate Flux versus Transmembrane Pressure

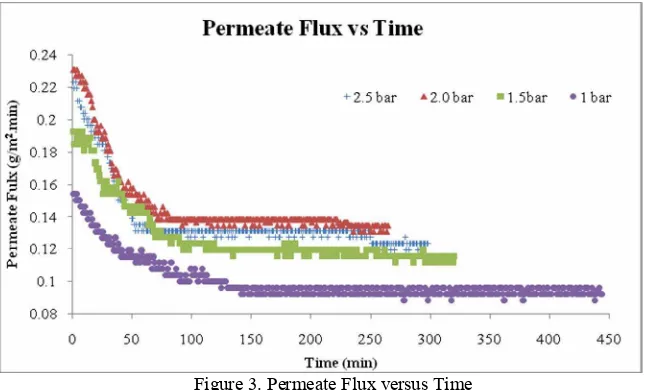

Figure 3 shows that the permeate fluxes decline continuously with time. This phenomenon occurs due to effects of concentration polarization, reversible/irreversible fouling or pore blocking, resistance build-up over the membrane (gel formation) or any combination of these effects depending upon the type of solute-membrane combination used. This was caused by the attachment of some molecules on the solute-membrane surface which will tend to increase permeate flow resistance at the membrane wall region and reduce the permeability. The retained solid particles in the membrane pores also contribute to the fouling of membranes. The result shows that the rate of deposition and fouling are higher at a higher transmembrane pressure. This can be explained by higher TMP is compressing the rejected solute into a thicker and denser fouling layer with increased fouling resistance (Zaid et al., 2006). This result is in agreement with the literature (Tanada-Palmu and Matta, 1999). The permeate flux rate can also decrease as the product becomes concentrated and more viscous.

Figure 3. Permeate Flux versus Time

The permeate flux-time curves (Figure 3) were divided in two sections: a rapid initial permeate flux decline region from 0 to 80 min and a relative slow decline section starting at 80 min. The sharp decrease observed at the beginning is probably attributed to the adsorption of colloidal species and the build-up of a concentration polarization layer. However, internal fouling due to pore plugging at the early stage of UF cannot be ruled out. The smoother and slower decline towards a quasi-steady state tends, in turn, to be attributed to fouling due to pore blocking and cake build-up. The effect of fouling can be superimposed on that of concentration polarization, which is often assumed to remain constant over time.

5 pressure increased from 1 bar to 2.5 bar, the oxalic acid recovery in permeated decreases from 64.6 to 58.7% as shown in Figure 4.

From our experiment, fouling and permeation did not show a direct relationship. Thus, the optimum pressure suggested is 2 bar since it has the highest permeate flux and shortest process time while giving a recovery percentage for oxalic acid in permeate with more than 60%.

Table 3. Concentration and Mass for Sample, Permeate and Retentate of Oxalic Acid at Different TMP

Mass Concentration (mg/g) Mass (g) Pressure

Sample Permeate Retentate Sample Permeate Retentate

1.0 4.61 4.11 6.34 0.74 0.48 0.25

1.5 3.13 2.71 4.26 0.50 0.31 0.19

2.0 3.13 2.59 4.64 0.50 0.30 0.20

2.5 3.13 2.47 5.12 0.50 0.29 0.20

Note: Green star fruit was used for 1bar transmembrane pressure while green-yellow star fruit were used for 1.5, 2, 2.5bar transmembrane pressure due to market availability.

Figure 4. Recovery Percentage for Permeate versus Transmembrane Pressure

5.3 Effect of Feed Flow Rate

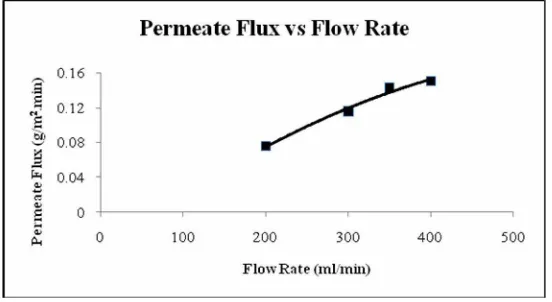

The effect of feed flow rate is important in the membrane filtration process because a higher flow rate can reduce membrane fouling by providing a shear force to sweep away deposited materials (De Bruijin et al., 2003). In Figure 5,the effect of flow rate from 200ml/min to 400ml/min on the permeate flux, at 25 °C, and 2 bar is shown. Higher feed flow rate cannot be examined in this research due to limitation of pump capacity. An increase in feed flow rate of the star fruit juice, the permeate flux increased. This is because resistances of membrane decrease with increasing flow rate which will enhance the mass transfer coefficient, reduce accumulation of solutes on the membrane surface and increase permeation flux.

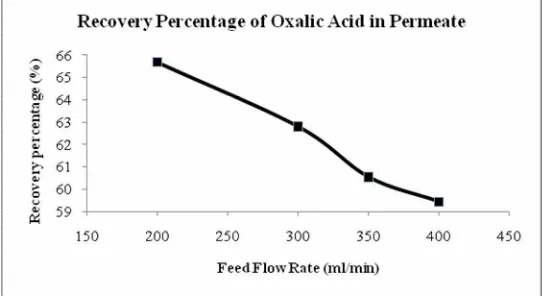

Figure 5. Permeate Flux versus Feed Flow Rate

6 rate from 200ml/min increased to 400ml/min feed flow rate, recovery percentage of oxalic acid content in permeate stream decreased from 65.7% to 59.4%. This showed that most oxalic content is recovered in permeate compared to retentate because of the molecular weight of oxalic acid is smaller than the molecular weight cut-off(MWCO) of membrane which is 10,000Da MWCO. Oxalic acid in star fruit juice passes through the membrane pore size into permeate. Higher feed flow rate in the membrane provide a shear force to reduce the deposited materials. This can slightly increase the retention of most components. However, at a higher flow rate, the more product passes through the pump in a given period. Oxalic acid need more time to pass through the membrane. In addition, a higher flow rate requires larger pumps and piping, which increase the system hold-up volume and product loss. These results are supported by the literature (De Bruijn et al., 2003). Thus, it is important to choose a flow rate which can balance the increase in flux with the increase in pump passes and hold-up volume. Therefore the optimum feed flow rate suggested is 350ml/min.

Table 4. Concentration and Mass for Sample, Permeate and Retentate of Oxalic Acid at Different Feed Flow Rate

Mass Concentration(mg/g) Mass(g) Flow Rate (ml/min)

Sample Permeate Retentate Sample Permeate Retentate

200 4.59 4.06 5.95 0.74 0.48 0.24

300 4.59 3.85 6.48 0.74 0.46 0.25

350 3.13 2.59 4.64 0.50 0.30 0.20

400 3.13 2.44 5.51 0.50 0.30 0.21

Note: Green star fruit was used for feed flow rate 200ml/min and 300ml/min while green-yellow star fruit were used for 350ml/min and 400ml/min feed flow rate due to market availability.

Figure 6. Recovery Percentage of Oxalic Acid in Permeate

6. Conclusions

1. The concentration of oxalic acid in start fruit juice decreased 42.7% from green to yellow colour (ripe) star fruit. It showed the almost same value of recovery percentage of oxalic acid in permeate and retentate for different stages of maturity. Thus, different maturity does not affect the ultrafiltration performance.

2. The permeate fluxes increase with the increase of transmembrane pressure. Fouling phenomenon causes the permeate fluxes to decline continuously with time. From the experiment, fouling and permeation did not show a direct relationship. So, the optimum pressure was 2 bar since it have highest permeate flux, shortest process time and the recovery percentage for oxalic acid in permeate with more than 60%.

3. Increase in flow rate of the star fruit juice causes increase the permeate flux. At high feed flow rate, less oxalic acid content was permeated through the membrane. Therefore, the optimum feed flow rate was 350ml/min.

7. Recommendations

7 membranes are easy to clean and allow recirculation of liquids with high level of solids and viscosity (Fox et al., 2004).

2. Analysis on other composition in the star fruit juice should also be carried out. In this research, only oxalic acid is analyzed in the star fruit juice since the research objective is separation of oxalic acid in star fruit juice. However, other nutrient or minerals in the star fruit juice should be considered since star fruit contains lot of vitamin and polyphenolics to human beneficial.

3. The effect of feed concentration is also very important in the filtration process because the ultrafiltration process is very sensitive to a critical concentration of moderately high molecular weight molecules. Therefore, effect of feed concentration of star fruit juice should be carried out to find out the optimum concentration of star fruit juice to separate oxalic acid in ultrafiltration process.

References

[1] De Bruijn, J. P. F., Venegas, A., Martínez, J.A., Bórquez, R.(2003). Ultrafiltration performance of Carbosep membranes for the clarification of apple juice. Food Sci. Technol. 36(4), pp: 397-406. [2] Diqiao S. W., M. H., and Zaid S. S. (2008), Separation of Polyphenolics and Sugar by Ultrafiltration:

Effects of Operating Conditions on Fouling and Diafiltration, International Journal of Chemical and Biomolecular Engineering.

[3] Fox P.F, McSweeny P., Timothy M. C., Timothy P. G. (2004), Cheese: Major Cheese Groups, 3rd Edition, Acedemic Press, pg 262-263.

[4] Sulaiman M.Z., Sulaiman N.M, Liew S.Y. (1997). Limiting permeate flux in the clarification of untreated star fruit juice by membrane ultrafiltration.

[5]

Wilson C.W., Shaw P. E., Knight R. J. JR (1982). Analysis of oxalic acid in carambola (Averroha carambola L.) and spinach by high-performance liquid chromatography.

[6] Yu Z.R., Chiang B.H and Hwang L.S., Retention of passion fruit juice compounds by ultrafiltration. J. Food Sci. 2006 Aug 25. 51 (3): 841-844.

[7] Zaid S. S., Roger S., Reginald W. (2006), Separation and Concentration of Health Compounds by Membrane Filtration, International Journal of Food, Engineering, Volume 2, Issue 3, Article 4. [8] Online Library (n.d.). “Oxalic Acid.” Available from: URL:

http://www.juicing-for-health.com/oxalic-acid.html