Published by Canadian Center of Science and Education

The Identification of Gas-liquid Co-current Two Phase Flow Pattern

in a Horizontal Pipe Using the Power Spectral Density and the

Artificial Neural Network (ANN)

Budi Santoso1,4, Indarto2, Deendarlianto2 & Thomas S. W.3 1

Graduate Program of Mechanical and Industrial Engineering, Faculty of Engineering, GadjahMada University, Indonesia

2

Department of Mechanical and Industrial Engineering, Faculty of Engineering, GadjahMada University, Indonesia

3

Departmen of Electrical Engineering and Information Technology, Faculty of Engineering, GadjahMada University, Indonesia

4

Department of Mechanical Engineering, Faculty of Engineering, SebelasMaret University, Indonesia

Correspondence: Budi Santoso, Department of Mechanical Engineering, Faculty of Engineering, SebelasMaret University, Jl. Sutarmi 36A Surakarta 57126, Indonesia. E-mail: [email protected]; [email protected]

Received: July 23, 2012 Accepted: August 18, 2012 Online Published: August 29, 2012 doi:10.5539/mas.v6n9p56 URL: http://dx.doi.org/10.5539/mas.v6n9p56

Abstract

This paper presents a new method of the flow pattern identification on the basis of the analysis of Power Spectral Density (PSD) from the pressure difference data of horizontal flow. Seven parameters of PSD curve such as mean (K1), variance (K2), mean at 1-3 Hz (K3), mean at 3-8 Hz (K4), mean at 8-13 Hz (K5), mean at 13-25 Hz (K6) and mean at 25-30 Hz (K7) were used as training vector input of Artificial Neural Networks (ANN) in order to identify the flow patterns. From the obtained experimental of 123 operating conditions consisting of stratified flow, plug and slug, ANN was trained by using 100 data operation and 23 tested data. The results showed that the new method has a capability to identify the flow patterns of gas-liquid two phase flow with a high accuracy.

Keywords: flow pattern identification, power spectral density (PSD), artificial neural network (ANN), two phase flow

1. Introduction

The knowledge of two phase flow is of important in engineering process, such as oil industry, chemical process, power generation, and phase change heat exchanger apparatus. The common characteristics of parameter related to the flow pattern are the pressure gradient and the void fraction. The main issue in two phase flow researches is the relationship between the pressure fluctuation and flow pattern. In general, the pressure fluctuations resulted from the liquid-gas flow and their statistical characteristics are very interest for the objective characterization of the flow patterns because the required sensors are robust, inexpensive and relatively well established, and therefore more likely to be implemented in the industrial systems (Drahos et al., 1991).

Artificial Neural Network (ANN) provides an alternative method for either modeling phenomena which are too difficult to model from fundamental principles, or reduce the computational time for predicting expected behavior. Artificial neural network is based on the important rules for classifying the flow pattern. Neural network stimulate human mind and demonstrate high intelligence and it can be trained to study the correct output and classify training exercises. Here, neural network needs knowledge input for training. After the training, the neural network can classify the similar flow pattern with a high accuracy.

Cai et al. (1994) applied the Kohonen self-organizing neural network in order to identify the flow pattern in a horizontal air-water flow. In their work, the neural network was trained with stochastic features derived from the turbulent absolute pressure signals obtained across a range of the flow regimes. The feature map succeeded in classifying samples into distinctive flow regime classes consistent with the visual flow regime observation. Next, Wu et al. (2001) recorded the pressure difference signal in pipe flow and used the fractal analysis to analyze them for identification of flow pattern. By using the ANN, the good result was obtained but it is only considered stratified, intermittent and annular flows. For this reason, Jia et al. (2005) proposed a new flow pattern identification method based on PDF and neural network at the horizontal flow in pipe.

Xie et al. (2004) examined the feasibility of the implementation of the artificial neural network (ANN) technique for the classification of flow regimes in three phase gas/liquid/pulp fiber systems by using the pressure signals as input. For this purpose, the flow behavior by using the power spectral density function is needed to implement the parameterization of the information contained in the spectral patterns.

Table1. The experiment conditions using pressure sensor Authors System Diameter/

Orientation Measurement technique Method and finding Franca et al.

(1991)

Water-air (wavy, plug, slug and annular)

D=19 mm; horizontal

Pressure drop, XDP=8D, N=5 000

Using fractal techniques for flow pattern identification and classification. Cai et al.

(1994)

Water-air (stratified, slug, intermittent transition, and bubble)

D= 50 mm; horizontal

Two absolute pressure, XDP=1D, SR=40Hz, N=40 000

Kohonen self-organizing neural network to identify flow regimes.

Drahos et al. (1996)

Water-air (plug and slug)

D=50 mm; horizontal

wall pressure

fluctuations, XDP=8D, SR=500Hz, N=60 000

Chaotic time series analysis to obtain a new insight into the dynamics of the intermittent flow pattern. Wu et al.

(2001)

Oil-gas-water, (stratified, intermittent and annular)

D= 40 mm; horizontal

Differential pressure, XDP=5D,

The fractal analysis to analyze the signal for identification of flow pattern.

Jia et al. (2005)

Water-air (stratified, churn, slug, annular)

D= 32 mm; horizontal

Differential pressure, XDP=10D, SR=200Hz, N=6 000

Flow pattern identification method based on PDF and neural network.

Matsui et al. (2007)

Water and nitrogen gas (small bubble train, plug and slug)

D= 7 mm; horizontal

Differential pressure, XDP=1D, XDP=7D SR=100Hz, N=2 000

The flow pattern, the void fraction and the velocity of gas phase were measured by PDF and cross correlation. Hao et al.

(2007)

Water-air, (wavy, bubble, plug and slug)

D=15 mm, 25 mm, 40 mm; horizontal

Differential pressure, XDP=250mm,

SR=200Hz, N=30 000

The application of the Hilbert–Huang Transform (HHT) to identify flow regimes.

Xie et al. (2004)

Gas-liquid-pulp fiber (churn, slug)

D= 50.8mm, vertical

Local pressure

fluctuations, SR=200Hz, N=2 000

The summ

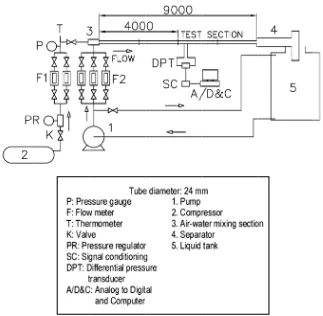

Figure 1 sh compresso are as follo m/s.

3. Results

3.1 Flow P

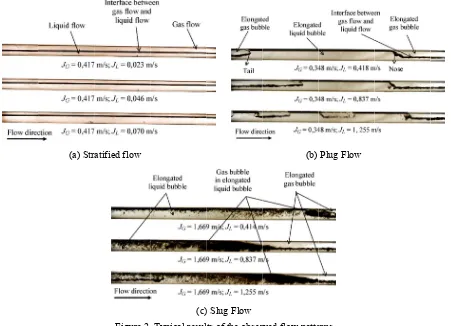

Figure 2 sh and (c) cor

mary of experim e tap (mm), SR entification, di ave contributed of researchers propagation ne was designed, stics of the po e flow regimes

ments Appara

hows a schema or and water ly by flow me d into the atmo inner diameter

n in the Figure r with 5D dista r were sent thr g time of exper ows: the range

and Discussi

Patterns

hows the typic rrespond to int

ment condition R is sampling r istance of pre d to our unde in flow patter eural network

trained and te ower spectrum s with good acc

atus and Proc

atic diagram o from pump eters. The air-w osphere and wa r and of 9 m to

Figure 1. Sc

e 1, the press ance of pressur rough amplifie rimental run w e of superficia

ons

cal results of th terfacial behav

ns from the pre rate and N is s essure tap, sam erstanding of f rn identification

was used to i ested for the cl for one of the curacy.

cedure

of the experime into an air-w water mixture

ater is measure otal length is m

chematic diagr

sure fluctuatio re tap. The tran er into a comp was 50 s. The w al air and wate

he flow pattern vior of the strat

evious research size of data. It mpling rate, si flow patterns n. In this pape identify flow p lassification of e normalized d

ental apparatus water mixing

flows through ed more accur made of transpa

ram of the exp

n was detecte nsducer has ± puter via A/D working fluids er velocities; J

ns obtained fro tified, plug and

her is shown i gave the infor ize of data an of two-phase er, the different

pattern of two f the flow regi differential pre

s used in the p section after h the tube into

rately by weigh arent acrylic re

perimental app

ed by Validyn 0.25% full sca converter. Sam were air and w G=0.085-3.204

om the present d slug flows, r

in Table 1, wh rmation about t nd flow pattern flows and los tial pressure, t

phase flow at imes using as essure signals

present study. A their flow ra an air-water s hing if necessa esin to observe

aratus

ne DP15-32 di ale accuracy. O mpling rate w water. The exp 4 m/s, and tho

experiment. T respectively. In

here XDP is dist the method of n identified. T sing the subje the analysis of t a horizontal

input some de and was show

Air supplied fr ates are meas separator, wher ary. A smooth e the flow patte

ifferential pre Output signals was 400 Hz an periment condi

se JL= 0.016-1

The Figures, (a n the stratified

the gas ph interfacial patterns. T of fluid. A of the tube same velo small diff magnitude the upper w at the high transported

hase travels alo waves. As sh The stratified fl As shown in th

e in a continuo ocity with the

ference betwee e of the waves

wall of the tub her velocity o d by the liquid rn is highly un en pressure pu

(a) Str

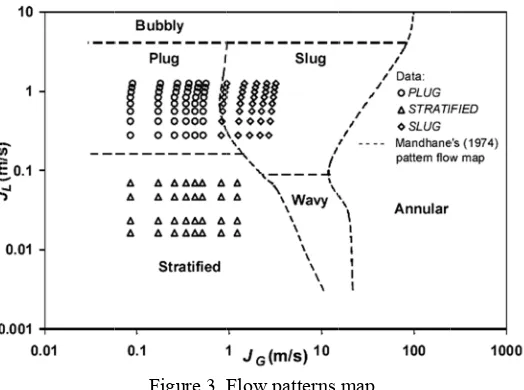

he obtained flo 4) as shown in ent with those

ong the upper h hown in Figure flow pattern oc he Figure 2(b) ous liquid flow

liquid, and th en the velocit increases. Th be to form som of the gas (Fig d phase, in slug ndesirable in p

lses and severe

ratified flow

Figure 2.

w pattern data n Figure 3. Clo

of Mandhane

half of the tub e 2(a), this flo ccurs at relative the plug flow w. Next, it is n he gas-liquid in

ties of the ph his condition is me liquid pack

gure 2(c)). Un g flow the liqu practical applic

e pressure osci

(c) . Typical resul

a is compared w ose observatio

et al. (1974).

e while the liq ow has the sim

ely low gas an is characteriz noticed that in nterface below hases at the in s called slug f kets, also liquid

nlike plug flow uid slugs are c cations. The fa illations that c

) Slug Flow lts of the obser

with the horizo on of this figur

quid flows alon mplest configu nd liquid mass ed by elongate n the plug flow w the bubbles nterface. With flow. Ultimatel d slugs. These w, in which th carried by the f aster moving li an cause dama

(b)

rved flow patte

ontal flow patt re reveal that th

ng the bottom uration of all t flow rates and ed bubbles flo w; elongated bu

is relatively s h the increase ly, the waves liquid slugs a he elongated b faster moving iquid slugs are age to downstr

Plug Flow

erns

tern map prop he obtained flo

with no signif the horizontal d density differ wing along th ubbles move a stable, indicati e gas velocity build up and r are then transp

bubbles of ga gas flow. The e usually assoc ream equipmen

posed by Mand ow pattern dat

Figure 4 sh

pressure d points and

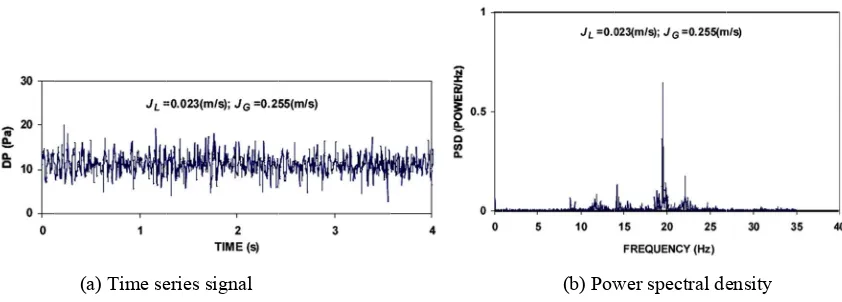

3.2 Typica

In this pap the differe

hows the struc m of flow patte

data processin part of the syst

normalized pre

P is differenti different signal d a Hanning W

al Flow pattern

per, three typic ent of the flow rns are shown tified Flow es signal and

with a small f between water one peak and sp

cture of the int ern identificat ng unit. Differ tem, while dat

Figure 4. S

essure fluctuat

ial pressure ( l (Pa). The po Window of the s

n and Power Sp

cal flow patter w patterns. Ex

in Figure 5 to

PSD of strati fluctuation. Th

flow and air f preads over wi

Figure 3. F

telligent identi tion is compos rential pressur ta processing u

Structure of the

tions in the tim *

rns ware ident amples of tim

Figure 7.

fied flow is s his flow pattern

flow is clear (n ide frequency

Flow patterns

ification system sed of differen re measuring unit constitutes

e intelligent id

me series is defi (

) D

DP

DP

average differ m was estimate

ty

tified. The cha me series press

shown at Figu n occurs at low no bubble). Fro range from 8 t

map

m used in pres ntial pressure unit and data s the software p

dentification sy

fined below: 2 sure different a

ure 5, in which w superficial v

om Figure 5(b to 27 Hz.

sent study. As measuring un a acquisition part of the syst

ystem

re (Pa) and D

egments with

f their PSD we and power spe

h it shows a l velocities of wa b), it is reveale

shown in Figu nit, data acquis unit constitute tem.

DP* is norma a length of 16

ere used to ide ectra for the m

low mean pre ater and air an ed that the strat

Figure 5

3.2.2 Plug Figure 6 sh difference due to the divided int

Figure

3.2.3 Slug Figure 7 sh when com peaks valu range pres of peak va

(a) Time se . Typical of th

Flow hows the time

of plug flow h e air bubble h

to two parts. T

(a) e 6. Typical of

Flow hows the time mpared with the ue that it is ca sent the bubble alue decreases

eries signal he time variatio

variation of p has a bigger fl has a compres There are in the

) Time series s f the time varia

e series signal e stratified flow aused by the h es flow with ze

(see Figure 7(b

on of pressure

JG=

pressure gradie luctuation than sible effect th e range of 0-11

signal

ation of pressur JG=

and the PSD s w and plug flow high water vel ero value. PSD

b)).

gradient and th =0.255 m/s

ent and the PSD n that of stratif hat cause large

1 Hz and 11-27

re gradient and =0.438 m/s

slug flow. Slug w, as shown in locity pushing D of slug flow h

(b) Pow he PSD in stra

D of plug flow fied flow as sh e fluctuations. 7 Hz (see Figu

(b) Powe d the PSD in p

g flow time se n Figure 7(a). g the elongated

has the frequen

wer spectral de atified flow at J

w. The time var hown in Figure . The spread v ure 6(b)).

er spectral dens plug flow at JL=

ries signal has Slug flow time d bubbles. Am ncy range in 2

ensity

JL=0.023 m/s a

riation the pre e 6(a). It is pos values of PSD

sity

=0.697 m/s and

s a different pa e series signal mong the top v

-35 Hz with sp and

ssure ssible D are

d

Figure 7.

3.3 Flow P

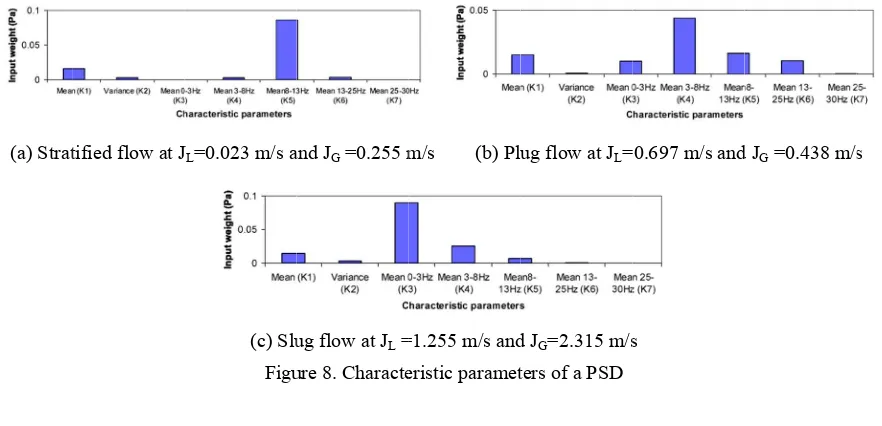

3.3.1 Char Based on t over 0-30 (2005). Th 0-30 (K2), (K7) use a

(a) Strat

(a) Typical of tim

Pattern Identif

racteristic Para the recorded p Hz is then di he mean value , mean 0-3 Hz as input of neur

tified flow at J

Time series si me series signal

fication Using

ameters of PSD power spectra, ivided into fiv e of power in (K3), mean 3 ral network tra

JL=0.023 m/s a

(c) Slu Figu

ignal l pressure grad

Back Propaga

D

this works fo ve bandwidths each of the a -8 Hz (K4), m aining.

and JG =0.255 m

ug flow at JL = ure 8. Characte

dient and PSD

ation Neural N

ocus on a frequ : 0-3, 3-8, 8-1 forementioned mean 8-13 Hz (

m/s (b) Plu

=1.255 m/s and eristic paramet

(b) Power in slug flow at

Networks

uency range up 13, 13-25, and d bands, denot (K5), mean

13-ug flow at JL=

d JG=2.315 m/s ters of a PSD

r spectral densi t JL=1.255 m/s

p to 30 Hz. Th d 25-30 Hz as ted as mean 0 -25 Hz (K6), a

=0.697 m/s and

s

ity

s and JG=2.315

he frequency r performed by 0-30 (K1), vari and mean 25-3

d JG =0.438 m/ 5 m/s

range y Xie iance 0 Hz

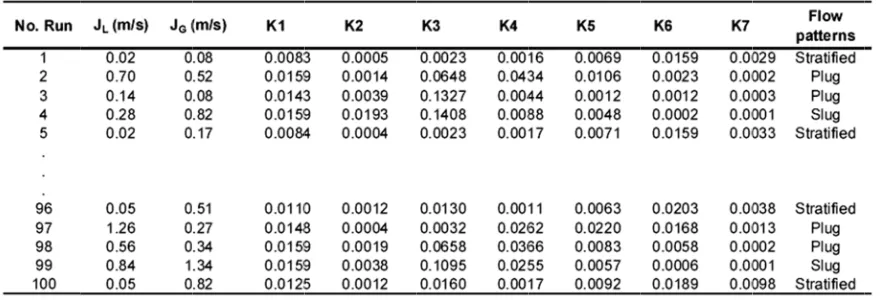

Table 2 sh operating flow) were

Table 2. E

3.3.2 Ident Neural net adding on train the n also get ne during trai generally i Back prop layer and componen three neura pipe (strat (0, 0, 1), th

Figu

hows part of condition. Tho e used to train

Examples of the

tifying Flow P tworks with a e or more/mul network to get etworking cap ining (but not it was begun b pagation neura one hidden nts of the inpu al cells, and co ified flow, plu hat of plug flow

ure 9. Back pro

characteristic ose parameter

the back propa

e vector charac

Pattern Using A single layer ha ltiple hidden l a balance the pabilities to pro

equal)). The by trying with o al network arch layer. The in ut vectors. The orresponds to ug flow and slu

w be (0, 1, 0),

opagation neural

parameters w rs and the outp agation ANN.

cteristic obtain

ANN ave a limitatio layers between

network's abil ovide the corr use of more t one hidden lay hitecture used nput layer co e hidden layer the three diffe ug flow). In th and that of slu

l network archit

with seven par put of the flow

ned from the pr

on in pattern re n input and ou lity to recogni rect response ( than one hidde yer.

d in the presen nsists of seve r consists of th erent flow patte his paper, let t ug flow be (1,

tecture is used in

rameter chara w patterns (str

resent study

ecognition. Th utput layers. B

ze patterns tha (with the inpu en layers have nt study is sho en neural cel hree neural ce erns of water-the expected o

0, 0).

n this research

acteristics of P ratified flow, p

his drawback c Back propagati

at will be used ut pattern is sim

e advantages f wn in Figure lls, correspond ells. The outpu

air two phase utput vector o

PSD for differ plug flow and

an be overcom ion neural net d during trainin

milar patterns for some cases 9. It has one ding to the s ut layer consis flows in horiz of stratified flo

rence slug

me by work ng. It used s, but input seven sts of

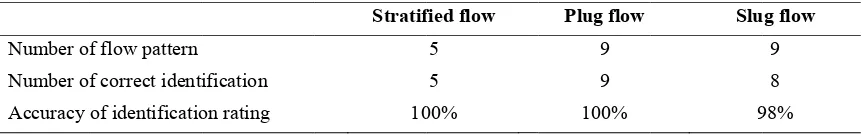

Table 3. P

art of test exam

red operating conditions are fication ability

Result of identi

f flow pattern f correct identi of identificatio

sion

r uses a differ eural network cteristics of th as the merits

his method ha tificial interve

ature

tificial neural n erential pressur

erage different rmalized press superficial ve uperficial veloc wer spectral de

edgments

k was supporte Education) M ascasarjana UG

e

Haluk, T., Jia ification in Air //dx.doi.org/10 H., & Beale, M

mples and iden

conditions of e selected as te

of the neural n

fication use Ba

ification as a advantag ntion.

network re (Pa) tial pressure (P

ure different s elocity (m/s)

city (m/s) ensity

ed by DP2M D Ministry of Edu

GM 2012”.

anhung, Q., & r-Water Two P 0.1002/cjce.545 M. (2000). Neur

ntification resu

f experiment a est samples. Ta network is very

ack Propagatio

Stratif

10

re transducer t dentifies the fl l pressure sign

computation ge method for

Pa) ignal (Pa)

DIKTI (Directo ucation and Cu

& John, S. A. Phase Flow. Th

50720308

ral Network To

ults

are selected as able 3 and Tab

y good.

on Artificial N

fied flow

5 5 00%

to measure th flow pattern. St

nals at differe and easily qu the industrial

orate of Resea ulture Indonesi

. (1994). Neu

The Canadian J

oolbox for Use

s training mod ble 4 show the

he differential tatistical analy ent flow cond uantifying the l application s

arch and Publi ia through the

ural Network

Journal of Che

e with MATLAB

dels to train th result of iden

ks

Slu

9

pressure of tw ysis of PSD w ditions. Result characteristic such as high

ic Service of D Competitive G

Based Object

emical Enginee

B. The MathW

he network an ntification, in w

ug flow

9 8 98%

wo phase flow as used to qua ts showed tha cs of the meas

accuracy, fast

Directorate Ge Grant Research

tive Flow Re

Drahos, J., Tihon, J., Serio, C., & Liibbert, A. (1996). Deterministic chaos analysis of pressure fluctuations in a horizontal pipe at intermittent flow regime. The Chemical Engineering Journal, 64, 149-156. http://dx.doi.org/10.1016/S0923-0467(96)03128-4

Drahos, J., Zahradnik, J., Puncochar, M., Fialova, M., & Bradka, F. (1991). Effect of operating conditions on the characteristics of pressure fluctuations in a bubble column. Chemical Engineering and Processing, 29, 107-115. http://dx.doi.org/10.1016/0255-2701(91)87019-Y

Ding, H., Zhiyao, H., Zhihuan, S., & Yong, Y. (2007). Hilbert–Huang transform based signal analysis for the characterization of gas–liquid two-phase flow. Flow Measurement and Instrumentation, 18, 37-46. http://dx.doi.org/10.1016/j.flowmeasinst.2006.12.004

Fausett, L. (1994). Fundamental of Neural Networks. Prentice Hill, New Jersy .

Jia, Z., Niu, G., & Wang, J. (2005). Identification of flow regimes in a horizontal flow using neural network.

Journal of Hydrodynamics, Ser. B, 17(1), 66-73, China Ocean Press.

Matsui, G., Fujino, G., & Suzuki, M. (2007). Two Phase Flow sensing using differential pressure fluctuations.

Jurnal of JSEM, 7, 50-55.

Wu, H., Zhou, F., & Wu, Y. (2001). Intelligent identification system of flow regime of oil-gas-water multiphase flow. International Journal of Multiphase Flow, 27(3), 459-475. http://dx.doi.org/10.1016/S0301-9322(00)00022-7

Xie, T., Ghiaasiaan, S. M., & Karrila, S. (2004). Artificial neural network approach for flow regime classification in gas-liquid-fiber flows based on frequency domain analysis of pressure signals. Chemical

Engineering Science, 59(11), 2241-2251. http://dx.doi.org/10.1016/j.ces.2004.02.017

Appendix

The PSD Theory

The goal of spectral analysis is to describe the distribution of the power contained in a signal over a frequency, based on a finite set of data. It converts information available in the time-domain into the frequency-domain. The averaged modified periodogram method was adopted to diminish the distortion of the spectrum due to a finite length of data record. If x(n) (n=0, 1, ... , N−1) is only measured over a finite interval, the power spectral density may be computed using the periodogram method:

k

fs f k i

e k x R f

Px( ) ˆ 2

(2)

Where: N is finite length of a discrete time signal, k is discrete time shift, f is frequency,fs is the sampling frequency and the autocorrelation is given as

N k

N n

n x k n x N k x R

1

) ( ) ( 1 ) ( ˆ

(3)

The Statistical Theory

The statistical analysis methods mentioned clustered PSD data are mean and variance. These features are used as inputs to the neural network.

The mean is given by,

N

i i

x

N 1

1

(4)

The variance is given as,

N

i i

x

N 1

2 1

1

(5)

These networks usually contain three types of layers: 1. An input layer

2. A hidden layer sigmoid bipolar and 3. An output layer linear transfer/ramp Training process:

Step 1. Design the structure of neural network and input parameters of the network Step 2. Get initial weights W and initial values from randomizing.

Step 3. Input training data matrix X and output matrix T. Step 4. Compute the output vector of each neural unit. (a) Compute the output vector H of the hidden layer

ik i k k W Xnet

(6)

k

k f net

H

(7) (b) Compute the output vector Y of the output layer

kj i j j W Hnet

(8)

j j f netY

(9) Step 5. Compute the distances

(a) Compute the distances d of the output layer

j j

jj T Y f'net

(10) (b) Compute the distances of the hidden layer

j

k kj

j

k W f' net

(11)

Step 6. Compute the modification of W and ( is the learning rate) (a) Compute the modification of W and of the output layer

k j kj H

W

(12) j

j

(13) (b) Compute the modification of W and of the hidden layer

i k

ik X

W

(14)

k k

(15) Step 7. Renew W and

(a) Renew W and of the output layer

kj kj kj W W

W

(16)

j j j

(17)

ik ik

ik W W

W

(18)

k k

k

(19) Step 8. Repeat step 3 to step7 until convergence.

Testing process:

Step 1. Input the parameters of the network. Step 2. Input the W and

Step 3. Input an unknown data matrix X Step 4. Compute the output vector

(a) Compute the output vector H of hidden layer

ik i k k W Xnet

(20)

k

k f net

H

(21) (b) Compute the output vector Y of the output layer

kj i j j W Hnet

(22)

j j f netY