A STUDY OF THE PLASTIC LIFE CYCLE ASSESSMENT

KOO CHAI HOON

BORANG PENGESAHAN STATUS TESIS

JUDUL: A STUDY OF THE PLASTIC LIFE CYCLE ASSESSMENT

SESI PENGAJIAN: 2005 / 2006

Saya KOO CHAI HOON

(HURUF BESAR)

mengaku membenarkan tesis (PSM/ Sarjana/ Doktor Falsafah)* ini disimpan di Perpustakaan Universiti Teknologi Malaysia dengan syarat-syarat kegunaan seperti berikut:

1. Tesis adalah hakmilik Universiti Teknologi Malaysia.

2. Perpustakaan Universiti Teknologi Malaysia dibenarkan membuat salinan untuk tujuan pengajian sahaja.

3. Perpustakaan dibenarkan membuat salinan tesis ini sebagai bahan pertukaran antara institusi pengajian tinggi.

4. **Sila tandakan (3)

SULIT

(Mengandungi maklumat yang berdarjah keselamatan atau kepentingan Malaysia seperti yang termaktub di dalam AKTA RAHSIA RASMI 1972)

TERHAD

(Mengandungi maklumat TERHAD yang telah ditentukan oleh organisasi/ badan di mana penyelidikan dijalankan)

3

TIDAK TERHADDisahkan oleh

(TANDATANGAN PENULIS) (TANDATANGAN PENYELIA)

Alamat Tetap:

2235, TAMAN MELATI,

09400 PADANG SERAI, PROF. DR. MOHD. RAZMAN SALIM

KEDAH. Nama Penyelia

4 MAY 2006 4 MAY 2005

Tarikh: Tarikh:

CATATAN: * Potong yang tidak berkenaan.

** Jika tesis ini SULIT atau TERHAD, sila lampirkan surat daripada pihak berkuasa/ organisasi berkenaan dengan menyatakan sekali sebab dan tempoh tesis ini perlu dikelaskan sebagai SULIT atau TERHAD.

υ Tesis dimaksudkan sebagai tesis bagi Ijazah Doktor Falsafah dan Sarjana secara penyelidikan, atau disertasi bagi pengajian secara kerja kursus dan penyelidikan, atau Laporan Projek Sarjana Muda (PSM).

the degree of Master of Engineering (Civil-Environmental Management)”

Signature : ____________________________________ Name of Supervisor : PROF. DR. MOHD. RAZMAN SALIM Date : 4 MAY 2006

A STUDY OF THE PLASTIC LIFE CYCLE ASSESSMENT

KOO CHAI HOON

A project report submitted in partial fulfillment of the requirement for the award of the degree of Master of Engineering (Civil – Environmental Management)

Fakulti Kejuruteraan Awam Universiti Teknologi Malaysia

“I declare that this project report entitled “A Study of the Plastic Life Cycle

Assessment” is the result of my own research except as cited in the references. The

report has not been accepted for any degree and is not concurrently submitted in candidature of any other degree.”

Signature : ________________

Name : KOO CHAI HOON

To my beloved father, mother, brother and also my supportive friends…

ACKNOWLEDGEMENT

I would like to take this opportunity to express my gratitude and appreciation to my supervisor, Professor Dr. Mohd. Razman Salim for his guidance, patience and invaluable advice throughout this project.

I also would like to express my appreciation to my family and friends for their endless support whenever I face problems. Without the mentioned parties, it is impossible for me to complete this project report successfully.

THANK YOU.

Koo Chai Hoon May, 2006

ABSTRAK

Secara tradisi, rawatan sisa pejal mempunyai perhatian yang terhad berkaitan dengan penilaian kitaran hidup (LCA). Biasanya, hanya jumlah sisa pejal sahaja diambilkira. Ini adalah tidak memadai sedangkan rawatan sisa pejal, contohnya, tambak tanah atau penunuan ialah operasi yang memerlukan input dan menghasilkan output yang perlu diterangkan dalam pengenalan LCA. Kertas kerja ini menganalisis tentang plastik dari perspektif LCA, menentukan tanggungan utama alam sekitar dan mengembangkan analisis dalam bidang pembaikan produk untuk tujuan mengurangkan tanggungan alam sekitar. Dalam lingkungan had dan sempadan yang dikenakan pada penyelidikan ini, anggapan dibuat, kertas kerja ini menerangkan pelbagai kaedah pelupusan tiga jenis komponen plastik dalam sisa pejal perbandaran. Penyelidikan ini juga memberi pengurus-pengurus sisa pejal dan ahli-ahli penyelidikan alam sekitar dengan idea untuk menilai pelan pengurusan sisa pejal dan memperbaiki prestasi alam sekitar dalam strategi pengurusan sisa pejal. Keputusan mengilustrasikan kitar semula bahan plastik lebih dicadangkan dengan penggunaan plastik digantikan dengan plastic yang diperbuat daripada bahan asal, membimbing kepada pengurangan penggunaan jumlah tenaga dan penghasilan gas yang mendorong kesan pemanasan global.

ABSTRACT

Traditionally, treatment of solid waste has been given limited attention in connection with Life Cycle Assessment (LCA). Often, only the amounts of solid wastes have been noted. This is unsatisfactory since treatment of solid waste, e.g., by landfilling or incineration, is an operation, requiring inputs and producing outputs, which should be described in the inventory of an LCA. This paper analyses the plastics from the LCA perspective, determines the main environmental burdens and expands the analysis on the improvement areas of the product for the purpose of lowering the environmental burdens. Within the constraints and boundaries imposed by the study, assumptions made, this paper describes different ways of disposing three plastic fractions in municipal solid waste. This study also provides solid waste decision-makers and environmental researchers with a mind set to evaluate waste management plans and to improve the environmental performance of solid waste management strategies. The results illustrated that recycling of plastic material, preferably combined with the use of plastics replacing plastics made from virgin materials, leads to decreased use of total energy and emissions of gases contributing to global warming effect.

TABLE OF CONTENTS

CHAPTER TITLE PAGE

DECLARATION DEDICATION ACKNOWLEDGEMENTS ABSTRAK ABSTRACT TABLE OF CONTENTS LIST OF TABLES LIST OF FIGURES ii iii iv v vi vii xii xiv 1 INTRODUCTION 1.1 Overview 1.2 Problem Statement 1.3 Objective of the Study 1.4 Scope of the Study 1.5 Significance of the Study

1 1 3 4 4 5 2 LITERATURE REVIEW

2.1 Environmental Management Issue 2.1.1 What is Waste?

2.1.2 Municipal Waste

2.2 The Concerns Over Waste

2.3 What is Life Cycle Assessment (LCA)? 2.3.1 History of LCA

2.3.2 The Product Life Cycle

6 6 6 7 8 9 10 11

2.3.3 Key Features of LCA 2.3.4 Components of LCA

2.3.5 Uses and Application of LCA 2.3.6 Benefits of the Life Cycle Approach 2.3.7 Limitations of the Life Cycle Approach 2.3.8 International Standards Organisation (ISO) – The ISO 14040 series 2.4 Issues Related to Life Cycle Stages 2.4.1 Inventory Assessment

2.4.1.1 Raw Material Acquisition Stage 2.4.1.2 Material Processing Stage 2.4.1.3 Manufacturing Stage

2.4.1.4 Filling/Packaging/Distribution 2.4.1.5 Use/Reuse/Maintenance Stage 2.4.1.6 Recycle and Disposal Stage

2.4.2 Reutilization/Reprocessing/Remanufacturing 2.4.3 Impact Assessment

2.5 An Integrated Approach to Solid Waste Management

2.5.1 The Basic Requirement of WM

2.5.2 Integrated Waste Management in Countries with Developing Economics

2.6 Element of Integrated Waste Management 2.6.1 Solid Waste Generation

2.6.2 Waste Collection 2.6.3 Central Sorting 2.6.4 Biological Treatment 2.6.5 Thermal Treatment 2.6.6 Landfilling

2.6.6.1 Composition of Landfill Gas 2.6.6.2 Landfill Gas Production

2.6.6.3 Factors Affecting the Production of Landfill Gas 2.6.6.4 Factors Affecting the Migration of Landfill Gas

13 14 16 17 19 20 21 21 21 22 22 22 22 23 23 23 25 25 27 28 28 31 32 34 35 35 36 36 38 39

2.6.7 Materials Recycling 2.6.7.1 Plastic Manufacturing 2.6.7.2 Plastic Recycling 2.7 Plastic

2.7.1 Types of Plastic and their Main Applications 2.7.2 Advantages of Using Plastic

2.7.3 Potential Impacts of Plastic

40 41 42 43 43 43 44 3 METHODOLOGY 3.1 Introduction

3.2 Life Cycle Inventory

3.3 Life Cycle Impact Assessment 3.4 Life Cycle Interpretation 3.5 Assumptions

3.6 Life Cycle Assessment Boundary 3.7 Methods 47 47 47 48 49 49 49 49

4 LIFE CYCLE INVENTORY 4.1 Plastic Production

4.1.1 Process of Making Plastics 4.1.1.1 Plastics from oil and gas 4.1.1.2 Additives

4.1.1.3 Plasticisers and stabilisers used in PVC 4.1.1.4 Brominated flame retardants

4.1.2 Production Stage – Emissions and Energy Requirements

4.1.2.1 Production Stage – Emissions and Energy Requirements for PET

4.1.2.2 Production Stage– Emissions and Energy Requirements for PVC

4.1.2.3 Production Stage– Emissions and Energy Requirements for PP 4.2 Use of Plastic 51 51 51 51 54 54 54 56 56 56 57 57

5

4.3 Transport of Plastic

4.3.1 Transportation Stage – Emissions and Energy Requirements for PET, PVC and PP

4.4 Disposal of Plastic Waste

4.4.1 Waste Recycled – Emissions and Energy 4.4.1.1 Waste Recycled – Emissions and Energy

Requirements for PET

4.4.1.2 Waste Recycled – Emissions and Energy Requirements for PVC

4.4.1.3 Waste Recycled – Emissions and Energy Requirements for PP

4.4.2 Waste to Landfill – Emissions and Energy Requirements

4.4.2.1 Waste to Landfill – Emissions and Energy Requirements for PET

4.4.2.2 Waste to Landfill – Emissions and Energy Requirements for PVC

4.4.2.3 Waste to Landfill – Emissions and Energy Requirements for PP

4.4.3 Waste Incinerated – Emissions and Energy Requirements

4.4.3.1 Waste Incinerated – Emissions and Energy Requirements for PET

4.4.3.2 Waste Incinerated – Emissions and Energy Requirements for PVC

4.4.3.3 Waste Incinerated – Emissions and Energy Requirements for PP

4.5 Summary – Emissions and Energy Requirements for PET, PVC and PP

LIFE CYCLE IMPACT ASSESSMENT 5.1 Introduction 5.2 Energy Use 57 58 58 58 59 59 60 60 60 61 61 61 61 62 62 62 64 64 64

6

7

5.3 Global Warming

5.3.1 Examples of Calculation for Global Warming Value

5.3.2 Carbon Dioxide (CO2) 5.3.3 Methane (CH4)

5.4 Other Impact of Using Plastics on the Environment and Human Health

LIFE CYCLE INTERPRETATION 6.1 Introduction

6.2 Process Improvement 6.2.1 Recycling

6.2.1.1 Emission Reduction

6.2.1.2 Energy Potential for Plastic Waste

6.2.1.3 Reduction of Global Warming Potential and Improvement of Energy Efficiency from Energy from Waste

CONCLUSIONS AND RECOMMENDATIONS 7.1 Conclusions 7.2 Recommendations 65 66 66 66 67 69 69 70 70 72 72 73 74 74 75 REFERENCES 77

LIST OF TABLES

TABLE NO. TITLE PAGE

2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 4.1 4.2 4.3 4.4 4.5 4.6 4.7 4.8 4.9 4.10 4.11 4.12 4.13 4.14 4.15

Types of solid waste

LCA Applications According to Objectives LCA Applications According to User Type Categories of solid waste

Composition of MSW (by weight) in North and Central America

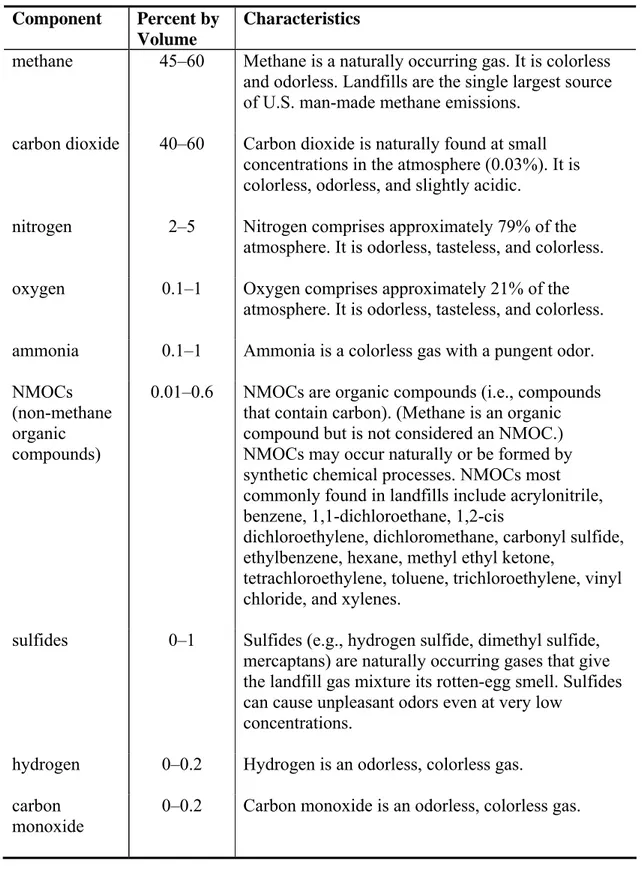

Typical Landfill Gas Components Uses of Major Plastic

Properties of Plastics and their Advantages Additives and their function

Environmental Profile for PET – Plastic Production Stage Environmental Profile for PVC – Plastic Production Stage

Environmental Profile for PP – Plastic Production Stage Environmental Profile – Transportation Stage

Environmental Profile for PET – Waste Recycled Environmental Profile for PVC – Waste Recycled Environmental Profile for PP – Waste Recycled Environmental Profile for PET – Waste to Landfill Environmental Profile for PVC – Waste to Landfill Environmental Profile for PP – Waste to Landfill Environmental Profile for PET – Waste Incinerated Environmental Profile for PVC – Waste Incinerated Environmental Profile for PP – Waste Incinerated Resources consumed and emissions released for entire

7 17 18 30 31 37 45 46 55 56 56 57 58 59 59 60 60 61 61 61 62 62

5.1

life cycle of 1kg of various polymers

Environmental impact for different treatment methods

63 65

LIST OF FIGURES

FIGURE NO. TITLE PAGE

2.1 2.2 2.3 2.4 2.5 2.6 3.1 4.1 4.2

Stages in the Life Cycle of a Product Interactions Among LCA Components

Element of an Integrated Waste Management System The spectrum of collection methods from bring to kerbside systems

The generic MRF with manual sorting The categories of rigid plastic containers Simplified life cycle of plastics

The role of additives in the production of plastics Generalised process for making plastics

13 16 29 32 34 42 50 53 53

CHAPTER I

INTRODUCTION

1.1 Overview

Nowadays, world population has been increased rapidly especially in developing country like Malaysia. The rapid growth of population in a country has contributed to high production of waste. Municipal waste and industrial waste can bring unhealthy and unpleasant environment or even diseases to human being if the wastes are not managed properly.

As a government, it is unreasonable to limit the number of children for a family just in order to control the high production of waste. Therefore, one of the methods to reduce the production of waste is by understanding the Life Cycle Assessment of the products itself. Basically, Life Cycle Assessment is not a tool to reduce the production of waste. Instead, by conducting a Life Cycle Assessment, the researcher can be more understand on the environmental attributes of a product from raw materials to landfill disposal or recycle as a new product, across its entire life.

Life Cycle Assessment (LCA) is a process to evaluate the environmental burdens associated with a product, process or activity by identifying and quantifying energy and materials used and wastes released to the environment, and to assess the impact of those energy and material used and released to the environment (Allen et. al., 1993). The assessment should include the entire life cycle of the product, process or activity encompassing materials and energy acquisition, manufacturing, use and waste management. In the inventory analysis component of an LCA, data on inputs

and outputs to and from the system under study are compiled and presented. Solid waste may be treated by different processes where landfilling and incineration are the most common. Through Life Cycle Assessment, researcher will be able to know which things contribute to pollution and how the pollution happens finally take an appropriate way to solve the problem.

In this case, plastics are a thoroughly investigated material because plastic waste is one of the components in municipal solid waste management. Besides, this is because there is least past research discussing on Life Cycle Assessment of plastics production. In addition, plastics are predominantly employed in packaging, construction and consumer products. The first commercial plastics were developed over one hundred years ago. Now plastics have not only replaced many wood, leather, paper, metal, glass and natural fiber products in many applications, but also have facilitated the development of entirely new types of products. The plastic fraction in municipal solid waste consists mainly of polyethylene (PE), polyethylene terephthalate (PET), polyvinyl chloride (PVC) and polypropylene (PP) and polystyrene (PS). Different types of plastics will perform differently in the environment, e.g. polyvinyl chloride (PVC) has caused concern because of their potential to cause environmental harms.

Plastic products are durable, which although having functional benefits, can cause problems at the end of products’ lives. As plastics have found more markets, the amount of plastic produced become increases. This phenomenal growth was caused by the desirable properties of plastics and their adaptability to low-cost manufacturing techniques. The life cycle of plastic products includes production, transportation, use and disposal which have contributed to the release of waste emissions. This results in toxins existing in the water, air and food chain, bringing the people around the polluted area severe health problems. Recently, environmental groups are voicing serious concern about the possible damaging impact of plastics on the environmental. Plastics end products and materials eventually contribute to the solid waste stream.

Since reliable scientific data have been lacking, an experimental investigation was required. According to life cycle thinking (LCT), potential burdens arising

during end-of-life management must be prevented in the course of the entire product chain. The question arose whether landfilling is an acceptable waste management option for plastics products. Landfills and deposited waste need to meet requirements with respect to the protection of human health and the environment. Any environmental impacts may either be due to landfilling practices, or due to inherent product properties and the resulting product-specific emissions.

By improving either products or end-of-life schemes, impacts and risks could thus be mitigated and investigated. Life cycle assessment (LCA) intends to aid decision-makers in this respect, provided that the scientific underpinning is available. Strategic incentives for product development and life cycle management can then be developed.

1.2 Problem Statement

In the last decades, with the increment of the world population and the society of consumption, the amount of waste generated has exponentially increased. Waste accumulation centres have been created culminating with the generation of epidemics and rodents, besides increasing the environmental contamination level. These facts generate the necessity of developing and using more rational methods for final waste disposal.

Over the past 20 years, environmental issues have gained greater public recognition. Production, use and disposal of virtually all goods present potential health and environmental impacts. The general public has become more aware that consumption of manufacturing products and marketed services, as well as daily activities of our society, adversely affects supplies of natural resources and the quality of the environment. These effects occur at all stages of the Life Cycle of a product, beginning with raw material acquisition and continuing through material manufacture and product fabrication. They also occur during product consumption and a variety of waste management options such as composting, biogasification, incineration, burning, landfilling and recycling. At each of these steps, pollutants

may be released into the environment with ecological consequences. Ecological consequences among other things also include the effects on the environment. The impacts because of the environment releases can occur during the life cycle stages, particularly manufacturing and disposal, for all consumer and commercial products. As public concern has increased, both government and industry have intensified the development and application methods to identify and reduce the adverse environmental effects.

1.3 Objective of the Study

The aim of the study is to compare the environmental performance of three polymer-based plastics which are polyethylene terephthalate (PET), polyvinyl chloride (PVC) and polypropylene (PP) in different disposal treatments.

The further objectives are:

a) to evaluate environmental burdens associated with plastic product, process or activity by quantifying energy and wastes released to the environment.

b) to determine the main environmental burdens.

c) to expand the analysis on the improvement areas of the plastic product for the purpose of lowering the environmental burdens.

1.4 Scope of the Study

Scope of the study covers the entire life cycle of the product encompassing raw material processing, manufacturing, transportation, use, recycling and disposal. This study concentrates only on air emissions released within the life cycle of plastic which contributes to the impact of global warming. Therefore, this paper focuses on the plastic from the LCA perspective. Plastics are chosen because lack of plastics life cycle flow is being investigated and performed previously.

Life Cycle Assessment (LCA) is a tool to evaluate the impacts associated with all stages of a product’s lifecycle from cradle to grave both downstream and upstream. The basis of an LCA study is an inventory of all the inputs and outputs of industrial processes that occur during the life cycle of a product. This includes the production phase and the life cycle processes including the distribution, use and final disposal of plastic product. In each phase the LCA inventories the inputs and outputs and assesses their impacts. Once the inventory has been completed, a LCA considers the impacts. This phase of the LCA is called the impact assessment: LCAs can be very large scale studies quantifying the level of inputs and outputs. This LCA is limited in scope to a basic inventory.

1.5 Significance of the Study

An LCA will help decision makers select the product or process that resulting the least impact to the environment. This information can be used with other factors, such as cost and performance data to select a product or process. LCA data identifies the transfer of environmental impacts from one media to another and from one life cycle stage to another. If an LCA was not performed, the transfer might not be recognized and properly included in the analysis because it is outside of the typical scope or focus of product selection processes.

The ability to track and document shifts in environmental impacts can help decision makers and managers fully characterize the environmental trade-offs associated with product or process alternatives. LCA also allows the plastic companies to identify an effective ways of designing and manufacturing the products themselves. LCA helps companies to keep a step ahead of rapidly changing regulatory requirements on solid waste, persistent toxic chemicals, emissions and effluent discharges. In addition, life cycle strategies for pollution prevention and minimizing energy costs are beginning to reveal economic benefits in term of more efficient production, improved product quality and minimization of the environmental risks.

CHAPTER II

LITERATURE REVIEW

2.1 Environmental Management Issue

Nowadays, Malaysia is running out of space to dispose of the urban waste generated daily by wasteful consumption. There simply aren’t enough landfills. According to Housing and Local Government Minister Datuk Seri Ong Ka Ting, 80% of the country’s landfills will be full in two years (Tan, 2005). In fact, landfills themselves cause many serious environmental problems both for us and for future generations.

Not many realize it, but each Malaysian throws away an average 0.8 kg of waste daily. Malaysia is among the countries that have a high rate of waste generation. Our country generates around 15,000 tons of waste every day. It is only a matter of time before we ran out of space to dispose of them. If we put them all together, we have enough waste to fill up the KL Twin Towers in just 9.5 days. In fact, the amount of waste is expected to increase by 2% every year, depending on our population, economic activity and waste disposal methods (Tan, 2005).

2.1.1 What is Waste?

Definitions of ‘waste’ invariably refer to lack of use or value or ‘useless remains’ (Concise Oxford Dictionary). Waste is by-product of human activity.

Physically, it contains the same materials as are found in useful products; it only differs from useful production by its lack of value.

Waste can be classified by a multitude of schemes: by physical state (solid, liquid, gaseous) and then within solid waste by: original use (packaging waste, food waste, etc), by material (glass, paper, etc.), by physical properties (combustible, compostable, recyclable), by origin (domestic, commercial, agricultural, industrial, etc.) or by safety level (hazardous, non-hazardous). Household and commercial waste often referred to together as Municipal Solid Waste (MSW). Household waste is one of the hardest sources of waste to manage effectively. It consists of a diverse range of materials (glass, metal, paper, plastics, organics) totally mixed together. MSW composition is also variable, both seasonally and geographically from country to country and from urban to rural area. In contrast, commercial, industrial and other solid wastes tend to be more homogeneous, with larger quantities of each material (McDougall et al., 2001).

2.1.2 Municipal Waste

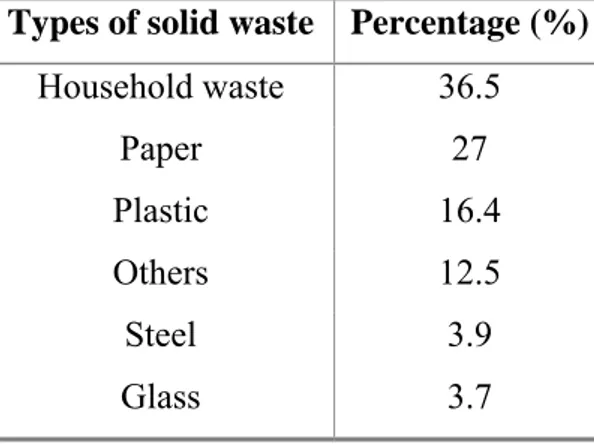

The focus for this title is on municipal waste which not includes industries waste. The municipal waste that was generated can be divided into recyclable and non-recyclable products. The breakdown of solid waste created by Malaysians is shown in Table 2.1.

Table 2.1: Types of solid waste (Housing and Local Government Ministry) Types of solid waste Percentage (%)

Household waste 36.5 Paper 27 Plastic 16.4 Others 12.5 Steel 3.9 Glass 3.7

2.2 The Concerns Over Waste

Generally, health and safety are the major concerns in waste management. Wastes must be managed in a way that minimizes risk to human health. Today, society demands more than this – as well as being safe, waste management must also be sustainable. Sustainability or Sustainable Development has been defined as development which meets the needs of the present without compromising the ability of future generations to meet their own needs (WCED, 1987). This identifies the synergy between economic development, social equity and the environment. Thus, sustainable waste management must be economically affordable, socially acceptable and environmentally effective.

In the past, the economic cost of a waste management system was the major controlled factor in the decision-making process. Recently, environmental considerations have played a more important role in this process. The inclusion of the social aspects of waste management in the decision-making process, although not a new concept in itself, has been limited as research into how to measure social concerns is only just beginning (Nilsson-Djerf, 1999).

Environmental concerns over the management and disposal of waste can be divided into two major areas: conservation of resources and pollution of the environment. The depletion of non-renewable is now not the urgent problem (UNDP, 1998) but two other concerns have become critical with respect to the ‘need of future generations’ are the generation of pollution and wastes that exceed the ability of the planet’s natural sinks to absorb and convert them into harmless compounds. The production and disposal of large amounts of waste is still seen by many to be a loss of the earth’s resources. Putting waste into holes in the ground certainly appears to be inefficient materials management. It needs to be remembered that although the earth is an open system regarding energy, it is essentially a closed system for materials. Whilst materials may be moved around, used, dispersed or concentrated, the total amount of the earth’s elements stays constant. Therefore, although resources of raw materials may be depleted, the total amount of each element present on Earth remains constant. In fact, the concentration of some useful materials is higher in

landfills than in their original raw material ores. Such materials could be dug up at a later date.

Pollution is the basis for most current environmental concern over waste management. Materials have been released into the atmosphere or watercourses or dumped into landfills and allowed to dilute and disperse. At low levels of emissions, natural biological and geochemical processes are able to deal with such flows without resulting changes in environmental conditions. However, as the levels of emissions have increased with rises in human population and activity, natural processes do not have sufficient turnover to prevent changes in environmental conditions. In extreme cases of overloading natural processed may break down completely, leading to drastic changes in environmental quality. Therefore, waste has to be dealt with somehow, somewhere. This can be done by setting an overall strategy to manage waste that reduces environment burdens at an affordable cost.

2.3 What is Life Cycle Assessment (LCA)?

Life Cycle Assessment is a framework and methodology for the identification of environmentally friendly products or processes. It is characterized by the analysis of cumulative environmental impacts over extended system boundaries. While conventional environmental assessment techniques focus only on either manufacturing processes or end-of life disposal or reuse, LCA considers the life cycle of a system or the entire chain of events and activities that are necessary to support the product or process (SETAC, 1991: ISO, 1997). This is often called the cradle to grave approach and has the obvious advantage of revealing potentially significant but hidden environmental impacts. Instead of focusing attention on large, concentrated and readily apparent point sources of impacts.

Life Cycle Assessment requirements have also been included in legislation. The European Community (EC) Ecolabelling Regulation (1992) requires that the whole Life Cycle be considered when setting labeling criteria. Provision for Life Cycle Assessment is also included in the EC Packaging and Packaging Waste

Directive (1994), which states that ‘Life Cycle Assessments should be completed as soon as possible to justify a clear hierarchy between reusable, recyclable and recoverable packaging.’ Practically, his will have to be carried out on a case-by-case basis. As it is develop further, it is likely that Life Cycle Assessment will find many additional applications (McDougall et al., 2001).

2.3.1 History of LCA

The first attempt to look at extended product systems can be traced back to as early as the 1960s. This work mainly focused on calculating energy requirements. Several such fuel cycle studies were conducted in the United States by the Department of Energy. Although they focused on energy characteristics, these studies also included limited estimates of environmental releases. With the oil shortages in the early 1970s, both the U.S. and British governments commissioned extensive studies of industrial studies to conduct detailed energy analyses.

As the oil crises faded, so did interest in the product system or LCA, approach for evaluating energy use. Then in the mid-1970s, landmark studies which focused on environmental issues were performed by Arthur D. Little and Midwest Research Institute (MRI). The main investigators who conducted the studies at MRI later left to form Franklin Associates Ltd. Activity in the United States on environmental LCAs continued at a slow but steady, pace of around two or three studies per year. The exact number is not certain because most studies were performed for private clients and not released for public consumption.

Similarly, extended system studies were conducted in Europe during this period; they looked mainly at packing systems such as beverage containers. But the 1980s found a renewed interest in LCA as the Green Movement in Europe brought the subject to public attention on issues related to recycling. As a result, environmental releases were routinely added to energy, raw materials and solid waste considerations (Curran, 1996).

Modern LCA methodology is rooted in the development of standards through the 1990s. The society for Environmental Toxicology and Chemistry (1991) published “A Technical Framework for Life Cycle Assessment,” the first attempt at an international LCA standard. It explicitly outlined the components of contemporary LCA: goal definition, inventory assessment, impact assessment and improvement analysis. By extending LCA beyond the mere quantification of material and energy flows, SETAC paved the way for the use of LCA as a comprehensive decision support tool. Similar developments took place some time later in North Europe, particularly in the Scandinavia. In 1995, detailed LCA protocols were specified in the “Nordic Guidelines on Life Cycle Assessments” (Nordic Council of Ministers, 1995).

In the late 1990s, the International Organisation for Standardisation (ISO) releases the ISO 14040 series on LCA as an adjunct to the ISO 14000 Environmental Management Standards. The series includes standards for goal and scope definition and inventory assessment (ISO 14041, 1998), impact assessment (ISO 14042, 2000a) and interpretation (ISO 14043, 2000b) as well as general introductory framework (ISO 14040, 1997). The ISO 14040 series actually bears a strong resemblance to the original SETAC framework, Azapagic’s review (1999) gives a comparison between the LCA standards. However, because of ISO’s dominant position in the development of international standards, the ISO 14040 series may eventually supercede the SETAC guidelines among LCA practitioners.

2.3.2 The Product Life Cycle

The life cycle a generic industrial product was defined by SETAC (1991) as being composed of the following stages:

(a) Raw Material Acquisition

All activities necessary to extract raw material and energy inputs from the environment, including the transportation prior to processing.

(b) Process and Manufacturing

Activities needed to convert the raw material and energy inputs into the desired product. In practice this stage is often composed of a series of substages with intermediate products being formed along the processing chain.

(c) Distribution and Transportation

Shipment of the final product to the end user.

(d) Use, Reuse and Maintenance

Utilization of the finished product over its service life.

(e) Recycle

Begins after the product has served its initial intended function and is subsequently recycled within the same product system (closed-loop recycle) or enters a new product system (open-loop recycle).

(f) Waste Management

Begins after the product has served its intended function and is returned to the environment as waste.

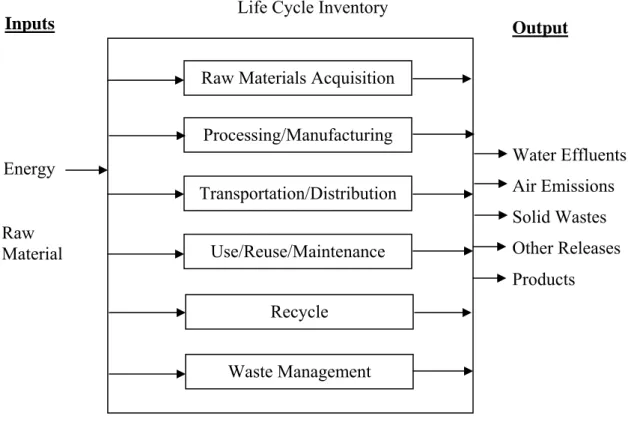

The interaction of these stages with each other and with the external environment are shown in Figure 2.1. The combined stages constitute the entire cradle to grave system.

Truncation of the chain yields partial life cycles which in some cases may be sufficient for the analysis demanded by the study objectives (Todd, 1996). There are three variants of partial LCAs:

(a) Cradle to Gate – analysis upstream of point of truncation.

(b) Gate to Grave – analysis downstream of point of truncation.

Life Cycle Inventory

Energy

Raw Material

Raw Materials Acquisition

Processing/Manufacturing Transportation/Distribution Recycle Use/Reuse/Maintenance Waste Management Output System Boundary Water Effluents Air Emissions Solid Wastes Other Releases Products Inputs

Figure 2.1: Stages in the Life Cycle of a Product (SETAC, 1991)

2.3.3 Key Features of LCA

LCA is a holistic framework that is distinguished by the following features:

(a) Macrosystem or “cradle to grave” perspective

LCA analyzes environmental interactions throughout the chain of activities supporting a given process or product technology.

(b) Multicriterion perspective

LCA analyzes different pathways by which environmental damage is done. This approach gives a balanced scrutiny of both immediate or local impacts (e.g., human toxicity, smog formation) as well as long-term or global concerns (e.g., global warming, depletion of non-renewable resources).

(c) Functional unit perspective

Comparison and analysis of alternative technological systems is based on equivalency of service delivered. For example, instead of comparing the environmental impacts of 1 liter of gasoline with 1 liter of diesel, environmental assessment is normalized with respect to the final service delivered. A more appropriate basis is 1 km of travel by gasoline- and diesel-powered vehicles of equivalent size.

2.3.4 Components of LCA

Early LCA-type studies focused exclusively on quantifying material and energy flows. The emergence of modern LCA standards in the 1990s (SETAC, 1991; Nordic Council of Ministers, 1995; ISO, 1997; ISO, 1998) was characterized by an increase in the level of sophistication of the general life-cycle concept, which has now been extended to include four components for a full LCA. These components are:

(a) Goal and Scope Definition

Specifies the objective of the assessment as well as the assumptions under which all subsequent analysis is done. LCA objectives can be classified broadly into system improvement studies, in which the goal is to identify opportunities for reducing the environmental effects of an existing system or process, and comparative studies, in which the intent is to select an optimal product of process from a number of predetermined alternatives. Scope definition involves specifying system boundaries, functional unit, allocation assumptions, inventory parameters, and impact categories that will be used. Depending on the scope and objectives, it may not be necessary for an LCA to have all four components. In some cases, for example, a simple inventory assessment may be sufficient.

(b) Inventory Analysis

Involves the quantification of environmentally relevant material and energy flows of a system using various sources of data. Essentially, an accounting of system inputs and outputs is performed. The data used may come from a variety of sources, including direct measurements, theoretical material and energy balances, and statistics from databases and publications. `

(d) Impact Assessment

Analyzes and compares the environmental burdens associated with the material and energy flows determined in the previous phase. The conventional approach is to classify the inventory flows into specific impact categories (e.g., global warming, resource depletion, ecotoxicity). Normalization and weighting (or valuation) of the impacts is also included in this stage. If necessary, the individual impacts can then be aggregated into a single composite environmental index.

(e) Interpretation (ISO, 2000b) or Improvement Assessment (SETAC, 1991)

Utilizes the results of the preceding stages to meet the specified objectives. Typically this phase will generate a decision or plan of action. For diagnostic LCAs, the data is used to identify critical segments or “hot spots” in the life cycle which contribute disproportionately to the total system environmental impact. These problem areas can then be eliminated or reduced through system modifications. In the case of comparative LCAs, the competing system life cycles are ranked based on environmental performance and the optimal alternative is selected.

Azapagic (1999) points out the strong similarities between the SETAC and ISO standards. Aside from terminology, the principal difference lies in the fourth component of LCA. In the SETAC framework, the principal focus of this final improvement assessment stage is to identify opportunities for improving environmental performance. Under the ISO framework, the fourth phase is called interpretation and is extended to include sensitivity analysis and final recommendations. The interactions among the four LCA components are shown schematically in Figure 2.2.

Goal Definition Inventory Analysis Impact Assessment Classification Characterization Valuation Scoping Improvement

Figure 2.2 Interactions Among LCA Components (SETAC, 1991)

2.3.5 Uses and Application of LCA

LCA is one of many environmental management tools (ISO, 1997). It can be used by governments, private firms, consumer organizations and environmental groups as a decision support tool (Wenzel et al, 1997; Krozer and Vis, 1998; Field and Ehrenfeld, 1999). The scope of the decisions covered by LCA ranges from broad management and policy choices to specific selection of product or process characteristics during design. Also, LCA may be applied prospectively or retrospectively (Ludwig, 1997). LCA applications (ISO, 1997) can be classified into the following:

(a) Indentification of opportunities to improve the environmental aspects of products at various points in their life cycles.

(b) Decision-making in industry, government, and non-government organizations (NGOs).

(c) Selection of indicators of environmental performance and measurement procedures.

Table 2.2 lists LCA applications based on broad objectives of “focus” and “choice” as suggested by Wenzel et al (1997). “Focus” refers to a stand-alone diagnostic LCA to identify points of interest within a single life cycle system, whereas “choice” refers to comparative LCAs of competing alternatives with the ultimate objective of ranking and selection. They also give a more detailed description of the uses of LCA in the private and public sectors as well as NGOs. LCA applications grouped according to users are given in Table 2.3.

Table 2.2: LCA Applications According to Objectives (Wenzel et al, 1997)

Objective Application Support for Decision Product Development Background for environmental

specifications; design strategies, principles and rules.

Ecolabelling Identifies important environmental properties for the product category. Diagnosis

Community Action Plans Identifies environmentally important product groups.

Product Development On-going identification of the best choices from alternative solutions.

Cleaner Technology Identifies the best available technology by means of LCA.

Community Action Plans Identifies the best community strategy for a certain problem or product.

Selection

Consumer Information Documents potential environmental impacts from a certain product.

2.3.6 Benefits of the Life Cycle Approach

Life Cycle Assessment is an inclusive tool. The Life Cycle Inventory phase is essentially an accounting process or mass balance for a system. All necessary inputs and emissions in many stages and operations of the Life Cycle are considered to be

within the system boundaries. This includes not only direct inputs and emissions for production, distribution, use and disposal but also indirect inputs and emissions, such as from the initial production of the energy used. It is essential that all of the processes are included in the boundaries to conduct a fair and transparent analysis. The reader should recognize that the analysis aggregates over time, i.e. all inputs and emissions over the whole Life Cycle, are included regardless of when they occur and aggregates over space, i.e. all of the sites are included, regardless of where they are located. If real environmental improvements are to be made, it is important to use LCA so that any system changes do not cause greater environmental deteriorations at another time or another location in the Life Cycle.

Table 2.3: LCA Applications According to User Type (Wenzel et al, 1997)

LCA User Application Example

Incineration versus Recycling Community Action Plans

Public Transport Systems Environmentally

Conscious Public Purchase

Cars, Office Supplies Government

Consumer Information Ecolabels & Standards

Identification of Areas of Improvement Product-Oriented Environmental Policy Establish Environmental Focus Environmental Management Concept Selection Component Selection Material Selection Design Choices Process Selection Company Environmental

Documentation ISO 14000 Certification, Ecolabels

LCA offers the prospect of mapping the energy and material flows as well as the resources, solid wastes and emissions of the total system, i.e. it provides a system ‘map’ that sets the stage for a holistic approach. Comparing such system maps for

different options, whether for different products or waste management systems, allows the identification of areas where environmental improvement can be made.

Concern over the environment is sometimes expressed in terms of individual issues, such as acidification. Concentrating on one issue alone, however, ignores and may even worsen the system with respect to other environmental issues. The power of LCA is that it expands the debate on environmental concerns beyond a single issue and attempts to address a broad range of environmental issues. By using a quantitative methodology, at least for the inventory inputs and outputs, it also gives an objective basis for decision making. The system map also allows other environmental information and assessment tools to be incorporated to be used in conjunction with LCA. This helps to take some of the emotional element out of environmental debates.

2.3.7 Limitations of the Life Cycle Approach

The seemingly all encompassing nature of LCA has proved very attractive. It may appear to new users that it is a single tool that can accomplish ‘everything’ with regard to environmental assessment. Many people have viewed LCA as being able to give a comprehensive, overall assessment of a product, service or package. As a result, there have been ill-advised efforts to use LCA as the only measurement tool when developing product labeling systems and during policy making.

Unfortunately, there is a dilemma at the heart of LCA. As LCA employs an overall system balance and functional unit to aggregate resource use, solid waste and emissions over time and space, it is not able to assess the actual environmental effects of the product, package or service system. The International Standards Organisation (ISO) Life Cycle Impact Assessment document (ISO/FDIS, 1999) specifically cautions that LCA does not predict actual impacts or assess safety, risks or whether thresholds are exceeded. The actual environmental effects of emissions and wastes will depend on when, where and how they are released into the environment and other assessment tools and information must be utilised.

For example, an aggregated emission if released in one event from a point source such as a refinery, will have a very different environmental effect than releasing it continuously over years from many diffuse sources. In addition to this, the inventory will allocate the inputs and outputs of are finery to many products, i.e. different product systems. Recalling that LCA deals with only the inputs to a dingle system, only a small percentage of the total activity will be considered for a single product. This problem is generally acknowledged and the term ‘indicator’ is now used to show that LCA does not predict actual environmental effects (ISO, 1999b, Owens, 1999).

The dilemma, therefore, is that LCA is the only tool that attempts to include the whole Life Cycle and all environmental issues associated with a product, package or service system and the only one that relates this to the functional unit. Clearly, no single tool can do everything. Therefore, a combination of tools with complementary strengths is needed for overall environmental management.

2.3.8 International Standards Organisation (ISO) – The ISO 14040 series

Based on the work carried out by the Society for Environmental Toxicology and Chemistry (SETAC), the ISO has further developed and has managed to reach agreement among its global membership on a series of standards: the ISO 14040 series on Life Cycle Assessment. These ISO 14040 series are listed as below:

(a) ISO 14040 Environmental Management –Life Cycle Assessment –Principles and Framework (ISO, 1997)

(b) ISO 14041 Environmental Management –Life Cycle Assessment –Goal and Scope Definition and Life Cycle Inventory Analysis (ISO, 1998)

(c) ISO 14040 Environmental Management –Life Cycle Assessment –Life Cycle Impact Assessment (ISO/FDIS, 1999)

(d) ISO 14040 Environmental Management –Life Cycle Assessment –Life Cycle Interpretation (ISO/FDIS, 1999)

2.4 Issues Related to Life Cycle Stages

2.4.1 Inventory Assessment

The inventory consists of a horizontal (input-output) and vertical (life-cycle) analysis. Each stage of the life-cycle receives input of material and energy and produces which move on subsequent life-cycle phases and emissions (solid, liquid, gaseous). (Brobak et al, 1995)

According to Caduff and Zust, Product Systems should be subdivided into a set of unit processes such that each unit process encompasses the activities of a structured in terms of material, energy and resources. Material and energy go through various existing unit processes. The desired output of a unit process is the product. In addition to the product by-products and emissions are generated. The term emissions signify the many types of output released directly into the ecosphere. Products and by-products undergo existing unit processes.

2.4.1.1 Raw Material Acquisition Stage

The resource requirements and environmental emissions are calculated for all of the processes involved in acquiring raw materials and energy. This analysis involves tracing materials and energy back to their sources.

2.4.1.2 Material Processing Stage

This step involves converting a raw material into a form that can be used to fabricate a finished product. For example, material scarp from a subsystem can be reused internally, sold as industrial scrap or disposed of as solid waste. The inventory account for each option is handled differently.

2.4.1.3 Manufacturing Stage

Manufacturing converts intermediate materials into products ready for their intended used by customers. Facilities for which date are reported on a plant wide basis will require allocation of the inputs and outputs to the product of interest.

2.4.1.4 Filling/Packaging/Distribution

This step includes all manufacturing processes and transportation required to fill, package and distribute a finished product. Energy consumption and environmental releases are caused by transporting the product to the retail outlets or to the customers are accounted for in this step of a product’s life cycle.

2.4.1.5 Use/Reuse/Maintenance Stage

This stage includes all of the activities undertaken by the user of the product or service as well as any maintenance that may be performed by the user or obtained elsewhere. Energy requirements and environmental wastes associated with product storage and consumption are included in this stage.

2.4.1.6 Recycle and Disposal Stage

Recycle and disposal management is the last stage in a product’s life cycle. In open loop recycling, products are recycled into different products. In closed loop recycling, products are recycled again and again into the same product.

2.4.2 Reutilization/Reprocessing/Remanufacturing

Reutilization includes any activity in which the product or package may be reconditioned, maintained or serviced extend its useful life. Secondary utilization is considered as the reutilization phase in this studies.

Reprocessing is the reformation or recycling of a recovered material. Reprocessing involves a series of activities including collection, separation and processing by which products or other materials are recovered in the form of raw materials for the manufacture of new product.

Remanufacturing is an industrial process that restores worn products to a new like condition. This done by first disassembling the product, cleaning and refurbishing the reusable parts. A new product is then reassembled by mixing the old and new parts.

2.4.3 Impact Assessment

Impact Assessment is at this time a poorly developed stage of LCA. Although some impact assessment methods have been advanced as either complete or partial approaches, none has been agreed upon. Nevertheless, an approach to impact analysis, known as ‘less is better’ is typically practiced. With this approach, process and product changes are sought that reduce most, if not all, generated wastes and consumed resources.

According to Guinee and Heijungs (1994), impact assessment includes a characterization step in which the contribution of resource extraction and pollution emission to impact categories such as resource depletion, global warming and acidification are quantified and aggregated as far as possible. This is achieved by multiplying extraction’s and emissions by a factor and by aggregating the results of these multiplication’s into one ‘effect score’ for each impact category:

Effect scoreproblem type = Σ equivalency factorproblem type x emission or extraction

Approach to assessing impacts include relating loadings to environmental standards, modeling exposures and effects of the burdens on a site-specific basis and developing equivalency factors for burdens which an impact category. In the valuation step of impact assessment, impacts are weighted and compared to one another.

It is important to recognize that an LCA impact assessment does not necessarily measure actual impacts. Rather, an impact in LCA is generally considered to be a ‘reasonable anticipation of an effect” or an impact potential (Sullivan and Young, 1995). The reason for sung impact potentials is that it is typically difficult to measure an effect resulting from the burdens of a particular product.

As far as Environmental impacts are concerned the choice for a supplier of a given material might be as important as the choice of material itself (Epelly et al, 1995). Ecobillan evaluated a particular plastic part of a car made of polypropylene supplied by two sources. The environmental impacts were compared with a reference thermoset part. It was concluded that depending on which supplier was chosen, the propylene part might be better or worse than the thermoset one. If the environmental impacts are a concern, the choice of supplier for a given material might be as important as the choice of material itself because of the tremendous discrepancies among environmental impacts of different processed or plants producing the same material.

In the valuation step of impact assessment, impacts are weighted and compared to one another. Further, attaching weighting factors to various potential impacts for comparison purpose is value laden. Because a consensus on the relative importance of different impacts is anticipated to be contentious, a widely accepted valuation methodology is not expected to be adopted in the foreseeable future.

2.5 An Integrated Approach to Solid Waste Management

An integrated approach to solid waste management can be delivered both environmental and economic sustainability. It is clear that no one single method of waste disposal can deal with all materials in waste in an environmentally sustainable. Ideally, a range of management option is required. The use of different options such as composing or materials recovery will also depend on the collection and subsequent sorting system employed. Hence, any waste management system is built up of many closely related processes, integrated together. Instead of focusing on and comparing individual options, an attempt will be made to synthesise waste management systems that can deal with the whole waste stream and then compare their overall performances in environmental and economic terms.

This approach looks at the overall waste management system and develops ways of assessing overall environmental burdens and economic costs. As part of this, the various individual techniques for collection, treatment and disposal of waste are discussed. This book gives an overall vision of waste management with a view to achieving environmental objectives using economically sustainable systems tailored to specific needs of a region or community.

2.5.1 The Basic Requirement of WM

Waste is an inevitable product of society. Solid waste management practices were initially developed to avoid the adverse effects on public health that were being

caused by the increasing amounts of solid waste being discarded without appropriate collection or disposal. Managing this waste more effectively is now a need that society has to address. In dealing with the waste, there are two fundamental requirements: less waste and then an effective system for managing the waste still produced.

Generally, sustainable development could be achieved if society in general and industry in particular learned to produce ‘more form less’; more goods and services from less of the world’s resources while generating less pollution and waste.

In this era of ‘green consumerism’ (Elkington and Hailes, 1998), this concept of ‘more from less’ has been taken up by industry. This has resulted in arrange of concentrated product, light-weighted and refillable packaging, reduction of transport packaging and other innovations (Handle et al, 1993). Production as well as product changes have been introduced, with many companies using internal recycling of materials as part of solid waste minimization schemes.

All of these measures help to reduce the amount of solid waste produced either as industrial, commercial or domestic waste. In essence, they are improvements in efficiency, i.e. ‘eco-efficiency’, whether in terms of materials or energy consumption. The costs of raw materials and energy and rising disposal costs for commercial and industrial waste will ensure that waste reduction continues to be pursued by industry for economic as well as environmental reasons.

There has been interest in promoting further waste reduction by the use of fiscal instruments. Pearce and Turner (1992) suggest ways to reduce the amount of packaging used by internalizing the costs of waste disposal within packaging manufacture, by means of a packaging levy. It is not clear how effective such taxes would be since they only affect a small section of the waste stream, packaging materials constitute approximately 3% by weight of the UK’s total waste stream (INCPEN, 1996) and 3% by weight of the total European waste stream (Pricewaterhouse Coopers, 1998). Furthermore, economic incentives for waste reduction already exist. Experience has often shown that extra taxes add to the total cost but do not reduce the base cost of waste management. Often they become in

effect an additional revenue stream rather than being used for specific environmental purposes.

‘Waste minimization’, ‘waste reduction’ or ‘source reduction’ is usually placed at the top of the conventional waste management hierarchy. In reality, however, source reduction is a necessary precursor to effective waste management, rather than part of it. Source reduction will affect the volume and to some extent, the nature of the waste but there will still be waste for disposal. What is needed, beyond source reduction is an effective system to mange this waste.

2.5.2 Integrated Waste Management in Countries with Developing Economics

The management of Municipal Solid Waste (MSW) is an integral but not much neglected aspect of environmental management in most low and middle income countries. Despite consuming a significant share of Municipal budgets, solid waste management services in the towns and cities of mist low and middle income countries are unreliable, provide inadequate coverage, conflict with other urban services and have adverse effects on public health and the environment (Bartone, 1999).

The IWM approach is as valid in countries with developing economies as it is in countries with developed economies, but the actual establishment of integrated systems differs considerably. In countries with developing economies the combination of a lack of existing waste management infrastructure and severely limited resources change the approach that must be taken. Under these conditions, a relatively simple but effective Integrated Waste Management system is desired.

The waste management systems that exist in the majority of countries with developing economies are often characterized by inadequate collection services, little or no treatment and uncontrolled dumping. The establishment of IWM systems will require the following:

(a) Data collection on waste composition. This in needed for the planning of collection, transport and treatment of MSW. Good date is the foundation of effective IWM systems.

(b) Progress from uncontrolled dumping to the use of simple sanitary landfills. (c) Separation of organic waste from MSW which can then be composted. (d) Formal involvement of scavengers in the collection of recyclable materials.

2.6 Element of Integrated Waste Management

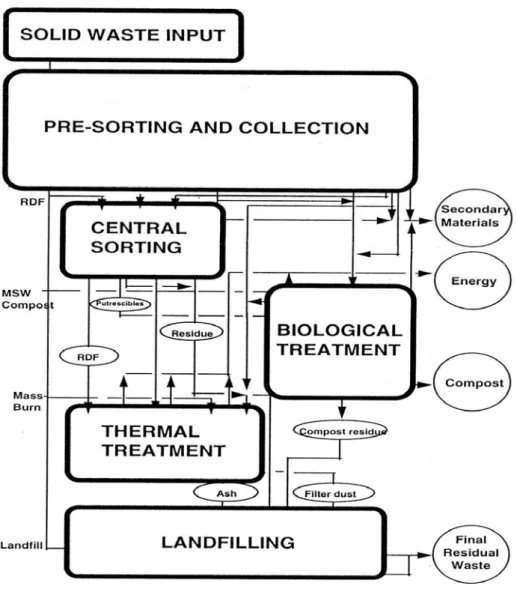

Element of Integrated Waste Management is consisted of solid waste generation, waste collection, central sorting, biological treatment, thermal treatment, landfilling and materials recycling. Every part of these elements play their role to bring the successfulness to the Integrated Waste Management. Basically, the Life Cycle of each material must be from the beginning stage of materials production to the final stage where the waste is to be disposed. The main stage and their interconnections in the Life Cycle of solid waste are shown schematically in Figure 2.3, comprising pre-sorting and collection, sorting, biological treatment, thermal treatment and landfilling.

2.6.1 Solid Waste Generation

A complete overview of data on the amounts of solid waste generated globally is difficult to obtain. This is because much of the date is simple not available and also due to the variety and quality of the available date sources. Different sources in each country use different definitions of total solid waste, Municipal Solid Waste (MSW), commercial waste (sometimes included in MSW, sometime not) and industrial waste. Solid waste data are often presented in different formats depending on the objectives of the reporter, further obscuring the true figures.

Figure 2.3 Element of an Integrated Waste Management System

Data are often reported as one or even several of the following: Total waste arisings, Total household waste, Total municipal waste, Total residual waste, Total collected waste, Total landfilled waste and the permutations, which depend on local circumstances. The main data sources available are the Organisation for Economic Co-operation and Development (OECD), the European Environment Agency (EEA), countries’ own Environmental Agencies and statistical organisations. Table 2.4 shows the categories of solid waste generated from different sources.

Data on the generation of MSW are difficult to interpret because of the different definitions used for MSW. National data that breaks down MSW according to the source of the materials, that is into collected household waste, delivered household waste, commercial waste and institutional waste are equally hard to obtain.

Collected household wastes are normally the best documented with poorer data available for delivered household and commercial waste.

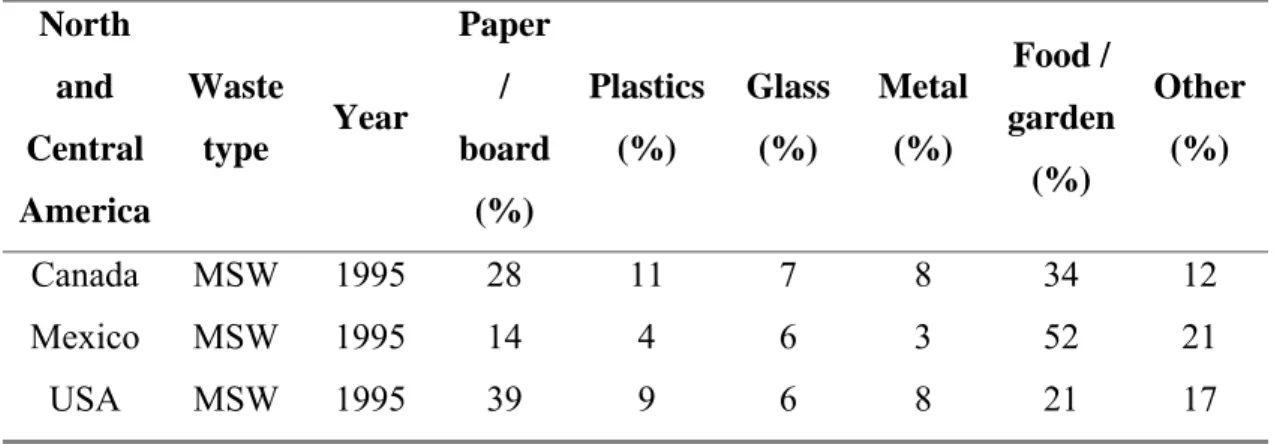

Knowledge of the material composition of MSW is essential for effective management and disposal. The composition of MSW by weight from various counties is given in Table 2.5.

Table 2.4: Categories of solid waste Solid waste category Description

Agricultural Waste arising from agricultural practices, especially livestock production. Often either used (applied to land) or treated in situ.

Mining and quarrying Mainly inert mineral wastes from coal mining and mineral extraction industries.

Dredging spoils Organic and mineral wastes from dredging operations. Construction and

demolition

Building waste, mainly inert mineral or wood wastes.

Industrial Solid waste from industrial processes. Sometimes will include energy production industries.

Energy production Solid waste from the energy production industries, including fly ash from coal burning.

Sewage sludge Organic solid waste, disposed of by burning, dumping at sea (soon to cease in the EU), application to land or composting. May result from industrial or domestic wastewater

treatment. Hazardous / Special

waste

Solid waste which can obtain substances that are dangerous to life is termed ‘Special waste’ in UK or ‘Hazardous water’ in EU directives.

Commercial Solid waste form offices, shops, restaurants, etc. often included in MSW.

Municipal Solid Waste (MSW)

Defined as the solid waste collected and controlled by the local authority or municipality and typically consists of household waste, commercial waste and institutional waste.

Table 2.5: Composition of MSW (by weight) in North and Central America. (OECD, 1997) North and Central America Waste type Year Paper / board (%) Plastics (%) Glass (%) Metal (%) Food / garden (%) Other (%) Canada MSW 1995 28 11 7 8 34 12 Mexico MSW 1995 14 4 6 3 52 21 USA MSW 1995 39 9 6 8 21 17 2.6.2 Waste Collection

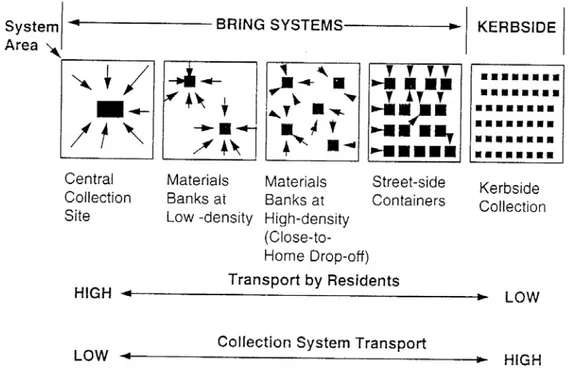

Collection methods are often divided into bring and kerbside collection schemes. ERRA (1993b) defined bring collection systems as those where households are required to take recyclable materials to one of a number of collection points. In kerbside collection schemes the householder places recoverables in container/bag which they position on a specific day, outside their property for collection. Note that collection need not be from kerbside, the key distinguishing point being that in bring systems, the householders transport the materials from their home, whereas in kerbside collection they are collected form the home. In reality, ring and kerbside are just the two ends of a spectrum of collection methods.

Figure 2.4 shows the spectrum of collection methods from bring to kerbside systems. The extreme form of bring system is the central collection site for householders transport materials such as bulky items and garden waste. This site often also has collection containers for recyclable materials such as glass bottles and cans.

Next in the spectrum of bring systems come materials banks at low density often situated locally at supermarkets. As the density of bring material containers increases, they become close-to-home drop off containers (ERRA, 1993b), to which householders can walk rather than drive. This applies particularly to high-rise

housing where residents of apartment blocks usually take their waste to large communal containers positioned outside the apartment blocks or at the side of the street. This is essentially a waste container in the street, outside, rather than inside, the property. The only difference between his bring system and a kerbside collection from individual properties is that the containers are communal, rather than for individual households.

The term bring system clearly includes a range of different schemes. Kerbside collection is more narrowly defined but collection can also be of separated fractions or of co-mingled waste. As a result, blankets comparisons of bring versus kerbside approaches must be made with caution.

Figure 2.4 The spectrum of collection methods from bring to kerbside systems. (Arrow lengths indicate distances traveled by residents to collection points.)

2.6.3 Central Sorting

Sorting is an important part of any waste’s Life Cycle. Solid waste is almost always mixed and household wastes are amongst the most heterogeneous in terms of

material composition. Separation of the different materials in waste to a greater or lesser extent is an essential part of almost all methods of treatment. This sorting can and odes occur at any point in the Life Cycle of waste; similarly it can occur any number of times. The earliest sorting will occur in the home, when, for example, materials are separated from the residual waste stream but the same materials can be sorted further during and after collection.

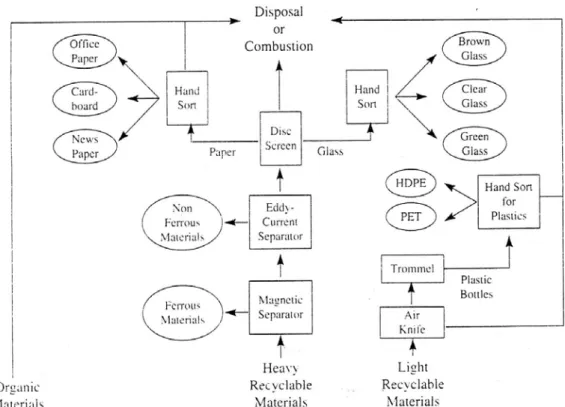

Sorting of the input also represents the first stage of many waste treatment processes, such as composting, biogasification and in some cases sorting of the outputs also occurs. Two particular central sorting operations are the sorting of mixed recyclables at a Material Recovery Facility (MRF) and the sorting of mixed waste to produce Refuse-Derived Fuel (RDF). The aim of MRFs is to separate materials that have enough value to make their recovery worthwhile. MRFs are relatively inexpensive when compared to most other waste treatment processes such as incineration and it is technically feasible to recover almost any fraction of the waste stream either manually or mechanically.

Figure 2.5 shows the generic MRF with manual sorting. RDF is produced by mechanically separating the combustible fraction from the non-combustible fraction of solid waste. The combustible fraction is then shredded and may also be pelletised. RDF production thus forms part of a thermal treatment system which aims to valorize part of the waste stream by recovering its energy content. The second stage, RDF combustion can either occur on the same site or RDF can be transported for combustion elsewhere. Production and combustion of RDF even if they occur on the same site, will be treated separately. There are two basic RDF processes, each producing a distinctive product, knows as densified RDF (dRDF) and coarse RDF (cRDF), respectively.

DRDF is produced as pellets, often similar on size and shape to wine corks. Prior to pelletising it is dried, so is relatively stable and can be transported, handled and stored like other solid fuels, it can either be burned alone or co-fired with coal or other solid fuels. dRDF requires considerable processing, including drying and pelletising and so has relatively high processing energy requirement. As a result,

Figure 2.5 The generic MRF with manual sorting

there has recently been interest in the alternative coarse RDF (cRDF). This comes in the form of a coarsely shredded product that has been compared in appearance to the fluff from a vacuum cleaner (Warmer Bulletin, 1993b). cRDF requires less processing but as it has not been dried, cannot be stored or long periods. It is suitable for immediate use in on-site combustion for power generation and local heating.

2.6.4 Biological Treatment

Biological treatment can be used to treat both the organic and non-recyclable paper fractions of solid waste. Biological treatment can be separated into two distinct processes which are aerobic and anaerobic treatment. Therefore, two main treatment types exist which are composting (aerobic) and biogasification (anaerobic). Either can be used as a pre-treatment to reduce the volume and stabilize material for disposal in landfills or as a way to produce valuable products such as compost and (from biogasification) biogas plus compost from the waste stream.