UNIVERSITI TEKNIKAL MALAYSIA MELAKA

NEW DESIGN USING FIBER GLASS COMPOSITE (FRPC) FOR

JIMNY BACK DOOR

This report submitted in accordance with requirement of the Universiti Teknikal Malaysia Melaka (UTeM) for the Bachelor Degree of Manufacturing Engineering

(Engineering Material) with Honours.

by

AZIANASHIMA HEEDAYU BINTI ZAINAL

UNIVERSITI TEKNIKAL MALAYSIA MELAKA

BORANG PENGESAHAN STATUS LAPORAN PROJEK SARJANA MUDA

JUDUL: New Design Using Fiber Glass Composite (FRPC) for Jimny Back Door

SESI PENGAJIAN: 2009 Semester 2

Saya AzianaShima Heedayu Binti Zainal

mengaku membenarkan tesis (PSM/Sarjana/Doktor Falsafah) ini disimpan di Perpustakaan Universiti Teknikal Malaysia Melaka (UTeM) dengan syarat-syarat kegunaan seperti berikut:

1. Tesis adalah hak milik Universiti Teknikal Malaysia Melaka dan penulis.

2. Perpustakaan Universiti Teknikal Malaysia Melaka dibenarkan membuat salinan untuk tujuan pengajian sahaja dengan izin penulis.

3. Perpustakaan dibenarkan membuat salinan tesis ini sebagai bahan pertukaran antara institusi pengajian tinggi.

4. *Sila tandakan (/)

SULIT

TERHAD

TIDAK TERHAD

(Mengandungi maklumat yang berdarjah keselamatan atau kepentingan Malaysia yang termaktub di dalam AKTA RAHSIA RASMI 1972)

(Mengandungi maklumat TERHAD yang telah ditentukan oleh organisasi/badan di mana penyelidikan dijalankan)

(AZIANASHIMA HEEDAYU ZAINAL)

DECLARATION

I hereby declare that this report entitled “NEW DESIGN USING FIBER GLASS COMPOSITE (FRPC) FOR JIMNY BACK DOOR” is the result of my own research except as cited in the references.

Signature : ……….

Author’s Name : AzianaShima Heedayu Binti Zainal

APPROVAL

This report is submitted to the Faculty of Manufacturing Engineering of UTeM as a partial fulfillment of the requirements for the degree of Bachelor of Manufacturing Engineering (Engineering Material) with Honours. The member of the supervisory committee is as follow:

... Mohd Yuhazri Bin Yaakob

ABSTRACT

ABSTRAK

DEDICATION

To my beloved parents

ACKNOWLEDGEMENTS

ﷲ ﺴﺒ

ﻴﺤﺮﻠﺍﻦ ﺤﺮﻠﺍ

TABLE OF CONTENT

List of Abbreviations xiii

2.3 The Role of Temperature on

Impact properties of Kevlar/Fiberglass

LIST OF TABLES

NO TITLE PAGES

2.1 Thermal Coefficient of Expansion for Polyester 10

2.2 Temperature Effect and the physical behavior of polyester 11

2.3 Burning Effect and the statement of polyester 11

2.4 Laminate construction combinations for vacuum bagging 13 2.5 Stacking sequence of the laminate and thickness (t) of each ply 28

3.1 The type of failure for each specimen in impact test 38

3.2 Tensile specimen geometry requirements 39

3.3 Tensile specimen geometry recommendations 39

3.4 Specimen alignment and chord modulus calculation strain ranges 41

3.5 Averages of coefficients of variation 41

3.6 The Comparison of hardness test 45

5.1 The Hardness Test data for seven specimens with nine testing 59 5.2 The average from data of testing and the difference between averages 60

5.3 Data of Impact test for seven specimens 62

5.4 The Impact Strength formula in Impact test 63

LIST OF FIGURES

NO TITLE PAGES

1.1 The specification of new and actual material for Jimny back door. 3

1.2 Stages for PSM 1 5

2.1 Fiber Glass type E 8

2.2 Polyester 9

2.3 Sample construction set-up for vacuum bagging 13

2.4 Micrographic cross-section of body panel 16

2.5 Bonded joint shear strength for carbon and glass fiber adherents for four values of bond-line thickness; three values of laminate thickness;

three types of environmental preconditioning 17

2.6 The flow diagram of the surface certification of high performing vehicle 19 2.7 (a) unbalanced laminate uniform temperature increase and

(b) balanced laminate uniform temperature gradient 21

2.8 Layers model of a unidirectional composite 23

2.9 Eight nodded layered element 25

2.10 Splitting of laminae at the interface between the two resin systems and

impacted face of vinylester 29

3.1 Research Methodology Flow Chart 34

3.2 The flow chart diagram for testing implementers in laboratory 35

3.3 Geometry of specimen for Charpy 36

3.4 Impact test machine for Charpy with labeling 37

3.5 Gage location for system alignment check coupon 40

3.6 Tensile test specimen drawing 40

3.7 Universal testing machine 42

3.9 The hardness scale 46

3.10 Vacuum pump for vacuum bagging 47

3.11 Resin trap 47

3.12 Spiral Tubing 48

3.13 Enkafusion nylon matting 48

3.14 Spring clamp and hose clamp 49

3.15 Composite design based on specimen preparation 52

4.1 The method in making the mold of Jimny 54

4.2 The mold of Jimny Back Door (JBD) 55

4.3 The steps in making the vacuum bagging for Jimny 55

4.4 The JImny afer the Vacuum process 56

4.5 The results of the Jimny produce excellently 56

5.1 The Hardness test in eight types of specimens with nine testing 60 5.2 The average value of seven types of specimen in nine testing 61

5.3 The average of the Impact Energy 63

5.4 The graph of the Impact Energy and the Impact Strength 65

5.5 Delamination failure of the Hinge Break 66

5.6 The complete break failure 66

5.7 The partial break failure 67

5.8 Impact energy and shear fracture of mild steel varies with temperature 68

5.9 Tensile graph of stress versus stroke strain 69

5.10 The compile data of Young Modulus in tensile test 71

5.11 The compile data of Force in tensile test 72

5.12 The compile data of Tensile Strength in tensile test 73 5.13 The compile data of Tensile Strain in tensile test 74

5.14 The failure of GAT 75

5.15 The failure of DGM 75

5.16 The failure of XGM 76

5.18 Flexural graph of stress versus stroke strain 77

5.19 The force applied by bending on the specimen 77

5.20 The compile data of Force in flexural test 79

5.21 The compile data of Flexural Strength in flexural test 80 5.22 The compile data of Flexural Strain in flexural test 81

5.23 The delamination failure 81

5.24 The pull out failure 82

LIST OF ABBREVIATIONS

ASTM - American Society for Testing and Materials

DI - Damage Index

E-glass - Electrical glass

FRC - Fiber Reinforced Composite FRP - Fiber Reinforced Polymer GRP - Glass Reinforced Plastic

HL - Hand Lay-up

ID - Inches Diameter

JBD - Jimny Back Door

MEKP - Methyl Ethyl Ketone Peroxide PSM - Projek Sarjana Muda

QA - Quality Assurance

S-glass - Strength glass

UTeM - Universiti Teknikal Malaysia Melaka UTM - Universal Testing Machine

UV - Ultra Violet

VI - Vacuum Infusion

LIST OF SYMBOLS

° - Degree

± - plus minus

µ - micro

ε - Strain

% - Percent

E b - Flexural modulus

m - Initial slope of the load vs. deflection curve b - Width of beam tested

h - Thickness of beam tested

CHAPTER 1

INTRODUCTION

Jimny back door is the part of Suzuki Jimny model designing. The current material of the jimny back door is a metal material that usually used in making any type of vehicles. The shape of the jimny back door is quite in simple shape with its specific dimension. The effect of the metal material condition is easily to corrode and hence will produce more brittle in its mechanical properties. Nowadays, corrosion matter must be preventing to ensure the materials particularly made by metals mostly in all vehicles are capable to extend the period of its life.

According to the type of fibers, the fiber glass was chosen to design the materials. The reinforcement of a medium by a network of fibers has evolved in the living world to be the natural solution for structures which respond to and resist mechanical stresses. Besides, the thicknesses of the fiber laminate are the most influences to the physical properties in making Jimny back door.

1.2 Objectives:

(a) Propose a new composite design using synthetic fiber material for Jimny Back Door.

(b) Test and analyze of the proposed composite on mechanical properties. (c) New design for Jimny back door using the proposed composite material.

1.3 Scopes:

(a) Literature review on existing Jimny back door.

(b) Study on synthetic fiber available in automotive industrial.

(c) Study the matrix for using hand layout or vacuum infusion technique. (d) Study mechanical properties such as tensile, hardness, impact, flexural. (e) Developed prototype of Jimny back door by using the proposed design.

1.4 Rational of Research:

(a) To find a material for replacing the actual material in produces a best material and efficient for Jimny back door.

(b) Shown a potential of FRP in the industrial field of automotive that can be used widely.

1.5 Problem Statement:

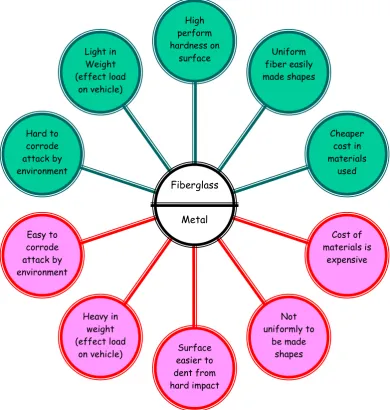

The comparing for current material of metal and the new material of fiber glass shows the problems that can be state and be solving in making the best way of upgrading the Jimny back door. Fiber glass is better to be used in many specifications and their properties in mechanical and physical.

Figure 1.1: The specification of new material of fiberglass and the actual material of metal for

Jimny back door (Anonymous, 2005).

glass reinforcement that used. In describing the diagram, the fiber glass is hard to be corroding when having an attack by the environment compare to the metal material which easily corroded as defined as the destruction or deterioration of a material because of reaction with its environment.

The light weight of the fiber glass makes the material highly easy to use and decreasing the load on the vehicle. The metal are high in weight thus the material will increasing the vehicle’s load. Increasing the vehicle’s load will increase the petrol usage besides effect in handling the vehicle. Other than that, the fiber glass can protect it shape and surface by high perform in hardness even though the material is more brittle compare to the metal material. The metal are easily be dent in hard impact on the material shape and surface.

In other hand, the material of fiber glass easily be uniform in any shapes by followed the molding specification while the material use more cheaper in cost and not as expensive as the metal material which are cannot be uniformly shaped.

1.6 Expected Result

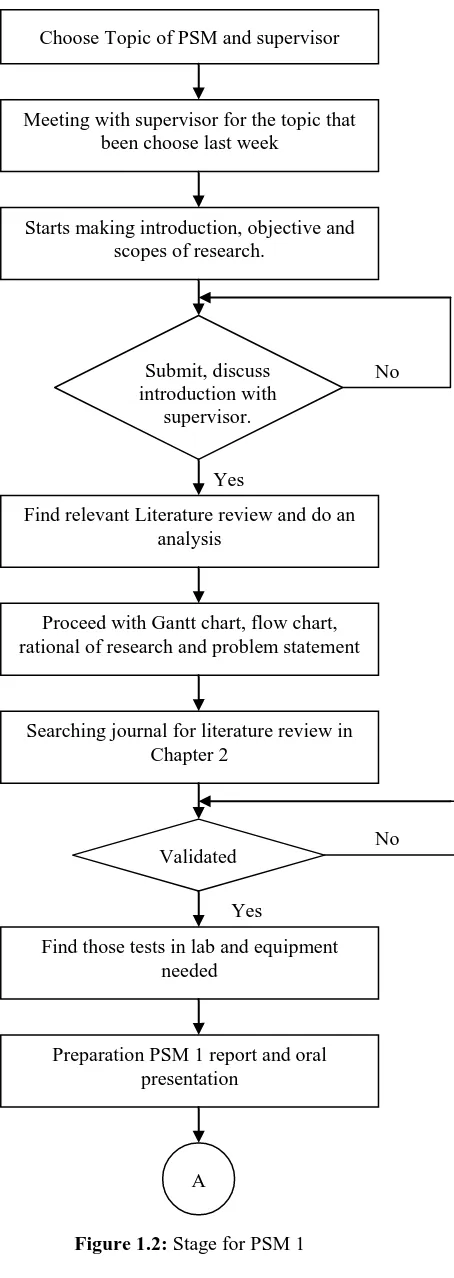

1.7 Flow Chart for PSM 1

Choose Topic of PSM and supervisor

Meeting with supervisor for the topic that been choose last week

Starts making introduction, objective and scopes of research.

Proceed with Gantt chart, flow chart, rational of research and problem statement

A

Searching journal for literature review in Chapter 2

Find relevant Literature review and do an analysis

Validated

No

Yes

Find those tests in lab and equipment needed

Preparation PSM 1 report and oral presentation

1.8 Thesis Frame Arrangement