A Comparative Study of Population-Based Optimizations for Tuning PID

Parameters

Gunawan Dewantoro1 and Banu Wirawan Yohanes2 Department of Electronics and Computer Engineering

Satya Wacana Christian University Salatiga, Indonesia 1

[email protected], [email protected]

Abstract—The tuning and optimization of Proportional-

Integral-Derivative (PID) parameters have always been a complicated but important issue in the field of automatic control. The recent optimization design methods are frequently difficult to consider the system requirements for speed, consistency and robustness. In this paper, methods of PID parameters using population-based heuristic optimization are presented. Some quantitative and qualitative comparisons are given together with their computational time. Simulations with Matlab have showed that Genetic Algorithm (GA) and Particle Swarm Optimization (PSO) are better based on the performance index than that of the traditional Ziegler-Nichols (Z-N) method, and are methods which have superior practical value of the PID parameter tuning and optimization.

Keywords-PID; optimization; Genetic Algorithm; Particle Swarm Optimization

I. INTRODUCTION

PID control method is one of the commonly used since it has straightforward algorithm, fine robustness and high reliability [1]. Most controllers design and optimization problems are multi-objective in nature, since they possibly have several conflicting objectives that must be satisfied simultaneously. Instead of aiming at finding a single solution at each iteration, the population-based optimizations methods try to produce a set of solution candidates from which the decision maker might choose one. Evolution algorithm approaches for determining the optimal values of the PID controller have been proposed. Ayala and Coelho [2] presented the design and the tuning of two PID controllers through the NSGA-II approach. Simulation numerical results of multivariable PID control and convergence of the NSGA-II were presented and discussed with application in a robotic manipulator of two-degree-of-freedom. The proposed optimization method based on NSGA-II offered an effective way to implement simple but robust solutions providing a good reference tracking performance in closed loop. To overcome the difficulties associated with the traditional PID tuning methods, Neath et al. [3] proposed a derivative-free optimization technique, based on GA, to determine the optimum parameters of PID controllers used in bidirectional IPT systems. The GA determined the optimal gains at a reasonable computational cost and often did not get trapped in a local optimum. In [4], the proportional gain, the integral gain, the derivative gain, and the saturation limit defined the

search space for the optimization problem. The approximate optimum values of the design variables were determined by the Taguchi method using analysis of means. Analysis of variance was used to select the two most influential design variables. A multi-objective GA was used to obtain the accurate optimum values of these two variables. GA was proposed as a global optimizer to find the optimized PID gains for position control of BLDC motor [5]. The efficiency of this method was compared with that of traditional method. Simulation results showed that PID control tuned by GA provided more efficient closed loop response for position control of BLDC motor. In [6], a PID controller was designed and attached to electrohydraulic servo actuator system to control its angular position. The PID parameters were optimized by the GA. The controller is verified on the state space model of servovalve attached to a rotary actuator by SIMULINK program.

transient response by minimizing overshoot, settling time and rise time of step response. First an objective function was defined, and then by minimizing the objective functions using real-coded PSO and GA, the optimal controller parameters could be assigned.

This study aims to compare the effectiveness and computational time of GA and PSO, both quantitatively and qualitatively, in order to seek the optimum PID parameters to control a predefined second-order system. This paper is outlined as follow: Chapter 2 describes the population-based optimization methods, Chapter 3 shows the results and discusses the findings, and Chapter 4 concludes the paper.

II. POPULATION-BASED OPTIMIZATIONS

A. Genetic Algorithm (GA)

GAs have been extensively used in control system design during last few decades. GAs are stochastic search methods where a population of possible solutions is adapted in successive iterations using the Darwinian principle of natural selection, crossover, mutation to yield a best solution. Each individual in the population is called a chromosome and represents a possible solution. A selection operator is used to select the best individuals in a population. The crossover operator creates new offspring by mixing couples of selected parents in a population and the mutation operator creates a new individual by randomly mutating a randomly-selected part of a selected individual. The steps of implementing GA are as follows:

1) Generate an initial, random population of individuals of fixed size where each individual represents a possible solution. In this study, the population size is 10 and the number of generations is 50. These selections are adequate for ensuring the convergence. The parameters Kp, Ki, and Kd

of the PID controller are encoded using the method of concatenated and real-valued fixed-point coding. This individual is a sequence of three parts representing Kp, Ki,

and Kd, with each part being real value ranging from 0 to 10,

as shown in Figure 1.

Figure 1. Real-valued encoding of each indivuals

Since the starting generation of GA is random, the parameters of PID at the initial stage could make the system unstable. Therefore, the range of the controller parameters is selected such that the system remains stable within this range.

2) Evaluate the fitness of each individual in the population. The objective function chosen in this study is the integration of error (IAE), which is formulated as:

Since fitness function is of the-higher-the-better type, then it is defined as:

3) Select the fittest members of the population using the Roulette-wheel method.

4) Implement crossover operation on the selected parents to produce offspring with crossover probability of 0.75. The operator used is extended intermediate operator [13], as

and is chosen randomly in the interval [-2,2].

5) Apply uniform mutation operator on the offspring with mutation probability of 0.01.

6) Repeat from step 2) to step 5) until 50 generations

B. Particle Swarm Optimization (PSO)

PSO is a heuristic population-based optimization method, which is based on swarm intelligence. It is inspired by idea coming from the research on the bird and fish flock movement behavior. PSO algorithm was first introduced by Kennedy and Eberhart in 1995 [14].

The particles, which are solution candidates, find for the local best (pbest) and subsequently global best (gbest) in every iteration in order to seek the optimal solution. Each particle is evaluated by cost function. Thus, all particles attempt to imitate their historical success and in the same time try to follow the success of the best agent. It means that the pbest and gbest are updated if the particle has a minimum cost value compared to the current pbest and gbest value. The new velocity and new position can be calculated as [15]:

where, φ represent random function values [0,1] while c1

is cognitive component and c2 is social component. The

function of inertial coefficient w is to balance between local and global search capabilities, while κ reduces the particle movement oscillations

III. RESULTS AND DISCUSSIONS

In this work, tuning or optimization of PID controller is conducted method using the population-based optimization as well as traditional Ziegler-Nichols (ZN) method. The

A. Tuning of PID Controller

The simulation is carried out via GA and PSO. The results are showed in the Figure 2. The blue line is the maximum of fitness, while the red dotted line is the average of fitness over 50 generations.

Figure 2. Fitness function of the GA (above) and cost function of PSO (below).

From the above figures, both objective functions converge to a specific value. It can be inferred that PSO possesses a faster convergence rate compared to that of GA.

0

Figure 3. Initial population (above) and final population (below) using GA

Figure 4. Initial population (above) and final population (below) using PSO

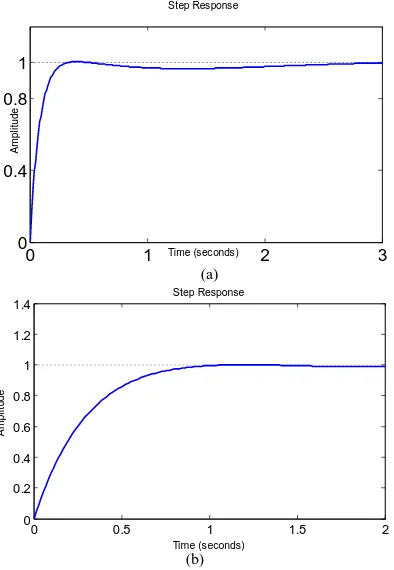

0 1 2 3 0

0.4 0.8 1

Step Response

Time (seconds)

A

m

p

li

tu

d

e

(a)

0 0.5 1 1.5 2

0 0.2 0.4 0.6 0.8 1 1.2 1.4

Step Response

Time (seconds)

A

m

p

lit

u

d

e

(b)

Figure 5. Step responses using (a) GA and (b) PSO

TABLE II. PERFORMANCES COMPARISONS

GA PSO Z-N

Rise Time (s) 0.1618 0.5469 0.3940

SettlingTime (s) 2.1320 0.8508 2.6714

Overshoot 0.4575 0.0817 7.5936

Peak 1.0046 1.0008 1.0759

Peak Time (s) 0.3939 1.2041 0.9058

TABLE III. COMPUTATIONAL TIME

Trial No.

1 2 3 4 5

GA 34.9366 s 34.2740 s 34.6829 s 35.0124 s 34.7825 s

PSO 28.5261 s 29.3803 s 28.5685 s 29.0584 s 28.9560 s

IV. CONCLUSIONS

In the design of the PID controller, PID parameters setting are a cumbersome and complicated work. Over the past few years, various techniques have been developed to obtain the optimum Kp, Ki, and Kd for PID controllers. The

population-based optimizations, including GA and PSO, try to produce a set of solution candidates which contains the best solution. From the simulation, we can see that compared with the method of Z-N, that the step response via PSO is a little bit more sluggish than that of GA and Ziegler-Nichols (ZN). However, PSO gives a better performance in terms of settling time and overshoot. Also, the computational time

needed to accomplish PSO algorithm is 18% faster than GA. This also illustrates that GA and PSO are promising to optimize the PID parameters in automatic control field.

ACKNOWLEDGMENT

This research is financially supported by Indonesian Directorate General of Higher Education.

REFERENCES

[1] Y. Chen, Y. J. Ma, and M. X. Yun, “Application of Improved Genetic Algorithm in PID Controller Parameters Optimization,” Telkomnika, vol. 11, no. 3, March. 2013, pp. 1524-1530.

[2] H. V. H. Ayala and L. D. S. Coelho, “Tuning of PID Controller Based on A Multiobjective Genetic Algorithm Applied to A Robotic Manipulator,” Expert Syst. Appl., vol. 39, 2012, pp. 8968-8974. [3] M. J. Neath, A. K. Swain, U. K. Madawala, and D. J.

Thrimawithana, “An Optimal PID Controller for a Bidirectional Inductive Power Transfer System Using Multiobjective Genetic Algorithm,” IEEE T. Power Electr., vol. 29, no. 3, March 2014, pp. 1523-1531.

[4] H. M. Hasanien, “Design Optimization of PID Controller in Automatic Voltage Regulator System Using Taguchi Combined Genetic Algorithm Method,” IEEE Syst J., vol. 7, no.4, December 2013, pp. 825-831.

[5] U. Ansari, S. Alam, and S. M. N. Jafri, “Modeling and Control of Three Phase BLDC Motor using PID with Genetic Algorithm,” Proc. 13th International Conference on Modelling and Simulation, 2011, pp. 189-194.

[6] A. A. Aly, “PID Parameters Optimization Using Genetic Algorithm Technique for Electrohydraulic Servo Control System,” Intelligent Control and Automation, vol. 2, 2011, pp. 69-76.

[7] D. Sharma and B. Kumar, “PSO Optimized PID Controller for Load Frequency Control,” European Journal of Advances in Engineering and Technology, vol. 2, no. 11, 2015, pp. 43-48.

[8] V. K. Bhaat and S. Bhongade, “Design Of PID Controller In Automatic Voltage Regulator (AVR) System Using PSO Technique,” International Journal of Engineering Research and Applications, vol. 3, no. 4, July-August 2013, 1480-1485.

[9] A.K. Singh, S. Patra, A. Singh, V. Shende, P. K.ray, and A. Mohanty, “Interval System Analysis and PID-PSO Control of Boost Converter for Uncertain Load Parameter,” Proc. IEEE International Conference on Power Electronics, Drives and Energy Systems, 2014, pp. 1-6. [10] S. M. Othman, M. F. Rahmat, S. M. Rozali, and S. Salleh, “PID

Parameters Optimization using PSO Technique For Nonlinear Electro Hydraulic Actuator,” Jurnal Teknologi, vol. 77, no. 28, 2015, 67-72. [11] H. I. Jaafar, Z. Mohamed, A.F. Z. Abidin, and Z. A Ghani,

“PSO-Tuned PID Controller for a Nonlinear Gantry Crane System,” Proc. IEEE International Conference on Control System, Computing and Engineering, November 2012, 515-519.

[12] M. Rathore, P. Verma, and R. Gupta, “Tuning of PID Controller Using GA and PSO Optimization Technique and Compare with Integral Errors,” International Journal of Science, Engineering and Technology Research, vol. 2, no. 4, 1993,25-49.

[13] H. Muhlenbein and D. S. Voosen, “Predictive Models for the Breeder

Genetic Algorithm I: Continuous Parameter Optimization,”

Evolutionary Computation, vol. 1, no. 1, April 2013, 900-905. [14] J. Kennedy and R. C. Eberhart, “Particle Swarm Optimization,” Proc.

IEEE International Conference on Neural Networks, 1995, pp. 1942-1948.

![Figure 3 and 4 show the initial population of PID parameters, which is within interval of [0, 10], and the final](https://thumb-ap.123doks.com/thumbv2/123dok/1110389.647657/3.612.80.271.407.692/figure-initial-population-pid-parameters-interval-final.webp)