MAINTE

ENANCE STRATEGY BASED ON RELIABILI Y IN COOPERATIVA CAFÉ TIMOR, EAST

THESIS

as Partial Fulfill of the Requirements Obtain the Bachelor of International

Industrial Engineering Degree

Arranged by:

NIZIA MARIA SARMENTO LOPES DA CRUZ Student number: 07 14 05284

INTERNATIONAL INDUSTRIAL ENGINEERING PROGRAM FACULTY OF INDUSTRIAL TECHNOLOGY

Dedicated to:

Pai, Mae

Gina, Ivo, Toni

v

ACKNOWLEDGEMENT

First, thanks for the blessing, spirit and

guidance of Jesus Christ, so the writer can finish this

thesis report entitled: MAINTENANCE STRATEGY BASED ON RELIABILITY (CASE STUDY IN COOPERATIVA CAFÉ TIMOR, EAST TIMOR) to fulfill one of the requirements to reach

bachelor degree of Industrial Engineering from

Universitas Atma Jaya Yogyakarta.

The successful completion of this thesis was also

able by splendid cooperation of everyone who support.

Therefore, in this opportunity, the writer would like

to say thank you to:

1. Mr. Ir. B. Kristyanto, M.Eng, Ph.D as the Dean of

Industrial Technology Faculty UAJY.

2. Mr. The Jin Ai, S.T., M.T., D.Eng, as the Chief of

Industrial Engineering Study Program FTI UAJY.

3. Mrs. Ririn Diar Astanti, D.Eng. as the Chief of

International Industrial Engineering Study Program

FTI UAJY.

4. Mr. Ag. Gatot Bintoro, S.T., M.T. as the advisor,

for the critical supports and suggestions during

this thesis process enabled the writer to

accomplish this thesis.

5. Mr. Josef Hernawan Nudu, S.T., M.T. as the

co-advisor, for the guidance and discussion during

the report constructing so that this report can be

vi

6. All the lectures and staffs of Industrial

Technology Faculty UAJY, for the knowledge and

help.

7. Mr. Bency Issac and Mr. Eusebio Dias Quintas for

letting the writer did the observation at

Cooperativa Café Timor (CCT).

8. Mr. Adelino do Carmo, as the co-advisor in

Cooperativa Café Timor (CCT), for the discussion

and inputs to this thesis.

9. My parents (Pai and Mae), Gina my elder sister,

Ivo my elder brother, Toni my younger brother, Tio

Pe. Iso, M’Nuno, Nita, and Nivio for all the

supports, prayers, loves, cares, and helps.

10. All my family, uncles, aunties, cousins, nieces,

and nephews, for all the prayers and supports.

11. Titina, Sela, Eka, Yani, Melly and kak Ima, all my

boarding house friends, for the friendship,

supports, helps, cares, and “stress therapy”.

12. Henny, Imelda, Rina, Marshela Pausha, Yosepina,

Ana and Ardi for the friendship.

13. My classmates, batch 2007, Randi, Danang, Phi,

Sherly, Melly, Phanie, Rachel, Panpan, Lilik,

Thomas, Alex (2006), and Chuck (2008) for such a

great friendship, supports and helps.

14. Other parties that could not say one by one that

have given much support to finish this thesis.

Last, the writer hopes that this report could bring

many advantages and new knowledge for the readers.

vii

TABLE OF CONTENT

Title Page... ... i

Statement of Work’s Originality... . ii

Approval... ... iii

Dedication... ... iv

Acknowledgement... ... v

Table of Content... ... vii

Figure List... ... ix

Table List... ... xi

Abstract... ... xii

CHAPTER 1 INTRODUCTION 1.1. Background... ... 1

1.2. Problem Statement... ... 4

1.3. Research Objective... ... 4

1.4. Scope of Research... ... 4

1.5. Research Methodology... ... 5

1.6. Report Outline... ... 9

CHAPTER 2 LITERATURE REVIEW 2.1. Previous Research... ... 12

2.2. Current Research... ... 14

CHAPTER 3 THEORY 3.1. Definition of Maintenance... ... 15

3.2. Types of Maintenance... ... 16

3.3. Reliability Function... ... 19

3.4. Failure Rate... ... 21

3.5. Time to Failure Distribution... ... 24

viii

3.7. Spare Part Inventory... ... 31

CHAPTER 4 COMPANY OVERVIEW AND DATA 4.1. Company Overview... ... 34

4.2. Data... ... 49

CHAPTER 5 ANALYSIS 5.1. Plant Reliability... ... 51

5.2. Failure Rate Test... ... 56

5.3. Optimum Interval Preventive Maintenance... .. 59

5.4. Spare Part Management... .... 63

CHAPTER 6 DISCUSSION... 66

CHAPTER 7 CONCLUSION AND RECOMMENDATION 7.1. Conclusion ... ... 72

7.2. Recommendation ... .... 72

REFFERENCE... 73

ix FIGURE LIST

Figure 1.1. Flow Chart of Research Methodology... 6

Figure 3.1. Reliability Curve... 20

Figure 3.2. Block Diagram of Reliability... 21

Figure 3.3. Failure Rate Curve... 23

Figure 3.4. Bath Tub Curve... 23

Figure 3.5. Form of Normal Distribution Curve... 24

Figure 3.6. Form of Weibull Distribution Curve... 25

Figure 3.7. Form of Gamma Distribution Curve... 26

Figure 3.8. Form of Uniform Distribution Curve... 27

Figure 3.9. Optimum Interval Preventive Maintenance 28 Figure 3.10. Interval of tp... 28

Figure 3.11. Elements of C(tp)... 30

Figure 3.12. Total Maintenance Cost per Time... 31

Figure 3.13. Classical EOQ Model... 32

Figure 4.1. Packaged Green Bean Coffee... 38

Figure 4.2. Packaged Roasted Coffee... 38

Figure 4.3. Packaged Ground Coffee... 38

Figure 4.4. Coffee Cherry... 44

Figure 4.5. Peeler Polisher Machine... 45

Figure 4.6. The Husks... 45

Figure 4.7. Dencimetric Table... 46

Figure 4.8. Grader Machine... 46

Figure 4.9. Women Sorting Using Sorting Conveyor.... 47

Figure 4.10. Women Sorting Manually... 47

Figure 4.11. Packaging of the Green Bean Coffee... 48

Figure 5.1. Plant Reliability System... 53

Figure 5.2. Machine and Plant Reliability System.... 56

Figure 5.3. Failure Rate Curve of Peeler Polisher... 58

Figure 5.5. C(tp) Curve of Peeler Polisher... 61

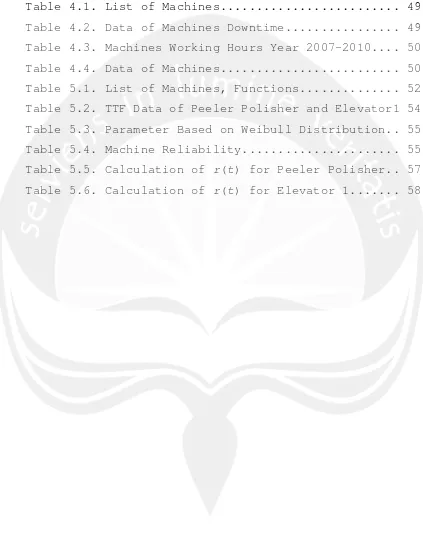

xi TABLE LISTS

Table 4.1. List of Machines... 49

Table 4.2. Data of Machines Downtime... 49

Table 4.3. Machines Working Hours Year 2007-2010.... 50

Table 4.4. Data of Machines... 50

Table 5.1. List of Machines, Functions... 52

Table 5.2. TTF Data of Peeler Polisher and Elevator1 54

Table 5.3. Parameter Based on Weibull Distribution.. 55

Table 5.4. Machine Reliability... 55

Table 5.5. Calculation of r(t) for Peeler Polisher.. 57

ABSTRACT

The purpose of this research is to determine the plant reliability and propose a proper maintenance strategy that can be applied in dry processing factory of Cooperativa Café Timor (CCT), East Timor. The analysis done such as: plant reliability, failure rate, optimum interval preventive maintenance, and spare part inventory.

The analysis of plant reliability is done to know the reliability of the plant and type of plant reliability system. The plant reliability is 0.99915 with series system. The analysis of failure rate is done with purpose to find a proper maintenance strategy for the potential subsystems (machines), such as peeler polisher and elevator 1. The analysis shows that the failure rate curve of peeler polisher and elevator 1 are increasing, therefore a proper maintenance strategy that can be applied is preventive maintenance. The analysis of optimum interval preventive maintenance is done to know the optimum interval time in doing the preventive maintenance. The optimum interval for peeler polisher and elevator are 1,229 Hours and 634 Hours respectively. The analysis of spare part inventory is done in order to ensure that the spare part is available when needed. This analysis is done using the Classical Economic Order Quantity (EOQ) Model, where the result shows that the order quantity of peeler polisher and elevator 1 are 7 and 9 Units respectively and reorder point are the same, which is 1 Unit.