UNIVERSITI TEKNIKAL MALAYSIA MELAKA

LIFE CYCLE AND SUSTAINABILITY OF DESIGN ON RTV

SILICONE RUBBER MOULD

This report submitted in accordance with requirement of the Universiti Teknikal Malaysia Melaka (UTeM) for the Bachelor Degree of Manufacturing Engineering

(Manufacturing Design) with Honours.

by

NUR HIDAYAH BINTI AMIR

LIFE CYCLE AND SUSTAINABILITY OF DESIGN ON

RTV SILICONE RUBBER MOULD

NUR HIDAYAH BINTI AMIR

ABSTRACT

ABSTRAK

DEDICATION

ACKNOWLEDGEMENT

This research was performed under the supervision of Mdm Ruzy Haryati Hambali and Mr Hassan b Attan, whom I would like to thank for the freedom granted in carrying out this project. I also would like to express my deep appreciation to both of them for understanding regarding the difficulties I had during the project.

I would like to gratefully acknowledge Mr Mohd Fairus b Ninggal for his consultation and for providing equipment that was required.

A special thank to all my friends who have worked together for our projects. I could not achieve it without their support and encouragement.

Most of all, I would like to thank my parents for their patience and support through all the years.

TABLE OF CONTENT

1.3 Objective of the Research……….4

1.4 Scope of Work………..4

2. LITERATURE REVIEW

………52.1 Life Cycle……….………5

2.1.1 Life Cycle Analysis………...………6

2.1.1.1 How does LCA Works? ……….…..……….6

2.1.1.2 Component of LCA………7

2.1.2 Life Cycle Management…………..………10

2.1.3 Why Life Cycle Management useful……….… 11

2.1.4 Drivers for the adoption of Life cycle management………12

2.1.4.1 Key Drivers………..12

2.2 Sustainable product………14

2.2.1 The Characteristic of Sustainable Product design………...…15

2.2.2 Drivers for more Sustainable Design……….…….15

2.3 Room Temperature Vulcanizing (RTV) Silicone……….………..18

2.3.1 Characteristics of RTV Silicone Rubber……….19

2.3.2 Making Silicone Rubber Mould……….…….26

2.3.3 Bonding………...27

2.3.4 Diluent……….……31

2.3.5 Causes of Poor Mould making and Solutions……….32

2.4 Vacuum Casting………..…..35

2.5 Rapid Tooling Background Information………37

2.5.1 Introduction to Rapid Tooling……….37

2.5.2 Classification of Rapid Tooling Methods………37

2.5.2.1 Indirect Methods of Rapid Tooling…………...………...41

2.5.2.2 Direct Methods of Rapid Tooling……….………42

2.5.3 Appropriate Rapid Tooling Selection……….……….45

2.6 Rapid Prototyping Background Information……….…….…48

2.6.1 Introduction to Rapid Prototyping……….………….……….48

2.6.2 Application of Rapid Prototyping……….………..50

2.6.3 Classification of Rapid Prototyping………..……….……….……50

2.6.3.1 Liquid-based Systems….……….….……….,…..51

2.6.3.2 Solid-based Systems……….….…………..….51

2.6.3.3 Powder-based Systems……….……….……….…..52

2.6.4 Basic processes of Rapid Prototyping……….….……….…..52

3. METHODOLOGY……….59

3.1 Introduction………59

3.2 Description of Methodology………..62

3.2.1 Project Proposal and Search for Project Information………..63

3.2.2 Virtual Prototyping Introduction……….63

3.2.2.1 Virtual part Design of Master Pattern………..63

3.2.2.2 Master Pattern………..………….………64

3.2.3 Physical Prototyping………65

3.2.4 Rapid Tooling………..65

3.2.5 Validation………65

3.2.6 Investigation on mould degradation………66

3.3 Mould Development………...66

3.3.1 Design of the mould………66

3.3.2 Riser and Runner……….67

3.3.3 Modeling Clay Parting Line………....67

3.3.4 Calculation of Required Silicon………..68

3.3.5 Positioning the Part……….……….69

3.3.6 Material of the Mould……….……….69

3.3.7 Vacuum Oven……….……….70

3.3.8 Pouring the Molding Material……….………72

3.3.9 Demold and Cutting the Mould………..……….72

3.3.10 Duplicating Process……….….……….73

3.3.11 Placing the Mould……….……….………74

3.3.12 Material of Casting……….….………..75

3.3.13 Preparation of Mixture……….……….75

3.3.14 Pouring the Material……….……….75

3.3.15 Removing the Pattern………76

3.4 Dimensional Accuracy………...77

3.4.1 Numerical Information………78

4. RESULTS……….….….80

4.1 Data for Pilot Test……….…….80

4.2 Data for Dimensional Accuracy……….……82

5.DISCUSSION………...84

5.1 Dimensional Accuracy Analysis………..…..84

5.2 Physical Testing Analysis……….….…….92

6. CONCLUSION……….…….…….93

6.1 Conclusion……….……...……..93

6.2 Future Work Recommendation……….…….……94

REFERENCES

……….…..95APPENDIX A………..……99

LISTS OF TABLES

Table 2.1 : General Characteristics……….21

Table 2.2: Typical example of mould making……….23

Table 2.3: To bond RTV silicone rubber to different material………...28

Table 2.4: Primers for two-component RTV silicone mould………..29

Table 2.5: Typical silicone rubber bonding agents……….30

Table 2.6: Causes of Poor Mouldmaking and Solutions……….32

Table 2.7: Commercially Available Indirect Tooling Processes……….…..43

Table 2.8: Commercially Available Direct Tooling Processes………..44

Table 4.1: Pilot Test Measurement for Dimensional Accuracy………...80

Table 4.2: Pilot Test Measurement for Physical Testing……….81

Table 4.3: Results for Dimensional Accuracy……….82

LISTS OF FIGURES

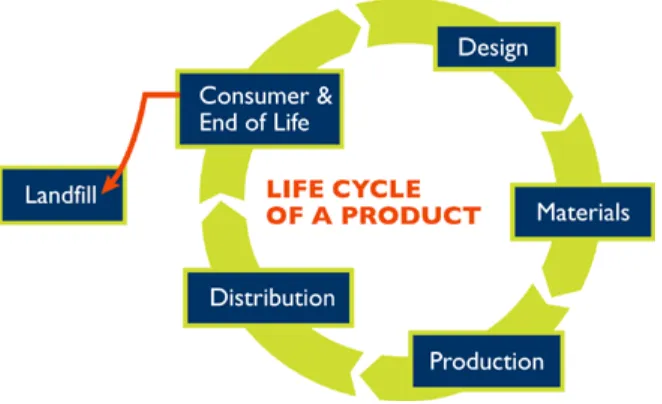

Figure 2.1 : Life Cycle of Product……….5

Figure 2.2 : The Product Life Cycle….……….7

Figure 2.3 : Phases of an LCA………..9

Figure 2.4 : Chain of Product’s material sustainability……..………14

Figure 2.5 : Method of making a Silicone Rubber mould using the Vacuum Pouring Methods………27

Figure 2.6 : Methods of Use………..28

Figure 2.7 : Amount of RTV thinner added in physical properties………...……..31

Figure 2.8 : Vacuum Casting process……….……….36

Figure 2.9 : Comparison of Rapid Prototyping to Rapid Tooling……….…..……37

Figure 2.10: Architecture of the RTV Integrated Manufacturing Systems….…………40

Figure 2.11: Classification scheme for Rapid Tooling Process……..………….………41

Figure 2.12: The use of RP system in different sectors……….….………….42

Figure 2.13: Classification of Rapid Tooling process……….………50

Figure 2.14: Flow Chart of RP Technology………54

Figure 3.1 : Process flow chart of Experimental Design of Experiment………61

Figure 3.2 : Master Pattern Isometric View………..64

Figure 3.3 : Component of the mould………..………66

Figure 3.4 : Location of the riser and runner from top position………67

Figure 3.5 : Master pattern in modeling clay………...…68

Figure 3.6 : Case for mould………...……69

Figure 3.7 : The two components of Silicon and Hardener mixed by stirrer……….70

Figure 3.8 : Container inside the Vacuum Machine………..71

Figure 3.12 : The mould with the runner attached to it………..………….74

Figure 3.13 : Process of pouring the material inside the mould……….………….76

Figure 3.14 : Removal of duplicate part after fully cured……….………..76

Figure 3.15 : Basic geometry dimension for the original part……….…………78

Figure 3.16 : Micrometer……….………79

Figure 3.17 : Profile Projector……….………79

Figure 5.1 : Graph length 1 versus number of parts……….……….85

Figure 5.2 : Graph length 2 versus number of parts……….……….85

Figure 5.3 : Graph height versus number of parts……….………87

Figure 5.4 : Graph radius versus number of parts……….………88

Figure 5.5 : Graph Thickness 1 versus number of parts………89

LIST OF ABBREVIATIONS

ABS - Acrylonitrile-butadiene-styrene CAD - Computer-aided Design

DSPC - Direct Shell Production Casting FOM - Fused Deposition Modeling LENS - Laser-engineered Net Shaping LOM - Laminated Object Modeling MJM - Multijet Modeling

MJS - Multiphase Jet Solidification RP - Rapid Prototyping

RPS - Rapid Prototyping System

RPTM - Rapid Prototyping, Tooling and Manufacturing RT - Rapid Tooling

RTV - Room Temperature Vulcanizing SAHP - Selective Adhesive and Hot Pass SCS - Solid Creation System

CHAPTER 1

INTRODUCTION

1.1 Background

Global competition, mass customization, accelerated product obsolescence and continued demands for cost serving are forcing companies to look for new ways to improve their business processes. It is now widely accepted that over 70% of final product costs are determined during design stage. (Pham, D.T., and Dimov, S.S., 2003) Therefore, it is important to produce a design that use the most optimize cost. Design has been included in the product life cycle because it will have an influence on all other parts of the life cycle. Reducing the overall impact by innovative new design is also a significant opportunity for any company.

Product development involved design, manufacturing, material choices, product type, use and final disposal. Generally, in mould manufacturing the goal of the manufacturer is to produce a mould that can have long life cycle and next to sustain it. Here, the design of the mould plays an important role as it is not only affected the final product cost but also its life cycle and sustainability.

The RT technique that base on RP offer a rapid and effective method to make mould, and show a high potential for faster response to market demands. ( Ding, Y. et al, 2003). With the increase in the technology of rapid prototyping technique, numerous processes have been developed for producing tooling mold from RP masters. The most widely employed method of rapid prototyping are to make silicon room temperature vulcanizing (RTV) moulds for plastic parts and as sacrificial models for investment casting of metal parts. ( Dickens, P.M. et al, 1995)

The production of room temperature vulcanizing (RTV) silicone rubber moulds has become one of the most popular types of RT applications and it being used to mold delicate and low temperature resistance materials. It also use to reproduce complex forms cast in metal and plastic. RTV silicone is an ideal mold material to use to reproduce prototypes and create sub masters from fragile, low-temp model materials. (Wohler, T., 2008) With the arrival of rapid prototyping technique, master pattern are often made of the RP models themselves.

The direction of this study is to identify the life cycle and sustainability of design on RTV silicone mould including the number of part the mould can duplicate and the changing of mould’s physical dimension. Further study will be implemented to prolong the life cycle of the mould and method to sustain it.

1.2 Problem Statement

Most of the current focus is on reducing the problem of current RTV Silicon mould, such as:

1. Prolong the life of the RTV Silicon mould

2. Reducing the time and cost by not frequently changing the mould

3. Maintaining/increasing the quality of product by using the mould that has long cycle time.

One of the key requirements is to improve resource efficiency by assessing: 1. The process of mould preparation.

2. The characteristic of RTV Silicon.

3. Causes of poor mold making and its solution.

4. Number of part being produce on a single RTV Silicon mould.

1.3Objective of the research

For this project, there are a few aims to achieve during implementation of this project for this semester such as:

1. To understand the process in developing silicone rubber mould.

2. To study the effect of the dimensional accuracy of the product in determine the total life cycle of RTV silicon mould.

3. To identify the factors that effect the longevity and sustainability of RTV silicon mould.

1.4 Scope of Work

The purpose of this project is to understand the process in developing Silicone rubber mould. The main focus is on the RTV Silicone rubber mould. The life cycle and sustainability of RTV Silicone rubber mould will be examined. The number of part that the mould can duplicate, the mould’s physical dimension, and the life of the RTV Silicone rubber mould will be recorded.

In order to understand the process in developing silicon rubber mould, the mold making methods is briefly defined and information, concepts, and some contents from previous research which is related about developing silicon rubber mould is discussed briefly in this report.

The total life cycle for a silicone rubber mould and its physical dimension are examined after the mould being produced and the part being duplicated. The cycle time and the mould life of silicone rubber mould is being recorded and analyzed.

CHAPTER 2

LITERATURE REVIEW

2.1 Life Cycle

Life cycle is a consecutive and interlinked stages of a product or service system, from the extraction of natural resources to the final disposal. The term “life cycle” refers to the major activities in the course of the product’s life-span from its manufacture, use, and maintenance, to its final disposal, including the raw material acquisition required manufacturing the product. A life cycle is made up of all the activities that go into making, selling, using, transporting and disposing of a product or service - from initial design, right through the supply chain. (Anonymous 2008) Figure 2.1 shows the life cycles of a product.

2.1.1 Life Cycle Analysis

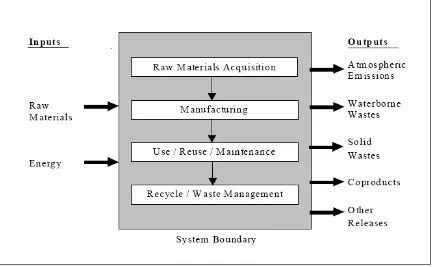

LCA is defined as identifies the material, energy, and waste flows associated with a product over its entire life cycle so that the environmental impacts can be determined. By using LCA, it is possible to evaluate the environmental performance of a product from ‘cradle to grave’, allowing the most significant environmental impacts associated with it during its lifetime to be considered, i.e from extracting the raw materials and fuels from the earth through to the product’s use and disposal. (Hamzah, N.A., 2006).

LCA involves making detailed measurements during the manufacture of the product, from the mining of the raw materials used in its production and distribution, through to its use, possible re-use or recycling, and its eventual disposal. LCAs enable a manufacturer to quantify how much raw materials are used and energy needed, and how much solid, liquid and gaseous waste is generated, at each stage of the product's life. (Hari, S., 2008)

2.1.1.1 How does LCA works?

LCA considers the different stages and geographical sites a product will pass through in its lifetime. LCA avoids the problem of shifting environmental impacts to other parts of life cycle by using a holistic approach, such as changing the materials use in production may create less environmental effect at the production site, but increase the environmental impact. (Bournemouth University, 2005)

Figure 2.2 : The product life cycle. (Hamzah, N.A., 2006)

2.1.1.2 Components of LCA

The LCA process is a systematic, phased approach and consists of four components: goal definition and scoping, inventory analysis, impact assessment, and interpretation as shown in Figure 2.3. The four linked components of LCA are:

1. Goal definition and scoping.

Identifying the LCA's purpose and the expected products of the study, and determining the boundaries (what is and is not included in the study) and assumptions based upon the goal definition. The goal and scope can be addressed by answering a number of questions:

1) What product is the LCA going to deal with?