All sources 22 Internet sources 22

1 documents with identical matches [11] https://patents.google.com/patent/EP0461166A1/en

1 documents with identical matches

9.0%

Results of plagiarism analysis from 2017-12-07 21:23 UTC26. Full Paper to Intl Conference.doc

Date: 2017-12-07 21:19 UTC

9 pages, 2214 words

PlagLevel: selected / overall

Settings

Data policy: Compare with web sources

Sensitivity: High

Bibliography: Bibliography excluded

Citation detection: No detection

--Design of Biogas Electricity Generator Pilot Plant by Cow-Palm

[0]

Plantation Integration

Irvan *), Bambang Trisakti *), Fahmi *), Yusuf Husni **), and Nevi Diana Hanafi **) *) Engineering Faculty, University of Sumatera Utara Medan , 20155, Indonesia

**) Agriculture Faculty, University of Sumatera Utara, Medan 20155, Indonesia

ABSTRACT

Wastewater treatment utility is one of the most important components in the palm oil

production. This utility is normally [2] used to treat a large volume of palm oil mill effluent (POME) generated during the production of crude palm oil (CPO) before the effluent is safely discharged to the surrounding environment through water ditch or river. [0]The production of POME in Indonesia is estimated around 28.7 million tonnes per year.[7] Most of the palm oil mills use conventional pond system to treat their POME. However this system has many disadvantages such as:[2] long retention time (90-120 days), large area required, high demand for maintenance, loss of nutrition and high emission of methane.[0]

Previous research in the laboratory scale have produced large volume of biogas and high decomposition rate of COD, however prior to be filled to the fermentor tank POME should be added by ammonium bicarbonate as nitrogen source. [0]In order to be applied to the industry, this method should find the alternative nitrogen source which has criteria such as; cheap, easy to obtain, and available in any time (continuity).[2] One of the nitrogen sources which fulfill this criteria is cow manure or dung.

The objective of the project is to design a more efficient POME treatment plant [1]

using an anaerobic continous stirred tank reactor (CSTR) in the pilot plant scale. The [2] produced methane gas will be used to generate electricity with capacity of 15-20 kWh. For natural nitrogen source cow manure will be used, and in order to obtain them easily [0]

and cheaply, cow-palm plantation integration concept will be adopted.

Biogas electricity generator pilot plant will be operated by making variation of hydrolic retention time (HRT), namely HRT 10, 8, 6 and 4 days.[0]Quality and quantity of produced biogas will be recorded daily on each HRT, produced electricity will be recorded as well.

INTRODUCTION

World consumption for palm oil in 2003-2007 was around 117.88 million tonnes.

Indonesia as the second largest palm oil producer can only supply around 6 million [2]

tonnes CPO while Malaysia can supply more or less 8-9 million tonnes of CPO. High [1]

production of POME concomitantly is followed by the high production of the mill waste,

either of waste water so-called palm oil mill effluent (POME) or solid waste such as

empty fruits bunch (EFB), shell, fibre etc. POME production is estimated about 28.[1]7

million tonnes/year and production of solid waste is about 15.2 million tonnes/year. This

high production of POME is surely the potential source to produce bigas.[0](Igwe, 2007)

Researchs to produce biogas from POME have been explored by many

1996). Based on the previous experiment using POME from palm oil mill Pagar Merbau

PTPN II, the ratio of COD: N: P was 350:4:1. This means POME from Pagar Merbau is

lack of nitrogen, therefore the decomposition rate is relatively low.

Nitrogen content in POME usually was enlarged by adding with other nitrogen

source such as urea. However, since the amount of POME is very big, of course, urea

needed in the big amount as well. As we know, the need of urea as fertilizer increases

everyday. Alternatively, nitrogen content in POME can be increased by adding the

POME with other waste which contains rich nitrogen sources. One of the wastes is cow

manure.

Cow-palm plantation integration which raising cows in the palm plantation area is

the ideal solution. The rich nitrogen content in cow manure will be available in the big

amount and the continuity is guaranteed. This integration system will also increase the

production of cow meat in big amount.

Agriculture Department of Republic Indonesia has introduced the cow-palm oil

plantation program. This program has succeeded in many plantations. Therefore

Agriculture Department prepared budget of 150 billion rupiah for buying cows to be

especially big plantation consider cows as plant disease. When the cows enter the

plantation area which surrounded by young palm trees, then the leaves of the young trees

will be ate by the cows, of course the growth of the young trees will be disturbed. This

problem can be solved by applying intensive or semi intensive methods. Intensive

method more expensive because the entire foodstuff should be available, but the cow

manure whether the solid or the liquid manure can be collected. Other method is semi

intensive method where the cows are released in the palm plantation, but their wastes

especially the liquid will scatter on the area.(Batubara, 1999)

This research will study the improvement of biogas production using combination

of POME and cow manure. Then, the gas production will be used as fuel to generate

electricity of 15 20 kWh. In order to achieve this target, this system will be designed – in

the pilot plant scale.

ANAEROBIC TREATMENT OF POME

The research of biogas production from anaerobic tank fermentor of POME has

been performed for two years. Experiments are conducted in laboratory scale and pilot

plant scale (on going).

A. Laboratory scale of anaerobic treatment of POME

It was started in 2008 when Lembaga Penelitian dan Pengabdian Pada Masyarakat

(LP3M) USU collaborated with Metawater Co. Ltd, one of Japanese big companies to

perform joint research to study the fermentation of POME to biogas. The purpose of this

joint research is to obtain the baseline data needed by palm oil companies in order to

apply clean development mechanism (CDM) project for their plant. Therefore besides to

reduce gas house gasses (GHG) emission, the plant can produce biogas as fuel to

generate electricity.

The experiment was conducted in Ecology Laboratory, Chemical Engineering [3]

Department USU. Besides lending their equipments Metawater Co., Ltd-Japan also sends

their experts to USU.[5] The fermentation process took place in a 2-litres-capacity

transparent jar digester (EYELA, Model MBF 300ME) which is provided with

turbine agitator as well as alarm indicator bulb anticipating temperature disorder. A data [5]

logger (KEYENCE, Model NR-250) is connected to computer to enable automatic

recording of temperature and pH provided by sensoring equipments attached to digester.

The experimental equipment for the 2-L digester is shown in Figure 1. [3]

Figure 1. Two litters fermentor used in this research

As the raw material for the experimental anaerobic digestion observed, a real POME

obtained from Pagar Merbau Mill of PTPN II and PT.[3] Sisirau Mill waste water treatment

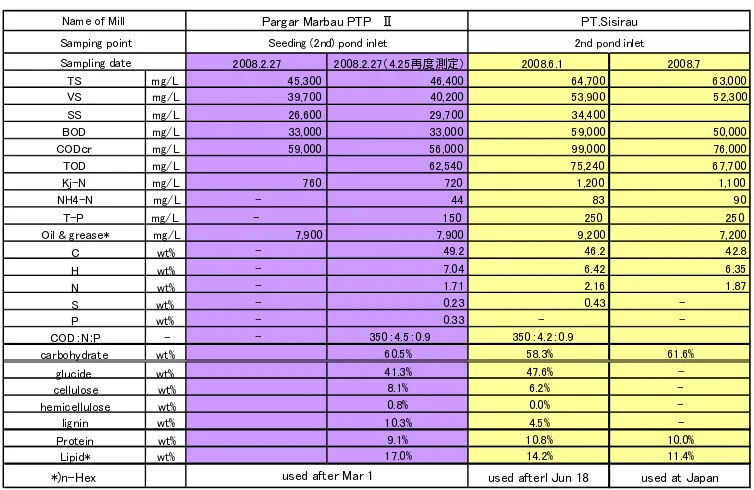

facilities were used. Table 1 summarizes the main physical and chemical properties of [18]

this material, while biogas production is shown in Table 2.

From Table 1, it can be seen that ratio of COD, N and P is not similar to ideal [9]

ratio recommended by some literature that is 350:7:1. It is clearly seen that both POME is

still lack of nitrogen, therefore in this experiment ammonium bicarbonate was added as

Tabel 1. Properties of POME from Pagar Merbau and PT.Sisirau

Tabel 2. Experimental results of laboratory scale

POME PKS PT. Sisirau PKS Pagar Merbau

HRT (days) 8 10 20 4 6 8 10

2008.2.27 2008.2.27(4.25再度測定) 2008.6.1 2008.7

TS mg/L 45,300 46,400 64,700 63,000

VS mg/L 39,700 40,200 53,900 52,300

SS mg/L 26,600 29,700 34,400

BOD mg/L 33,000 33,000 59,000 50,000

CODcr mg/L 59,000 56,000 99,000 76,000

TOD mg/L 62,540 75,240 67,700

Kj-N mg/L 760 720 1,200 1,100

NH4-N mg/L - 44 83 90

T-P mg/L - 150 250 250

Oil & grease* mg/L 7,900 7,900 9,200 7,200

C wt% - 49.2 46.2 42.8

*)n-Hex used afterl Jun 18 used at Japan Name of Mill

Sampling date Samping point

Pargar Marbau PTP Ⅱ

used after Mar 1

Seeding (2nd) pond inlet 2nd pond inlet

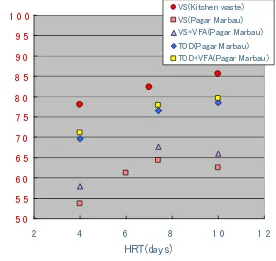

From table 2 shows that although biogas production from both POME are relatively high,

Figure 2. Relationship between HRT and decomposition rate

B. Pilot plant of anaerobic treatment of POME

Another anaerobic treatment of POME will be performed using a pilot plant

equipped with a fermentor type continuous stirred tank reactor (CSTR). The CSTR type

was chosen, because this type of fermentor has relatively low energy consumption, less

risk in operation and an easy start up. Furthermore a high performance could be expected.

The following aspects are considered: [0]

a. performance (max. loading rate, efficiency, min.[1] hydraulic retention time)

b. risk of plugging

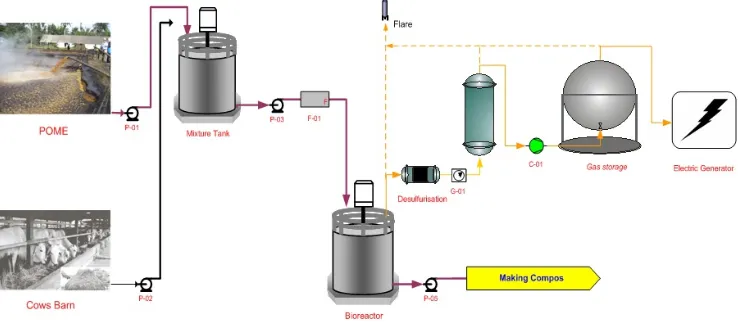

The pilot plant was located at Pusdiklat LP3M USU Jl. Dr. Mansyur. Figure 3 shows the

flowsheet of the pilot plant. The pilot consists of main equipment such as: the mixture

tank, biogas fermentor, gas storage, compressor, biogas generator set.

Figure 3. Flowsheet of pilot plant in this research

The technical data of the pilot plant components:

1. Mixture Tank:

Volume : 1000 L

Motor : 1400 rpm

Power : 1 Hp

Gear Box : ratio 1: 60

Accesories: Baffle, level controller, main hole, sampling hole

2. Pump:

Type : Centrifugal

Power : 1 Hp

Accessories: ball valve, check valve

3. Fermentor Tank:

Volume : 3000 L

Motor : 1400 rpm

Gear Box : ratio 1: 60

Heater : 3 kW

Accessories: main hole, sampling hole, insulator,

4. Biogas Tank:

Volume : 2000 L

Accessories : man hole, water trap.

5. Compressor:

Type: Reciprocating

Power : 1 Hp

6. Generator set

Machine: ex engine of Daihatsu car

Cylinder: 1600 cc

Combustion: Carburetor

Dynamo: 12 kVa

7. Others: Control Panel, Controller, wet gas meter, analysis equipments

The fresh POME and cow manure are filled into the mixture tank, where the POME

is maintained to pH 7 using the manure. The pump sucks the mixture wastes from the

mixture tank and fed into the upper of the fermentor tank. Nearly all equipments involved

were electricity driven. Feeding and temperature recordings were done automatically, as

well as mixing and operations of reactor. The mode of the fermentor operation is

intermitten, where POME from mixture tank is flown into the fermentor four times

maintained by using timer. The fermentor occurs at thermophilic condition of 55 oC. The

liquid inside the fermentor are analyzed periodically.[1] Variables checked and analyzed

here consisted of volume of biogas produced, pH, M-alkalinity, total solid, volatile solid

and rough measurement of CO2 and H2S concentration. Other examinations such as

CODcr, T-N, elemental composition analysis (C,H,N,S) and gas composition (CH4, CO2,

H2S) were completed at the external laboratory.

Produced gases are then flown into the water trap to collect the unexpected water in

the bogas. The flow of the produced biogas is measured by using gas meter. Biogas are

Acknowledgements

This research was developed thanks to a research grant from Hibah Kompetitif

Penelitian Unggulan Strategis Nasional No: 429/SP2H/PP/DP2M/VI/2009 date 25 June

2009, and also special thanks to Prof. Darwin Dalimunthe for his supervision

References

Speece, R.E. 1996. Anaerobic Biotechnology for Industrial Wastewaters. USA: Archae

Press.

APHA. 1992. Standard Methods for the Examination of Water and waste water. 18th ed.

New York. American Public Health Association.

Batubara, A., I. Kasup, A.A. Kesma. A. Irfan, H. Simanjuntak dan Harahap. 1999. Kajian

integrasi penggemukan ternak sapi potong di lahan perkebunan kelapa sawit.

Laporan Hasil Kegiatan BPTP Riau. 2000

Dinas Pertanian, Direktorat Jenderal Perkebunan, 2006. Statistik Perkebunan Indonesia,

Kelapa Sawit (Oil Palma).

Igwe JC dan Onyegbado CC. 2007. A review of Palm Oil Mill Effluent (POME) Water

Treatment. Global Journal of Environmental Research 1 (2): 54-62.

Metcalf dan Eddy. 1991. Wastewater Engineering: Treatment Disposal Reuse.