CHARACTERISTICS AND LIQUEFACTION OF

COAL FROM WARUKIN FORMATION,

TABALONG AREA, SOUTH

KALIMANTAN–INDONESIA

Edy Nursanto*1, Arifudin Idrus2, Hendra Amijaya2, and Subagyo Pramumijoyo2

1Mining Engineering Department, Faculty of Mineral Technology, Pembangunan Nasional "Veteran" University 2Geological Engineering Department, Faculty of Engineering, Gadjah Mada University

Abstract

Since the coal characteristic is the main controlling factors in coal liquefaction, thus five coal seams with different coal rank from Warukin Formation in Ta-balong Area, South Kalimantan have been used in this study. Three seams were low rank coal (Wara 110, Wara 120, Wara 200) while two seams were medium rank (Tutupan 210 and Paringin 712). The objectives of this study was to investigate the effect of coal rank on the rate of coal conversion factor. Coal liquefaction was conducted in an autoclave on low pressure (14.7 psi) and temperature 120°C. Experi-ments were designed with time intervals 30, 60 and 90 minutes, respectively. The average coal proper-ties of seam Wara 110, Wara 120 and Wara 200 were 26.65%, 5.08%, 46.26% and 30.60% for inher-ent moisture, ash continher-ent, volatile matter and. fixed carbon, respectively. In contrast, coal properties for seam Tutupan 210 and Paringin 712 were 18.42%, 1.81%, 23.02% and 35.76% for inherent moisture, ash content, volatile matter and fixed carbon, respec-tively. The maximum yields for Wara 110, Wara 120 and Wara 200 were 48.60% (30 minutes), 51.27% (60 minutes) and 46.72% (90 minutes). In compari-son, Tutupan 210 and Paringin 712 resulted max-imum yields of 8.22% (30 minutes), 18.35% (60 minutes), 6.23% (90 minutes). In conclusion, low

*Corresponding author: E. NURSANTO, Mining Engi-neering Department, Faculty of Mineral Technology, Pem-bangunan Nasional "Veteran" University. E-mail: edynur-santoyyk@yahoo.com.au

rank coal has higher yield conversion compared to medium rank coal since it has higher H/C ratio.

Keywords: Coal liquefaction, low rank coal, Kali-mantan.

1 Introduction

Increasing utilization of fossil fuel particularly coal is triggered by economic growth in Indone-sia. Coal has been used directly as fossil fuel from decade for power plants, steel industries, transportation and many others industries from small to big scale. In the future, coal also has important role as indirect fuel which means coal is converted into other forms before utilized as a fuel. Coal liquefies into oil is one of the exam-ple as indirect fuel.

Present research focuses on examining the liquefaction process of several coals from Kali-mantan, Indonesia which has different rank. The effect of coal characteristics and reaction time on liquefaction yields will be briefly exam-ined.

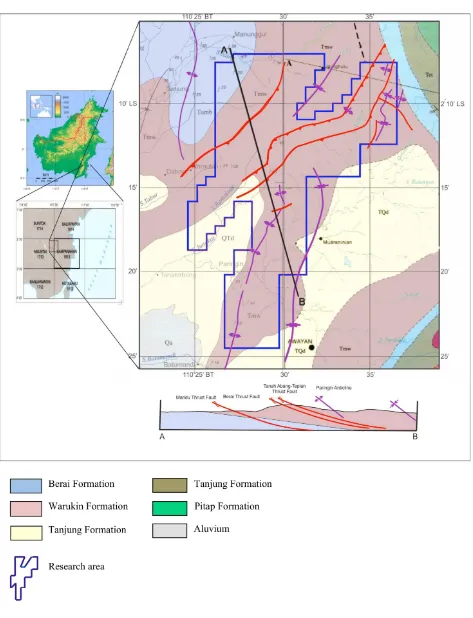

2 General geology

NURSANTOet al.

and claystone is found in this area as well as Dahor Formation which is not a coal bearing formation. Morphologically it is a hilly ter-rain. Well known Tutupan hill ranges 20 miles in length, extending up from the North-East to South-West (Adaro Inc., 1997). This hill is formed and bordered by the movement of two thrust faults with a parallel direction. Fault lo-cated in west part of hill is known as Dahai fault serving as the western border of Dahor Forma-tion. Another fault which becomes the eastern border of the hill is known as the reverse fault Tanah Abang-Tepian Timur.

3 Samples and experimental methods

Samples

Coal samples were obtained from Tabalong area, South Kalimantan-Indonesia and were classified as low rank coal. Sampling was con-ducted in the coal mining of Adaro Indonesia Inc (Figure 1). Research on coal liquefaction process was conducted in seam Wara 110, Wara 120, Wara 200, Tutupan 210 and Paringin 712. Typical of proximate and ultimate properties of the coals were shown in Table 1 and 2.

Experimental methods

The liquefaction experiments were conducted in autoclave bath-type with automatic temper-ature control, capable of producing a maximum pressure of 15 psi at 120°C. 1 g of coal sample with added alkali (NaOH) in the range 0–0.025 mol/g (0.01 g), alumina catalyst 0,03 g and sol-vent of water 39 g were mixed in the 50 mL cell. The coal slurry which is a mixing substance of coal, water, hydrogen donor, NaOH and cata-lyst then was put into the autoclave with tem-perature and pressure of 120° and 14.70 psi. The temperature 120°C and pressure 14.70 psi were chosen based on previous studies by Stone and Park (1970) who conducted liquefaction of lig-nite and sub-bituminous coal. Liquefaction pro-cess was conducted on three variable reaction time i.e. 30, 60 and 90 minutes. After cooling down, cell of liquids is taken from autoclave. The coal slurry was filtered with Whatman

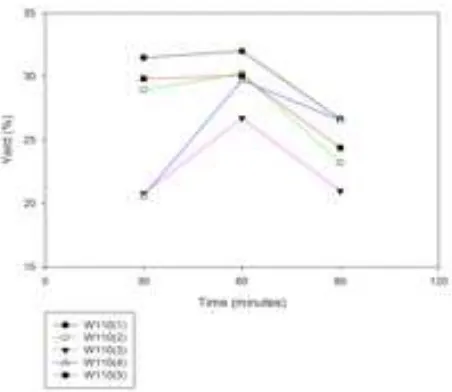

pa-Figure 2: Correlation between liquefaction time and yields of Wara 110 coal.

Result of filtering and drying will be compared to calculate its yield.

Characteristics of coal

Based on inherent moisture and volatile mat-ter as depicted in Table 1, the coal samples can be classified as lignite and sub-bituminous (see coal classification in Speight, 2005). Moreover, analysis of chemistry on Wara 110, Wara 120, Wara 200, Tutupan 210 dan Paringin 712 coals were shown on Table 2.

4 Results and discussion

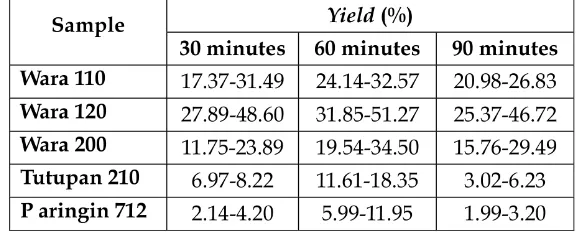

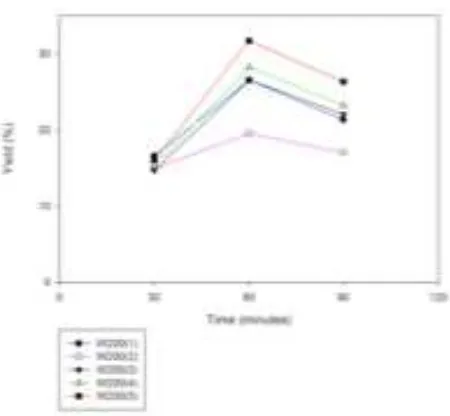

The maximum result of liquefaction process as function of time variable for seam Wara were 48.60% (30 minutes), 51.27% (60 minutes), and 46.72% (90 minutes). In case of seam Tutupan, the results were 8.22% (30 minutes), 18.35% (60 minutes) and 6.23% (90 minutes). Further-more, Paringin 712 resulted 4.20% (30 minutes), 11.95% (60 minutes) and 3.20% (90 minutes). The average value of yield shows that coals in seam Wara has higher yield conversion com-pared to Tutupan and Paringin seam (see Table 3 and Figures 2–6).

NURSANTOet al.

Table 1: The results of proximate analysis of coal samples from study area.

Table 2: The results of elemental composition of coal samples from study area.

Figure 3: Correlation between liquefaction time and yields of Wara 120 coal.

Figure 4: Correlation between liquefaction time and yields of Wara 200 coal.

Figure 5: Correlation between liquefaction time and yields of Tutupan 210 coal.

NURSANTOet al.

low-rank coal is easier to be converted. Wara coal is lignite and is classified into low-rank coal. It has H/C ratio of maximum 1.28. In contrast to Tutupan and Paringin seam which is classified as medium rank coal, the H/C ratio was only 1.17.

A fundamental study by Whitehurst (1978) stated that high hydrogen content in coal re-sults in higher conversion percentage than in coal with low hydrogen content. More-over, low-rank coal such as lignite is known to produce more oil during liquefaction pro-cess compared to high-rank coals such as sub-bituminous, bituminous, and anthracite (Speight, 1994).

Increasing conversion factors of liquefaction from 30 minutes to 60 minutes reaction times was controlled mainly by chemical reaction processes. A long reaction time gives oppor-tunity for coal to have more contact with sol-vent and hydrogen donor. Hence, longer reac-tion times give higher conversion result. This phenomenon also has been reported by previ-ous studies (Vassalloet al., 1983; Priyantoet al., 2001; and Maloletnev, 2009). They concluded that the longer reaction time of liquefaction pro-cess, the higher result will be obtained.

5 Conclusions

Based on its characteristics, the rank of coals in Tabalong, South Kalimantan are lignite for seam Wara 110, Wara 120 and Wara 200 while Tutupan 210 and Paringin 712 coals are sub-bituminous. Lignite coal tend to have better result in liquefaction process compared to sub-bituminous coal. This is due to higher H/C ra-tio of lignite coal than sub-bituminous coal.

Increasing percentage of liquefaction process only occurred for the reaction time of 30 to 60 minutes. In case of 90 minutes reaction time, the result of liquefaction process was decreas-ing. Maximum yield of Wara coal was 51.27% in 60 minutes reaction time and decreasing to 46.72% in 90 minutes reaction time. This phe-nomenon was also observed for Tutupan and

Paringin seam where the maximum yield of 60 minutes reaction time was 18.35% and decreas-ing to 6.23% in 90 minutes reaction times. Acknowledgement

We express our deepest gratitude to the man-agement of Adaro Indonesia Inc. for giving per-mission to collect samples and other support during the field research.

References

Adaro Indonesia Inc. (1997) Adaro Resources Report, Departemen Geologi PT. Adaro In-donesia.

Darman, H. dan Sidi , F.H. (2000) An Outline of The Geology of Indonesia, Indonesian As-sociation of Geologist (Ikatan Ahli Geologi Indonesia-IAGI), p.69-73.

Krevelen, D.W. (1992) Coal Typology-Physics-Chemistry-Constitution. University Of Tech-nology, Delft, The Netherlands. 750p.

Maloletnev, A.S. (2009) Current Status of The Hydrogenation of Coal, Solid Fuel Chem-istry, Vol. 43, pp. 165-176.

Priyanto, U., Sakanishi K., Okima O., Murti S.D.S., Watanabe I, Korai Y., Mochida I. (2001) Optimization of Two-Stage Liquefaction of Tanito Harum Coal With Fe-Ni Catalyst Sup-ported Carbon Black, Energy & Fuel, pp. 856-862.

Speight, J.G. (1994) The Chemistry and Technol-ogy of Coal, Marcel Dekker Inc., New York, 642p.

Speight, J.G. (2005) Handbook of Coal Analysis, John Wiley & Sons, Inc., Publication, 222p. Stone, R.D. and Park, L.G. (1970) Coal

Liquefac-tion Process. Patented, United States Patent Office, 4p.

Vassallo, A.M., Fredericks P.M., and Wilson M.A.(1983) FTIR Studies of Deutorium Incor-poration In to Coal, Associated Mineral Mat-ter and Hydrogenation Residues, Organic Geochemistry, Vol.5 No.2, pp. 75-85.