Flowback water from shale gas wells has a high TDS (total dissolved solids) content, ranging from 5000 ppm to 261,000 ppm, along with a TSS (total suspended solids) content of 300-3000 mg/L. In this project, a process based on ceramic membrane filtration and ion exchange is optimized for the treatment of the flowback water from Marcellus Formation. 15 Figure 3: Average permeate flux for the treatment of the flowback water using different MF ceramic membranes.

To treat the flowback water from Marcellus shale gas production using ceramic membrane and ion exchange technologies. The reflux water sample that will be used in this project will be prepared in the laboratory based on the characterization of reflux water.

Membrane treatment system 9

The types and amounts of fouling depend on many different factors, such as feedwater quality, membrane type, membrane materials, and process design and control.

Microfiltration 10

These contaminants cause a higher workload to be required to guarantee a continuous capacity of the membranes. At a certain point, the pressure will rise to such an extent that it is no longer economically and technically responsible. In its normal operation, MF removes little or no organic matter; however, when pretreatment is applied, increased removal of organic matter, as well as a delay in membrane fouling, can be realized.

MF membranes provide absolute removal of particulate contaminants from the feed stream through separation based on retention of contaminants on the membrane surface. It is the loosest of the membrane processes and, due to its large pore size, is mainly used for particulate and microbial removal and can be carried out under ultra-low pressure conditions. Compared to conventional water clarification processes where coagulants and other chemicals are added to the water prior to filtration, hollow fiber systems have few pretreatment requirements when particles and microorganisms are the target contaminants.

Pre-filters are necessary to remove large particles that can clog the inlet to the fibers in the membrane module. More complex pretreatment strategies are sometimes used either to reduce fouling or to increase the removal of viruses and dissolved organic matter. In some cases, the cake layer built up on the membrane during the water production cycle can remove some organic materials.

It may be necessary to adjust the pH of the return water by chemical dosing prior to membrane filtration to maintain the pH within the recommended operating range for the membrane material used.

Ultrafiltration 11

In the simplest implementations, the MF process involves pre-filtering raw water and pumping it under pressure to a membrane. It should be noted that pH adjustment is not necessary for scale control as MF membranes do not remove uncomplexed dissolved ions. Therefore, membrane productivity is still an important topic that should be thoroughly investigated to better understand this phenomenon and its mechanisms.

UF is a pressure-driven process by which colloids, particles, and soluble species of high molecular mass are retained by a size-exclusion process, thus providing means to concentrate, fractionate, or separate dissolved or suspended species. filter. UF allows most ionic inorganic species to pass through the membrane and retain discrete particles and nonionic and ionic organic species. UF is a single process that removes many water-soluble organic materials, as well as microbiological contaminants.

Fortunately, due to the chemical and hydrolytic stability of UF membrane materials, some of the essential pretreatments for RO membranes, such as pH adjustment or chlorine concentration levels, do not apply. However, it may be necessary to adjust the pH to decrease the solubility of a solute in the food so that it can be filtered. Therefore, commercially available modules are designed to accept return water carrying high solids loads.

Because of the many uses for UF membranes, pilot studies are normally conducted to test the suitability of a given stream for direct UF.

Ion Exchange Treatment 13

Before use, the resins will be soaked in deionized water with gentle mixing for 10 minutes to obtain complete moisture. The well-mixed cation and anion resins will be packed into a 2 cm diameter, 30 cm length anion exchange column (Kontes Chromaflex, Fisher). Ion exchange between the resins and water occurred as the return water would be pumped through the resin column.

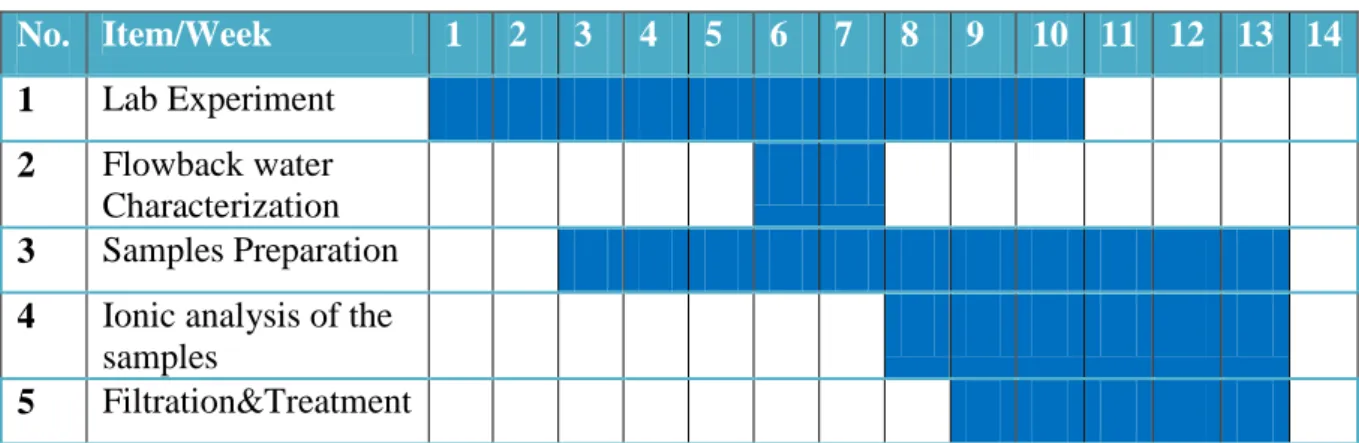

Project Activities: 15

Project Flow 15

Understanding the composition of the return water is essential in determining the extent of treatment required. The intensity of the color is proportional to the amount of that element in the sample. Membrane TSS removal (%) Turbidity reduction (%) Conductivity (µS/cm) TOC removal (%). Table.8) Characteristics of permeate from MF ceramic membranes.

Fig.3) Average permeate flux for the treatment of the flowback water using different MF ceramic membranes. For example, the conductivity of the final permeate from the MU-2 operation was 12% lower than the conductivity of the raw flowback water. The TOC of the final permeate from the MU-2 operation was 17% lower than the TOC of the raw flowback water.

The TOC and conductivity of the final permeate from the MM operation were 640mg/L and 63,900 µS/cm, respectively. Moreover, the UF membranes were not suitable for the treatment of the reflux water, based on the consideration of cost-performance. However, the combination of the MF membranes cannot effectively reduce the TDS and TOC of the reflux water.

The combined process of MF membranes and ion exchange showed a desirable performance for the treatment of the reflux water.

Preliminary Research Work 16

Lab Experiment 16

During the first three weeks of the hydraulic fracturing process, approximately 20-30% of the water used to fracture the well is returned to the surface and is called flowback. Until recently, and depending on the location of the fracturing operation, extraction was done from surface water and municipal treatment plants and discharge of return water into disposal wells. However, reconstitution and reuse of return water for future fracturing operations presents advantages in the form of reduced volumes of fresh water for fracturing operations and the need for disposal options, with concomitant reductions in operating costs and environmental and regulatory issues.

The backflow water is contaminated with suspended and dissolved solids, with concentrations varying depending on location. The goal of the flowback water treatment is to produce clear and largely desalinated water with minimal tendency to interfere with fractionation of liquid components or with shale formation. Thermal technologies are less sensitive to some of the contaminants, but are still sensitive to hardness and TSS due to scaling issues.

In addition, the concentration of divalent ions in the water such as barium, calcium and magnesium can cause scaling and plugging of the formation and must therefore be removed from the flowback water. Although all water analyzes necessary to characterize the flowback water before, during and after treatment can be performed at off-site laboratories, it is clear that the greatest challenge is to analyze the flowback water in the field for rapid and reliable monitoring for efficient decision-making regarding required treatment, treatment performance or reuse, and safe disposal. Laboratory methods for analysis of reflux water range from titration to spectroscopic determinations such as atomic absorption (AA) and inductively coupled plasma (ICP), X-ray fluorescence (XRF); in some cases these methods are cited as standard ASTM methods or practices.

However, field operations for reflux water treatment often require evaluation techniques that are less delicate and easier to mobilize and use, yet sufficiently accurate and reliable to enable operators and service providers to monitor key operating variables for timely process adjustment to ensure target objectives are achieved.

Testing Methods 19

Turbidity depends on the detection of light transmission through the suspension and any inherent precipitation in the sample.

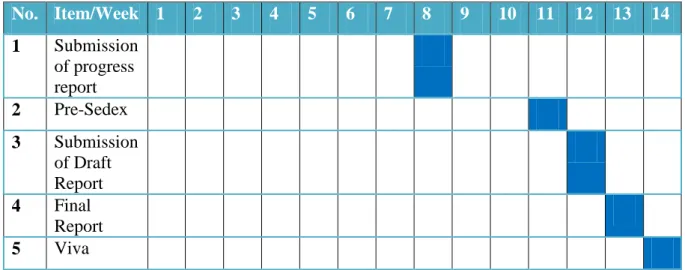

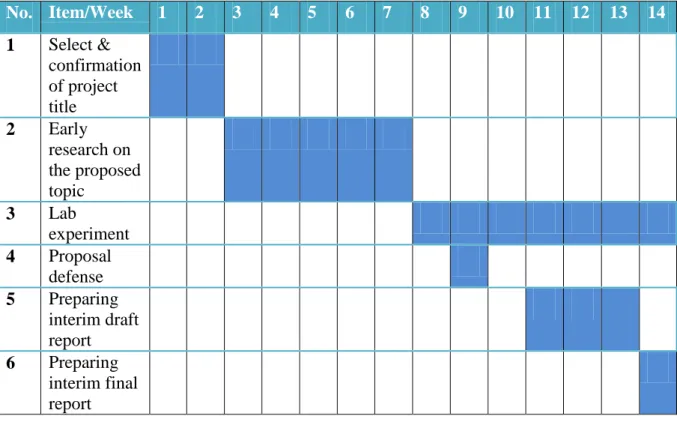

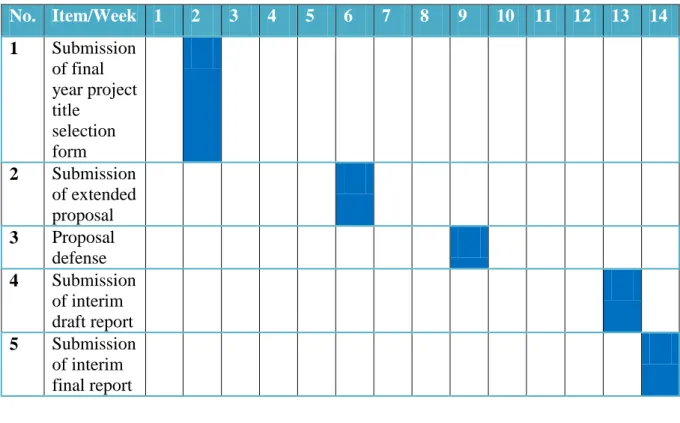

Gantt Chart 21

However, the permeation flux of the 0.2 µm MF membrane in the second stage of serial MM operation showed a more stable value without permeation interruption (Fig. 4). This phenomenon confirmed that the operation of the batch membrane was more feasible for the treatment of return water, since most of the solid particles were rejected by the 1.4 µm MF membrane, and the permeation performances of the subsequent membranes in the batch treatment were improved. It was also observed that the final permeate fluxes of the batch filtration varied according to the different types of membranes used.

Specifically, after decreasing the flux within the first 30-40 minutes, the final permeate flux of the MM. As described above, the final permeate flux of the serial MF operation (the MM operation) was much higher than the final flux of the serial MF-UF operation (the MU-1/MU-2 operation), indicating that more membrane surfaces will be required to treat the same volume of flowback water for the serial MF-UF operation. After treatment through the serial membrane filters, the TSS and turbidity of the reflux water were significantly reduced, while the TDS and conductivity remained high.

The water treated by the ion exchange resin was collected and characterized to determine the performance of the ion exchange treatment. The characterization of the raw reflux water is TOC (mg/L)TOC (mg/L) for comparison shown in Table 10. After the ion exchange treatment, the conductivity of the water is 54 mm/cm, less than 1% of the raw reflux water.

Therefore, the studied combined process of the serial MF membranes and ion exchange can be used to treat flowback water with high TDS, TSS and TOC from a technical perspective. Further studies are underway on the effectiveness of the process on backflow water from various wells. A serial MF operation (1.4 mm and 0.2 mm diaphragms) proved very effective in removing the TSS and improving the appearance of the reflux water.

Key Milestone 22

Tools & Software Required 23