NISA KYO UMARETA

THE EFFECT OF HEAT MOISTURE TREATMENT OF SAGO

(

Metroxylon sago sp

) AND ARENGA (

Arenga pinnataa mer.)

STARCHES

ON NOODLES QUALITY

DEPARTMENT OF FOOD SCIENCE AND TECHNOLOGY

FACULTY OF AGRICULTURAL ENGINEERING AND TECHNOLOGY BOGOR AGRICULTURAL UNIVERSITY

STATEMENT OF MANUSCRIPT,

LITERATURE REVIEW, AND SOURCES OF INFORMATION*

Hereby I declare that manuscript entitled The Effect of Heat Moisture Treatment of Sago (Metroxylon sago sp) and Arenga (Arenga pinnataa mer) Starches On Noodles Quality is my authentic scientific work supervised by advisor commissionary and has not been proposed to other higher education institution. Review based on published or not published literature has been written in the manuscript and references.

Therefore, I give my manuscript copyright to Bogor Agricultural University (IPB).

Bogor, 30 November 2014

Nisa Kyo Umareta

ABSTRACT

Abstract. Sago (Metroxylon sago sp) and arenga (arenga piñataa merr) starches were commonly used to make starch noodles in Indonesia. In native forms, starch does not always have the appropriate physical and chemical properties for certain types of processing in noodles manufacturing. Physical modification such as heat moisture treatment is applied in order to improve starch physical properties. It is expected to make the starch more suitable for starch noodles manufacturing. This study aims to analyze starch noodles made from sago and arenga starches in their native, HMT, and composite (ratio 1:1) forms based on the quality parameter measured (cooking quality and textural quality) and also to compare which starch noodles that has better qualities. Heat moisture treatment was conducted with autoclaving the starch (20% moisture content) for 60 min for sago starch and 90 min for arenga starch at the temperature of 120oC. Starch noodles were made by kneading, extruding, boiling, cooling and drying. Based on cooking quality, HMT had significantly lowered the cooking quality where the HMT sago and arenga starch noodles had higher cooking loss (19.26% & 19.34%) and longer cooking time (7min & 8min) compare to starch noodles made from native sago and arenga starches. On their textural properties, HMT sago and arenga starch noodles had lower extension modulus but less sticky (lower adhesiveness value) compare to starch noodles made from native sago and arenga starches.

Manuscript

as one of requirements to achieve degree of Sarjana Teknologi Pertanian

at

Food Science and Technology major

THE EFFECT OF HEAT MOISTURE TREATMENT OF SAGO

(

Metroxylon sago sp

) AND ARENGA (

Arenga pinnataa mer.)

STARCHES

ON NOODLES QUALITY

NISA KYO UMARETA

DEPARTMENT OF FOOD SCIENCE AND TECHNOLOGY

FACULTY OF AGRICULTURAL ENGINEERING AND TECHNOLOGY BOGOR AGRICULTURAL UNIVERSITY

Manuscript Title : The Effect of Heat Moisture Treatment of Sago

(Metroxylon sago sp) and Arenga (Arenga pinnataa mer) Starches Noodles Quality

Name : Nisa Kyo Umareta

NIM : F24090106

Approved by,

Dr. Ir. Dede R. Adawiyah, M.Sc Advisor

Acknowledge by,

Dr. Feri Kusnandar, M.Sc

Head of Food Science and Technology Department

FOREWORD

Praise to Allah for the mercy, graciousness, and guidance throughout the research and manuscript completion. Author would like to thank his family, especially her beloved parents, sister, and brother for their unending love, support, and encouragement. Author owe her deepest gratitude to her advisor, Dr. Ir. Dede R. Adawiyah, M.Sc for all support, advice, patience, and guidance during the research. Special thanks to Mr. Yahya, and Mrs. Antin who helped collecting data, my family, friends, and colleagues who had given me support and prayer through this manuscript writing.

Bogor, 30 November 2014

TABLE OF CONTENTS

TABLE LIST vi

FIGURE LIST vi

INTRODUCTION 1

Background 1

Objectives 2

MATERIALS AND METHODS 2

Materials 2

Methods 3

Heat Moisture Treatment 3

Starch Noodle Preparation 3

Water Content Analysis 3

Cooking Quality Analysis 4

Optimum Cooking Time Analysis 4

Rehydration Capacity and Cooking Loss Analysis 4

Texture Property Analysis 4

Extension Analysis 4

Texture Profile Analysis 5

Statistical Analysis 5

RESULT AND DISCUSSION 5

Starch Noodles Preparation 4

Starch Noodles Visual Appearance 7

Cooking Quality Analysis 7

Texture Profile Analysis 8

Hydration properties analysis 8

Texture analysis 10

CONCLUSIONS AND RECOMMENDATIONS 11

Conclusions 11

Recommendations 11

REFERENCES 12

TABLE LIST

Table 1 Cooking properties of noodles made ffrom sago starch and arenga starch in native, HMT, and composite forms 7 Table 2 Texture profile analysis of noodles made from sago starch and

arenga starch in native, HMT, and composite forms 8

Table 3 Classification of Characteristics 9

Table 4 Definition of Mechanical Parameters of Texture 9 Table 5 Extension of noodles made from sago starch and arenga starch in

native, HMT, and composite forms 11

FIGURE LIST

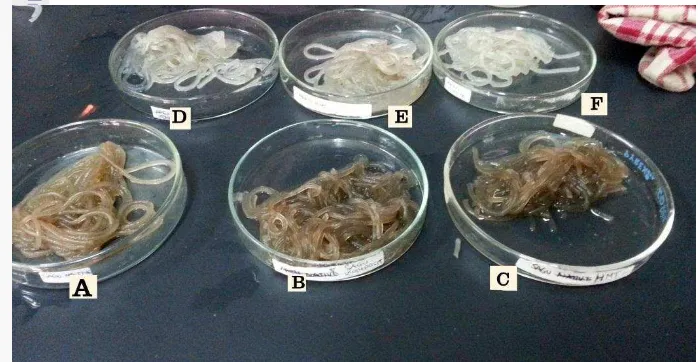

Figure 1 Cooked starch noodles: (A) native sago starch (B) composite sago starch (C) HMT sago starch (D) native arenga starch (E) composite arenga starch (F) HMT arenga starch

INTRODUCTION Indonesia can be made from various starches. Ones of the starch sources are obtain from the palm trees.The common two types of palm trees used for making starch noodles are sago (metroxylon sagu) and arenga (arenga pinnataa merr). Noodles from sago are commercially sold in Bogor, it is also consumed in Riau Archipelago and Kalimantan. Arenga is commonly used as main ingredients for sohun, replacing the mung bean flour. It is also widely sold in Java Island, especially in central java and east java (Widaningrum et al., 2005).

Starch noodles are different with noodles made from the wheat flour. The noodles made from wheat containing gluten which plays an important role to form the network to integrate other components to form visco-elastic dough. The physical properties of starch play an important role to the starch noodles final quality that will be produced. Starch noodle qualities are usually defined by visual attributes of the dry and cooked noodles. The most important characteristics for cooked starch noodles are texture and mouth feel where they should remain firmness, not sticky after cooking, high tensile strength, short cooking time and low cooking loss (Galvez & Ressurection, 1992). The quality of starch noodles usually is measured by three different aspects which are sensory evaluation, cooking quality and textures (Baek, Cha, & Lim, 2001; Chen et al., 2002)

Some modification to the native starch is done in order to make the starch has appropriate properties for certain types of processing. Physical modification has advantages as it has no by products, considered natural and highly safe ingredients. Heat moisture treatment (HMT) is one of physical modification by using hydrothermal treatments which is carried out under restricted moisture content (10-30%) and higher temperature (90-120oC). HMT alters physicochemical properties of starch such as promotes an increase in the gelatinization temperature, a widening gelatinization temperature range, a decrease in granular swelling and amylose leaching and an increase in thermal stability (Zavareze & Dias, 2011). The decrease in granular swelling and amylose leaching and the increase in heat and shear stability of HMT starch could be desirable properties for noodles manufacture (Horndok & noomhorn, 2007).

2

native and HMT forms of sago and arenga starch were also conducted. This research was aim to study the starch noodles quality made from arenga starch and sago starch both in native and HMT based on its cooking quality and textures. This research was also aim to see, which one has the better quality based of the parameter measured.

Objectives

The objectives of this study were to analyze the starch noodles quality made from sago starch and arenga starch on native form, HMT form, and composite of native and HMT (ratio 1:1), to compare starch noodles quality made from sago starch and arenga starch, compare the starch noodles quality made with native form starches with HMT form as well as with composite starches. It also aimed to determine which starch noodles had the best quality on the quality parameters measured (cooking quality and measurement instruments used was texture analyzer (TA-XT2).

Methods

Heat Moisture Treatment

Heat moisture treatment was done by using autoclave method based on the optimum parameters obtained by Adawiyah (2012). Starch moisture content was adjusted to 20% (wet basis) by mixing certain amount of water into the starches for 15min and then was wrapped into sealed HDPE (High density polyethylene) plastics for one hour before autoclave process. The sago starch was autoclaved for 60min while the arenga starch was autoclaved for 90min at the temperature of 120oC. The HDPE plastics were being cooled down to room temperature and dried overnight at 45oC in hot-air-oven.

Starch Noodles Preparation

There were six starch noodles sample that were prepared for this study. The starches were native starches of sago and arenga, HMT starches of sago and arenga, and composite starches (mixture of native and HMT forms of starch with the ratio of 1:1) of sago and arenga starches.

3

times. The noodle’s strands were then directly boiled for 2 minutes and then dried in room temperature for 18 hours by separating each strand. The noodles were then sealed in plastic bag until used for analysis.

Water Content Analysis

The empty cups were dried in the oven for 15 minutes and were cooled down in decikator then scaled. 5gr of sago and arenga starch were put in the dried cup and then scaled. The cups were dried in the oven for 6 hours in temperature of 105oC, then they were cold down in decikator for 15min and were scaled until the constant weight was achieved (AOAC, 1995). Water content was measured by using the equation below

Keterangan :

a = starch and cup weight before drying (gr) b = starch and cup weight after drying (gr) c = starch weight before drying (gr) Cooking Quality Analysis

Optimum Cooking Time Analysis

The optimum cooking time was determined by crushing cooked noodles between a pair of glass plates until the white hard core in the noodles strand disappeared. The cooked noodles were filtered with a nylon screened and drained for 10 minutes (Li & Vasanthan, 2003; Tan et al.,

2009). The optimum cooking time was measured every minute in the interval of 3-8 minutes

Rehydration Capacity and Cooking Loss Analysis

5gr of noodles were cut into 3-5 cm lengths and cooked in 200mL of boiling distilled water for 1 min more than the optimum cooking time. The cooking loss was measured by drying the rehydrated cooked noodles into dried cooked noodles. The noodles were rinsed with fresh distilled water, placed in a preweighed glass beaker, dried in an oven at 110oC for 18 hours and weighed. Percentage of weight differences before and after cooking in dried form was measured as cooking loss (Purwani et al., 2006). The equation of cooking loss and rehydration percentage are served below

Keterangan:

CL = Cooking loss (%)

DN1 = dried noodle weight before cooking (gram) DN2 = dried noodle weight after cooking (gram)

4

Keterangan:

RE = Rehydration percentage (%)

W1 = rehydrated cooked noodle weight (gram) W2 = dried starch noodle before cooking (gram)

Texture Property Analysis Extension Analysis

The textural starch noodles analysis was measured on rehydrated cooked noodles. The analysis was measured by using texture analyzer (TAXT-2). The extension of rehydrated cooked starch noodle (one strand) was measured by using 5kg load cells with test speed set on 3 mm/s. The extension modulus (E) represents the stretch firmness of starch noodles, while the relative extension (re) of the noodle strand was a measure for the stretchability of the starch noodle (Chen et al., 2003). The extension modulus and relative extension were measured by the following equation

Keterangan

E= Extension modulus re= Relative extension F= Extension force (Kgf)

A= Cross-sectional area of the starch noodle (m2)

∆L= Increased length of starch noodle (m) L= original length of starch noodle (m)

Texture Profile Analysis

The texture profile analysis were conducted by using texture analyzer (TA-XT,Stable mycro system, UK). Load cell forced used was 5kg. the two starch noodle strands were compressed twice with test speed set on 3mm/s to 75% strain.

5

Statistical Analysis

Statistical analysis was conducted by using general linear model univariate with Duncan test in SPSS 17.0 to compare the differences among sample mean values at the 95% confidence level. It was used to carry out the data obtained from two replications.

RESULTS AND DISCUSSION

Starch noodles preparation

Starch products, such as noodles, lacked with gluten that was available in wheat based flour. The gluten allowed dough development and binding became easy to be handled during processing. In the production of starch noodles, a portion of starch was gelatinized by mixing it with water and served as binder which was replacing the function of gluten in order to form dough. The binder was then kneaded with the rest of starch and extruded into boiling water, and then kept in cold water and dried in room temperature.

During the extrusion process, the dough need to be extruded for three times as one time extrusion made the starch noodles sticky and easily tear down during the handling and cooking. This three time extrusions were required to increase barrel’s temperature. Increasing of barrel temperature increased the cohesiveness of the noodle strands (Charutigon et al., 2008).

Noodles then were dropped into boiling water and removed after sufficiently cooked as they were floated into water surface. The cooked starch noodles then were transferred into cold water which initiating retrogradation. During retrogradation, cooled gelatinized starch reformed to an ordered system. Process such as low-temperature conditioning after boiling was applied after the gelatinization of the noodle strands to enhance retrogradation of starch noodles (Tam et al., 2004). On the drying process, the starch noodles strands made from native form starches need to be separated one to another, as the starch noodles strands would be adhered though it were rehydrated. In local industry, starch noodles made from sago or arenga were usually added with vegetable oil in order to reduce the stickiness of the surface and better starch retention properties during cooking.On the other hand, HMT starch noodles did not necessarily need to be separated one to another strand. It showed that HMT tend to be less sticky compare to native starch noodles.

Starch noodles visual appearance

6

appearance. The same thing went to composite arenga where the noodles had higher clarity and brighter white color

Some studies showed that the heat moisture treatment affect the lightness and hue of starch. Hydrothermal treatment influenced the color of germinated brown rice (Chung et al., 2012). It has been reported as well that heat moisture treatment resulted in darker color for flours from rice and beans (Lorlowhakarn and Naivikul, 2006). Purwani et al (2006) found that the noodle color was significantly affected by sago origin and HMT. It was also reported that the starch clarity can be influenced by the interaction of several factor such as particle size of granules, total solids concentration, degree of granule dispersion and granules and the capacity of granules to form aggregates (Amani et al., 2005; Lase et al., 2013). The size of flour particles affected the color of the flour where fine particle resulted with brighter and whiter flours than coarse particles (Widjaya, 2010). Objectives measurement should be conducted to compare the starch noodles made rom sago and arenga starches in their native, HMT, and composite forms with tangible data as the comparison above were only done by visual appearances.

Figure 2 Cooked starch noodles: (A) native sago starch (B) composite sago starch (C) HMT sago starch (D) native arenga starch (E) composite arenga starch (F) HMT arenga starch

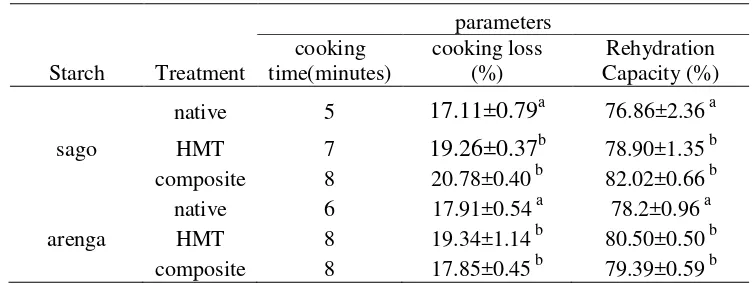

Cooking Quality Analysis

Table 1 below serves the cooking properties of noodles made from sago starch and arenga starch in native, HMT, and composite forms. The optimum cooking time was obtained when the cooked starch noodles strand was crushed between two pair of glass plates and the white hard core in the noodle strand disappeared (Li&Vasanthan, 2003). In cooking stage, small parts of starch noodles will be separated from the noodle itself and suspended in the water. The noodle becomes weaker and less slippery while the cooking water becomes cloudy and thick. This is usually quantitatively

described by the term “cooking loss” (Chen et al., 2002; Tan, Li, & Tan,

7

Table 1 Cooking properties of noodles made from sago starch and arenga starch in native, HMT, and composite forms.

Starch Treatment

Data with different letters in the same column were significantly different at p<0.05

Mean values of two replicates

The optimum cooking time of sago and arenga starch noodles in their HMT forms (7minutes and 8 minutes) and composite forms (8 minutes) showed similar time needed to be fully cooked whereas the optimum cooking time of sago and arenga native forms starch noodles (5 minutes and 6 minutes). The optimum cooking time of sago and arenga starch noodles on their native, HMT, and composite forms were comparable to those sweet potato, mung bean, and their bland starch noodles studied by Thao and Noomhorm (2011) which were ranging from 8 minutes-11 minutes.

Referring to analysis obtained from univariate linear model (appendix 3.1 and appendix 3.2), the type of starch which were sago and arenga affected significantly cooking loss and rehydration capacity of the starch noodles. the treatment as well as the interaction between were also significantly affecting those two parameters. HMT resulted with higher cooking loss compare to composite forms and the native forms.

Based on cooking loss parameter, starch noodles made from native sago(17.11%) was the lowest, followed by composite arenga (17.84%), native arenga (17.91%), HMT sago(19.26%), HMT arenga (19.34%) while the starch noodles made from composite sago starch was the highest (20.79%). Galvez et al (1994) considered a cooking loss of 10% or less as acceptable. All starch noodles that were analyzed had cooking loss values higher than 10% which were undesirable. The Chinese Agriculture Trade Standars for starch noodles set ≤ 10% solid loss during cooking as accepted (NY 5188-2002). While in Indonesia, according to SNI of bihun which is one of the starch based noodle types, the noodles was considered as accepted if the noodles were not broken down while it were soaked in water at the room temperature for 10 minutes (SNI, 1992)

8

noodles (Thitipranphunkul et al, 2003). The higher cooking loss of HMT starch noodles was caused by partial breaking that would affect the internal bonding structure, making the HMT based starch gel on the surface unstable and weaker than the native ones in cooking stages.

An optimal degree of rehydration is desirable. The water uptake during cooking was closely related to the the texture and cooking qualities of starch noodles (Lee et al., 2005). Insuffiecient rehydration usually resulted in noodle with hard and coarse texture, but excess water uptake often resulted noodles that were too soft and sticky (Jin, Wu & Wu, 1994).

It was found that as the swelling power decreased in red sorghum starch but increased water absorption capacity and pasting temperature of the starch after treated with heat moisture treatment. It indicated that the amorphous region may expand slightly and some hydrogen bonds between amorphous and crystalline regions could be broken (Adebowale et al., 2005). Adawiyah (2012) found that heat moisture treatment decreased the swelling power capacity of arenga and sago starches. It was also reported by other studies on red sorghum (Adebowale et al., 2005), sweet potato (Widya et al., 2014). It was correlated as the rehydration capacity of native sago, and arenga starch noodles were slightly lower than the starch noodles made from HMT and composite sago and arenga starches.

Starch granules, which consist mostly amylose and amylopectin are held together by hydrogen bonding in ordered crystalline bundles called micelles (Leach et al., 1959). When a starch granule is heated in an aqueous medium, the hydrogen bonds granule is also heated in an aqueous medium, the hydrogen bonds holding the structure weaken, allowing the granule to absorb water and swell.

According to study conducted by adebowale on red sorghum starch (2005), The solubility of all starches increased with temperature where the heat moisture treatment showed the highest solubility. This is probably due to the weathering of the starch granules during HMT leading to improved solubility (Shieldneck and Smith, 1971; Adebowale 2005). HMT allowed the amylose molecules located in the bulk amorphous regions to interact with the branched segments of amylopectine in the crystalline regions (Hoover et al., 1993; Hoover and Manuel, 1994; Adebowale et al., 2005). Due to the increased quantity of the amorphous phase, induced by transformation of the intercrystalline and crystalline regions by HMT might cause an increased readiness of the structural transformation (Lim et al., 2001). This condition might resulted with swelling restriction which caused longer cooking time and increasing amounts of water to hydrate to induce sago and arenga starch noodles made from HMT forms become swollen at the temperature of 90-95oC during the cooking stage.

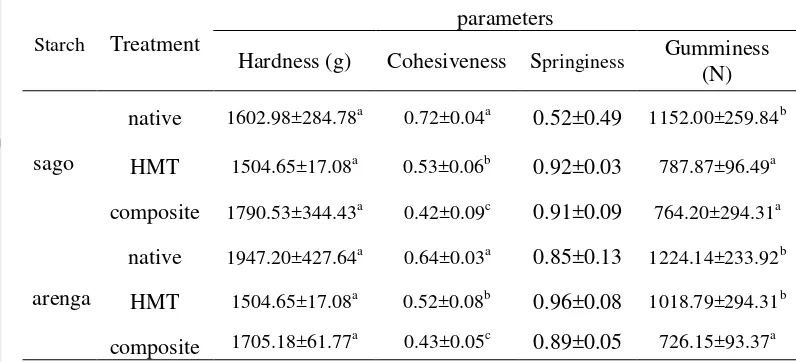

Textural Analysis

9

Table 2 Texture profile analysis of noodles made from sago starch and arenga starch in native, HMT, and composite forms

Starch Treatment

parameters

Hardness (g) Cohesiveness Springiness Gumminess

(N)

sago

native 1602.98±284.78a 0.72±0.04a 0.52±0.49 1152.00±259.84b

HMT 1504.65±17.08a 0.53±0.06b 0.92±0.03 787.87±96.49a

composite 1790.53±344.43a 0.42±0.09c 0.91±0.09 764.20±294.31a

arenga

native 1947.20±427.64a 0.64±0.03a 0.85±0.13 1224.14±233.92b

HMT 1504.65±17.08a 0.52±0.08b 0.96±0.08 1018.79±294.31b

composite 1705.18±61.77a 0.43±0.05c 0.89±0.05 726.15±93.37a

Data with different letters in the same column were significantly different at p<0.05

Mean values of two replicates

The classification of textural terms for solids and semi-solids gave rise to a profiling method of texture description (TPA) applicable to both sensory (Brandt, Skinner, & Coleman, 1963; Szczesniak, 2002) Since texture is a multi-parameter attribute, as evidenced by a large number of words used to describe it, it is only logical to try to introduce some order and classify these terms sensations into certain categories (Szczesniak, 1963; Civille & Szczesniak, 1973, Szczesniak, 2002). From texture profile analysis, textural parameters which were analyzed were hardness, cohesiveness, springiness and gumminess.

Hardness is the force necessary to attain a given deformation (Gerardo & Othon, 1998). From univariate general linear model analysis, neither of the type of starch, treatments, or interaction between them affected the hardness value of the starch noodles (appendix 5). Heat moisture treatment were not affecting the hardness value of starch noodles. HMT sago starch noodles had the lowest value of hardness where HMT arenga starch noodles were the highest (2005.57) followed by arenga native (1947.20), composite sago (1790.53), composite arenga (1602.96), and native sago starch noodles. (1602.96)

10

sample to withstand the second compression (Adawiyah, 2012). The partial breaking of starch effect the quality of starch noodles made. in the cohesiveness measurement, the treatment had significantly affected the cohesiveness value. Heat moisture treatment was remarkably decreased the cohesiveness of sago starch and arenga starch. Mixing the native starch with HMT starch showed significantly decreasing value compare to the starches in their native form and HMT forms (Appendix 6.1 and Appendix 6.2). Low value of cohesiveness might indicate the starch noodles were less likely to withstand the mechanical disruption during cooking stage.

Springiness is defined as rate at which a deformed material goes back to its underformed condition after deforming force is removed. It was also defined as the degree to which a product return to its original shape once it has been process between the teeth (Szczesniak, 1963; Szczesniak, 2002). The springiness characteristics showed as whether the product was plastic or elastic (Brandt, Skinner, & Coleman, 1963; Szczesniak, 2002). Springiness is measured by the distance of the detected height of the product on the second compression as divided by the original compression distance. (Alvarez et al., 2002).

In springiness parameter, springiness values among treatments were significantly different yet the type of starches and the interaction between type of starches and the treatments were not significantly different. However heat moisture treatment had a significantly higher value compare to the native starch noodles, composite were not significantly different either to the starch noodles made from native and HMT forms (Appendix 8.1 and Appendix 8.2). Less springy gels, will break down more easily during mastication than a firm and springy gel (Huang et al., 2007; Simi and Abraham, 2010; Naji et al., 2012). This was also in the heat moisture treated starch noodles which tend to have higher firmness, shown by higher hardness value in texture profile analysis, as their springiness were higher as well.

Gumminess is defined as energy required to disintegrate a semi-solid food to a state ready for swallowing: a product of a low degree of hardness and a high degree of cohesiveness. It showed us the denseness that persists throughout mastication (Civille and Szczesniak, 1973; Szczesniak, 2002).

11

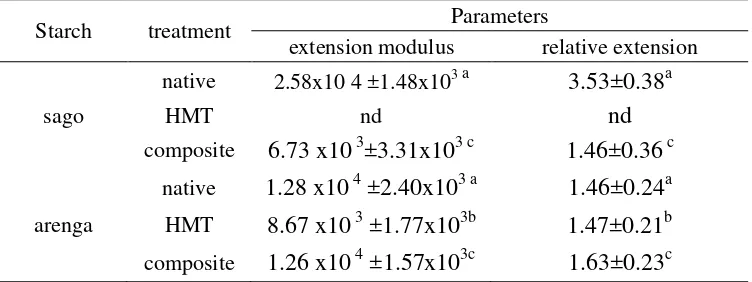

Extension modulus E (table 3) represented the stretch firmness of starch noodles, while the relative extension (re) of the noodle strand was a measurement for the stretch ability of the starch noodle (Chen et al., 2002). In terms of extension modulus and relative extension, the type of starches did not have significantly different value whereas the treatment shifted the extension modulus as well as the relative extension of starch noodles significantly; the interaction between the type of starch and treatment that applied to the starch had significantly different value as well. The heat moisture treatment and composite forms shifted the extension modulus and relative extension values to lower point (Appendix 9.1, Appendix 9.2, Appendix 10.1 and Appendix 10.2).

Sago native starch noodle E value was remarkably higher compare to other starch noodles. native arenga starch noodle was not significantly different with HMT arenga starch noodle with the initial length of 10mm used to determine the extension modulus of starch noodles, HMT starch

noodles measurement couldn’t be detected. The noodle strands were too

weak so it could not withstand the cooking stage and were cut into short strands.

Table 3 Extension of noodles made from sago starch and arenga starch in native, HMT, and composite forms.

Data with different letters in the same column were significantly different at p<0.05

Mean values of two replicates Nd= Not detected

Chen et al. (2003) suggested that the starch gel properties can be used

to predict the cooked noodle quality. The storage modulus (G’) represents

the firmness of the starch gel, while the loss tangent (tan δ) is a measure for

the elasticity of the starch gel. It was found that the G’ (0.997, P<0.01) and

tan δ (-0.960, P<0.05) had a significant correlation with E of the cooked

starch noodles where suggested that high firmness and elasticity of the starch gel can predict high stretch stiffness and bite firmness of the cooked starch noodles (Chen et al., 2003). However, on this study the result showed inversely. Based on previous study conducted by Adawiyah (2012), heat

12

value significantly but HMT sago and arenga starch noodles had lower E values compare to native sago and arenga starch noodles.

On textural property of starch by using compression test, It is shown that the lower the value of breaking strain the more rigid the starch gel will be (Mauluddin, 2014). HMT clearly shifted breaking point to lower strain especially in arenga starch (Adawiyah, 2012). This means that the HMT starch gel is more rigid than the native starch gel. Adawiyah (2012) also found that the retrogradation ratio was greater in HMT starches than those of native starches. Increasing ratio in HMT sago starch was more significant than HMT arenga starch. It showed that the amylose and amylose-amylopectin bound in HMT were strengthened, resulting with more rigid starch gel. As the HMT starch gel was more rigid than the native one, the starch noodles made from HMT were likely to be less elastic, and cannot stand the boiling temperature which happened to starch noodles made from HMT sago.

CONCLUSION AND RECOMMENDATION

Conclusion

13

REFERENCES

Adebowale, Kayode O., Bamidele l. Olu-Owolabi, Olufunmi O. Olayinka, & Olayide S. Lawal. 2005. Effect of heat moisture treatment and annealing on physicochemical properties of red sorghum starch.

African Journal Biotechnology 4(9): 928-933.

Adawiyah, Dede R. 2012. Effect of heat moisture treatment on physical properties and textural quality of food products from arenga and sago starches [Final Report]. Japan National Agriculture and Food Research Institute (NFRI).

Amani, N.G.G., Kamenan A., Sebate A.R., Colonna P. 2005. Stability of yam starch during processing. Afr J Biotechnology 4:94-101.

AOAC [Association of Official Analytical Chemist]. 1995. Official Methods of Analytical of The Association of Official Analytical Chemist.Wahington, DC: AOAC

Baek, M.H., D.S. Cha, and S.T. Lim.2001. Effect of chitosan addition ontextural properties of sweet potato starch noodle. Food Science Biotechnology, 10(2): 161-165.

Bourne, M.C. 2002. Food texture and viscosity: Concept and measurement. New York: Academic Press, chapter 4.

Brandt, M.A., L.Z. Skinner, & J.A. Coleman. 1963. Texture profile method.

Journal of food Science 28:404-409.

Charutigon, Chanpen, Jintana Jitpupakdree, Pimjai Namsree, and Vilai Rungsardthong. 2008. Effects of processing conditions and the use of modified starch and monoglyceride on some properties of extruded rice vermicelli. LWT (41): 642-651.

Chen, Z.H.2003. Physicochemical properties of sweet potato starches and their application in noodle products.[Thesis]. Wageningen University, The Netherlands

Chen, Z., L. Sagis, A. Legger, J.O.H Linssen, H.A. Schols, and A.G.J Voragen. 2002. Evaluation of starch noodles made from three typical chinese sweet-potato starch. Journal offood Science, 67(9): 3342-3347.

Chung, Hyun-Jung, Dong-Wha Cho, Jong-Dae park, Dong-Keon Kweon. 2012. In vitro starch digestibility and pasting properties of germinated rice affected after hydrothermal treatment. Journal of Cereal Science 56: 451-456.

Civille, G.V., A.S. Szczesniak. 1973. Guidelines to training a texture profile panel. Journal of Texture Studies 4:204-223.

Collado, L.S., and H. Corke. 1997. Properties of starch noodles as affected by sweetpotato genotype. Cereal Chemistry 60: 116-121.

Collado, L.S, L.B. Maresa, C.G Oates, and H. Corke. 2001. Bihon-type noodles from heat-moisture-treated sweet potato starch. Journal of Food Science vol. 66 no. 4:604-609.

14

Galvez, F.C.F, A.V.A Resurreccion, G.O Ware. 1994. Classification and measurement of nutritionally important starch fractions. Eur. J. Clin. Nutr. 46 (Suppl. 2):33.

Gerardo, Feldhaus Herrmann, and Serna Saldivar Sergio Othon, inventors. July 6th 1998. Use of bentonites as additives to flour and dough. WO 2000001241 A1.

Haung M., Kennedy J.F., Li B., Xu X., Xie B.J. 2007. Characters of rice starch gel modified by gellan, carrageenan, and glucomannan: A texture profile analysis study. Carbohydrate polymer 69:411-418.

Hoover, R.A., and Vasanthan T. 1994. Effect of heat moisture treatment on the structure and physicochemical properties of tuber and root starches.

Carbohydrates res. 252: 33-53.

Hoover, R.A., and Maunal H.1996. Effect of heat moisture treatment on the structure and physicochemical properties of legume starches. Food res international 29: 731-750.

Hormdok, rungarun, and Athapol Noomhorm. 2007. Hydrothermal treatments of rice starch for improvement of rice noodle quality. LWT-Food Science and Technology vol. 40(10): 1723-1731.

Hui, Y.H. 2007. Handbook of Food Products Manufacturing Priciples, Bakery, Beverages, Cereals, Cheese, Confectionary, Fats, Fruits, and Functional Food. Wiley Interscience, A John Wiley & Sons, Inc. New York.

Jin, M., J. Wu, and X. Wu. 1994. A study on properties of starches used for starch noodle making. In G. Xie & Ma. Z, (Eds.), Proceedings 1994 international symposium and exhibition on new approaches in the production of food stuffs and intermediate products from cereal grains and oil seeds CCOA/ICC/AACC Meeting (pp. 488-496). Beijing: CCOA.

Karim AA, Norziah MH, Seow CC. 2000. Methods for the study of starch retrogradation. Food Chem 71:9-36.

Kasemsuwan, T., T. Bailey, J. Jan. 1998. Preparation of clear noodles with mixture of tapioca and high amylose starches. Carbohydrate Polymer 32: 301-312.

Kennedy, H.M. 1989. Starch and dextrin-based adhesives: In: Adhesives from Renewable Resources, R.W. Hemingway, A.H. Corner and S.J. Branham (eds.). Chemical Society, Washington DC, USA.pp: 326-336 Khandker, A.K., M.B. de Mosqueda, R.R. del Rosario, & B.O. Juliano. 1986. Factors affecting properties of rice noodles prepared with an extruder. ASEAN Food J., 2: 31 -35.

Kim, Y.S., D.P. Wiesenborn, J.H. Lorenzen, P. Berglund. 1996. Suitability of edible bean and potato starches for starch noodles. Cereal Chem 73:302-308.

Lase, Vera Apryana, Elisa Julianti, and Linda Masniary Lubis. 2013. Bihon type noodles from heat moisture treated starch of four varieties of sweet potato. J. Teknologi dan Industri Pangan vol. 24 (1):89-96.

15

Lee, Seung-Young, Kyung-Soo Woo, Jae-Kag Lim, Hyuk Il Kim, and Seung-Taik Lim. 2005. Effect of processing variables on texture of sweet potato starch noodles prepared in a nonfreezing process. Cereal Chem. 82 (4): 475-478.

Li, J.H., and T. Vasanthan. 2003. Hypochlorite oxidation of field pea starch and its suitability for noodle making using an extrusion cooker. Food Research International 36: 381-386.

Lorlowhakarn, Korrakot, Onanong Naivikul. 2006. Modification of rice flour by heat moisture treatment (HMT) to produce rice noodles.

Kasertasart J. (Nat.Sci) 40: 135-143.

Masumbu, F.F.F., W.R.L. Masamba, and E. Fabiano. 2003. Development and evaluation of maize and cassava starch-based cold-setting adhesives for case-sealing. Malaqi Journal of Agricultural Sciences 2 (1): 65-76.

Mestres, C., P. Collona., A. Buleon. 1988. Characteristics of starch networks within rice flour noodles and mungbean starch vermicelli. J. Food Sci. 53: 1809-1812.

Miskelly, D.M. 1993. Noodles – a new look at an old food. Food Australia 45: 496-500.

Purwani, E.Y., Y. Setiawaty, H. Setianto, N. Richana, Sunarmani, S. J. Munarso, D. Amiarsi dan

Misgiyarta. 2003. Pengembangan Teknologi Pangan Tradisional Prospektif Sebagai Alternatif

Naji, Sara, Seyed M.A. Razavi, Hojjat Zarazhiyan, Arash Koocheki. 2012. Influence of thermal treatments on textural characteristics of cress seed (Lepidium sativum)gum gel. EJEAFche 11(3): 222-237.

Pangan Pokok. [Final Report]. Balai Penelitian Pascapanen Pertanian. Jakarta.

Purwani, E.Y., R. Widaningrum, R. Thahir, and Muslich. 2006. Effect of heat moisture treatment of starch on its noodle quality. Indonesian Journal of Agricultural Science 7(1): 8-14.

Simi, C.K., Abraham T.E. 2010. Hydrocolloids as thickening and gelling agents in food: a critical review. J Food Sci Tech 47(6):587-597.

Singh, U., J. Singh, and N.S. Sodhi. 2002. Morphological, thermal, rheological and noodle-making properties of potato and corn starch.

Journal of the Science of Food and Agriculture 82: 1376-1383.

Szczesniak, Alina Surmacka. 2002. Texture is sensory property. Food Quality and Preference 13:215-22.

Szczesniak, Alina Surmacka. 1963. Classification of textural characteristics.

Journal of Food Science28: 385-389.

Takahashi, S., R. Kobayashi, K. Kainuma, and M. Nakamura. 1986. Effect of added soybean protein on physic-chemical propertis of starch noodles (harusame). Journal of Japanese Society of Starch Sciences (Depun Kagaku), 33(1): 21-30.

16

Tan, Hong Zhuo, Zai-Gui Li, Bin Tan. 2009. Starch noodles: History, classification, materials, processing, structure, nutrtion, quality evaluating and improving. Food Research Internation 42: 551-576.

Thitipranphunkul, K., D. Uttapap, K. piyachomkwan, Y. Takeda. 2003. A comparative study of edible canna starch from different cultivars. Part I. Chemical composition and physicochemical properties.

Carbohydrate polymer (53): 317-324.

Wang, R. L., Stec, A., Hey, J., Lukens, L., and Doebley, J. (1999). The limits of selection during maize domestication. Nature 398, 236-239.

Widaningrum, B.A, Santosa, Endang Yuli Purwani. 2005. Proceeding. Seminar Nasional Teknologi Inovatif Pascapanen untuk Pengembangan Industri Berbasis Pertanian. Bogor, September 7th–8th 2005.

Widjaya, Cecilia. 2010. The impact of ingredient formulation and processing parameters on colour and texture of instant noodles. [Thesis]. RMIT University, Australia.

Williams, R.H., 1986. Corrugating and adhesive indsutries: In: Modified starches: Properties and uses, O.B. Wurzburg, (Eds.), CRC Press, Boca Raton USA:253-263.

Zavereze, Elessandrra da Rosa, Alvaro Renato Guerra Dias. 2011. Impact of heat-moisture treatment and annealing in starches: A review.

17

APENDICES

Apendix 1 Raw data of starch noodles parameters

Sample elongasi RE cooking_loss Rehydration hardness cohesiveness gumminess

springiness

native sago 17.85 2.36 17.27 79 1429 0.67 951.30 0.996

16.53 2.076 17.2 76.26 1294.9 0.7 907.77 0.99 18.54 2.77 17.93 78.4 1812.9 0.74 1414.752 0.94 20.71 2.89 16.04 73.79 1875.1 0.75 1066.58 0.95

native arenga 2.45 0.277 17.5 79.54 1515.1 0.66 992.47 0.94

2.64 0.287 18.13 80.49 1647.4 0.65 1066.06 0.96 4.08 0.554 17.43 77.66 2357.6 0.63 1488.102 0.66 7 0.75 18.56 77.91 2268.7 0.6 1349.93 0.81

HMT sago 0 0 19.49 81.33 1517.9 0.544 826.85 0.86

0 0 19.57 82.91 1512.6 0.6 900.70 0.94

0 0 19.25 81.83 1508.4 0.45 679.11 0.97

0 0 18.74 82.02 1479.7 0.5 744.80 0.86

HMT arenga 3.41 0.7132 19.76 76.33 2288.7 0.409 936.37 1.05

2.67 0.5778 20.76 80.89 2171.5 0.5 1084.32 0.96 4.06 1.039 18.42 77.67 1767.7 0.6 1066.58 0.86 5.28 0.885 18.4 77.91 1794.4 0.55 987.82 0.93

composite sago 0.41 0.172 20.8 80.405 1508.4 0.35 533.65 1.02

0.56 0.11 20.36 80.54 1479.7 0.33 487.86 0.91 4.47 0.738 21.31 80.43 2042.9 0.51 1048.20 0.87 3.57 0.8 20.67 80.63 2131.1 0.46 987.10 0.82

composite arenga 7.1 1.51 18.38 78.21 1673.6 0.403 675.67 0.94

18

19

4 1602.9750 284.77946 142.3897

S

1149.8273 2056.1227 1294.90 1875.10

native

arenga

4 1947.2000 427.54371 213.7718 1266.8826 2627.5174 1515.10 2357.60

HMT sago 4 1504.6500 17.08147 8.54074 1477.4696 1531.8304 1479.70 1517.90

HMT

arenga

4 2005.5750 263.86251 131.9312 1585.7109 2425.4391 1767.70 2288.70

composite

sago

4 1790.5250 344.42763 172.2138 1242.4638 2338.5862 1479.70 2131.10

composite

arenga

4 1705.1750 61.76803 30.88401 1606.8883 1803.4617 1642.30 1784.30

Total 24 1759.3500 303.98421 62.05052 1630.9887 1887.7113 1294.90 2357.60

20

HMT

arenga

4 .5148 .08147 .04073 .3851 .6444 .41 .60

composite

sago

4 .4125 .08655 .04328 .2748 .5502 .33 .51

composite

arenga

4 .4257 .04952 .02476 .3470 .5045 .40 .50

Total 24 .5378 .12292 .02509 .4858 .5897 .33 .75

gumminess

sagu

native

4 1151.9950 259.83960 129.919 738.5322 1565.4578 907.30 1414.75

aren native 4 1224.1400 233.92184 116.9609 851.9182 1596.3618 992.47 1488.10

sagu HMT 4 787.8650 96.49493 48.24746 634.3200 941.4100 679.11 900.70

aren HMT 4 1018.7875 69.13055 34.56528 908.7854 1128.7896 936.38 1084.38

sagu

komposit

4 764.2000 294.30882 147.1544 295.8890 1232.5110 487.86 1048.20

aren

komposit

4 726.1450 93.37432 46.68716 577.5656 874.7244 651.93 860.35

Total 24 945.5221 265.47208 54.18926 833.4231 1057.6211 487.86 1488.10 springiness

sagu

native

4 .5225 .48788 .24394 -.2538 1.2988 .10 .95

aren native 4 .8475 .13745 .06872 .6288 1.0662 .66 .96

sagu HMT 4 .9175 .03862 .01931 .8560 .9790 .86 .94

aren HMT 4 .9625 .07848 .03924 .8376 1.0874 .86 1.05

sagu komposit

4 .9050 .08505 .04252 .7697 1.0403 .82 1.02

aren komposit

21

Apendix 3.1 Tests of between subjects from cooking loss parameter Source

Type III Sum of

Squares df

Mean

Square F Sig.

Corrected Model 35.814a 5 7.163 15.849 .000

Intercept 8399.293 1 8399.293 18585.134 .000

pati 2.857 1 2.857 6.321 .022

treatment 17.281 2 8.641 19.119 .000

pati * treatment 15.676 2 7.838 17.343 .000

Error 8.135 18 .452

Total 8443.242 24

Corrected Total 43.948 23

a. R Squared = .815 (Adjusted R Squared = .763)

Apendix 3.2 Duncan test from cooking loss parameter Duncana,,b

treatment N

Subset

1 2

native 8 17.5075

HMT 8 19.2988

komposit 8 19.3163

22

Apendix 4.1 Tests of between subjects from rehydration parameter

Source

Type III Sum of

Squares df

Mean

Square F Sig.

Corrected Model 64.696a 5 12.939 6.010 .002

Intercept 150973.723 1 150973.723 70126.755 .000

pati 5.583 1 5.583 2.593 .125

treatment 24.711 2 12.356 5.739 .012

pati * treatment 34.402 2 17.201 7.990 .003

Error 38.752 18 2.153

Total 151077.171 24

Corrected Total 103.447 23

Apendix 4.2 Duncan test from rehydration capacity parameter

treatment N

Subset

1 2

native 8 77.8813

komposit 8 79.9469

HMT 8 80.1113

23

Apendix 5 Tests of between subjects from hardness parameter

Source

Type III Sum of

Squares df

Mean

Square F Sig.

Corrected Model 756585.660a 5 151317.132 1.990 .129

Intercept 7.429E+07 1 7.429E+07 976.923 .000

pati 384864.027 1 384864.027 5.061 .037

treatment 3183.002 2 1591.501 .021 .979

pati * treatment 368538.631 2 184269.315 2.423 .117

Error 1.369E+06 18 76042.307

Total 7.641E+07 24

24

Apendix 6.1 Tests of between subjects from cohesiveness parameter

Source

Type III Sum of

Squares df

Mean

Square F Sig.

Corrected Model .279a 5 .056 14.753 .000

Intercept 6.940 1 6.940 1832.544 .000

pati .004 1 .004 1.003 .330

treatment .266 2 .133 35.125 .000

pati * treatment .010 2 .005 1.255 .309

Error .068 18 .004

Total 7.288 24

Corrected Total .348 23

a. R Squared = .804 (Adjusted R Squared = .749)

Apendix 6.2 Duncan test from cohesiveness parameter Duncana,,b

Treatment N

Subset

1 2 3

Komposit 8 .4191

HMT 8 .5191

native 8 .6750

25

Apendix 7.1 Tests of between subjects from gumminess parameter

Source

Type III Sum

of Squares df

Mean

Square F Sig.

Corrected Model 925946.354a 5 185189.271 4.796 .006

Intercept 2.146E+07 1 2.146E+07 555.712 .000

pati 46821.083 1 46821.083 1.213 .285

treatment 805989.784 2 402994.892 10.437 .001

pati * treatment 73135.487 2 36567.743 .947 .406

Error 694988.393 18 38610.466

Total 2.308E+07 24

Corrected Total 1.621E+06 23

a. R Squared = .571 (Adjusted R Squared = .452)

Apendix 7.2 Duncan test of gumminess parameter Duncana,,b

treatment N

Subset

1 2

komposit 8 745.1725

HMT 8 903.3263

Native 8 1188.0675

26

Apendix 8 Tests of between subjects from springiness parameter

Source

Type III Sum of

Squares df

Mean

Square F Sig.

Corrected Model .515a 5 .103 2.259 .093

Intercept 16.985 1 16.985 372.168 .000

pati .085 1 .085 1.867 .189

treatment .300 2 .150 3.284 .061

pati * treatment .130 2 .065 1.429 .266

Error .821 18 .046

Total 18.322 24

Corrected Total 1.337 23

27

Apendix 9.1 Tests of between subjects effects from extension modulus

Source

Type III Sum of

Squares df

Mean

Square F Sig.

Corrected Model 1.471E+09 5 2.942E+08 72.167 .000

Intercept 2.944E+09 1 2.944E+09 722.199 .000

pati 1.477E+06 1 1.477E+06 .362 .555

treatment 9.150E+08 2 4.575E+08 112.231 .000

pati * treatment 5.545E+08 2 2.772E+08 68.005 .000

Error 7.338E+07 18 4.077E+06

Total 4.489E+09 24

Corrected Total 1.544E+09 23

a. R Squared = .952 (Adjusted R Squared = .939)

Apendix 9.2 Duncan test from extension modulus parameter Duncana,,b

treatment N

Subset

1 2 3

HMT 8 4335.3400

komposit 8 9638.1300

native 8 19253.8525

28

Apendix 10.1 Tests of between subjects effects from relative extension Dependent Variable:RE_extension

Source

Type III Sum of

Squares df

Mean

Square F Sig.

Corrected Model 29.025a 5 5.805 80.587 .000

Intercept 74.029 1 74.029 1027.702 .000

pati .222 1 .222 3.089 .096

treatment 13.365 2 6.682 92.769 .000

pati * treatment 15.437 2 7.719 107.154 .000

Error 1.297 18 .072

Total 104.350 24

Corrected Total 30.321 23

a. R Squared = .957 (Adjusted R Squared = .945)

Apendix 10.2 Duncan tests from relative extension paramaeter Duncana,,b

treatment N

Subset

1 2 3

HMT 8 .7325

komposit 8 2.0464

native 8 2.4900

29

CURRICULUM VITAE

Writer named Nisa Kyo Umareta was born in Kyoto, Japan at August 13th, 1991 as the third child from Soeprapto and Rosita Schohib. Writer educational background was 48 Senior High School, East Jakarta then accepted to IPB through SNMPTN in 2009 and enlisted as an undergraduate student of Food Science and Technology department.

Writer actively participated in various organizations such as International Association of Students in Agriculture and Related Sciences (IAAS LC IPB) since 2009, Shutter Photography Community, member of Food Science and Technology Student Association in 2011.